D&H DH05A/B User manual

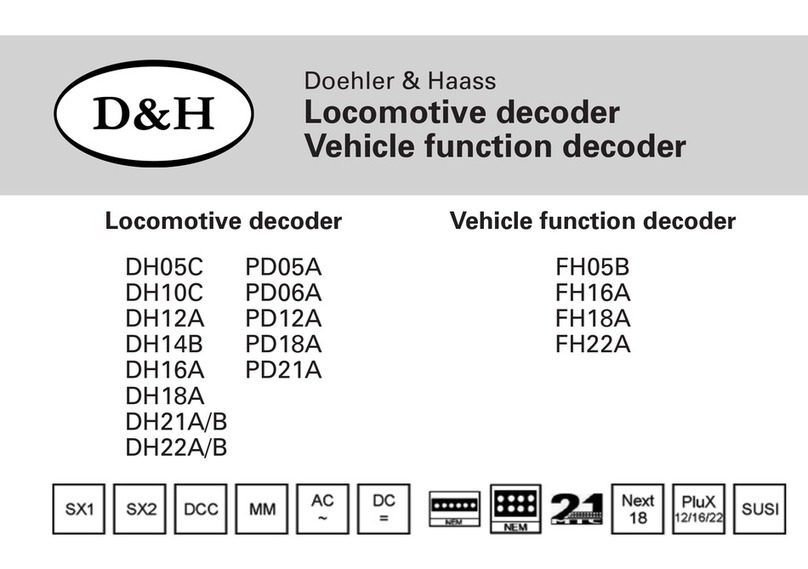

Doehler & Haass

LOCOMOTIVE DECODER

DH05A/B

DH10A/B

FH05A

2

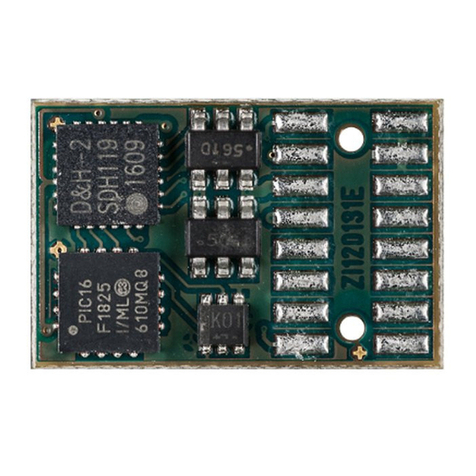

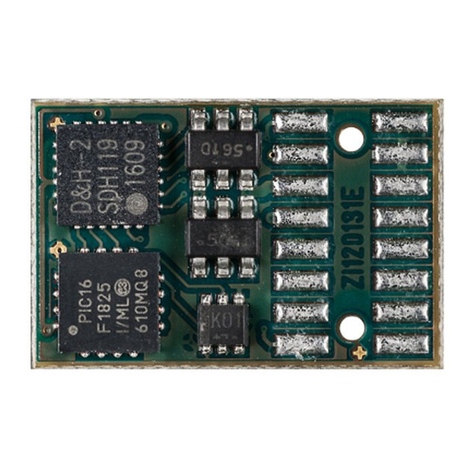

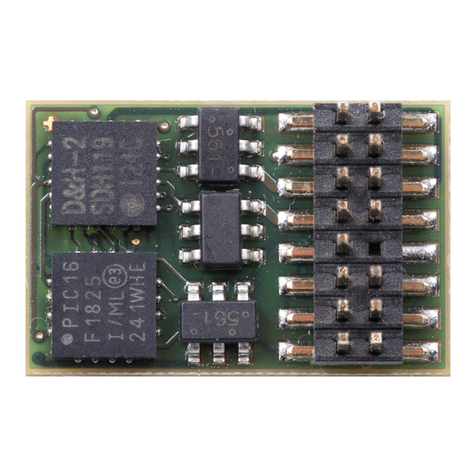

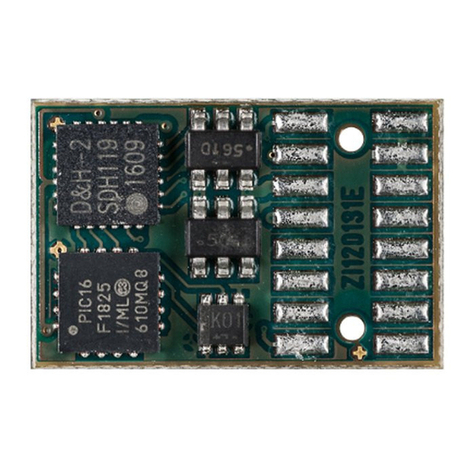

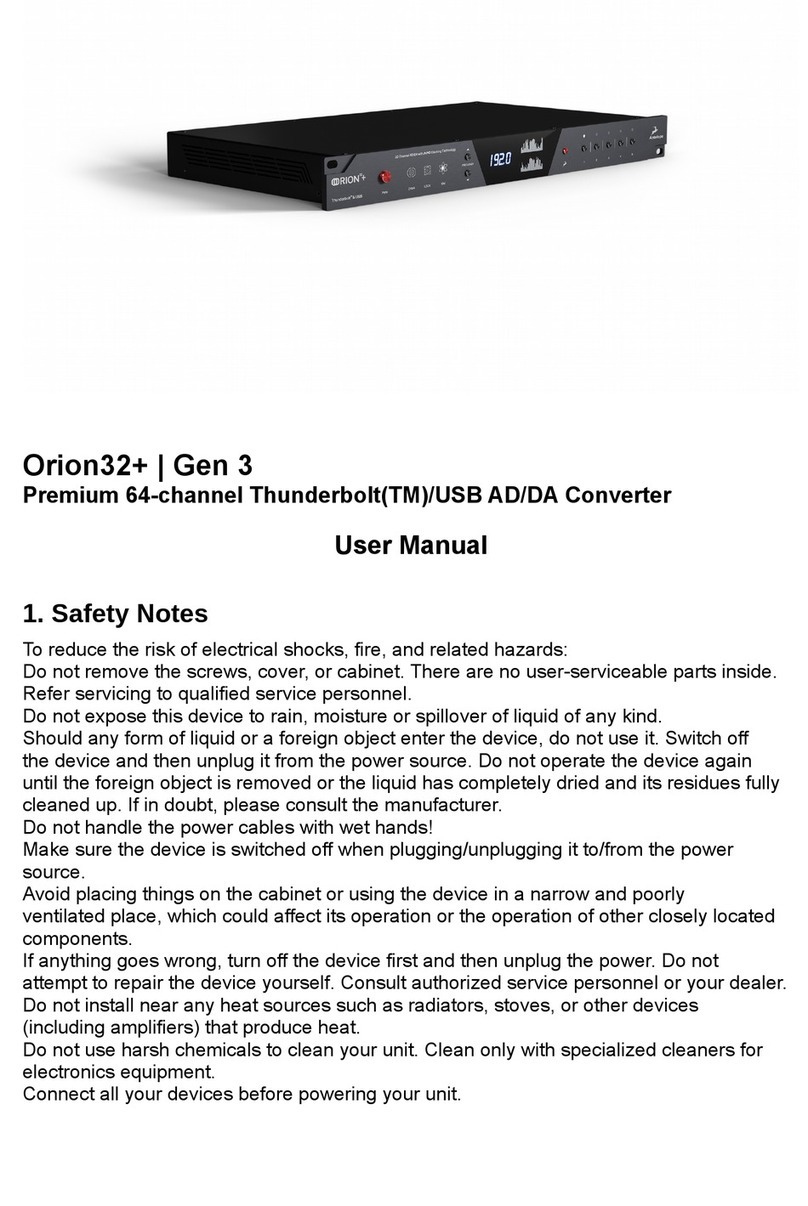

Loco Decoder DH05A/B

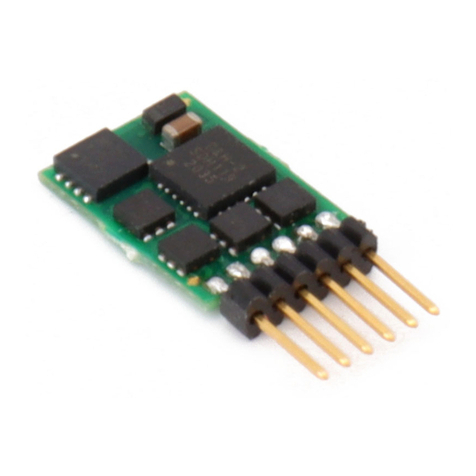

Loco Decoder DH10A/B

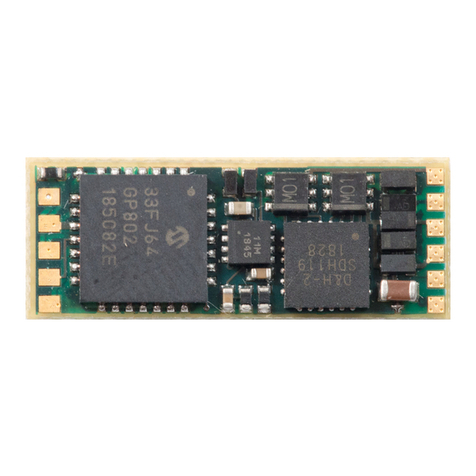

Function Decoder FH05A

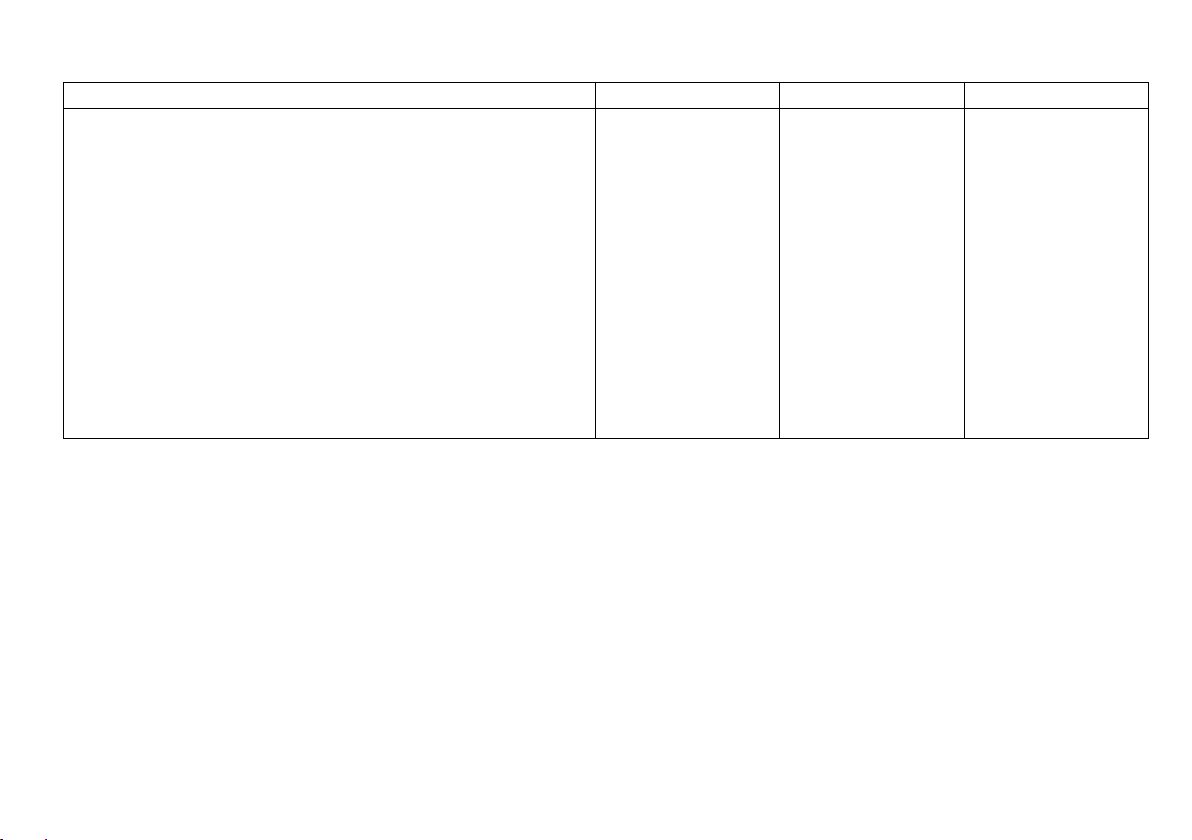

G1, G2 Track 1, 2

M1, M2 Motor 1, 2

LV Front light

LR Rear light

AUX1, AUX2 Additional functions 1, 2

ZVS SUSI supply voltage

ZCLK SUSI clock

ZDAT SUSI data

GND SUSI ground

3

Content

1 Introduction 4

2 Safety instructions 5

3 Warranty 5

4 Support and Help 5

5 Functions 6

6 Decoder-Installation 7

6.1 Preparation 7

6.2 Check after the insertion 7

6.3 Installation 8

7 Operating system SelecTRIX 1 (SX1) 11

7.1 Functions 11

7.2 Setup features 11

7.3 Operation 14

7.4 Explication of the signal-stopping section 14

8 Operating system DCC 15

8.1 Functions 15

8.2 Setup features 15

8.3 Operation 22

9 Operating system SelecTRIX 2 (SX2) 23

9.1 Functions 23

9.2 Setup features 23

9.3 Operation 30

Supplement 1 31

Supplement 2 33

4

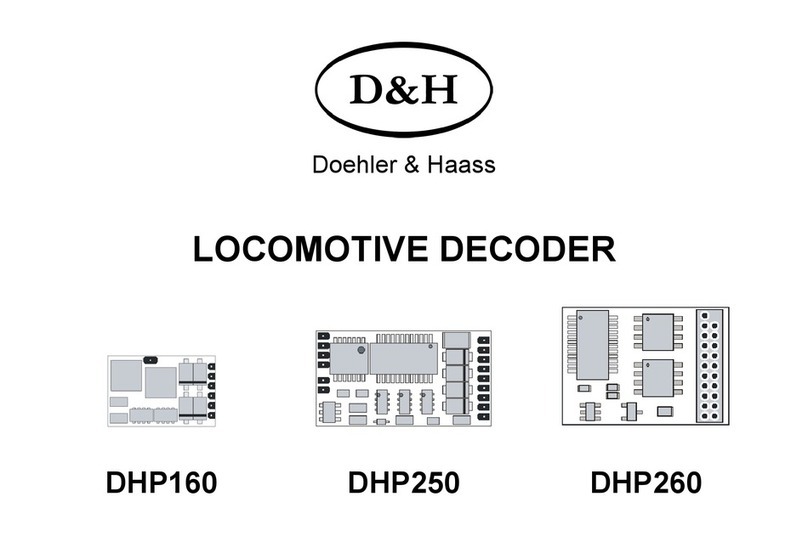

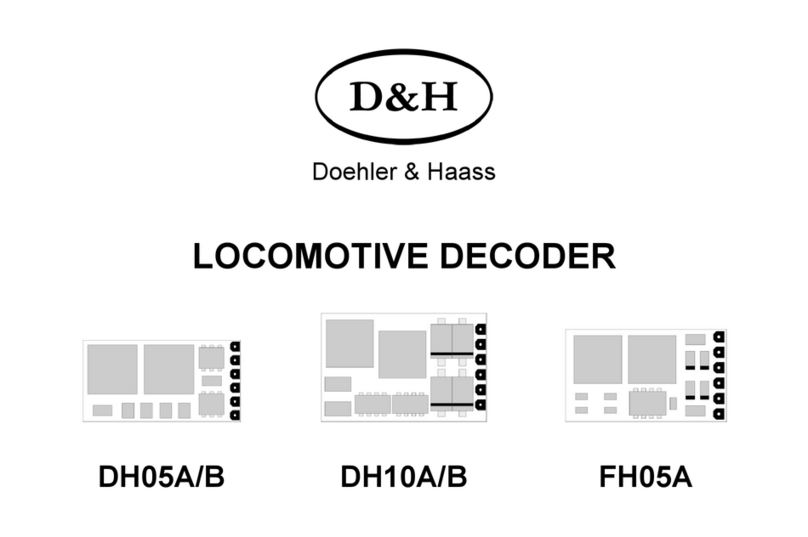

DH05A/B

DH10A/B

FH05A

Specifications

