G640 Micro Inverter User Manual

G640 UM draft v1 20180928 © 2018 Darfon Electronics Corp. p. 2 / 19

TABLE OF CONTENTS

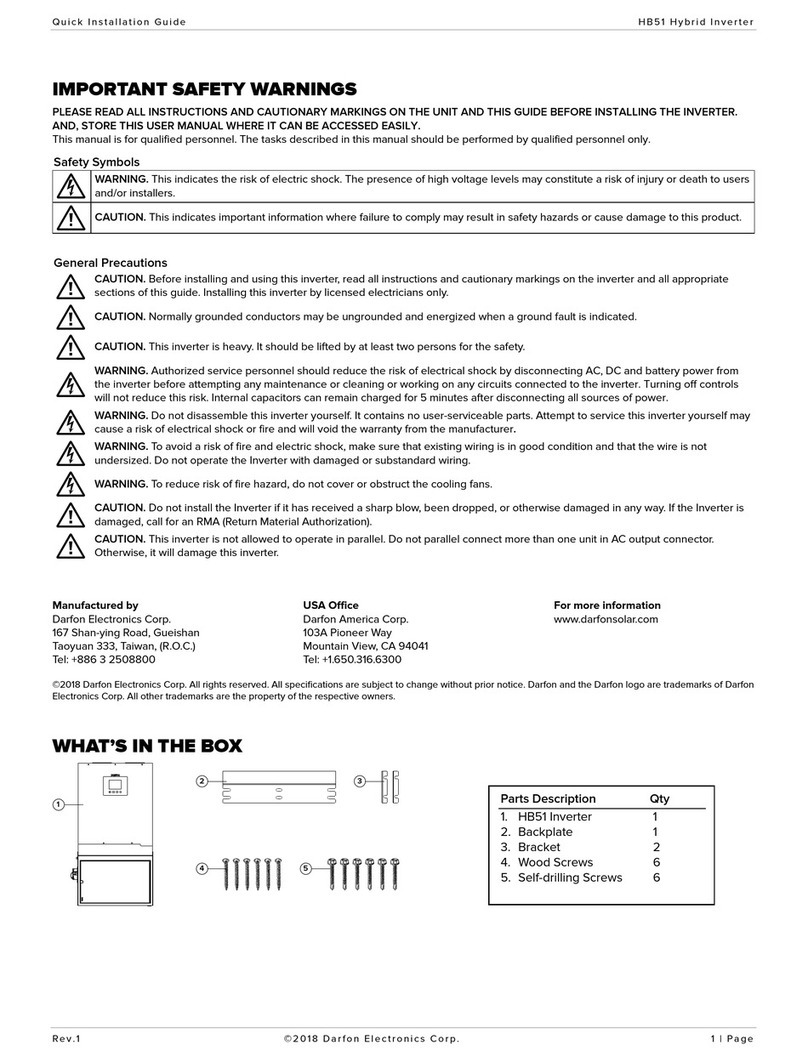

IMPORTANT SAFETY INSTRUCTIONS ...................................................................... 3

SAFETY INSTRUCTIONS .................................................................................................3

SURGE SUPPRESSION ...................................................................................................3

FCC COMPLIANCE ......................................................................................................4

OTHER INFORMATION..................................................................................................4

PRE-INSTALLATION ................................................................................................ 5

THE MICRO INVERTER .................................................................................................5

PV SYSTEM LAYOU T ....................................................................................................5

PARTS AND TOOLS.......................................................................................................5

COMPATIBILITY AND CAPACITY .......................................................................................5

AC TRUNK CABLE .......................................................................................................6

GROUNDING OPTIONS ................................................................................................. 6

MICRO INVERTER LAYOU T ............................................................................................7

SURGE PROTECTION ....................................................................................................7

INSTALLING THE MICRO INVERTER......................................................................... 8

INSTALLING ONTO A PV RACKING SYSTEM ........................................................................8

POST-INSTALLATION ............................................................................................ 10

COMMISSIONING AND OPERATING ...............................................................................10

GFDI FAULT ............................................................................................................10

DISCONNECTING A MICRO INVERTER.............................................................................10

MONITORING SYSTEM......................................................................................... 11

PLC BOX OVERVIEW .................................................................................................11

DATA LOGGER OVERVIEW ...........................................................................................11

INSTALLING THE PLC BOX AND DATA LOGGER .................................................................12

REGISTERING THE PV SYSTEM .......................................... ERROR!BOOKMARK NOT DEFINED.

