Danfoss MMIGRS2 User manual

Other Danfoss Controllers manuals

Danfoss

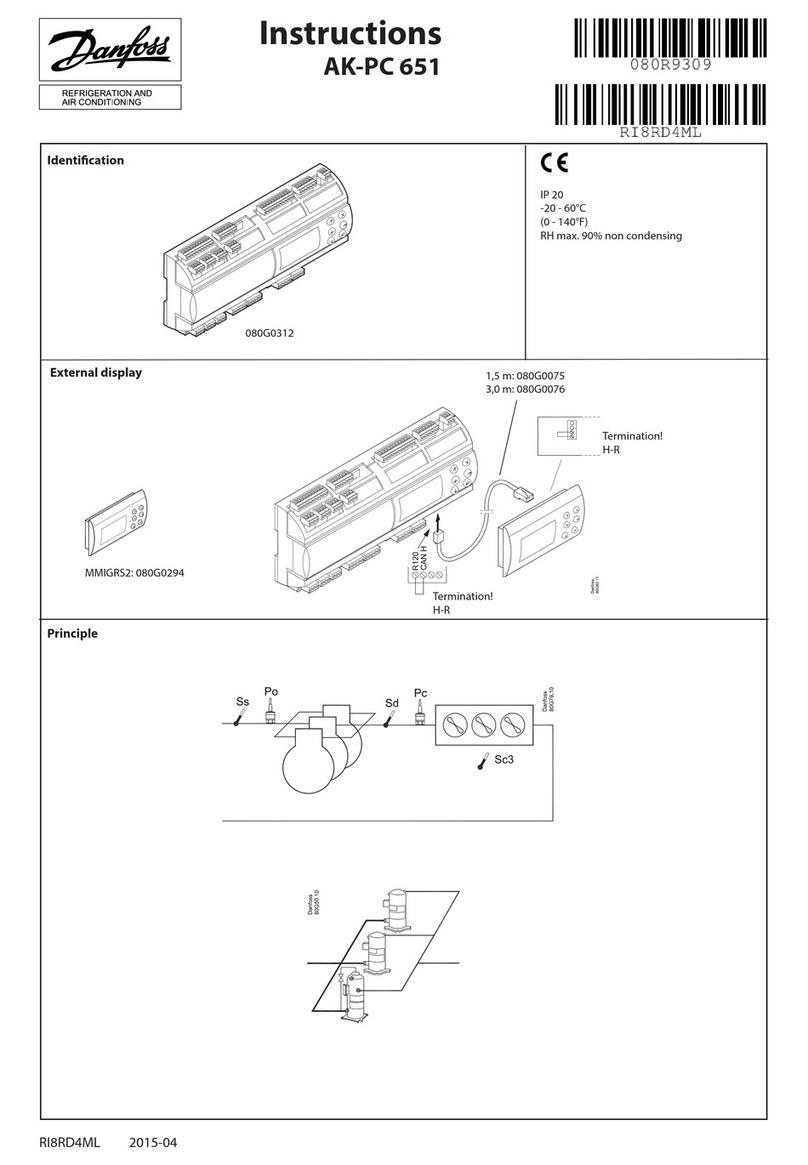

Danfoss ADAP-KOOL AK-PC 651 User manual

Danfoss

Danfoss RT 5 User manual

Danfoss

Danfoss FP975 User manual

Danfoss

Danfoss ERC 213 User manual

Danfoss

Danfoss AME 15 QM User manual

Danfoss

Danfoss AMV 610 User manual

Danfoss

Danfoss AME 130H User manual

Danfoss

Danfoss EKE 1B User manual

Danfoss

Danfoss AK-UI55 User manual

Danfoss

Danfoss EKC 331 User manual

Danfoss