Dimensions [mm]

Total load

Maximum motor current

Maximum operating voltage

Function outputs light: LV, LR

Function outputs AUX1, AUX2

SUSI interface

Connection options

Without connection wires

With ribbon cable for interface per NEM651

With connection wires

13,2 x 6,8 x 1,4

0,5 A

0,5 A

18 V

each 150 mA

each 300 mA

not available

DH05A/B-0

DH05A/B-1

DH05A/B-3

14,3 x 9,2 x 1,8

1,0 A

1,0 A

30 V

each 150 mA

each 300 mA

not available

DH10A/B-0

DH10A/B-1

DH10A/B-3

13,7 x 7,8 x 1,5

0,5 A

--

30 V

each 150 mA

each 300 mA

available

FH05A-0

FH05A-1

FH05A-3

1 Introduction

The locomotive decoder DH05A/B, DH10A/B and FH05A are compatible with the protocols of SelecTRIX

Standard SX1 / SX2 as well as with NMRA-DCC-Standard. They can be controlled by every central control

unit working with one of these data formats.

They can be used for normal direct current motors as well as for coreless motors.

The operation on alternating current supplied layouts with switching impulse is not allowed. The

impulse excitation will destroy the decoder.

5

2 Safety instructions

This product is not suitable for children under 14 years! It might be swallowed by children under 3 years!

An improper use involves a risk of injury due to sharp edges and points.

3 Warranty

The functioning of every decoder is fully tested before delivery. The warranty period is 2 years from the date

