cushion packcushion pack

cushion packcushion pack

cushion pack

cushion packcushion pack

cushion packcushion pack

cushion pack

CP 333 NTi

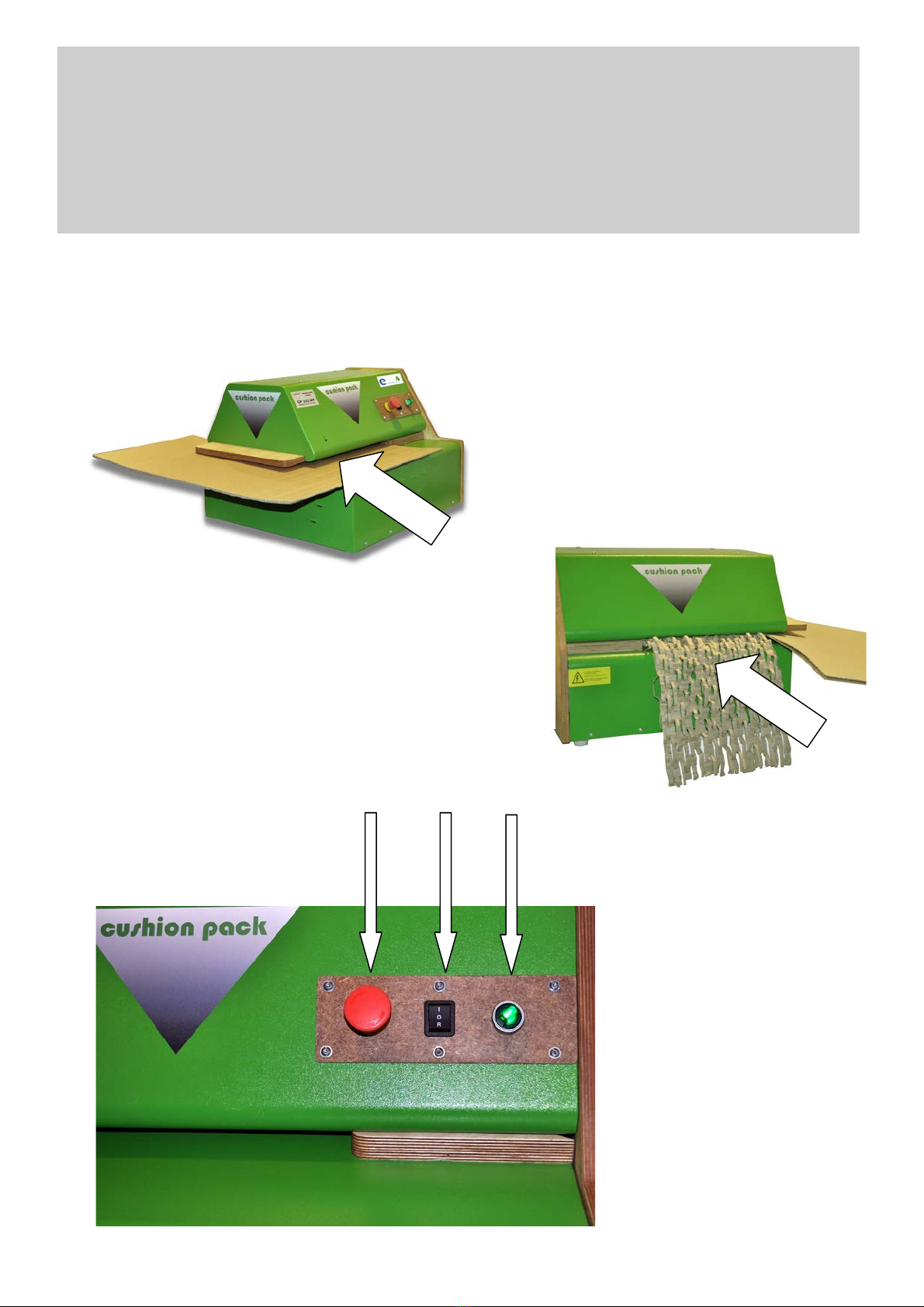

Operating Instructions – Start-up

Electrical connection - commissioning

A230/240 Volt, 50/60 Hz,AC connection is required to operate the CP 333 NTi.A2 metre

cablewith aplug isconnected tothe CP333NTi10A„inert“fuses must be provided by the

customer.

Commissioning

Connectplug to mains.Beforeputting themachineinto operation, switchonat mainswitch

(5),theoperating lamp (5)islit. Thenthemachine canbeswitched on withtheswitch (4)–the

machinestarts.

The cardboard material can now be inserted into the feed slot (1) and production of the

packaging padding can begin.

Afterpressing theEmergency-Stop switch(3),to switchonagainunlock theEmergency-Stop

switch.Press therocker switch(5) short to „R“torestart (R=resetafterpushed the

Emergencyswitch orafterover loadingthemachine). Theoperatinglamp (5) islit again.

Thenthe machine canbeswitched onwiththeswitch (4) onPos.I- themachinestarts.

Only press the Emergency Stop button in the event of danger -

do not use as an Off switch!

To switchthe machine off,place theswitch( 4)andthe mainswitch(5) off.The machineis

thencompletelydisconnected fromthe mains!

Whenthe CP333 NTiisnot inuse,the mainswitch(5) mustbeswitched offand prevented

frombeing switched onagainwhere necessary.

Iftoo thickcardboardis fedin,switch themachineoff immediatelyatthe switch(4) (pushup

toposition „0“) .Thenbriefly putrockerswitch(4) inposition„R“ (reverse/reset),switch

machineoff againandthe toothickcardboard cannowbe removedfromthe machine.

Disconnect the mains plug before opening the housing!

Rear

Atthe rear(2)the packagingpaddingmaterial comesout automatically.

Caution–the paddedmaterialmustalways fall unobstructedoutofthe outlet

channel. Do not block the channel.