Danfoss MCO 305 Guide

Danfoss

Danfoss VLT 2800 User manual

Danfoss

Danfoss MCI 50-3 I-O User manual

Danfoss

Danfoss EKC 347 User manual

Danfoss

Danfoss Link Hydronic Controller User manual

Danfoss

Danfoss MCO 305 User manual

Danfoss

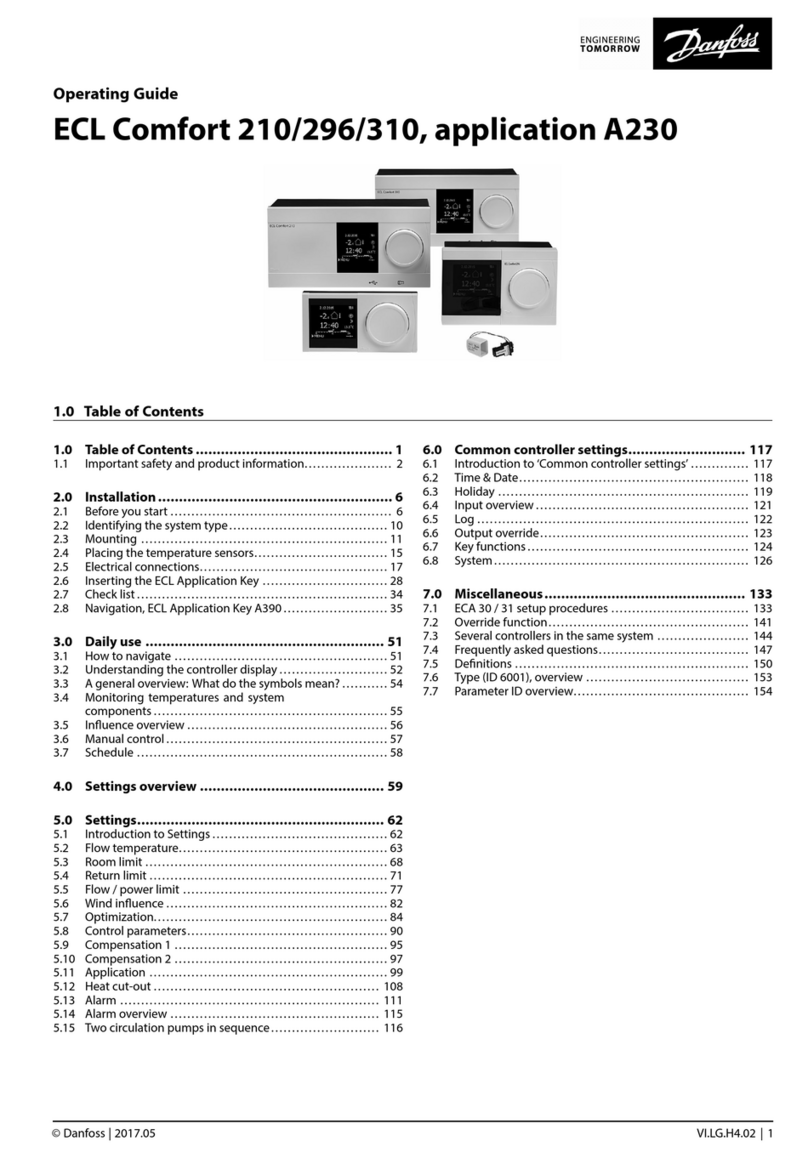

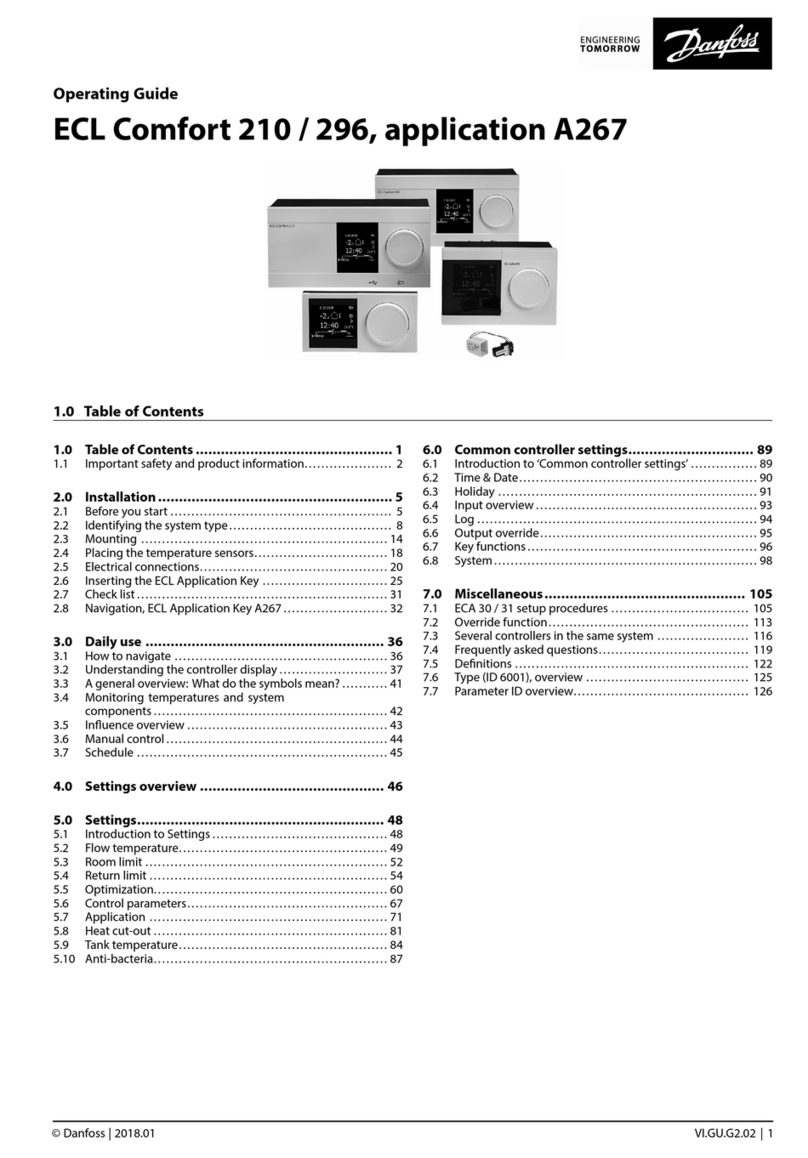

Danfoss ECL Comfort 296 User manual

Danfoss

Danfoss ERC 211 User manual

Danfoss

Danfoss FC 300 User manual

Danfoss

Danfoss EKC 223 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions