1 of 3 LPN00207X0001A0

LEDway® Series

High Output LED Street Light

Includes: Single and Double Modules

INSTALLATION INSTRUCTIONS

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should always be followed

including the following:

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

1. To avoid the possibility of electrical shock, turn off power supply before installation

or servicing. Installation and servicing should be performed by qualied personnel.

2. When closing cover of xture, be sure all wires are inside housing to avoid pinching

wires.

3. If NEMA photo control is installed refer to NEMA Receptacle section for instructions.

4. Product must be installed in accordance with NEC or your local electrical code.

If you are not familiar with these codes and requirements, consult a qualied

electrician.

5. If mounting bolts are completely removed in the eld they should be hand threaded

(prior to use of power tools) to ensure proper engagement of the thread when

re-installing. Failure to pre-start threads may result in cross-threading or stripping of

the bolts during reinstallation.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

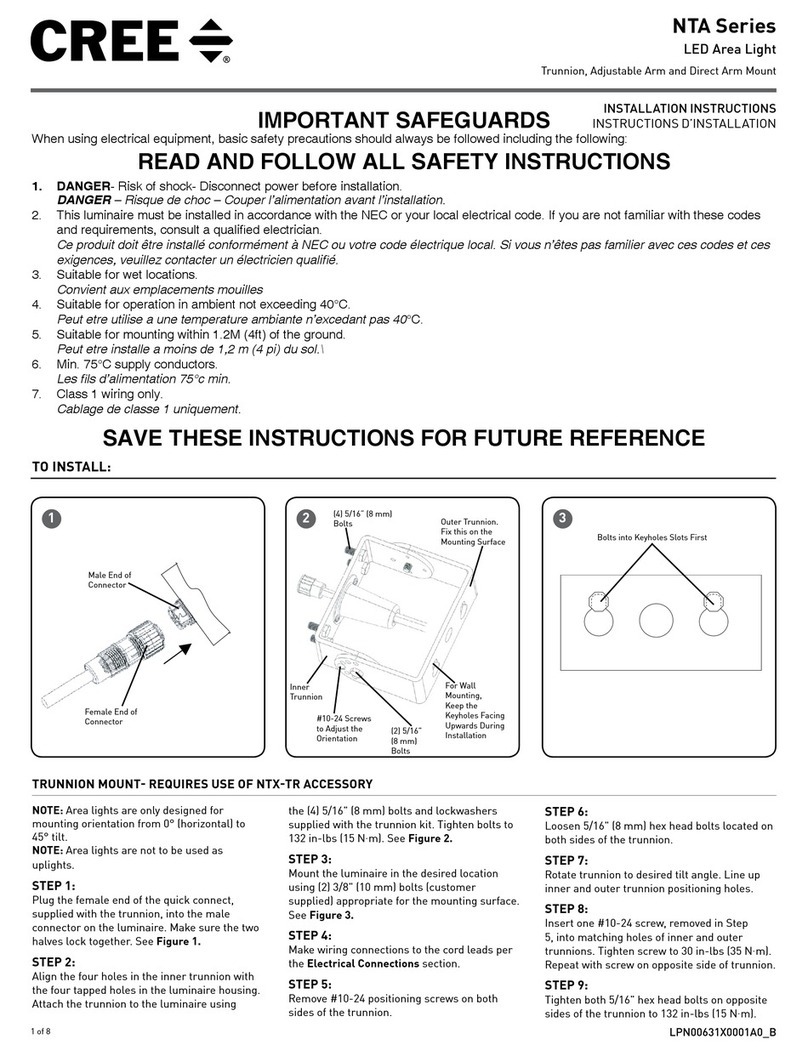

TO INSTALL:

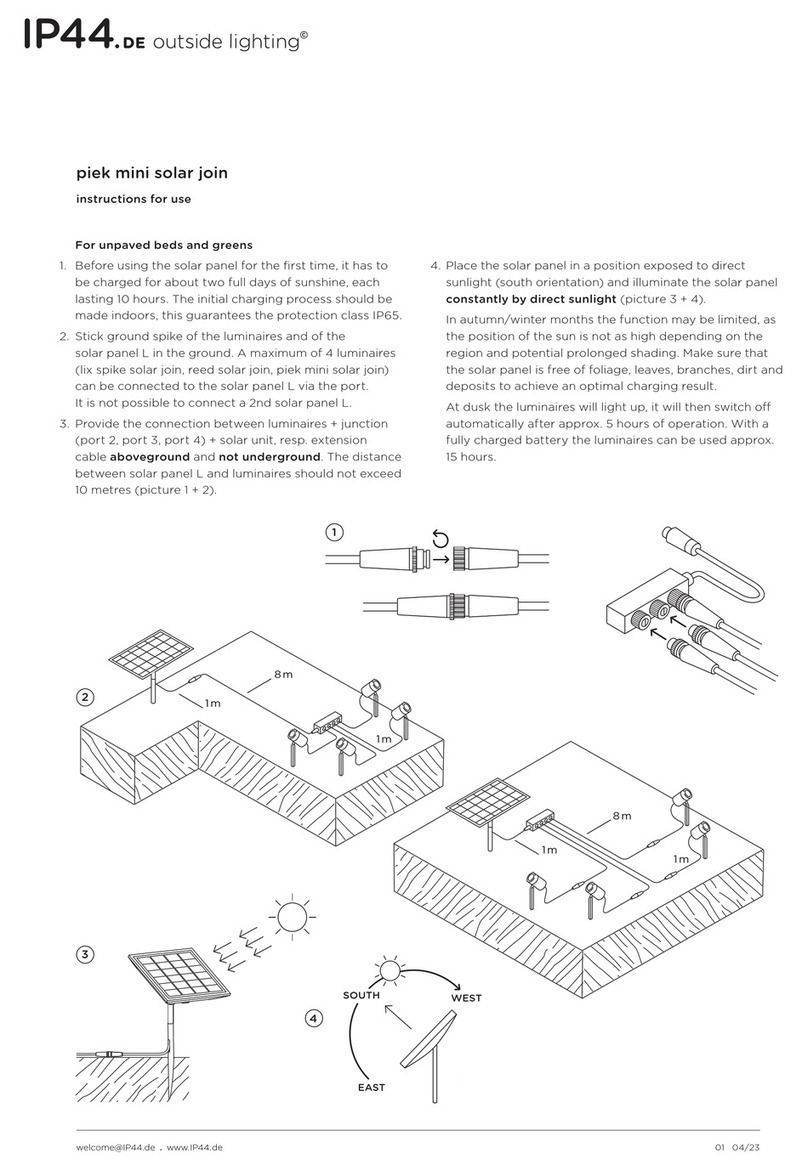

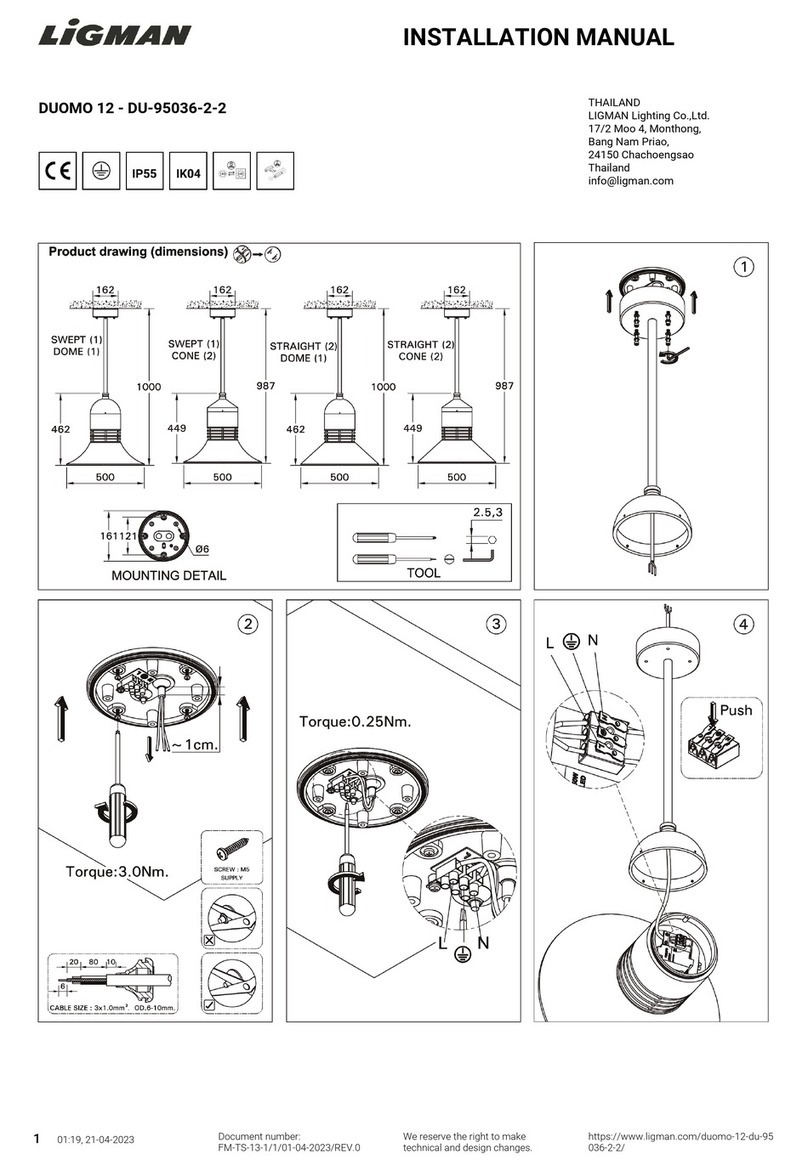

STANDARD MOUNTING

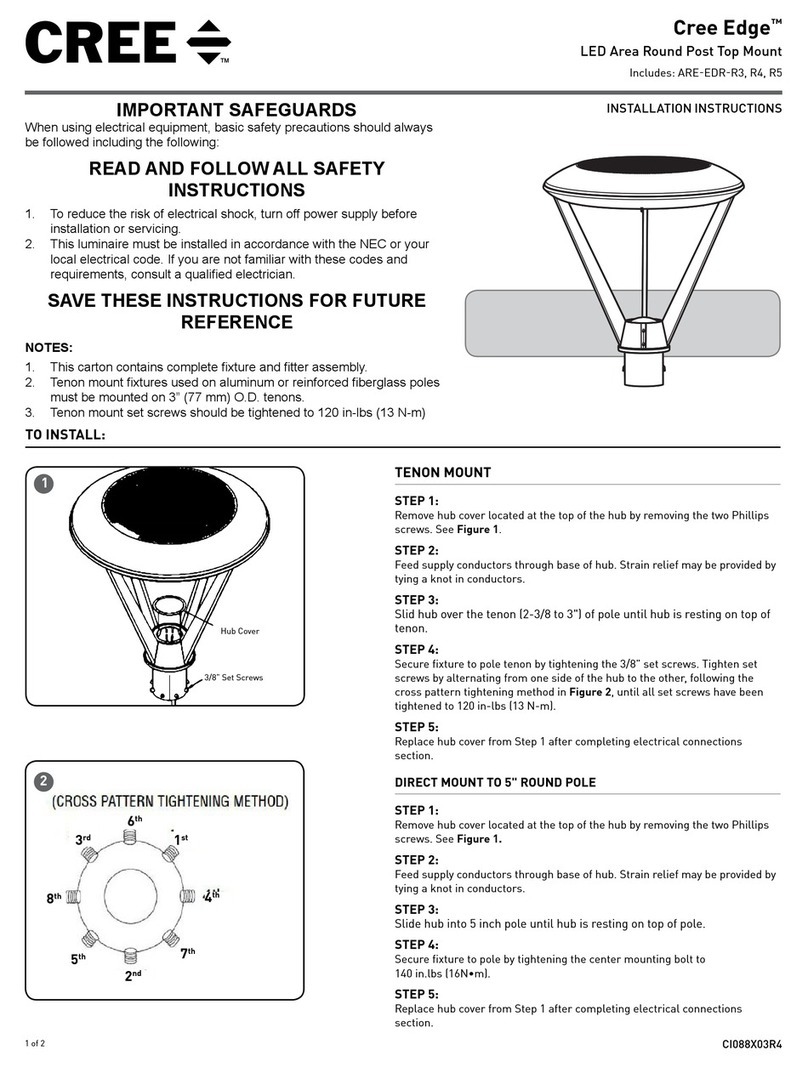

STEP 1:

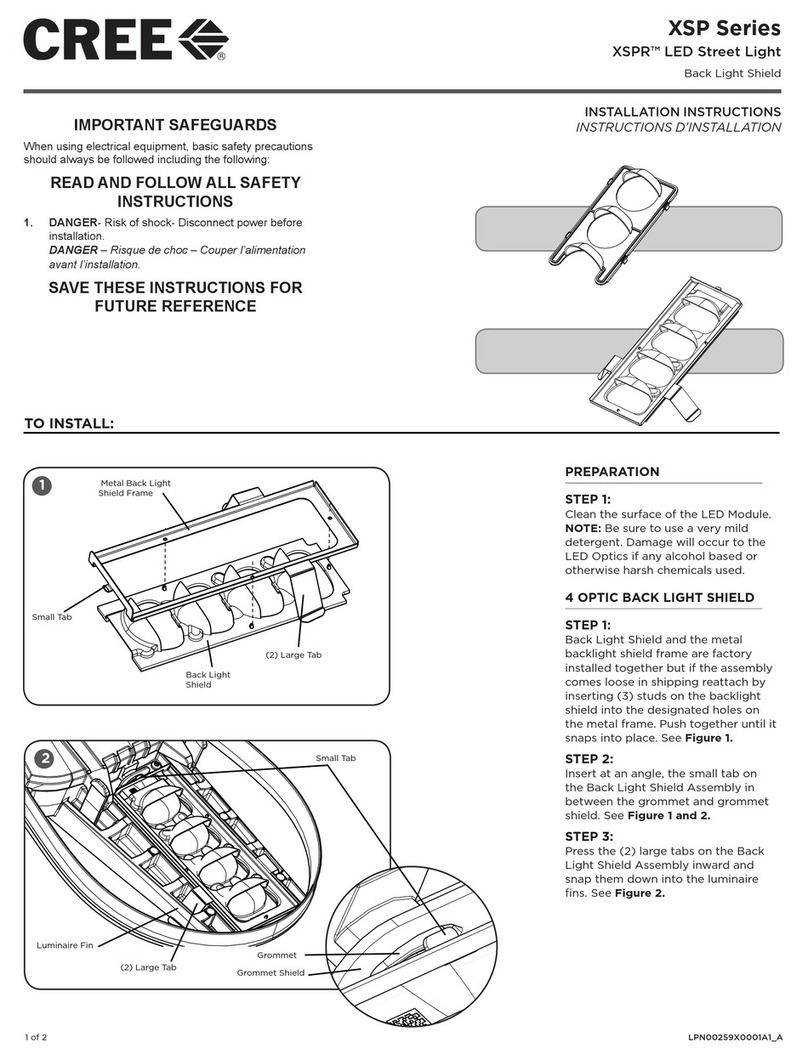

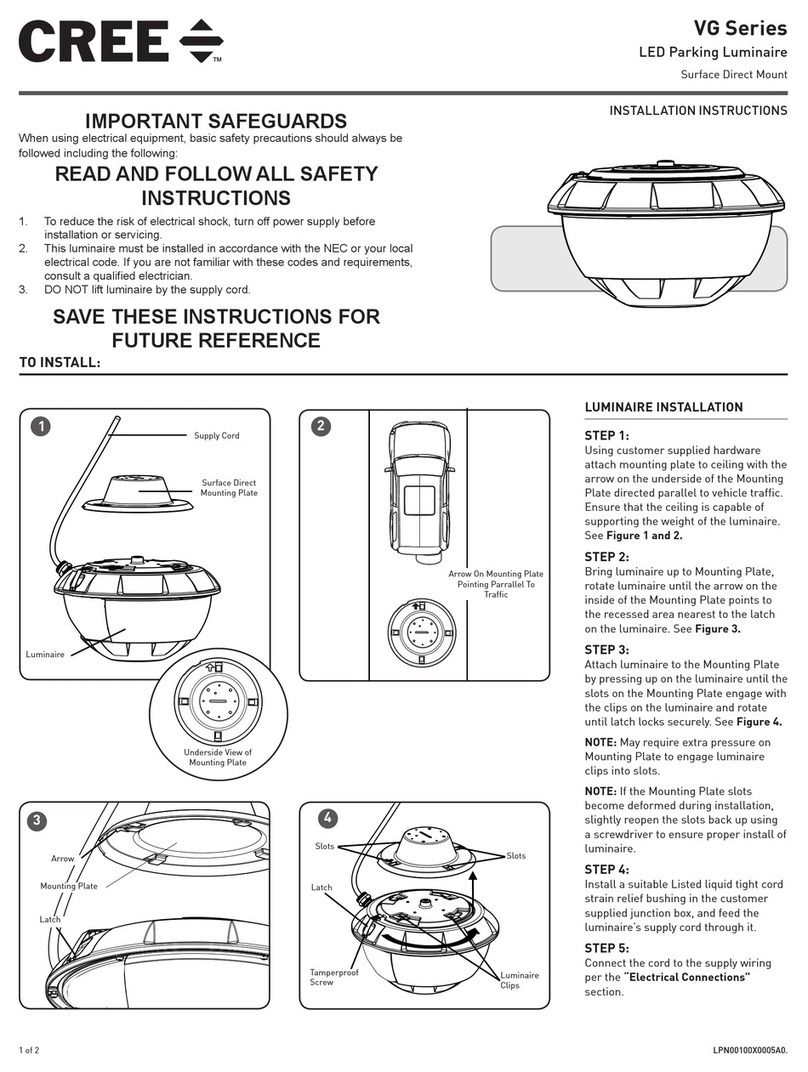

DO NOT remove splashguard from fixture. If

mounting fixture to 1.25 IP pipe (1.66 O.D.),

there is no need to modify the splashguard. If

mounting fixture onto 2.0 IP pipe (2.38 O.D.),

remove the knockout of the splashguard

thru the rear opening of the fixture while the

fixture is closed. See Figure 2.

STEP 2:

To open cover, hold fixture by heat sink

with the light bars facing down and hinges

facing away. Simultaneously pull latches

and the cover to swing open. Splashguard

may dislodge from fixture, but should be

repositioned once ready to mount. See

Figure 1.

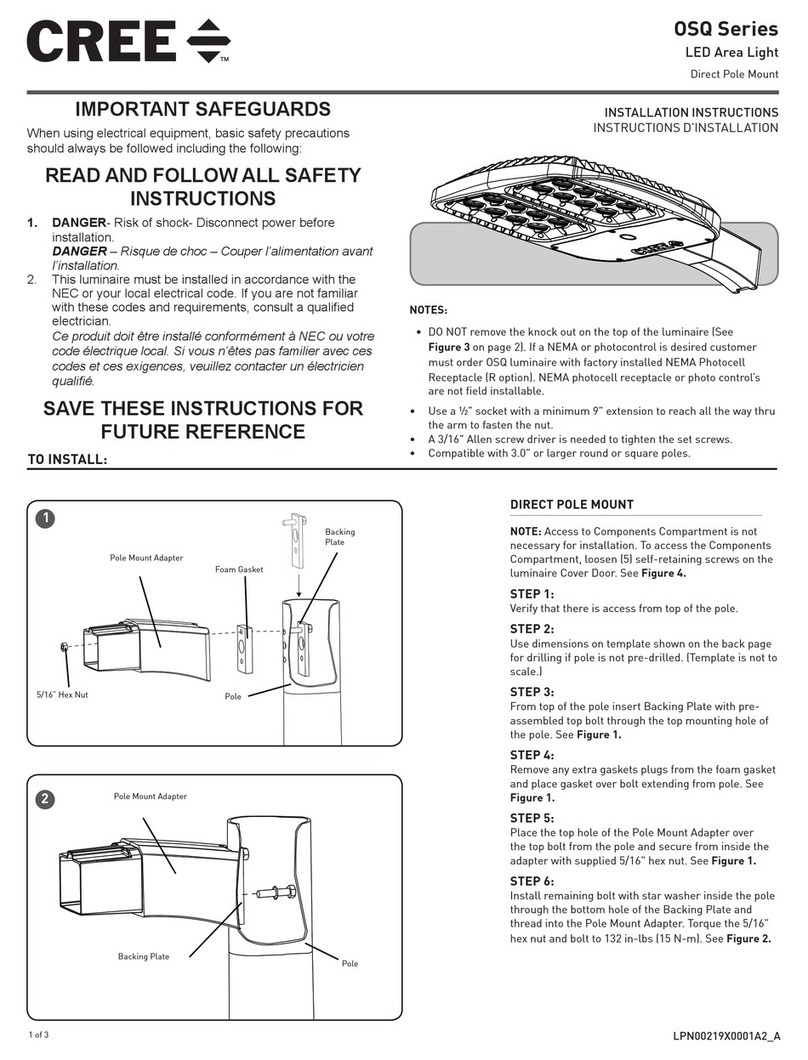

STEP 3:

Slide fixture on to pole through opening on

the rear of housing and through splashguard.

