5

Expert-50 rev.10

The Expert-50 is an electronic device used for environmental control in

livestock buildings. It allows the user to maintain a specified target

temperature by controlling the operation of ventilation and heating equip-

ment. Eight heater stages, 15 fan stages, tunnel curtains and 4 clock

outputs can be connected to the controller. Fan stages can be configured

to activate cooling systems in timer mode. In all, the Expert-50 provides

up to 32 relay outputs and 2 variable-speed outputs. In addition, up to 12

air inlet modules can be connected to the Expert-50.

The main features of the Expert-50 are as follows:

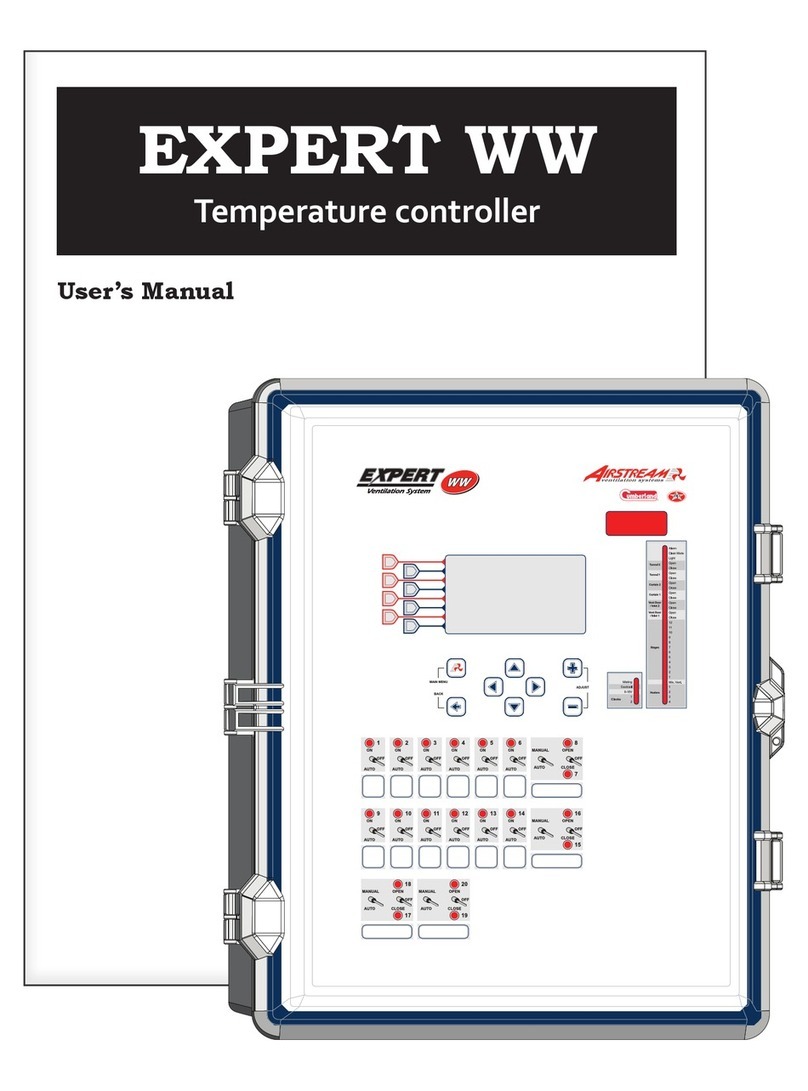

LCD DISPLAY

An LCD display provides an efficient interface for displaying, monitoring

and adjusting parameter values.

PILOT LIGHTS

Pilot lights indicating the state of outputs allow the user to monitor the

operation of the system without having to enter the building.

MINIMUM VENTILATION CYCLE

When ventilation is not required for reducing room temperature, vari-

able-speed outputs can be operated either continuously or intermittently

to reduce the level of humidity and supply oxygen to the room.

TEMPERATURE AND MINIMUM VENTILATION CURVES

The controller can be set to automatically change the temperature set

point and the minimum ventilation fan speed over a given period of time

in accordance with the user's requirements by specifying a temperature

curve and a minimum ventilation speed curve with ten different points

each.

PROBE READINGS RECORDED FOR PAST DAYS

Minimum and maximum readings from temperature and humidity probes

are recorded for the current day and the previous six days.

WATER MONITORING

A pulse input is provided for monitoring water consumption for the

current days and the previous six days.

ALARM MANAGEMENT

Alarms are provided for high-low temperatures, defective probes and

other system functions. Alarm states are kept in memory until acknowl-

edged even if alarm situation has been rectified.

FEATURES