3

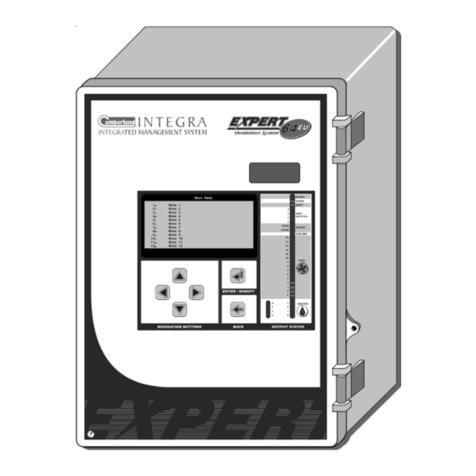

EXPERT WW rev.12

EXPERT WW

TABLE OF CONTENTS

1. INTRODUCTION ...................................................5

1.1. Precautions .....................................................5

1.2. Symbols of the Manual .....................................5

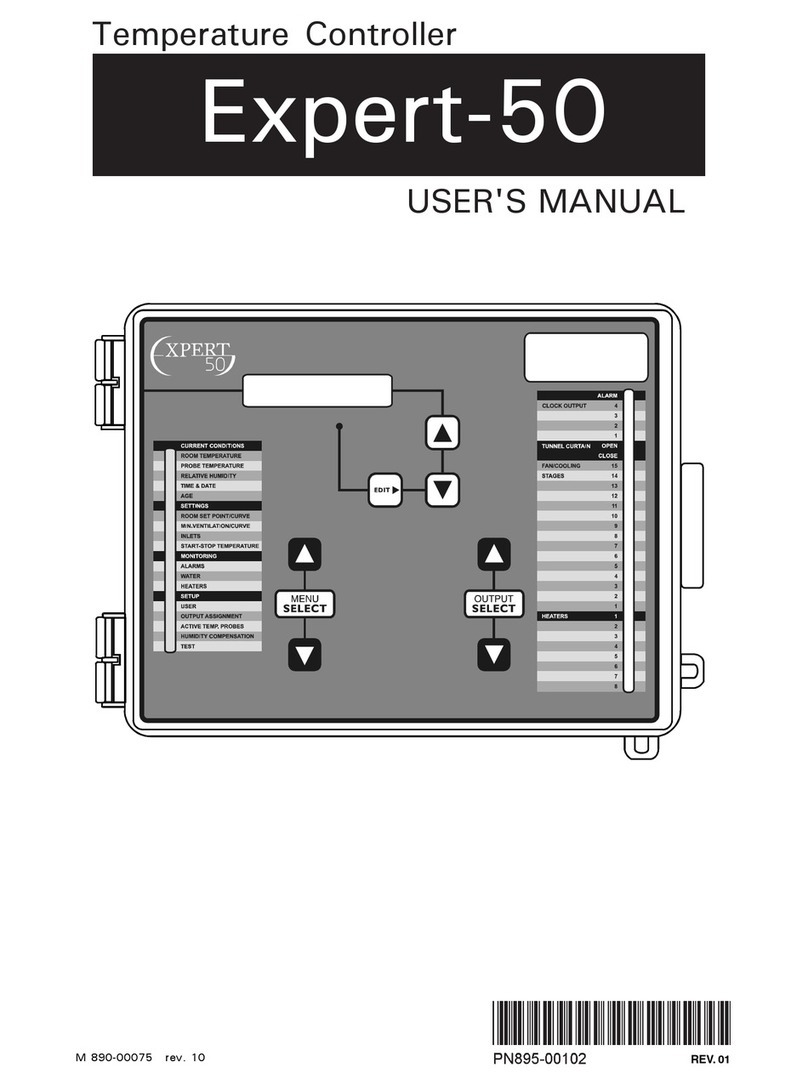

1.3. Controller’s Overview .......................................5

1.4. Main Features ..................................................6

2. MOUNTING INSTRUCTIONS ..................................6

2.1. Installing the Controller on the Wall ....................6

2.2. Connections ....................................................6

2.2.1. Main Wiring ...............................................6

2.2.2. Alarm Connection ...................................... 7

2.2.3. Sensor Inputs ............................................ 7

2.2.4. 0-10V Output Connection ........................... 7

3. USER INTERFACE .................................................7

3.1. Location of the Controls ....................................7

3.2. Parameter Adjustment ......................................8

3.3. Language Selection ..........................................8

3.4. LED Meaning ...................................................8

4. INSTALLATION SETUP ..........................................9

4.1. Setting the Time & Date ...................................9

4.2. Password .......................................................9

4.2.1. Changing the Password .............................. 9

4.2.2. Retrieving a Lost Password.......................... 9

4.3. Controller Programs ..........................................9

4.3.1. Program Selection & Settings ...................... 9

4.3.2. Copying & Pasting Programs ...................... 10

4.4. Measuring Units .............................................10

4.5. Installation Setup ...........................................11

4.6. RH Compensation Setup .................................13

4.7. Probe Setup ..................................................13

4.7.1. Probe Activation ...................................... 13

4.7.2. Probe & Water Meter Calibration ................ 13

4.7.3. Probe Assignment .................................... 14

4.8. Relay Assignment ..........................................14

4.8.1. Assigning Relays to the Outputs ................ 14

4.8.2. Assigning Min. Vent. Relays ...................... 15

4.9. Night Settings ................................................15

4.10. Clean Mode ...................................................15

4.11. Test Mode .....................................................16

4.12. Version .........................................................16

5. TEMPERATURE & SET POINT SETTINGS ...............17

5.1. Temperature Set Point ....................................17

5.2. Static Pressure Set Points ...............................17

5.3. Temperature Curve .........................................18

5.3.1. Principle of Operation ............................... 18