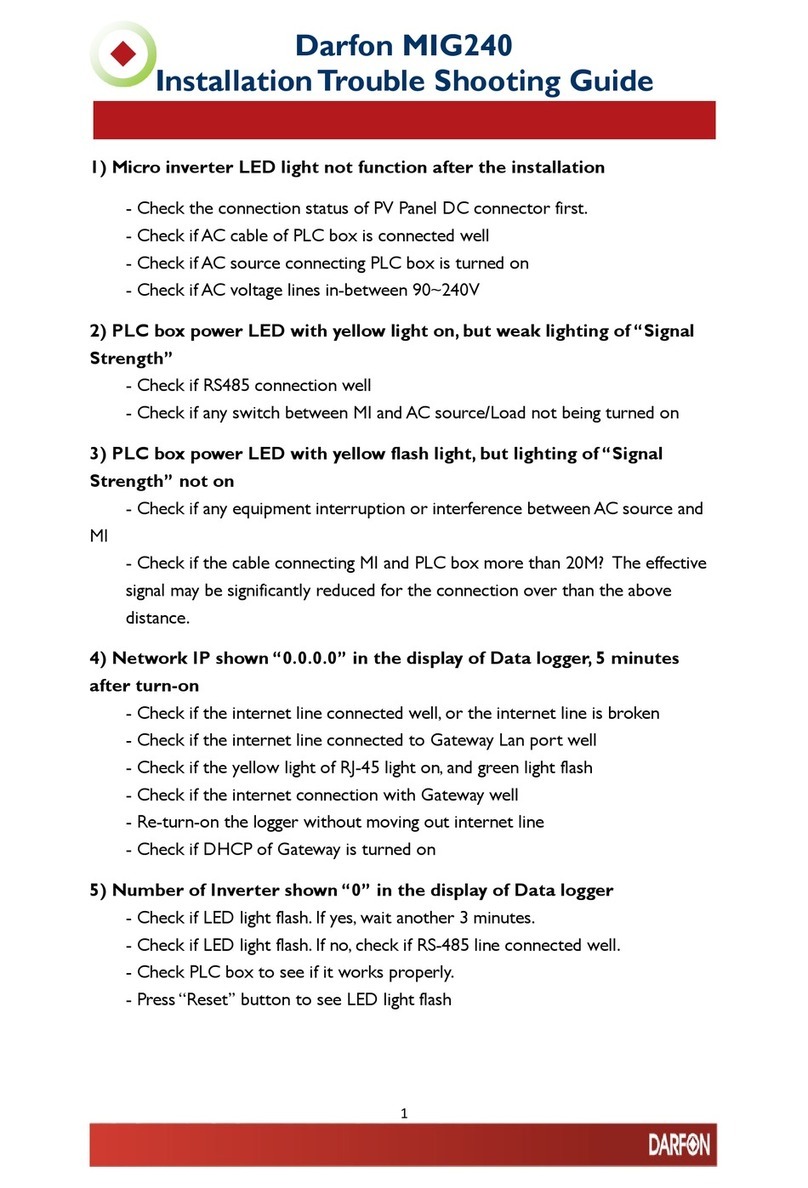

TROUBLESHOOTING ............................................................................................ 14

TROUBLESHOOTING THE MICRO INVERTER .....................................................................14

TROUBLESHOOTING THE PLC BOX ................................................................................14

TROUBLESHOOTING THE DATA LOGGER..........................................................................15

EQUIPMENT AND PARTS..................................... ERROR! BOOKMARK NOT DEFINED.

TECHNICAL SPECIFICATIONS ................................................................................ 16

MICRO INVERTER......................................................................................................16

PLC BOX ................................................................................................................16

DATA LOGGER ..........................................................................................................16

SAMPLE WIRING.................................................................................................. 17

240V 1Φ...............................................................................................................17

INSTALLATION MAP TEMPLATE .......................................................................... 181

NOTES ............................................................................................................... 192