0045

0539 II2G

0539

© Danfoss | Climate Solutions | 2022.11

2 | AN179486437343en-001102

Technical data

Maximum Working Pressure:

Type RT 113E RT 112E RT 1AE RT 116E RT 5E

RT 6AEW

RT 6AEB

RT 6AES

RT 117E RT 121E RT 260AE RT 262AE

MWP

[bar] 0.4 722 22 22 34142 722 11

128 bar Pewhen used as safety equipment acc. to EN12263

Permissible ambient temperature: -20 – 65 °C

Intrinsically safe specication:

Ui = 29 V Ci = 0.5 nF

li = 0.5 A Li = 0.2 µH

Pi = 1 W

Contact load:

max. 100 mA, 30 V AC / DC

min. 1 mA, 5 V AC / DC

Must be used with a certied Ex ia barrier

satisfying the input parameters.

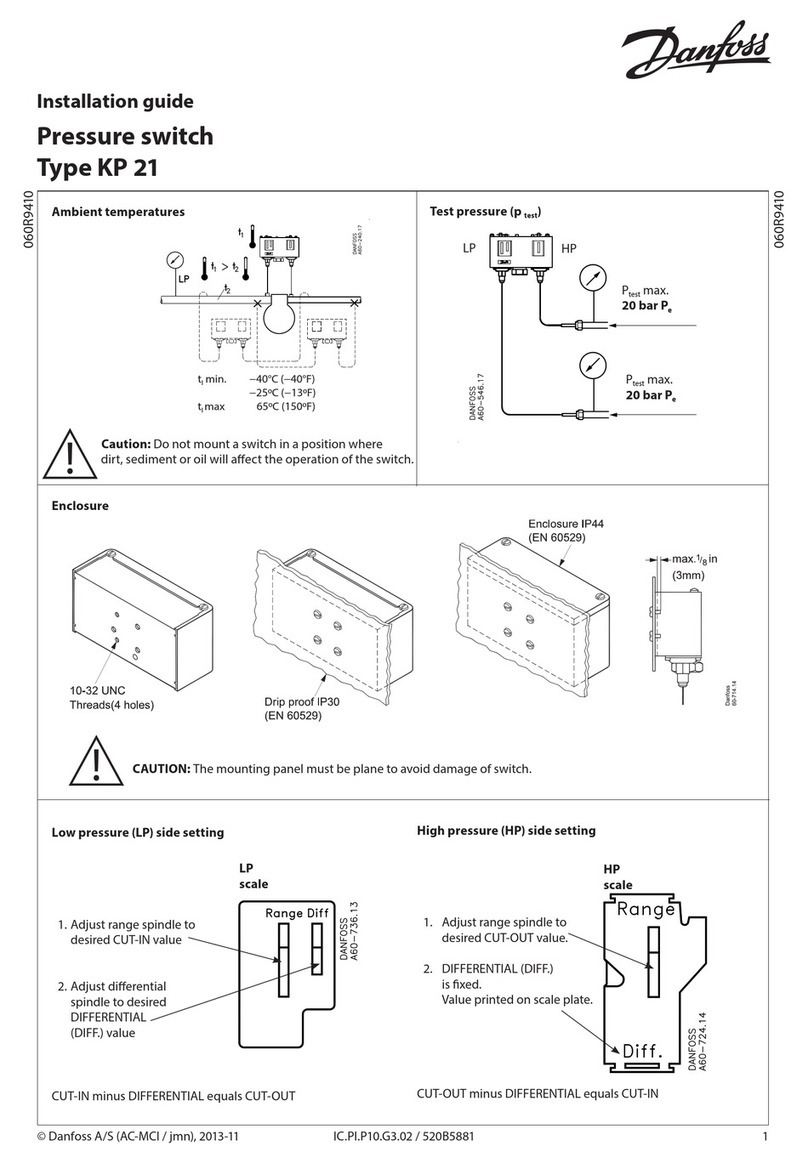

Installation

A set of Pg13.5 cable gland is attached to the RT in a separate bag. To

ensure IP66 (units with automatic reset) or IP54 (units with external

reset) grade of RT enclosure it is necessary to assemble this gland

as shown in the g. 6. If this gland is not used with a cable, a metal

blinding should be also assembled.

The RT pressure switch is designed for tting on the valve panel or the

compressor. Use the mounting holes (25). If the unit can be exposend

to vibration, it should be mounted on a resilient pad. If pressure

pulsations occur in the system at the point where the pressure switch

is connected, these should be eectively damped, as for example, by

connecting the RT unit to the system via damping coil.

