3

Unframed Glass Screens

Glass screens should be mounted according to standard glazing practices for indoor installation only by those possessing proper

knowledge and tools. Use suction cups only on the polished side. Slings may be used with larger screens.

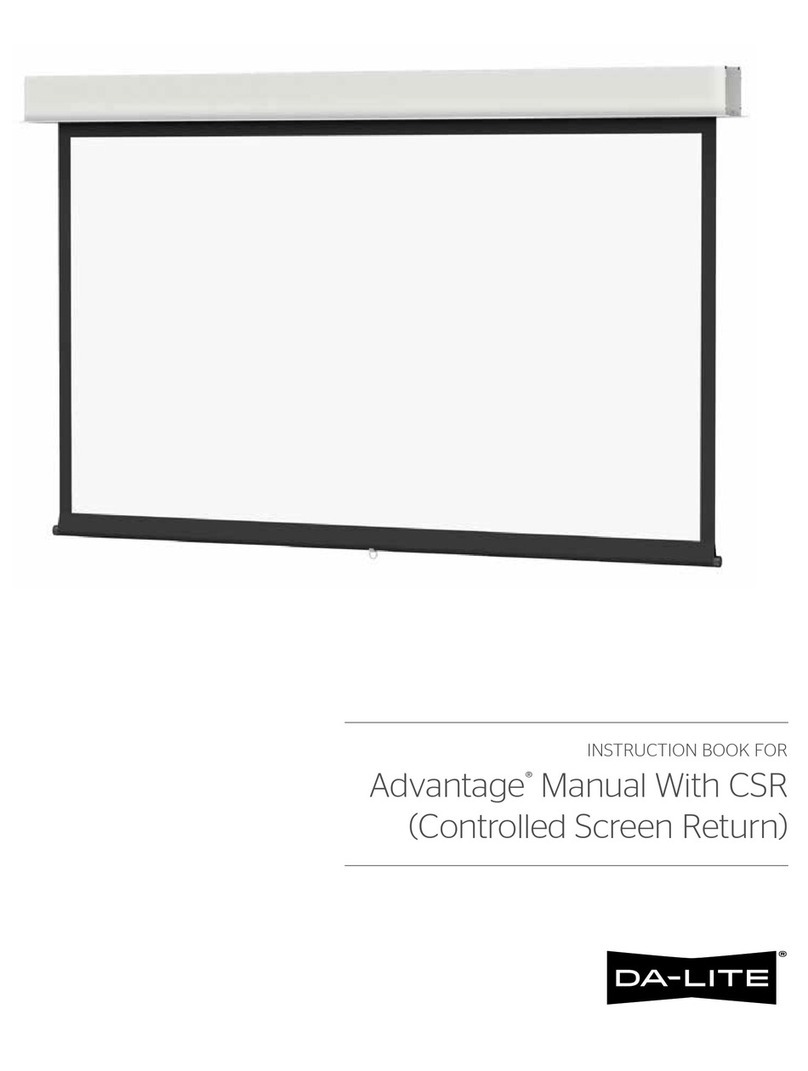

Clearance And Bite

Recommended clearance and bite are listed in Figure 1 and vary with the thickness of the glass. These recommendations should be

strictly adhered to in design and glazing. Inadequate edge clearance can result in glass-to-metal contact which will damage the glass.

Setting Blocks

Glass screens larger than 2' x 3' or thicker than 1/8" (3mm) should be set on neoprene, EPDM, elastometer or lead setting blocks placed

every foot starting 6" from the edge. When this is impractical, setting blocks should always be spaced equal distance from the center of

the glass. The length of each setting block should be 0.1" for each square foot (27mm per square meter) of glass area but never less

than 4" (100mm) in length. The setting blocks should be 1/16" (1.6mm) less than full channel width and high enough to provide the

recommended nominal bite and minimum edge clearance for the glass. This is to ensure that the glass will be supported under its

entire width and will reduce the risk of misalignment of the setting blocks during installation, either of which will cause point pressures

and could result in glass breakage.

Face Shims

Glass screens larger than 2' x 3' or thicker than 1/8" (3mm) should be set on neoprene, EPDM, elastometer or lead setting blocks placed

every foot starting 6" from the edge. When this is impractical, setting blocks should always be spaced equal distance from the center of

the glass. The length of each setting block should be 0.1" for each square foot (27mm per square meter) of glass area but never less

than 4" (100mm) in length. The setting blocks should be 1/16" (1.6mm) less than full channel width and high enough to provide the

recommended nominal bite and minimum edge clearance for the glass. This is to ensure that the glass will be supported under its

entire width and will reduce the risk of misalignment of the setting blocks during installation, either of which will cause point pressures

and could result in glass breakage.