of purchase. Should a failure occur during this period please contact the dealer where you purchased the

decoder respectively directly the producer Doehler & Haass.

4 Support and Help

In case you have any problems or questions, please contact us by E-Mail under the address

Normally you will get an answer within a few days.

6

5 Functions

Operation can be controlled either by conventional DC command stations or by digital central units

supporting the formats SelecTRIX 1 and 2 or NMRA-DCC

Automatically switchover from conventional DC to digital operation

In case of digital operation the last programmed system will be activated (no automatically switchover!)

SelecTRIX 1 31 speed steps, 100 addresses

SelecTRIX 2 127 speed steps, 10.000 addresses, 16 additional functions

DCC Short addresses (1-127), long addresses (0001-9999),

with 14, 28, 126 speed steps

Load compensation state of the art, that way an especially smooth regulation behavior

Various regulation variants for an optimal adaptation to the motor

127 internal speed steps

Adjustable motor frequency (low frequency, 16 kHz, 32 kHz)

Block system operation by simple diodes (digital operating system)

Light and function outputs can be dimmed and activated analogically

Shunting gear

Electronic interchange ability of motor, lighting and track connections

All function outputs freely programmable

Thermal protection, insulation

Reset function for DCC and SX2

Decoder can be updated:

The update can be executed on the incorporated decoder when the loco is standing on the track (no

need to open the engine, the SW-Download can be downloaded from the Internet cost free)

7

6 Decoder-Installation

6.1 Preparation

Check if the locomotive is in perfect running order electrically and mechanically, prior to any mounting work.

Defects and dirt must be eliminated first. Pay attention to the instructions of the locomotive producer. Only

locomotives running smoothly in analogue mode, should be equipped with a digital decoder. New

locomotives should be run in at least 30 minutes in each direction of travel.

Before you start, insulate the motor and all its terminals completely against track connections (chassis,

collector slipper, etc.).

Both motor connections must be disconnected from the ground!

Further on, all condensers have to be removed, particularly those associated with the connections of light

and motor.

Fix the decoder with a double sided adhesive tape.

6.2 Check after the insertion

The first test should be executed in the programming mode (e.g. by reading out the address). In case of an

incorrect feedback (confirmation signal) to the central unit ("error"), please check again the correct

assignment of the connections respectively if the motor is really disconnected from the chassis electrically.

