Electrical contacts/wiring test

TRIP (main lever)

use FINGERS ONLY!

(Do NOT use screwdriver)

Note:

KP 1, KP 5 and KP 7B w/man. reset:

Push manual reset knob during manual

tripping.

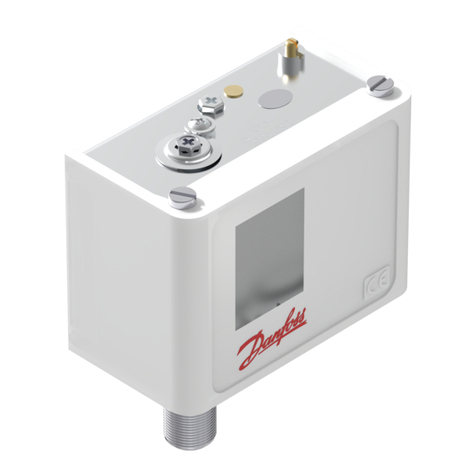

Wiring

CAUTION: Disconnect power supply before

wiring connections are made to avoid

possible electrical shock or damage to

equipment.

All wiring should conform to the National

Electrical Code and local regulations.

Terminal block

CAUTION: Use terminal screws furnished

in the contact block.

Use tightening torque 20 lb. in (2.3 Nm).

Use copper wire only.

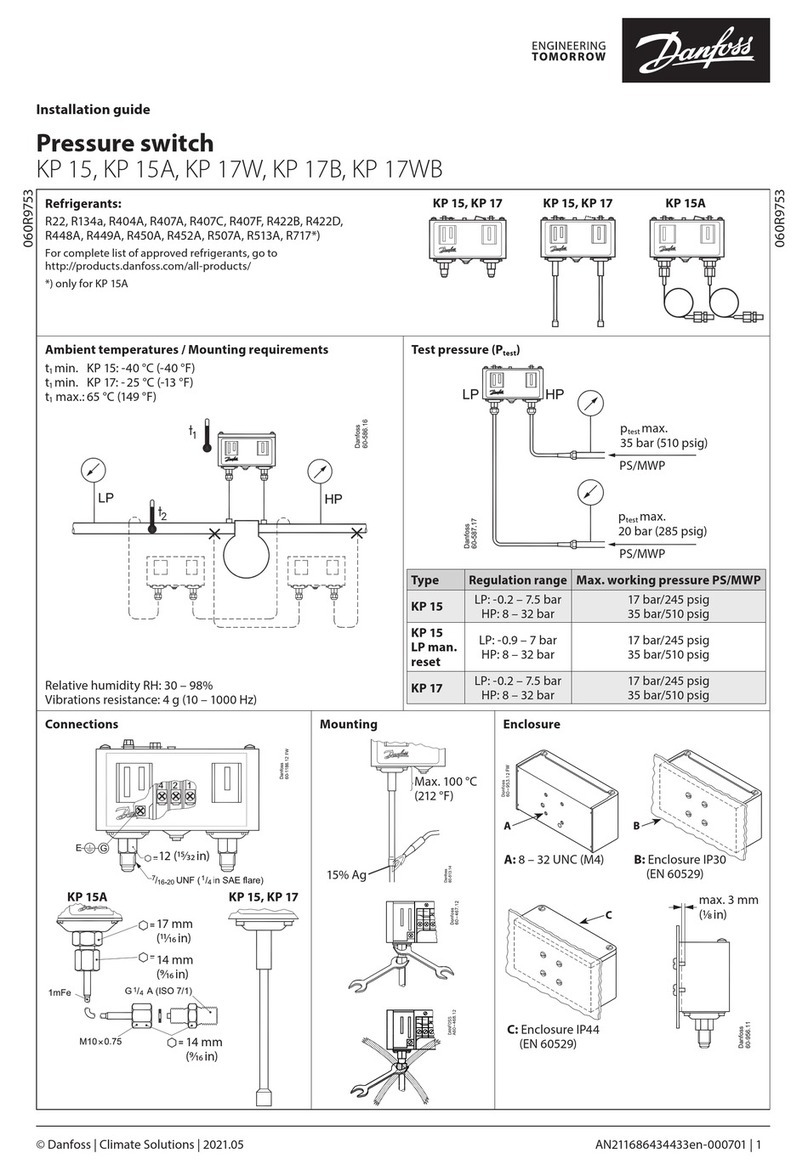

Contact load ratings

Load Option A

CUT-OUT on pressure drop

Wire terminals 1-4:

CUT-IN = High Set Point (HSP)

see “Setting”

CUT-OUT = Low Set Point (LSP)

see “Setting”

Terms 1-4 close on pressure rise

Terms 1-4 open on pressure drop

Example: CUT-IN = 30 psig

CUT-OUT = 10 psig

This means CUT-IN = HSP = 30 psig

CUT-OUT = LSP = 10 psig

Note:

= Bellows movement on pressure rise

Ø= Bellows movement on pressure drop

The free terminal can be used for signal

purpose.

