3

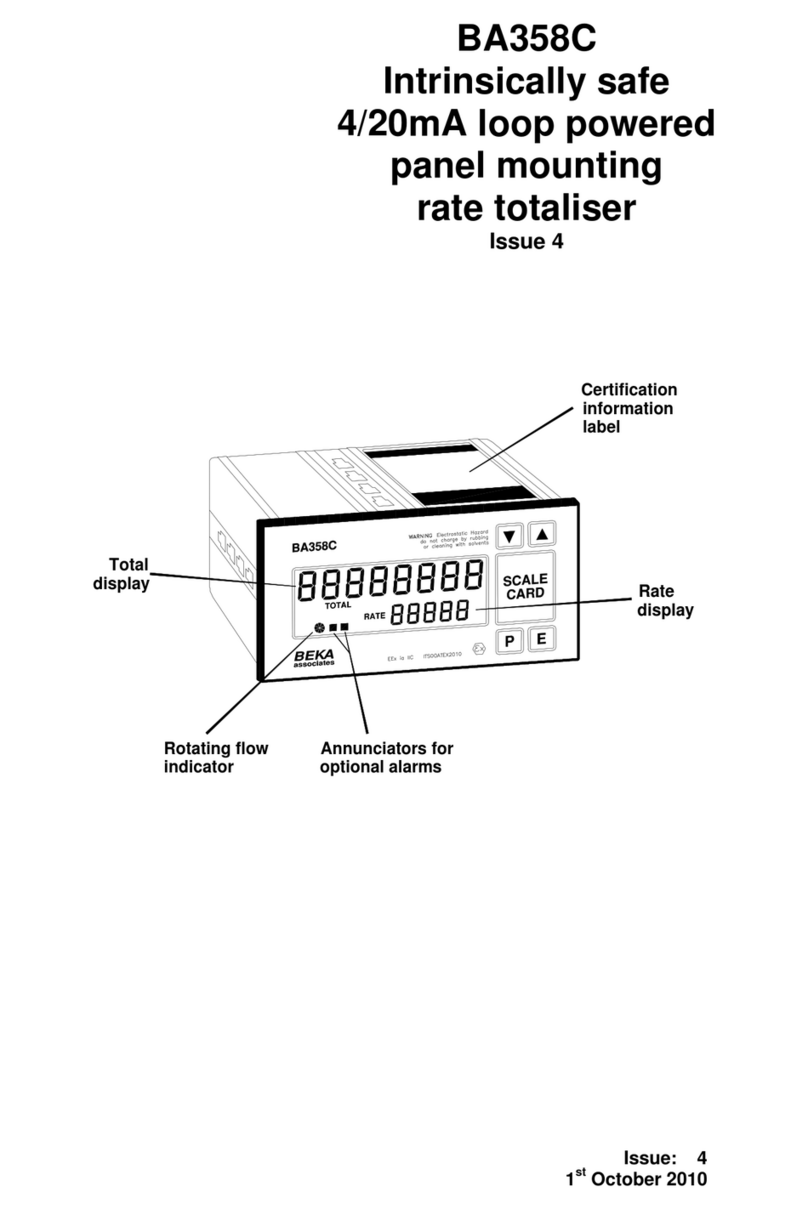

1. DESCRIPTION

The BA418CF-F Fieldbus Indicator is an

intrinsically safe, FOUNDATION™ fieldbus ins-

trument that can display one fieldbus process

variable on a five digit LCD and 31 segment

analogue bargraph. The instrument is bus

powered so no additional power supply is required.

Communication Fieldbus Function

Protocol Block

FOUNDATION™ fieldbus Input Selector (1 x IS)

The Device Description files may be downloaded

from The Fieldbus Foundation or the BEKA

associates web site.

Housed in a robust 72 x 144 panel mounting DIN

enclosure, the BA418CF-F fieldbus indicator has

an IP66 front panel and is supplied with a gasket to

seal the joint between the instrument and the

panel.

The instrument is intrinsically safe and has been

certified by European Notified Body Intertek

Testing and Certification Ltd (ITS) to the ATEX

Directive 94/9/EC for use in explosive gas

atmospheres.

The BA418CF-F also has intrinsic safety and

nonincendive FM and cFM Approval allowing

installation in the USA and Canada – see

Appendix 1.

For international applications the BA418CF-F

fieldbus indicator has IECEx intrinsic safety

approval – see Appendix 2.

The instrument’s communication protocol is shown

on the rear of the instrument. The ‘-F’ order code

suffix also indicates the protocol but is not shown

on the instrument certification label.

1.1 Documentation

This instruction manual describes ATEX system

design and installation of the BA418CF-F Fieldbus

Indicator. For commissioning information please

refer to:

FOUNDATION™ fieldbus

Fieldbus Interface Guide

for

Fieldbus Displays and

Fieldbus Indicators

which can be requested via the BEKA web site

www.beka.co.uk

System design information for FM, cFM and IECEx

is shown in separate appendices to this manual.

2. INTRINSIC SAFETY CERTIFICATION

2.1 ATEX certificate

The BA418CF-F has been issued with an EC-Type

Examination Certificate by Notified Body Intertek

Testing and Certification Ltd (ITS) confirming

compliance with the European ATEX Directive

94/9/EC for Group II, Category 1G, gas

atmospheres, Ga Ex ia IIC T4. The instrument

bears the Community Mark and, subject to local

codes of practice, may be installed in any of the

European Economic Area (EEA) member

countries. ATEX certificates are also acceptable

for installations in Switzerland.

This manual describes ATEX installations in

explosive gas atmospheres that conform with

EN 60079:Part14 Electrical Installation in

Hazardous Areas. When designing systems for

installation outside the UK, the local Code of

Practice should be consulted.

2.2 Zones, gas groups and T rating

The BA418CF-F has been issued with EC Type

Examination certificate ITS06ATEX25314/2X

confirming that it complies with the requirements

for Group II Category 1G Ga Ex ia IIC T4 (Tamb

–40 to 70oC) specified in the ATEX Directive.

When connected to a suitable certified system the

BA418CF-F may be installed in:

Zone 0 explosive gas air mixture

continuously present. Note:

Special conditions for safe use

apply see section 4.1

Zone 1 explosive gas air mixture

likely to occur in normal

operation.

Zone 2 explosive gas air mixture not

likely to occur, and if it does will

only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

Having a temperature classification of:

T1 450oC

T2 300oC

T3 200oC

T4 135oC

At an ambient temperature between –40 and

+70oC.

Note: the guaranteed operating temperature range

of the Fieldbus Indicator is –20 to +70oC.