8

6.3 Installation

There are three variants to connect the decoder:

1 In case your locomotive is equipped with an interface (NEM 651), you should take the decoder

DH05A/B-1, DH10A/B-1respectively FH05A-1. They have already the appropriate connections for this

plug. Shorten the ribbon cable up to approximately 5 mm and remove the rest of the insulation. The

decoder can be inserted into the interface without any problem now.

2 If the locomotive is not equipped with an interface jack, the decoder must be wired up individually. For

this purpose you should use decoder with flexible wires (DH05A/B-3, DH10A/B-3respectively

FH05A-3).

3 The decoder DH05A/B-0, DH10A/B-0respectively FH05A-0should be used by experienced model

railroaders only as the connection wires must be soldered directly onto the decoder.

9

Connect the decoder wires accordingly to the following diagram:

red wire with the right track wire (G1)

black wire with the left track wire (G2)

orange wire with the motor wire, which was connected to the right track (M1)

gray wire with the motor wire, which was connected to the left track (M2)

white wire with the front light (LV)

yellow wire with the rear light (LR)

In addition for SUSI interface (only if available):

red wire SUSI supply voltage (ZVS)

blue wire SUSI clock (ZCLK)

gray wire SUSI data (ZDAT)

black wire SUSI ground (GND)

10

Function outputs:

The function outputs AUX1 and AUX2 are on the underside of the decoder and must be connected to

the consumers with individual wires (see Illustration, page 2).

Notice:

In case of an incorrect wiring of motor, lighting and track, there is no need to solder off the wires as the

assignment can be interchanged electronically by programming (see adjustment options of the

respective operating system).

11

7 Operating system SelecTRIX 1 (SX1)

7.1 Functions

Speed steps 31

Speed steps (internal) 127

Front light / rear light

Additional functions 2

Additional channel available

(Loco address + 1) with 8 additional functions

7.2 Setup features

All locomotive parameters can be varied by programming freely at any time. Please, take the information

concerning the programming from the instructions of your programming device.

Basic setups

Loco address 01 … 111 (01)

Velocity 1 … 7 (5)

Acceleration / Deceleration 1 … 7 (4)

Impulse width (duration) 1 … 4 (2)

Signal-stopping section 1 / 2 parts (1)

12

Extended setups

Interchange of connections (V) 0 … 7 (4)

Activation of AFB and additional channel (A) 1 … 6 (1)

Motor regulation variant (I) 1 … 4 (3)

AFB ("Automatische Fahr-/Bremssteuerung") = Automatically acceleration / deceleration control

Interchange of connections 0 … 7 (4)