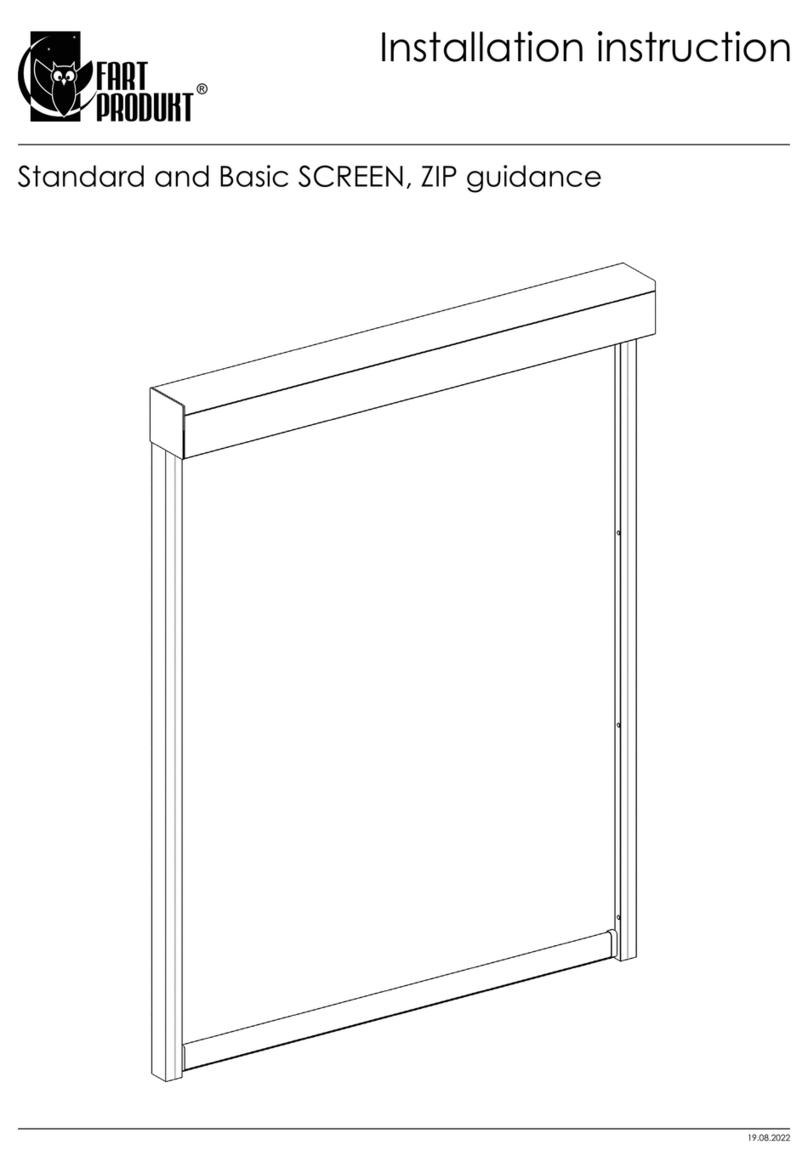

Unframed Acrylic Screens

Follow the same procedures as for glass screens, but take care to allow for the greater expansion and contraction characteristics of

acrylic plastic. Support large acrylic screens by clamping along their top edge. Refer to Figures 1 and 2.

NOTE: Drilling or reworking glass or acrylic Da-Lite In-Wall screens will void their warranty. Contact your system specialist for assistance

with alternate installation techniques or a Da-Lite Sales Partner for assistance.

HEADER

HEADER

HEADER

TRIM

TRIM

ALT. #1

SLOT

SCREEN

ALCOA

#5137

ALT. #2

NOTE:

Grip may be improved

with friction tape at “A”.

Support screen with

wedges at “B” until

clamping is completed.

Leave clearance along

lower edge.

Strip cemented

to polished side

(Use an epoxy of

sufficient strength to

support the weight

of the screen).

NOTE:

Top Clamping is not required

when mounting 1/4" thickness

less than 72" high; 3/8" thickness

less than 85" high or 1/2" thickness

less than 98" high.

A

A

B

SCREEN

ALT. #3

Trim and moulding by others.

Minimum Face Clearance (“A”): 1/4 in., 6.4 mm

Bite Dimensions (“B”)

Glass Thickness Min. Max.

1/4" (6.4 mm) 3/8" (9.5 mm) 5/8" (15.9 mm)

3/8" (9.5 mm) 1/2" (12.7 mm) 3/4" (19.1 mm)

1/2" (12.7 mm) 3/4" (19.1 mm) 1" (25.4 mm)

Minimum Edge Clearance (“C”)

Glass Thickness Min. Clearance

1/4" (6.4 mm) 1/4" (6.4 mm)

3/8" (9.5 mm) 5/16" (7.9 mm)

1/2" (12.7 mm) 3/8" (9.5 mm)

WALL or PARTITION

Steel,

Wood or

Aluminum Frame

“A”

“B”

“C”

Glass

____ x ____

Viewing

Area

Overall Panel

Size __ x __

Figure 1

Figure 2

Glass Panel Mounting and Frame Suggested Top Clamping for Acrylic Panels