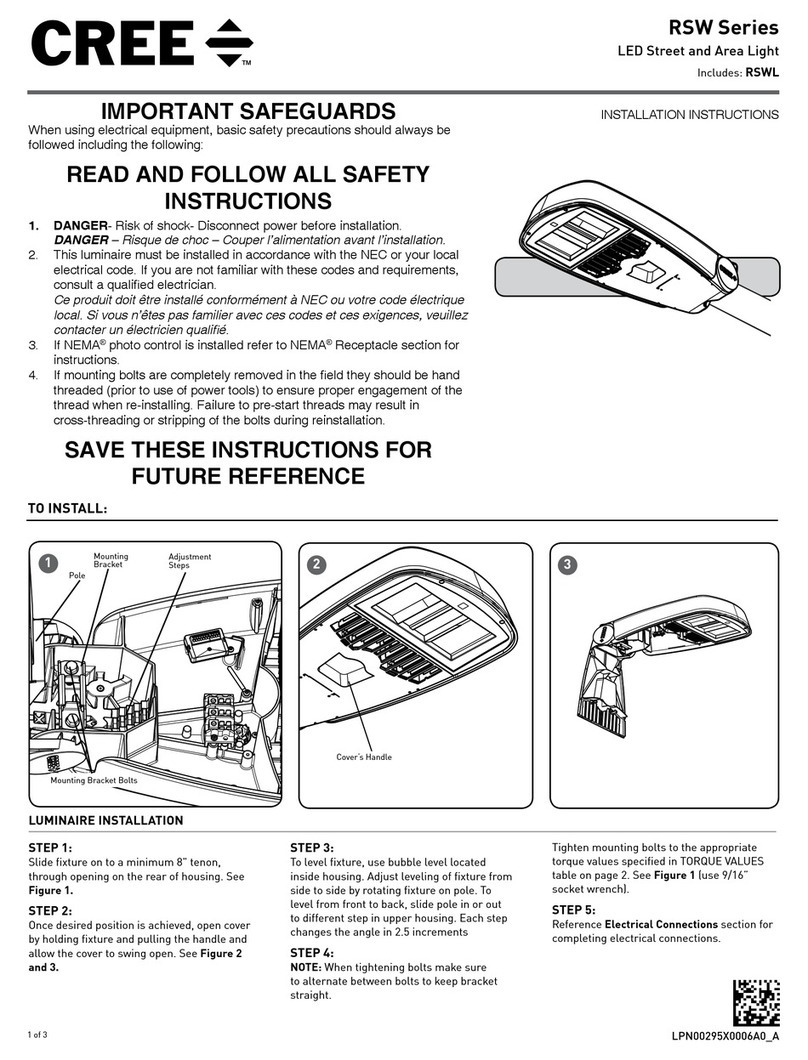

STEP 4:

To level fixture, use bubble level located inside

housing. Adjust leveling of fixture from side

to side. To level from front to back, slide pole

to different step in upper housing. Each step

changes the angle in 2.5° increments. See

Figure 3.

STEP 5:

Once desired position is achieved, tighten

(2) mounting bolts to the appropriate torque

values specified in TABLE 1. See Figure 1 (use

9/16" wrench socket).

IMPORTANT - DO NOT exceed these

torque levels on the mount bolts. Exceeding

recommended torque value resulting in

excessive deformation of mounting bracket

will cause stripping of mount hardware which

could lead to an unsafe mounting condition.

STEP 6:

Reference “Electrical Connections” section

for completing electrical connections.

