9 of 37

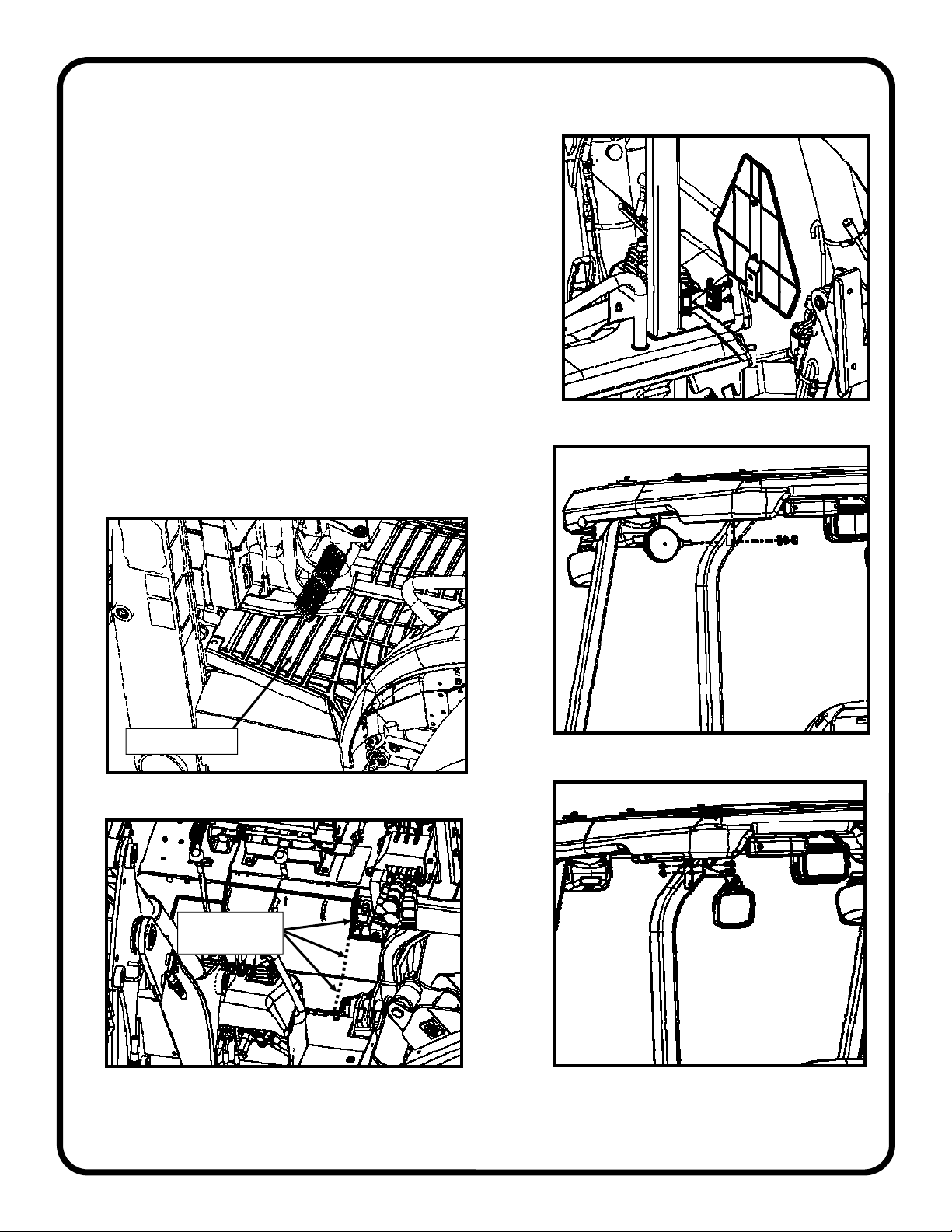

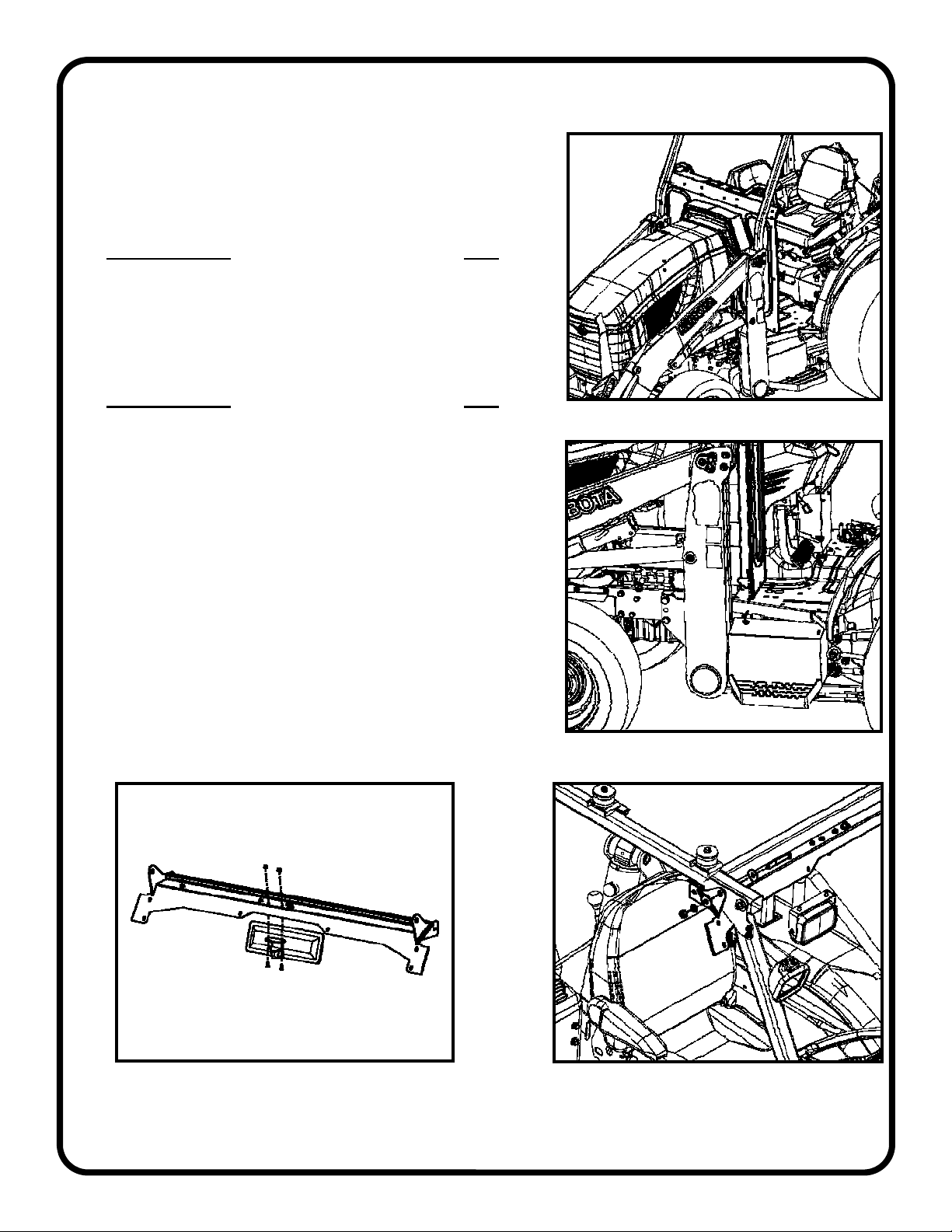

STEP 4: Rear Panel

Note: If installing this cab on a tractor with optional rear remote

hydraulics installed, Curtis kit 1KTLBL47HYD must be installed.

Refer to Step 1 in the installation manual for the kit before

installing the following rear panel otherwise there will be an

interference.

4.1 Remove and retain the outer most M12 nut, lock washer,

and flat washer from the upper front ROPS, just under the

canopy (see Figure 4.1). Push the end of the bolt flush

with the OEM side frame bracket, but do not remove.

Repeat for the other side.

4.2 With assistance, place the rear panel against the ROPS

per Figure 4.1 and push the M12 ROPS bolts through the

holes in the rear panel. Secure with the flat washer, lock

washer, and M12 nut removed in step 4.1. Leave loose.

4.3 Remove the bulb rubber trim on the right side of the rear

panel to expose the u-shaped slot.

4.4 Slice the supplied rubber grommet and install around the

vehicle wire harness

4.5 Install the grommet into the slot and re-install the bulb

rubber trim from step 4.3. The grommet will deform when

the rubber is re-installed.

STEP 5: Left Side Frame

5.1 Set a ROPS clamp in place on the left side ROPS tube

with the larger flange towards the rear as shown in Figure

5.1.

5.2 Disconnect the gas shock at the top of the door and

remove the door with assistance by unlatching at the front

via the outer handle button or inside lever, and lift the door

off the hinge pins. Remove the rear window by opening the

latch, squeezing the buttons to release the latch and lifting

the window off the hinge pins.

CAUTION: Be wary of the brass washer at each hinge pin.

For best results, remove the washers and set them aside

until the windows and doors are re-installed later.

Figure 4.1: Fasten Rear Panel

Figure 5.1: ROPS Clamp Set In Place

INSTALLATION

Figure 4.3: Install Grommet on Harness

Grommet

Bulb Rubber

ROPS Clamp