6 Form 122039

3.2 Available Options

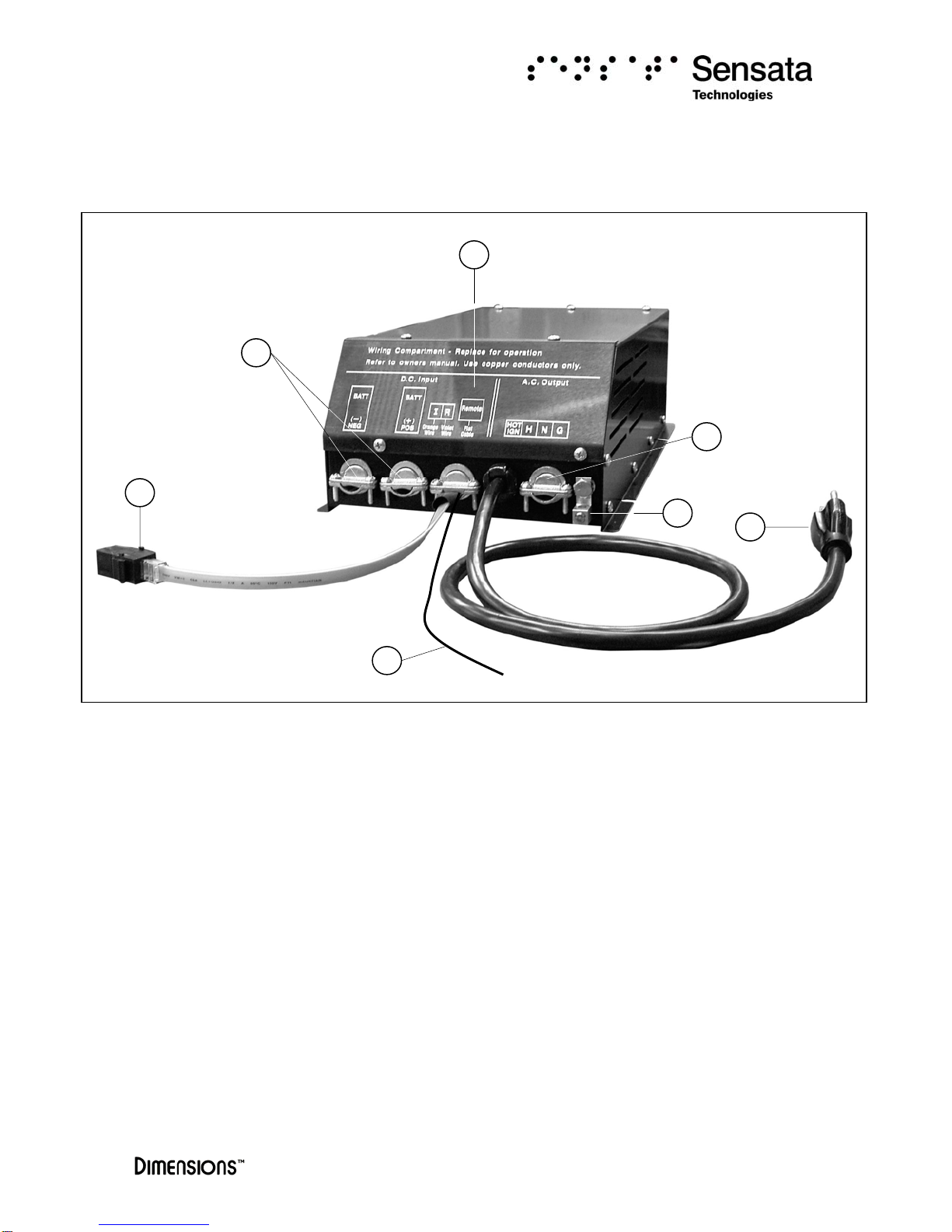

3.2.1 External Power Mode – “T” option: 120 VAC, 60 Hz external power can

be applied directly to the inverter when connecting the AC plug cord extending from the

inverter (available with the “T” option only) to an AC outlet. If external power is

available, the internal transfer switch cannot be defeated; it automatically turns the DC

to AC inverter OFF and activates the three-step battery charger “B3” if included

(available with 12W8 model only). At this time the loads attached to the inverter output

will operate directly from the external power line even if the inverter has been turned

OFF manually. The internal transfer relay automatically switches the inverter back to

“inverter power” mode in the absence of external power whenever the inverter was

previously set to ON.

3.2.2 Battery Charger – “B3” Option (12W8 model only): The three-step

battery charger feature requires the transfer switch “T” option to operate. External

power 120 VAC, 60 Hz is applied as explained in section 3.1.2 The internal transfer

switch automatically turns the DC to AC inverter OFF and turns the three-step built-in

battery charger ON. The battery charger cannot be defeated at this time and will engage

even if the inverter has been set OFF manually.

The 3-step charging process goes through the following stages: The bulk stage, here

the electrical current is returned to the batteries until a factory set voltage limit is

reached. The acceptance stage is then engaged immediately; the battery voltage is kept

constant while decreasing the charging current gradually up to the transition point or

when it reaches the pre-set timer limit. In the floating stage the batteries are recharged

at a very low current rate to prevent them from self-discharging. Finally the condition

stage is engaged every 20th complete battery charging cycles to ensure full restoration

of active materials in all the plates of the battery cells.

3.2.3 100 VAC, 60 Hz Output – “F3” Option: The inverter accepts and supplies

100 VAC, 60 Hz single-phase quasi-sine waveform output.

3.2.4 LED Remote Control/Status Panel – “R” Option: Remote control panel

“R” provides inverter status and allows remote ON/OFF operation. The remote control

panel has an “On/Off” switch and five LED indicator lights: External power, Inverter

power, Low battery, Overload and High temperature. The remote inverter control panel

is connected to the inverter module by a flat 8-conductor telephone type cable.

3.2.5 LED Remote Control/Status Panel – “R3” Option: Remote control

panel “R3” provides inverter status and allows remote ON/OFF operation. The “R3”

option has a single red wire extending from the inverter module, which must have

+12VDC for the inverter to operate (used as a master disconnect in recreation vehicles).

The remote control panel has an “On/Off” switch and five LED indicator lights: External

power, Inverter power, Low battery, Overload and High temperature. The remote

inverter control panel is connected to the inverter module by a flat 8-conductor

telephone type cable.