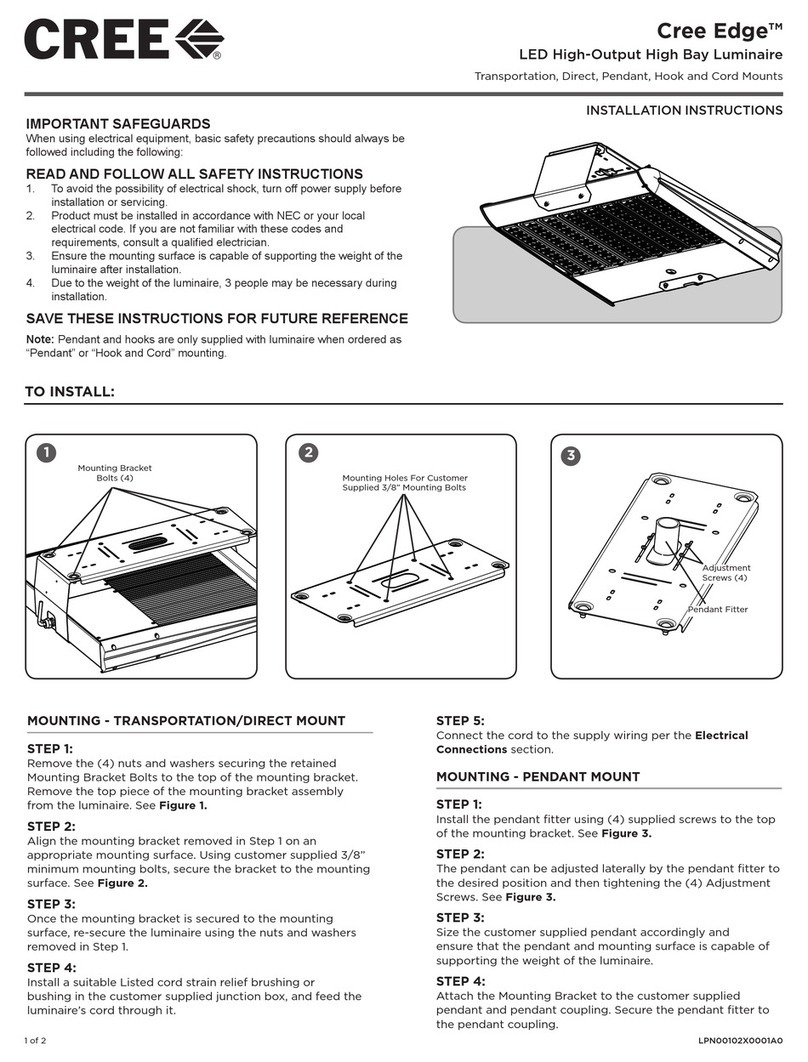

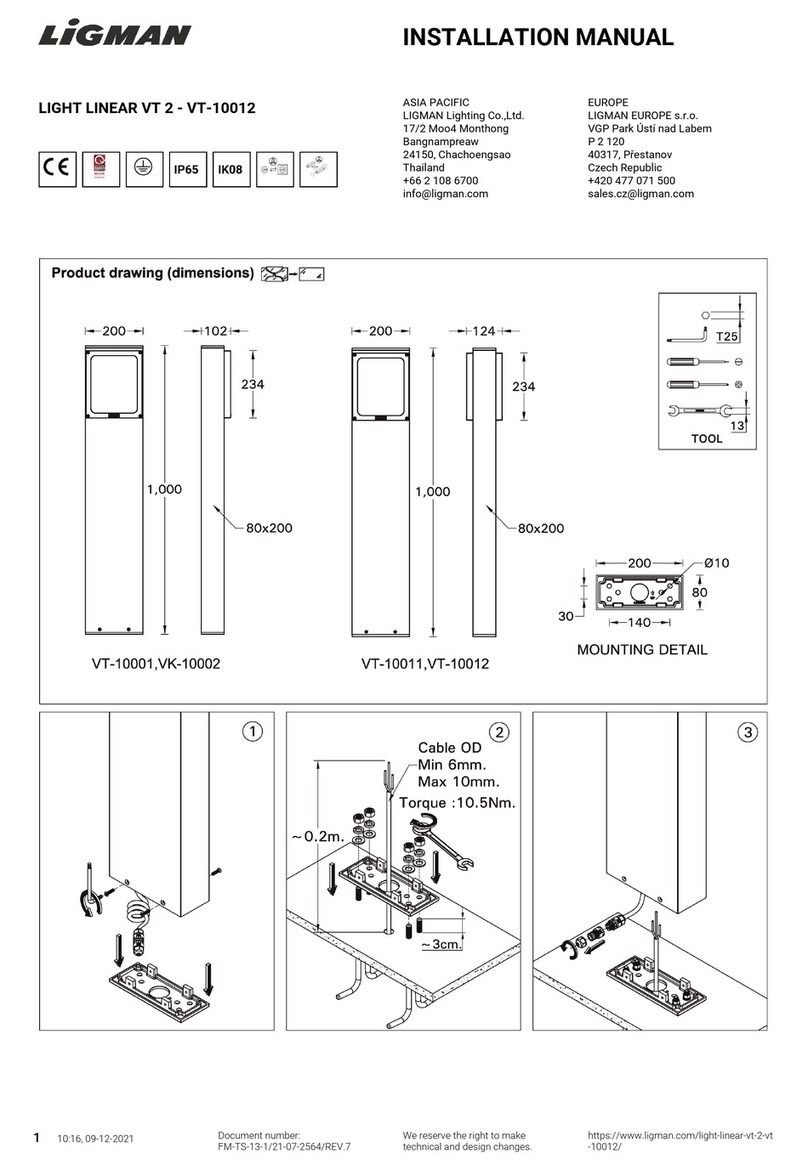

1

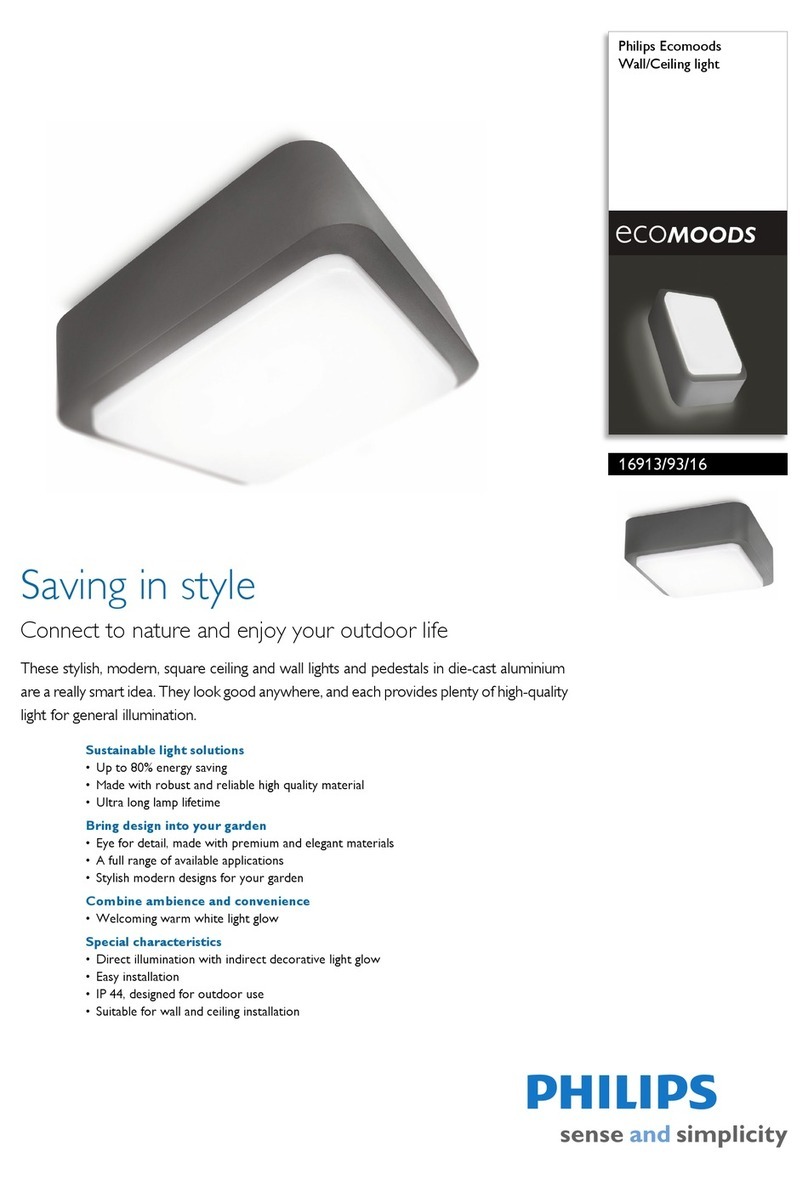

Pipe Size Pipe Position Bolt Torque

Required (in-lbs)

Bolt Torque

Required (N-m)

1.66 in O.D.

+5.0 degrees tilt 400 45

+2.5 degrees tilt 400 45

0 degrees (no tilt) 400 45

-2.5 degrees tilt 700 79

-5.0 degrees tilt 850 96

2.38 in O.D.