Interchange motor connections 1

Interchange light connections 2

Interchange track connections 4

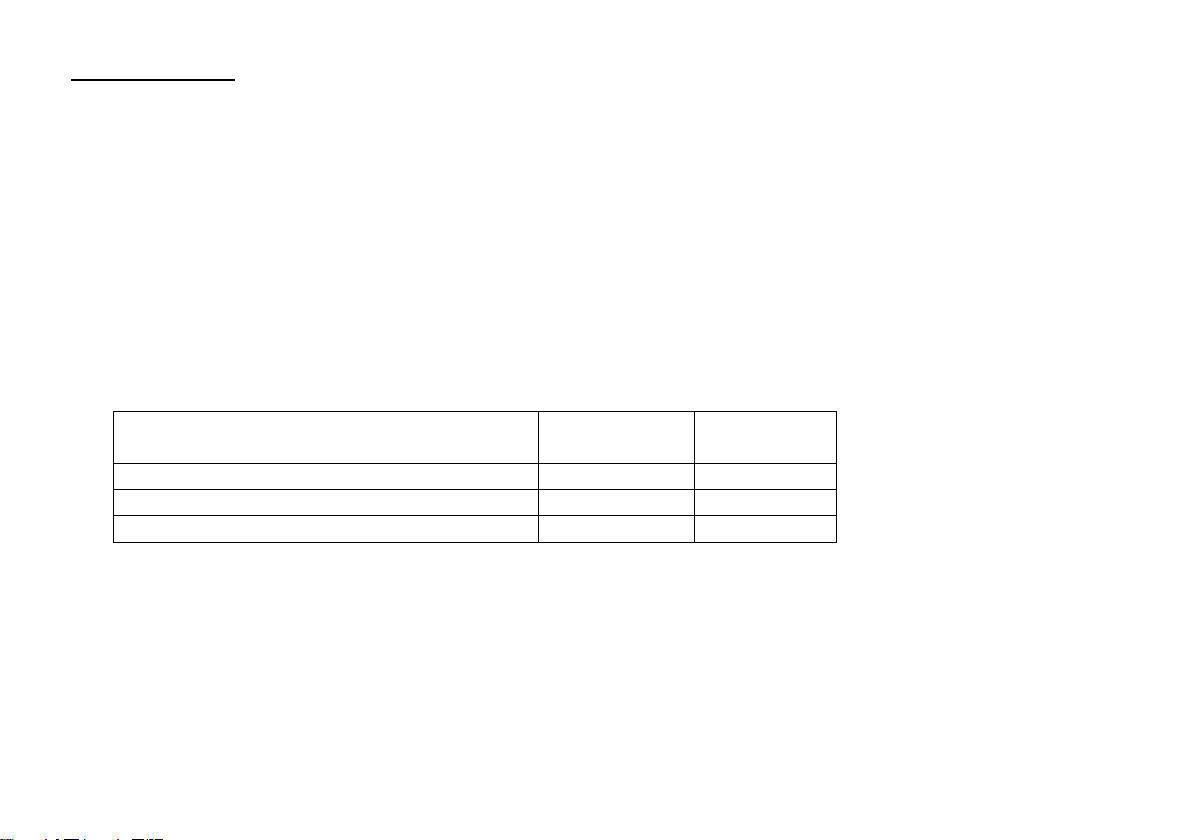

Activation of AFB and additional channel

Function

With

AFB

Without

AFB

Without additional channel

1

2

With ZK*) without function mapping

3

4

With ZK*) with function mapping

5

6

*) the additional channel ZK ("Zusatzkanal") has always the address: Loco address + 1

Motor regulation variant 1 … 4

User defined by par056 ff. 1

Hard 2

Soft 3

Very soft 4

13

Reading out the extended characteristic values is executed by the entry of the character sequence

00–111

and a subsequently push on the programming key.

Writing of the extended characteristic values is executed by the entry of the character sequence

00=VAI

and a subsequently push on the programming key.

Notice:

Coreless motors should be operated with regulation variant 4 and pulse width 1. Damages due to

incorrect adjustments are excluded from the warranty.

Caution!

Reading out and entering extended characteristic values overwrites the default-values of the decoder.

In case you have varied the extended characteristic values, the default characteristic values of the

decoder must be entered anew.

14

7.3 Operation

Put the locomotive on the programming track and read out the programming parameters of the decoder.

The default value should be 01-542. Program the desired locomotive address and start running the

locomotive keeping the other parameter values. After the first check you can vary the parameters of the

engine freely according to your requirements.

In case your programming device indicates "error", please check again the correct wiring of the locomotive

and pay attention to the wiring instructions of the programming track. Never put such a locomotive into

operation!

7.4 Explication of the signal-stopping section

One-part signal-stopping section:

In front of the signal one track section is controlled by a diode. The decoder must be programmed on

one-part stopping section (-). The locomotive will be braked to a halt.

Two-part signal-stopping section:

In front of the signal there are two track sections. The first one is controlled by a diode and the

locomotive will be braked down to internal speed step 3 in this section. The second one is without

supply and the locomotive will stop just in front of the signal. The decoder must be programmed on

two-part stopping section (=).

15

8 Operating system DCC

8.1 Functions

Short addresses 1 –127

Long addresses 0001 –9999

Speed steps 14, 28, 126

Speed steps (internal) 127

Front light / rear light (can be dimmed)

Additional functions (can be dimmed) 2

Operation with break diodes yes

Operation with break generators yes

Consist mode yes

Full NMRA conform yes

Programming on the main (POM) yes

8.2 Setup features

The characteristics of a locomotive operated in the DCC-operating mode can be varied by programming the

configuration variables (CV) freely at any time. The programming procedure is described in the instructions

of your programming device.

Notice:

In case the speed steps programmed on the decoder differ from those of the control device,

malfunctions may occur. Please pay attention to the respective information concerning your digital

system.