Load Option B

CUT-OUT on pressure rise

Wire terminals 1-2:

CUT-IN = Low Set Point (LSP)

see “Setting”

CUT-OUT = High Set Point (HSP)

see “Setting”

Terms 1-2 close on pressure drop

Terms 1-2 open on pressure rise

Example: CUT-IN = 250 psig

CUT-OUT = 350 psig

This means CUT-IN = LSP = 250 psig

CUT-OUT = HSP = 350 psig

120 V a.c. 16 FLA, 96 LRA

240 V a.c. 8 FLA, 48 LRA

240 V d.c. 12 W pilot duty

Manual reset

To resume control operation after safety

cutout, push reset knob as indicated.

Note:

KP 1, man. reset is possible only after a

pressure rise of 10 psi (0.7 bar).

KP 5 and KP 7B, man. reset is possible only

after a pressure drop of respectively 43 psi

(3.0 bar) and 58 psi (4.0 bar)

RI.5A.J1.22 © Danfoss A/S

Bellows Bellows

Diff. (fixed)

KP 1: 10 psi (0.7 bar

KP 5: 43 psi (3 bar)

KP 7B: 58 psi (4 bar)

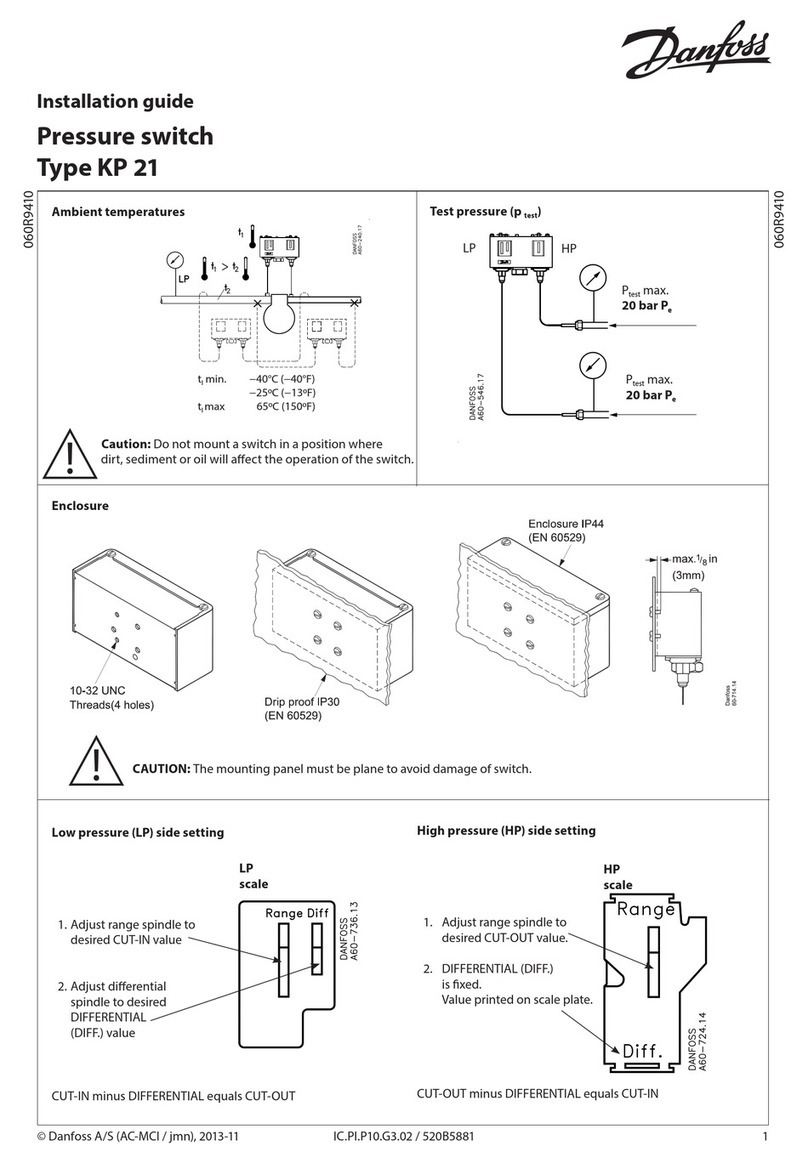

Adjustment spindle(s) location

Auto reset Manual reset

KP 1, 2, 5, 7W KP 1, 5, 7B