+5.0 degrees tilt 300 33

+2.5 degrees tilt 300 33

0 degrees (no tilt) 300 33

-2.5 degrees tilt 300 33

-5.0 degrees tilt 300 33

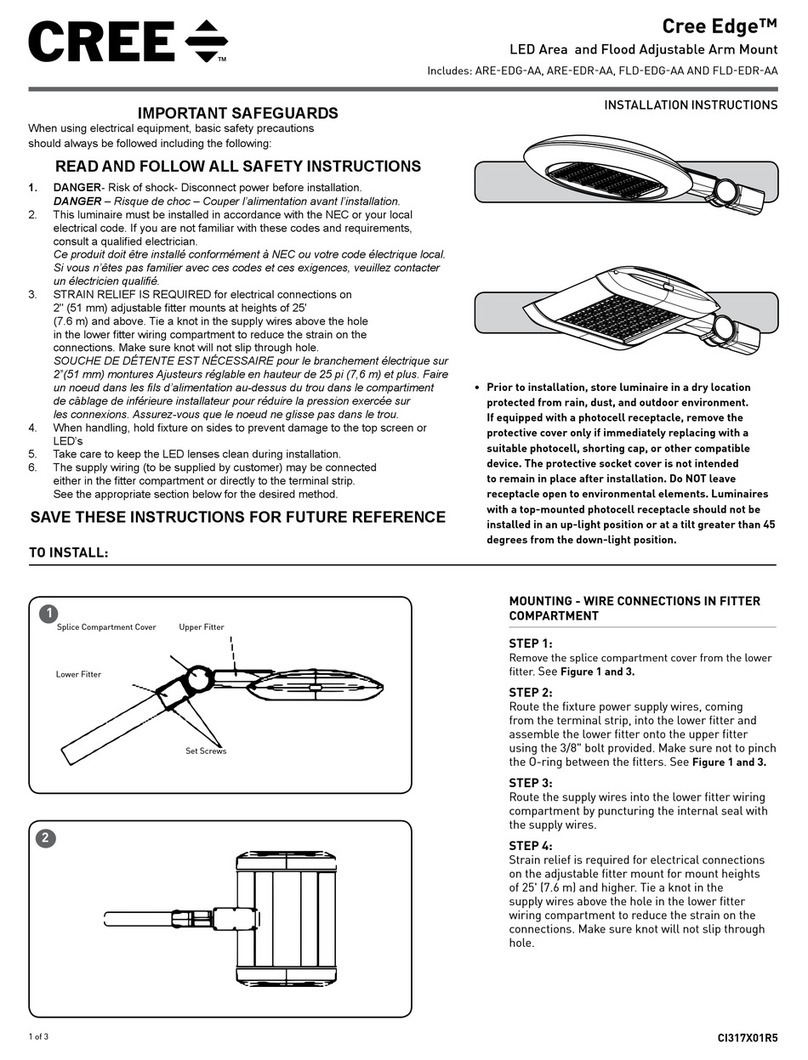

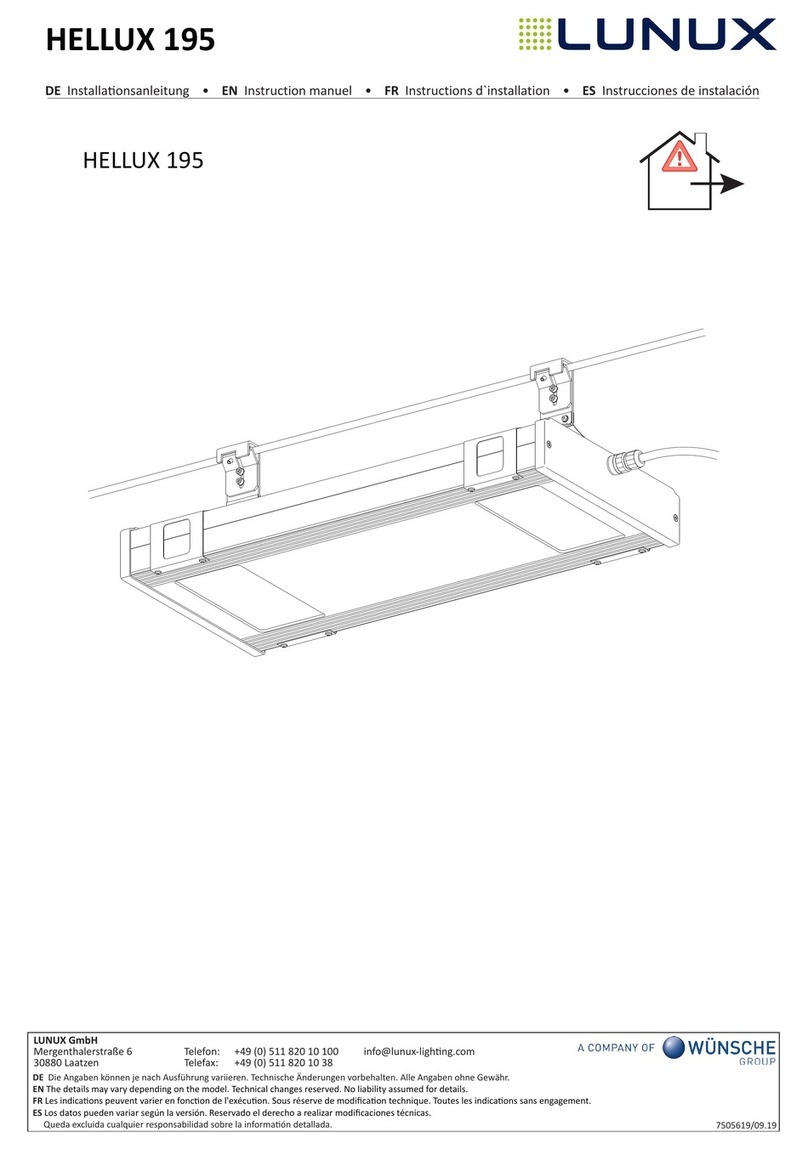

Heatsink

Mounting Clamp

Bracket

Mounting Bolts (2)