16

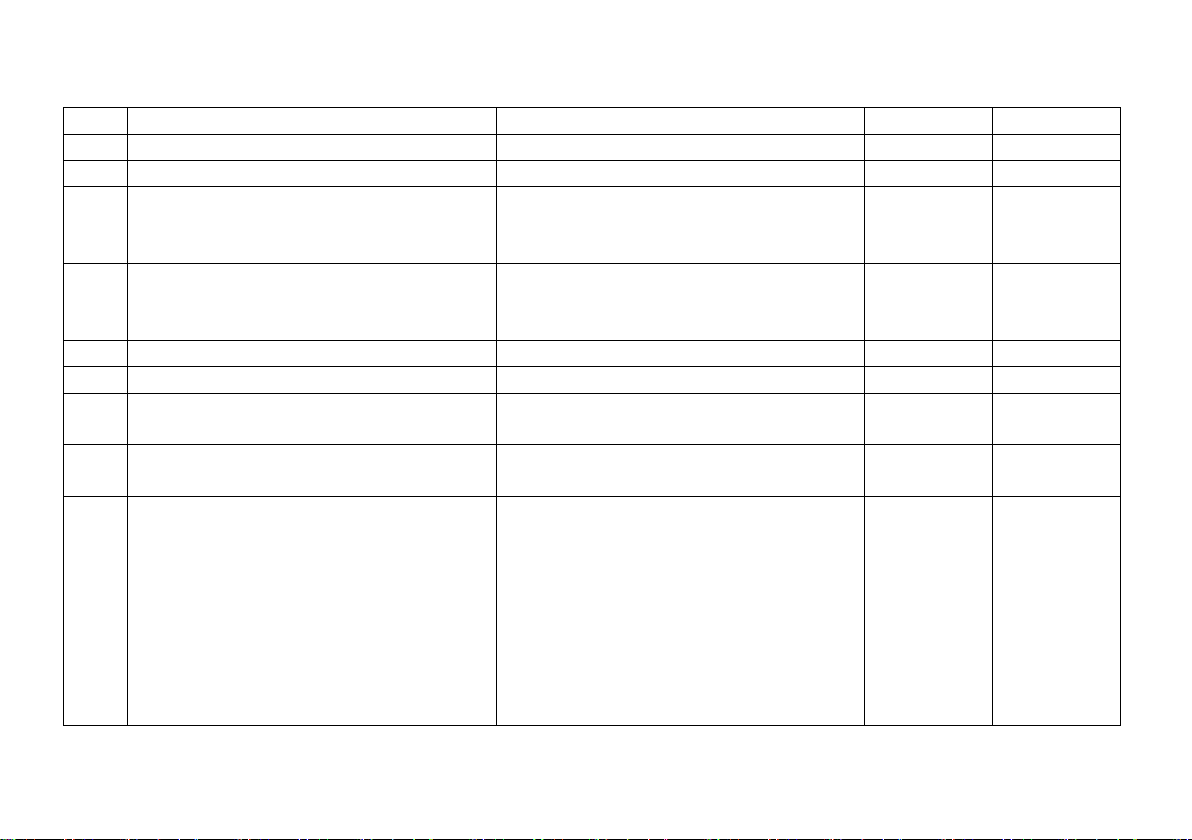

List of supported CV:

CV

Name

Definition

Range

Standard

01

Short address

0 –127

3

02

Starting voltage

Minimum speed

0 –15

0

03

Acceleration time

The value corresponds to the time

in seconds from start to maximum

speed

0 –255

3

04

Deceleration time

The value corresponds to the time

in seconds from maximum speed to

stop

0 –255

3

05

Maximum speed

See supplement 2

0 –127

92

07

Version number

Version number

08

Manufacturer identification

97 = Doehler & Haass

Decoder Reset by "8"

09

Motor frequency

0 = 32 kHz, 1 = 16 kHz,

2 = low frequency

0 –2

0

13

Analog mode F1 –F8

Bit Function Value

0 F1 1

1 F2 2

2 F3 4

3 F4 8

4 F5 16

5 F6 32

6 F7 64

7 F8 128

0 –255

1

17

14

Analog mode FL, F9 –F12

Bit Function Value

0 FL (f) 1

1 FL (r) 2

2 F9 4

3 F10 8

4 F11 16

5 F12 32

0 –63

3

17

18

Long address

CV17 contains the most significant

byte, CV18 contains the least

significant byte,

Only if activated by CV29

0 –255

192

0

19

Consist address

Several compound locos run under

this address.

