Cascade HC/HFC - CO2system Application guide RA8AB102 © Danfoss 10/2010 3

Temperatures and pressures

in cascade systems (contin-

ued)

On systems with low temperatures of the dis-

charge CO2 gas (low superheat), the superheat

of the expansion valve can be the dimensioning

factor for the heat exchanger.

If a CO2 system has high superheat, then desu-

per-heaters need to be used in order to reduce

the load on the high temperature side.

Optimal intermediate pressure in CO2 cascade

systems depends on a number of parameters

(high temperature refrigerant, load pattern etc.).

Generally 2 cases need to be considered:

Operating sequence of cas-

cade systems

1) Systems with load at the medium temperature.

In this case intermediate pressure should be as

high as possible in order to reduce the load at

the high temperature stage. The limitations are

therefore required temperature on the intermedi-

ate level and pressure rating of the system.

2) Systems without load at medium temperature.

In this case the intermediate temperature should

be in the range of -10 - 0°C (due to the high pres-

sure of the CO2LT) where lower limit is defined

by efficiency and higher by system pressure

rating

In Cascade Systems, it is essential that at least

one compressor in the high temperature side is

running before the first compressor in the low

temperature side can start. Otherwise, the com-

pressor in the low temperature side may be cut

out due to high pressure.

The same sequence is also valid for filling up the

system. First of all, the high temperature circuit

needs to be filled with refrigerant and started up.

When this is done, the CO2can be filled into the

low temperature system.

The high temperature expansion valve (ETS) to

the cascade heat exchanger should begin simul-

taneously with the high temperature compres-

sors. After this, the valve controls the superheat

of the high temperature gas. LT compressors are

then started up by the CO2pressure increase on

the suction line.

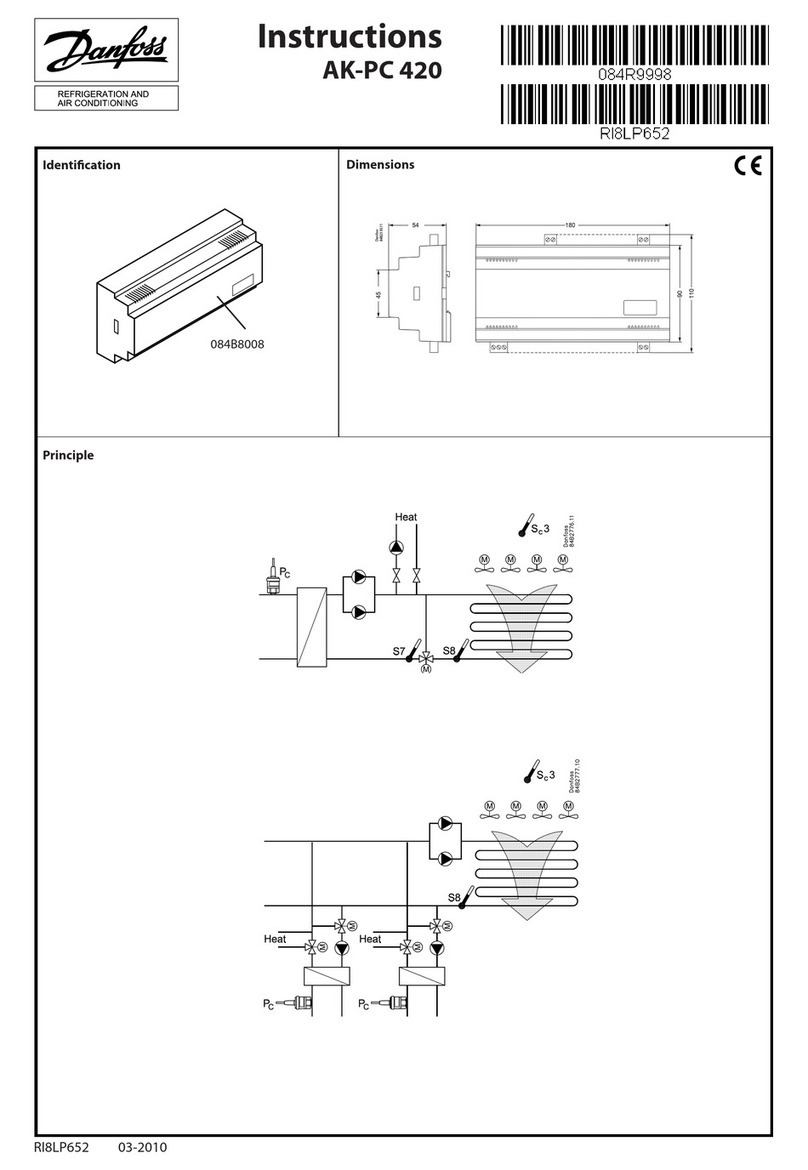

Danfoss pack controllers such as AK-PC 740 and

AK-PC 780 are specially designed with built in

control functions to coordinate these operations.

Injection into cascade heat

exchanger

Injecting liquid into a plate heat exchanger is

not a trivial matter. The heat exchanger is often

compact and therefore the time constant is very

low. AKV valves are not recommended for this

application.

It is recommended to use motor valves or other

valves that give constant flow. Desuper-heating

of CO2gas entering the cascade heat exchanger

can also be recommended for three reasons.

One reason is that the gas is often 60°C and

therefore the heat can be rejected to the ambient

or used for heat recovery without problems. The

second reason is to reduce thermal stress in the

heat exchanger. The third reason is that the CO2

gas gives very high heat fluxes which therefore

create unstable conditions on the evaporation

side. Therefore it is recommended to reduce the

superheat on the CO2side.

Distribution on the CO2side is also a critical

issue. This is why the heat exchanger has to be

designed for direct expansion to make sure the

mixture of gas and liquid is evenly distributed to

the heat exchanger.

When the heat exchanger is designed for reason-

able pressure drop at part load, the oil transport

and distribution should work under most condi-

tions.