5.3.2. Settings .................................................. 18

5.3.3. Modifying Curve Points ............................. 18

6. VENTILATION & COOLING ..................................19

6.1. Minimum Ventilation ......................................19

6.1.1. Minimum Ventilation Cycles ...................... 19

6.1.2. Minimum Vent. Settings ............................ 19

6.1.3. Minimum Ventilation Curve........................ 19

6.2. Fan Stages ....................................................20

6.2.1. Principle of Operation ............................... 20

6.2.1.1. Operation of Fan Stages ..................... 20

6.2.2. Stage 1 Ramping...................................... 20

6.2.3. Fan Stage Settings ................................... 20

6.2.4. 0-10V Ventilation Outputs ........................ 21

6.3. Natural Ventilation Curtains .............................22

6.3.1. Principle of Operation ............................... 22

6.3.2. Transition Between Natural & Tunnel Vent. . 23

6.3.3. Natural Ventilation Settings ....................... 23

6.3.4. Curtain Compensation............................... 24

6.3.5. Stopping the Fans in Natural Vent. ............. 24

6.3.6. Purge ...................................................... 25

6.4. Tunnel Doors ................................................25

6.4.1. Pressure-based Tunnel Doors ..................... 25

6.4.2. Temperature-Based Tunnel Doors .............. 26

6.4.3. Tunnel Door Settings ................................ 27

6.5. Vent Doors (Inlets) .........................................28

6.5.1. Timer-based Vent Doors (Inlets) ................. 28

6.5.1.1. Principle of Operation ......................... 28

6.5.1.2. Vent Door Settings ............................ 28

6.5.1.3. Actuator Reset .................................. 29

6.5.2. Potentiometer-based Vent Doors (Inlets)...... 30

6.5.2.1. Principle of Operation ......................... 30

6.5.2.2. Vent Door Settings ............................ 30

6.5.2.3. Vent Door Calibration ......................... 31

6.5.3. Static Pressure-Based Vent Doors (Inlets) .... 31

6.5.3.1. Principle of Operation ......................... 31

6.5.3.2. Vent Door Settings ............................ 32

6.6. 0-10V Air Inlet ...............................................32

6.7. Cool Cell .......................................................33

6.8. Misting Output ...............................................33

7. HEATING ...........................................................34

8. LIGHTS .............................................................35

9. CLOCK OUTPUTS ..............................................36

10. RELATIVE HUMIDITY (RH) COMPENSATION ..........37

11. ALARMS ...........................................................38

11.1. Alarm Log .....................................................38

11.2. Alarm Conditions ...........................................38

11.3. Alarm Settings ...............................................39