0 = deactivated

Value + 128 = inverse direction

0 –127

0

21

Consist mode F1 –F8

Bit Function Value

0 F1 1

1 F2 2

2 F3 4

3 F4 8

4 F5 16

5 F6 32

6 F7 64

7 F8 128

0 –255

0

18

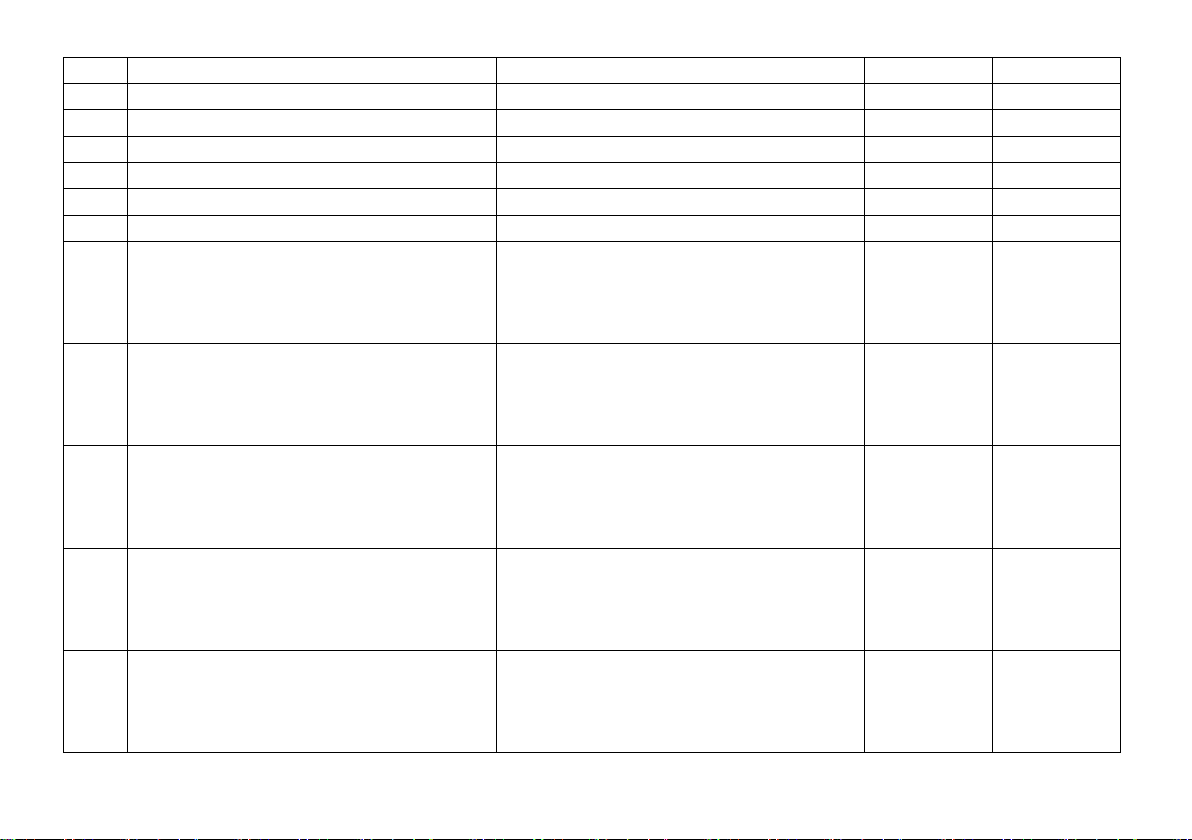

22

Consist mode FL, F9 –F12

0 FL (f) 1

1 FL (r) 2

2 F9 4

3 F10 8

4 F11 16

5 F12 32

0 –63

0

29

Configuration register

Various adjustments

Bit Function

0 Inverse direction

1 14 ↔ 28/126 speed steps

2 Analog operation permitted

3 ---

4 ---

5 Long address by CV17/18

6 ---

7 ---

0 –255

6

33

Function mapping F0(f)

See supplement 1

0 –255

1

34

Function mapping F0(r)

See supplement 1

0 –255

2

35

Function mapping F1(f+r)

See supplement 1

If CV35 is written, CV47 will be set

to the same value

0 –255

4

36

Function mapping F2(f+r)

See supplement 1

If CV36 is written, CV64 will be set

to the same value

0 –255

8

37

Function mapping F3

See supplement 1

0 –255

16

38

Function mapping F4

See supplement 1

0 –255

128

39

Function mapping F5

See supplement 1

0 –255

32

19

40

Function mapping F6

See supplement 1

0 –255

0

41

Function mapping F7

See supplement 1

0 –255

0

42

Function mapping F8

See supplement 1

0 –255

64

43

Function mapping F9

See supplement 1

0 –255

0

44

Function mapping F10

See supplement 1

0 –255

0

45

Function mapping F11

See supplement 1

0 –255

0

46

Function mapping F12

See supplement 1

0 –255

0

47

Function mapping F1(r)

See supplement 1

In case CV47 should have

another value as CV35, you have

to set CV35 first and then CV47

0 –255

4

48

Characteristic diagram

Response curve

0 = linear

7 = logarithmic

See supplement 2

0 –7

5

49

Impulse with

0 = 1 ms

1 = 2 ms

2 = 4 ms

3 = 8 ms

0 –3

1

50

Regulation variant

0 = User defined by CV56 ff.

1 = Hard

2 = Soft

3 = Very Soft

0 –3

2

51

Interchange of connections

Bit Function Value

0 Motor connections 1

1 Light connections 2

2 Track connections 4

0 –7

0

20

52

Dimming light "normal"

0 = off … 31 = full brightness

0 –31

31

53

Dimming light "alternative"

0 = off … 31 = full brightness

0 –31

15

54

Dimming AUX1

0 = off … 31 = full brightness

0 –31

31

55

Dimming AUX2

0 = off … 31 = full brightness

0 –31

31

56

Motor proportional controller

Only if activated by CV50 = 0

0 –7

3

57

Motor integral controller

Only if activated by CV50 = 0

0 –3

3

58

Motor measurement period

Only if activated by CV50 = 0

0 –3

1

59

Motor impulse width

Only if activated by CV50 = 0

0 –7

3

60

Signal-stopping section

1 or 2

0, 1

0

61

Shunting gear speed

0 –127

63

62

Shunting gear deceleration

See CV03

0 –255

1

63

Start delay speed step 1

0 –250

0

64

Function mapping F2(r)

See supplement 1

In case CV64 should have

another value as CV36, you have

to set CV36 first and then CV64

0 –255

8

105

User identifier 1

0 –255

0

106

User identifier 2

0 –255

0

113

Preclusion for LV

Bit 0 = F1 to bit 7 = F8

0 –255

0

114

Preclusion for LR

See CV113

0 –255

0

115

Preclusion for AUX1

See CV113

0 –255

0

116

Preclusion for AUX2

See CV113

0 –255

0

117

Timer for clear AUX1

Each 100 ms, 0 = deactivated

0 –250

0

118

Timer for clear AUX2

Each 100 ms, 0 = deactivated

0 –250

0

119

Timer for clear AUX3

Reserved

120

Timer for clear AUX4

Reserved

This manual suits for next models

2

Table of contents

Other D&H Media Converter manuals