See Table 1

Cover in Open

Position

Pole

Driver

Splashguard

Cover in Open

Position

Terminal Block

TABLE 1

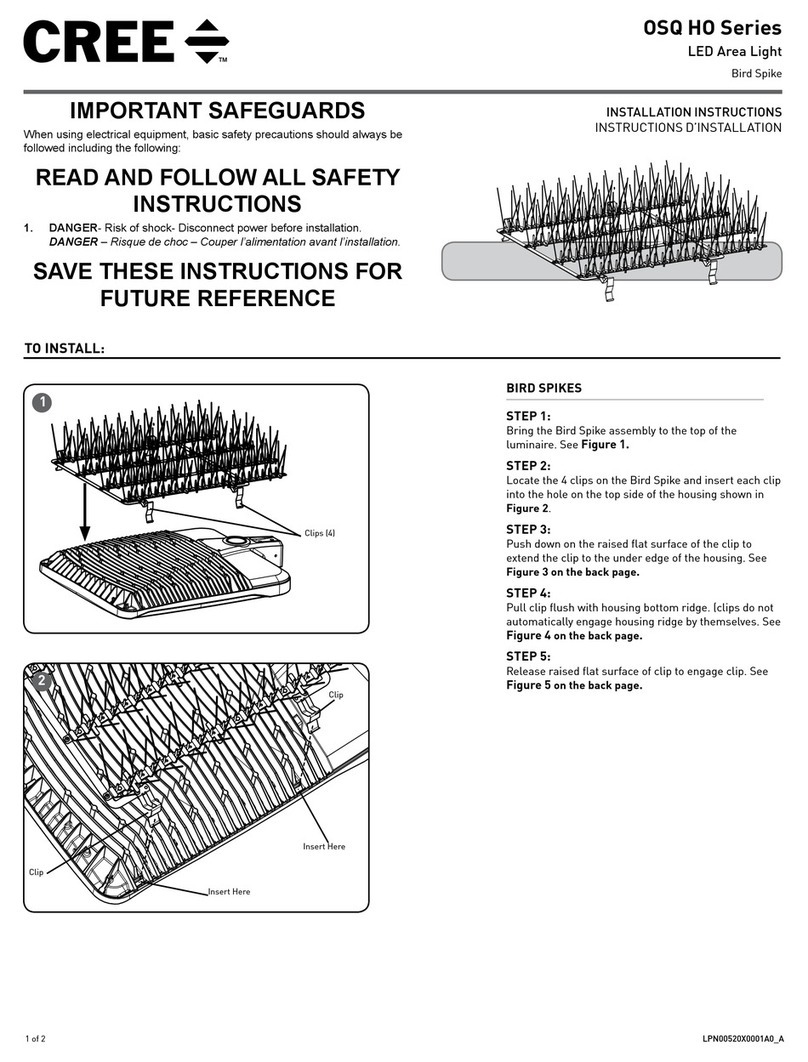

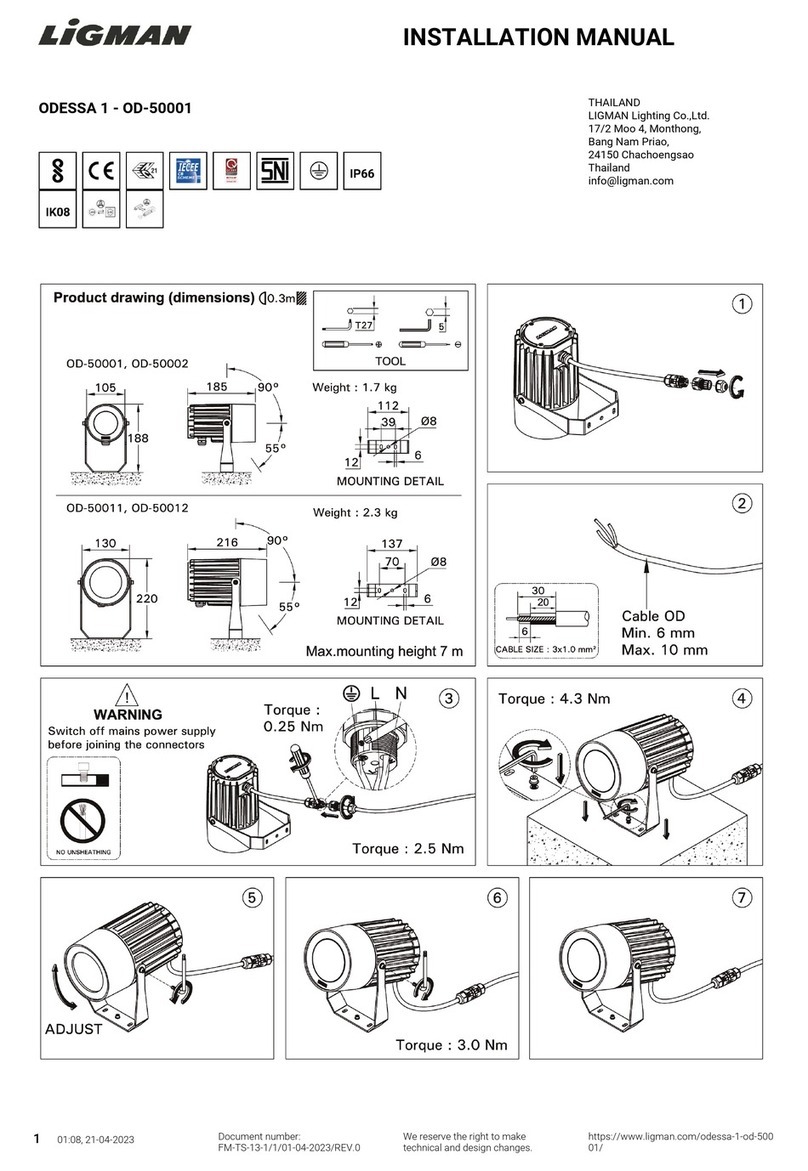

2

3

Fitter Pipe end

Final Stop Boss

2nd Stop Boss

3rd Stop Boss