General Information

Introduction .....................................................................1

Model Identification ..................................................... 2-3

Failure Analysis ...........................................................4-5

Inspection........................................................................6

Differential Carrier Assembly - Parts................................7

Remove Differential Carrier..........................................8-9

Install Differential Carrier...............................................10

Remove Wheel Differential (All Standard Models) ..........11

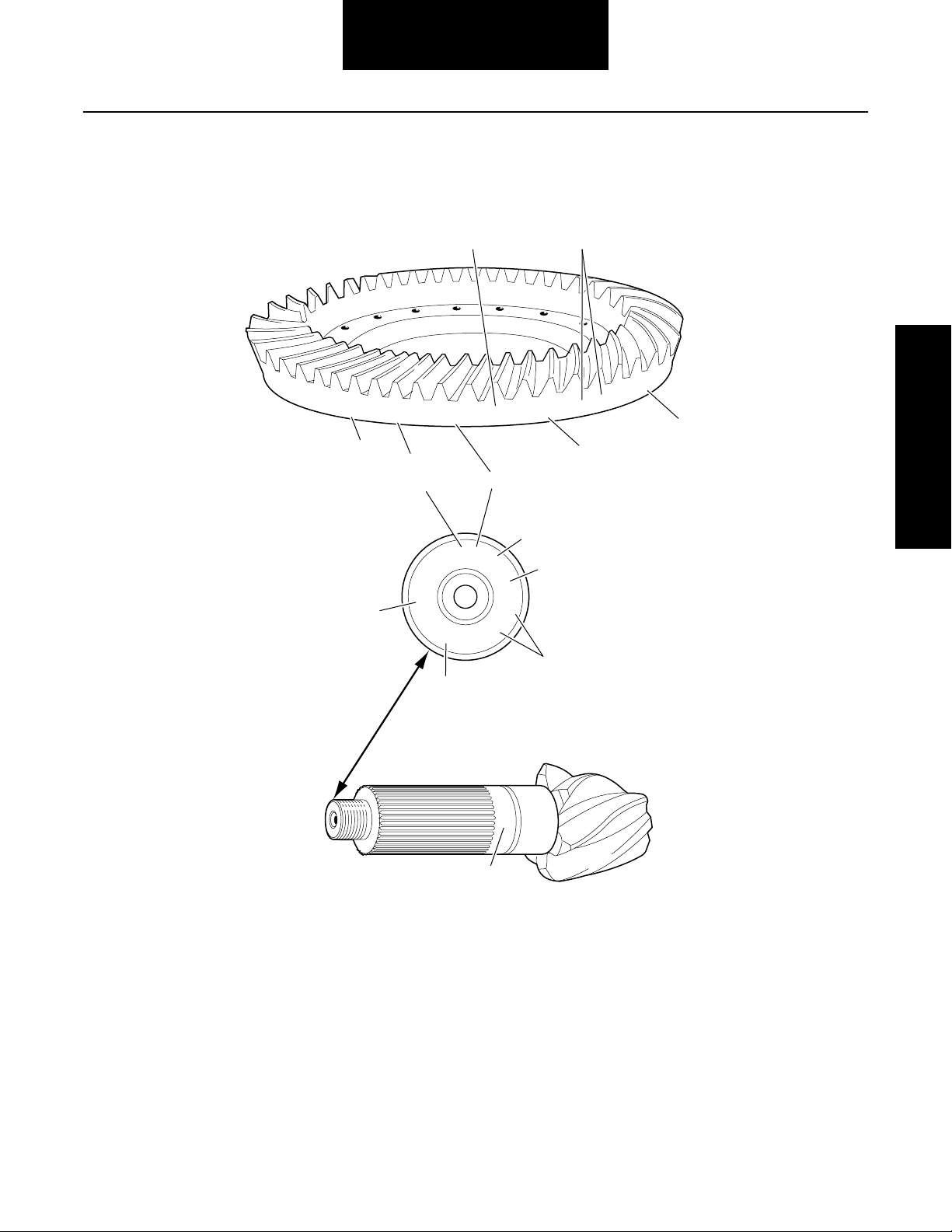

Pinion Removal .........................................................12-13

Pinion Assembly - Parts Exploded View .........................14

Drive Pinion Overhaul and Assembly.........................15-19

Wheel Differential - Parts Exploded View...................... 20

Wheel Differential Disassembly - Before July 2013

Forward Carrier Assembly .................................. 21-22

Wheel Differential Assembly -

Forward Carrier Assembly .................................. 23-24

Install Wheel Differential Assembly -

Forward Carrier Assembly .................................. 25-29

Wheel Differential Disassembly - After July 2013

Forward Carrier Assembly .................................. 30-31

Wheel Differential Assembly -

Forward Carrier Assembly .................................. 32-34

Install Wheel Differential Assembly -

Forward Carrier Assembly .................................. 35-37

Adjust Tooth Contact Position ..................................38-39

Wheel Differential Lock - Parts Exploded View.............. 40

Install and Adjust Wheel Differential Lock ......................41

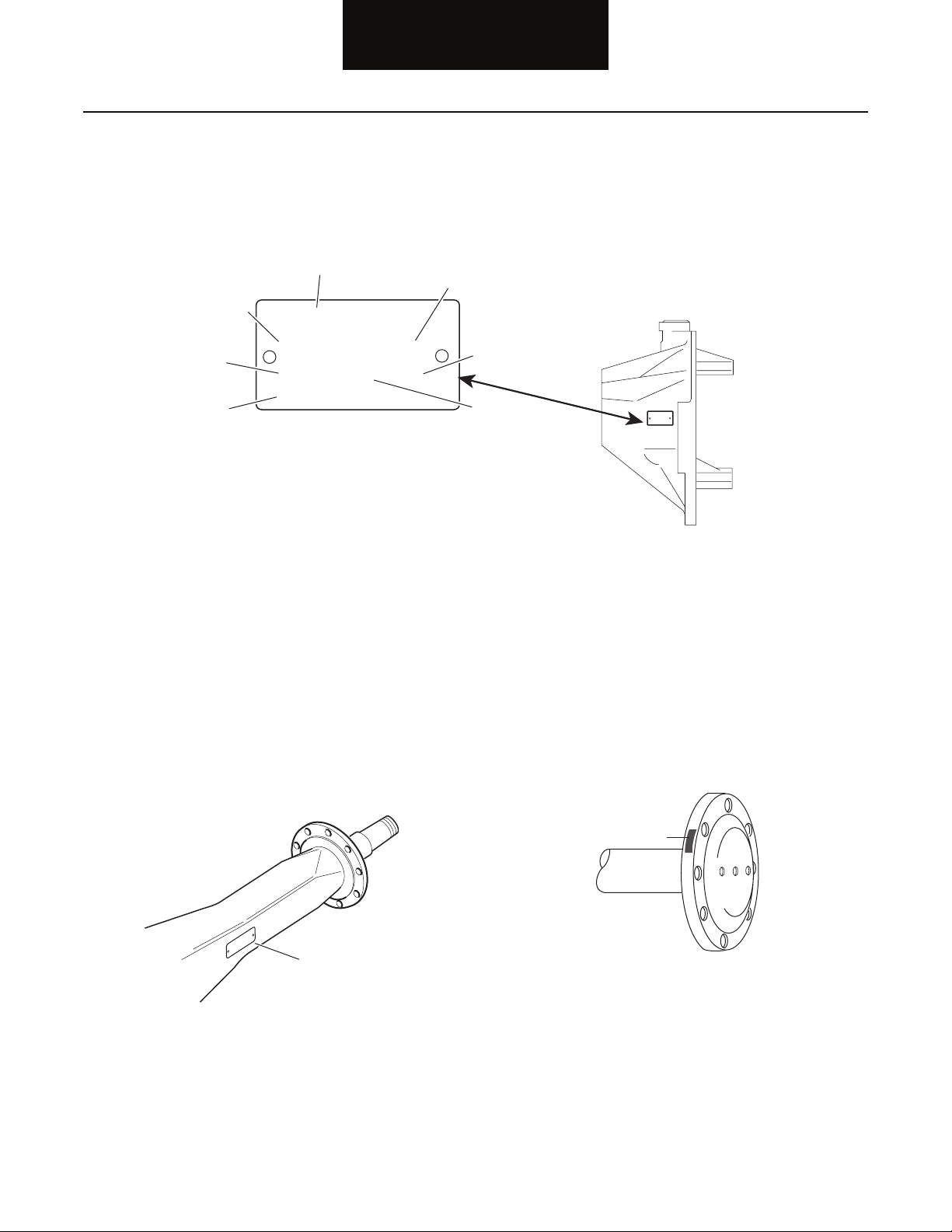

Housing and Output Shaft Assembly -

Parts Exploded View.................................................42

Replace Seal............................................................43-44

Service Kit.................................................................... 45

Housing Breather.......................................................... 46

Wheel End Seal - Parts Exploded View ..........................47

Remove and Overhaul Wheel End Seal.......................... 48

Adjust Wheel Bearing...............................................49-50

Verify Wheel Endplay Procedure ....................................51

Lubricate Wheel End................................................ 52-53

General Lubrication Information.................................... 54

Lube Change Intervals .................................................. 55

Change Lube ................................................................ 56

Standpipes .............................................................. 57-58

Proper Vehicle Towing....................................................59

Power Divider Operation

(Power Flow and Torque Distribution) .................60-61

Operate Wheel Differential Assembly.............................62

Direct Driver-Controlled System.................................... 63

Wheel Differential Lock............................................64-65

Pinion Assembly - Parts Exploded View ........................ 66

Wheel Differential -

Parts Exploded Views ...............................................67

Wheel Differential Lock Assembly -

Parts Exploded Views .............................................. 68

Housing and Output Shaft Assembly -

Parts Exploded View................................................ 69

Fastener Torque Specifications ......................................70