Electrical connection (see g. 8 and g. 9)

START = make. STOP = break. DIFF = dierential.

Cable diameter: 6 – 14 mm

The earth terminal (38) should be connected to earth.

Wire dimension: min. 0,75 mm²

Adjustment

RT 1AE, RT 116E, RT 5E, RT 117E, RT 112E, RT 113E, RT 121E

(see g. 1, g. 2 and g. 8)

Set the pressure switch for minimum actuating pressure (range setting).

Setting is done by rotating the knob (5), at the same time reading the

main scale (9).

The dierential is set by rotating the dierential adjusting nut (19)

according to the nomogram concerned (g. 5 or g 7).

Maximum actuating pressure is the sum of the pressure setting and the

dierential.

RT 260AE, RT 262AE

See g. 4 and g. 8

Set the required dierential pressure with the setting disc (5) while at

the same time reading the scale (9).

RT 6AEW, RT 6AEB, RT 6AES (see g. 3 and g. 9)

After removing the seal cap (7), set the cut out pressure with the

uncovered range spindle while reading the scale (9).

Safety requirements

1. The refrigeration system must always comply with European

Ex installation standard, EN 60079-14, any local directive and

legislation as well as any other regulation applying in the area of

installation.

2. RT-E switch must be used only with reliable means of limiting

the voltage and current to prevent sparks between the contact

surfaces. The equipment to be used for electrical load limiting

must always be approved for use in the zone concerned.

3. Cable and cable entries approved for the application must be used.

Cables must not be in contact with sharp edges. The cable must

be connected with adequate stress relief in order to prevent that

pulling forces can be carried through the cable to the terminal.

4. In the event of pressure pulsations in the system, where the switch

is connected, these must be eectively damped to prevent fatigue

failure on the bellows. The cycle frequency of the RT-E switch must

be kept as low as possible. The vibration level must be kept as low

as possible.

5. It is recommended to regularly check the function of theRT-E

switch.

6. Only apparatus designed, constructed and released by Danfoss

must be used for application concerned. Danfoss can accept no

responsibility in case of alterations made on the pressure switches

or the use of them against the instructions of Danfoss.

7. Any overload of the RT switch must be prevented. Overloaded or

damaged apparatus must be exchanged.

8. Only authorised persons, who are certied in installing and

maintaining refrigration system may do the installation,

maintenance and exchange of the switch.

9. Use only appropriate tools.

10. Dispose of the switch in an environmentally-friendly way.

11. RTE switches must be installed in area where is low risk of

mechanical damage.

12. Components within the equipment can exceed the enclosure

temperature by 1K (1°C). When the media temperature exceeds

80°C, it is the responsibility of the user to ensure that the media

temperature does not cause a thermal ignition risk on parts

between the media and the switch enclosure. Maximum media

temperature on pressure switch is 100°C.

13. Isolation of the intrinsically safe circuit to ground and to the

contact mounting screw has been veried through 500VACrms

dielectric strength testing, carried out in accordance with IEC

60079-11:2011 sec tion 10.3.

14. Surface of the front cover is sputtered with stainless steel - avoid

abrasion.

15. Power must be switched o before maintenance and opening the

RT-E.

Specic conditions of use:

The enclosure fascia has been coated with a layer of stainless steel to prevent the

accumulation of electrostatic charge. In order to ensure that there is no accumulation of

electrostatic charge on the enclosure, the end user shall ensure that the external metal

work of the enclosure is locally bonded to earth. Information on the durability of the

coating with regards to use of the equipment is contained within the instruction manual.

Temperature class

Process temperature limit [°C]

T4 – T1

T5

T6

100

94

79

Product marking: RT 6AEW, RT 6AEB, RT 6AES

Ex ia IIC T6...T1 Gb-20 °C ≤ Ta ≤ 65 °C

DEMKO 14 ATEX 1406X, Rev. 3

IECEx ULD 14.0013X

Ui= 29 VIi= 0.5 APi= 1 W

Ci= 0.5 nFLi= 0.2 μH

II2G

Product marking: RT112E, RT113E, RT1AE, RT116E,

RT5E, RT117E, RT260AE, RT262AE, RT9E, RT14E,

RT101E, RT107E, RT121E, RT123E

Ex ia IIC T6...T1 Gb-20 °C ≤ Ta ≤ 65 °C

DEMKO 14 ATEX 1406X, Rev. 3

IECEx ULD 14.0013X

Ui= 29 VIi= 0.5 APi= 1 W

Ci= 0.5 nFLi= 0.2 μH