DAV TECH DAV 150 Product manual

VOLUMETRIC DISPENSING VALVE DAV 150

DAV TECH SRL

Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALIA

Tel. 0039 0444 574510 - Fax 0039 0444 574324

Installation and

maintenance guide

Indice generale degli argomenti

1 INTRODUZIONE pag. 3

1.1 Il Manuale

1.2 Garanzia

1.3 Ricevimento merce

2 DESCRIZIONE TECNICA pag. 3

2.1 FunzionI delle valvole

2.2 Specifiche tecniche

3 AVVERTENZE pag. 4

4 FORMAZIONE DEL PERSONALE pag. 8

5 RILEVAZIONE DI ERRORI ED ELIMINAZIONE DEI GUASTI pag. 8

6 MANUTENZIONE pag. 8

7 ESPLOSO E COMPONENTI pag. 10

7.1 Componenti

Installation and maintenance guide

pag.3

1 INTRODUCTION

1.1 The manual

The user guide is the document that accompanies the valve from the time of its construction and throughout the period of

use, it is therefore an integral part of the valve. It requires reading the manual before taking any action involving the valve. The

manual must be readily available for use by staff and maintenance of the valve. The user and the attendant use are required

to know the contents of this manual.

Reproduction of any part of this manual, in any form, without the express written permission of DAV Tech. The text and

illustrations in this manual are not binding, the DAV tech reserves the right, at any time and without notice, the right to make

any changes to improve the product or for reasons of character manufacturing or commercial.

1.2 Warranty

The warranty is valid for a period of 12 months from the date of commissioning and no later than 15 months from the

date delivery. The interventions carried out during the warranty period does not extend in any way the validity period of the

guarantee. The seller is not liable for defects caused by normal wear of parts which by their nature are subject to wear.

1.3 Goods receiving

The original configuration of the valve must never be changed.

Upon receipt of the goods, check that:

• The packaging is intact

• The exact correspondence of the material ordered.

2 TECHNICAL DESCRIPTION

2.1 Valve operation

The DAV 150 volumetric dispensing valve is a pneumatically operated component designed for precision dispensing of low

viscosity lubricants.

The exchange of the pneumatic supply, at a pressure equal to or greater than 6 bar, will lead to the emptying of the volumetric

chamber and the relative outflow of a constant and adjustable quantity of fluid.

2.2 Technical specification

Model DAV 150

Configuration Standard (assembly block)

Dispensing range [mm³] 3-200

Dispensing range [ml] 0,003-0,200

Weight [kg] 0,78

Connection (medium intake) inside thread G 1/8”

Connection (medium discharge/pressure discharge) inside thread G 1/8”

Optimal medium intake working pressure [bar] 1-6

Max. medium intake working pressure [bar] 12

Connection (compressed air) inside thread M5 for hose ø4 mm

Bleed hose connection ø 4 mm

Min./max. pneumatic operating pressure [bar] 5/7

Optimal pneumatic operating pressure [bar] 6

Compressed air quality ISO 8573-1:2020 [6:4:4]

VOLUMETRIC DISPENSING VALVE DAV 150

Safety warnings

Read this operating manual carefully to familiarise yourself with the safe and efficient operation of the product. Retain

this manual as a reference. This operating manual contains important provisions and information for the safe and proper

operation of the product. It is also intended to help operating and maintenance personnel to minimise hazards, repair costs

and downtime, and to improve the reliability and service life of the product. It is therefore important to ensure access to this

document at all times for any person assigned to the care of the product.

Intended use

The product may be used only under the intended operating conditions. Any other or further use is considered improper use.

The manufacturer is not liable for damage due to improper use. Intended use includes:

• Observing and complying with all notices and warnings in this operating manual.

• Performing all inspection and maintenance work.

Obligations of the operating company

The person responsible for the safety of the product has to ensure that:

• Only qualified personnel is assigned to work on the product.

• The operating manual is always available to said personnel during all work, and the personnel is obliged to consistently

follow it.

• The accident prevention rules and regulations applicable for the place of use are observed, and the prescribed maintenance

and repair work is carried out.

Fundamental safety instructions

The following must be observed for the safe handling and trouble-free operation of this product:

• Using the product for other than its intended use is prohibited.

• No changes may be made to the product.

• A safe operating state has to be maintained at all times. Upon request, we can provide equipment training to bring your

personnel up to the required level of knowledge.

• Disconnect the product from all energy sources prior to any maintenance work.

• All lines, hoses and screw connections must be inspected for leaks and externally visible damage at regular intervals.

Damage has to be repaired promptly by qualified personnel; damaged parts must be replaced with original parts.

• Protective devices may only be removed after the product is standing still and has been secured to prevent restarting.

• All safety equipment must be installed properly and has to be fully functional each time before the product is put into use.

• The required personal protective equipment must be provided by the operating company.

• All safety and protective devices have to be inspected regularly.

WARNING OF A HAZARD

Warnings are information about hazards that may lead to physical injury and/or damage to property.

NOTE

Notices provide valuable information and user tips.

RISK OF CRUSHING

Warning of danger of crushing.

ENVIRONMENTAL HAZARD

Proper disposal of the various materials protects the environment.

3. WARRANTY

Installation and maintenance guide

pag.5

Hazards due to hydraulic and pneumatic energy

Depending on the version, the product works with high hydraulic or pneumatic pressure (see technical data). Sections of the

system that need to be opened, such as pressure lines, valves or loads, have to be de-pressurised before the start of repairs.

No residual pressure is permitted to remain.

Hazards due to lubricants

The safety notices and instructions of the lubricant manufacturer have to be observed and followed. The manufacturer of this

product disclaims any liability for incidents resulting from failure to follow the regulations,instructions and recommendations

of the lubricant manufacturer.

Maintenance, upkeep and troubleshooting

• Prescribed adjustment and maintenance tasks according to the maintenance schedule have to be carried out in a timely manner.

• Inform the operating personnel about adjustment and maintenance work.

• The master switch (if any) has to be turned off.

• Disconnect the energy supply from the network and secure it against unintentional reconnection.

• Pneumatic and/or hydraulic systems must be de-pressurised.

• Check all threaded connections and fittings for tightness.

• All safety devices and operating functions have to be checked after completion of the work.

Warranty and liability

Warranty and liability claims for personal injury and damage to property are excluded when they are due to one or more of

the following causes:

• Improper use of the product.

• Work carried out by other than qualified personnel.

• Improper transportation, storage, assembly, commissioning, operation and maintenance of the product.

• Failure to observe the information in the operating manual regarding safety, transportation, storage, assembly,

commissioning, operation, maintenance and setup of the product.

• Operating the product with defective protective devices or improperly installed or non-functional safety and protective

devices.

• Structural changes to the product.

• Changing the compression ratios for pressure protection, and operating at pressures higher than intended for the product.

• Insufficient monitoring of machine components that are subject to wear.

• Improper repairs and using third-party components.

Safety notices for using the product

All parts and assemblies were developed and built according to recognised safety-related rules. Nevertheless, improper use or

handling may result in hazards for the user or third parties or damage to the product or other material assets.

The product may only be used:

• According to the intended use.

• In safe and proper technical condition.

SPECIFIC HAZARDS

Electrical energy

Hydraulic and pneumatic energy

ELECTRICAL VOLTAGE

Warning of electrical hazards that may lead to physical injury and/or damage to property.

CAUTION

The product always has to be shut off prior to all work.

ENVIRONMENTAL HAZARD The various materials/liquids have to be handled properly and disposed of

separately according to the respective applicable national regulations.

HYDRAULIC AND PNEUMATIC SYSTEMS

Warning of hydraulic and pneumatic hazards that may lead to physical injury and/or damage to property.

VOLUMETRIC DISPENSING VALVE DAV 150

Safety warranty

Read the instructions carefully to familiarize yourself with the safe and efficient operation of this product.

Keep this manual for future reference. These operating instructions contain important instructions and warnings for the safe

and correct operation of the product. They will also assist operational and maintenance personnel

maintenance in order to minimize hazards, repair costs and downtime, increasing the reliability and life of the product.

Therefore, it is important to ensure that all persons entrusted with product assistance are consulted at all times by this

document.

Product description - Purpose

The needle metering valve is used for dispensing low viscosity lubricants.

Labelling

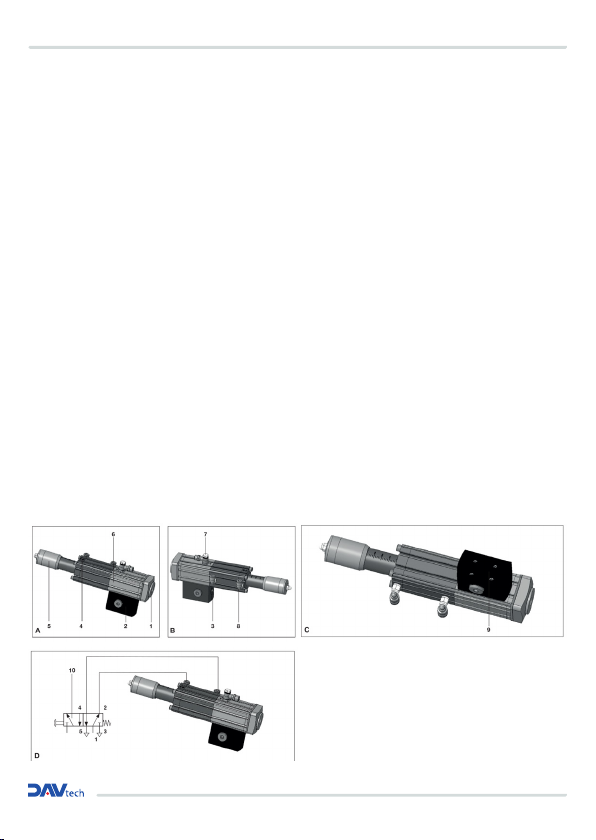

The needle metering valve is labelled according to the model code (Figure A/No. 6).

Functionality

Due to the compressed air connections, the needle metering valve can be controlled externally via a 5/2-way valve (Figure D/

No. 10). This initiates dispensing in the hydraulic section, provided the needle metering valve is connected to an active pump.

The desired dispensing volume is continuously adjustable in the range from 3 mm3 to 200 mm3 with the adjustment screw

(Figure A/No. 5). A locking screw (Figure A/No. 4) is provided to retain the set quantity. The vent with hose connection (Figure

B/No. 7) permits the clean discharge of the medium.

Description of the pictured components (Figures A – D)

1 Medium discharge

2 Connection block

3 Medium intake

4 Locking screw

5 Dispensing screw

6 Type key

7 Bleed screw

8 Pneumatics connection

9 Mounting holes

10 5/2-way valve (Not included in the scope of delivery)

Assembly/installation

The product has to be set up or installed at the intended installation site under consideration of the following conditions.

• The applicable legal provisions on site have to be clarified and compliance must be assured.

• The available space has to be clarified prior to installation/setup of the product in order to ensure ongoing safe

operation for the personnel and product. The product has to be set up/installed so that ongoing safe operation is

assured.

• The product may only be set up and put into operation by qualified personnel with corresponding special training.

• The product is designed for use in rooms protected against the effects of weather (industry standard).

• Operation and storage in aggressive, excessively damp environments or outdoors may lead to corrosion damage.

• The valves can be installed in any position.

• The distance to the application surface depends on the desired application pattern.

Installation and maintenance guide

pag.7

Commissioning

• The lubricant supply hose must be filled with lubricant before connecting a needle metering valve (bleeding process).

• Then connect the supply hose to the medium input (Figure B/No. 3).

• Connect control air to the pneumatic connections (Figure B/No. 8).

• The maximum flow volume has to be adjusted during commissioning. In order to do so, loosen the locking screw (Figure A/

No. 4) and turn the dispensing screw (Figure A/No. 5) to the rear stop (display: 100 %).

• Open the bleed screw (Figure B/No. 7) until medium is discharged, then close the screw again immediately.

• For clean bleeding, a pneumatic hose can be connected to the bleed screw to cool the air/medium mixture.

• Adjust the dispensing volume for application by changing the

- dispensing volume using the dispensing screw (Figure A/No. 5)

- medium pressure (if applicable with the optional material pressure regulator or directly with the pump pressure)

- control air pressure (changes the dispensing time) until the application quality is correct.

Operation

• As a rule, the needle metering valve works with a control air pressure of 6 bar and material pressure of 1 – 6 bar. For

consistent application, ensure that the air and lubricant supply is constant without pressure fluctuations and the lubricant

viscosity does not change.

• Depending on the application case, the control air pressure has to be adjusted to the switching frequency that is used on the

one hand and the higher or lower material pressure on the other hand.

Packaging, transportation and storage

DAV Tech prepares the product for transportation to the respective initial destination. The packing unit must not be subjected to

excessive strain. Protect the packaging and contents against exposure to moisture. Keep the temperature between -20 °C and

+40 °C during transportation.

Transport damage

If transport damage is found during the receiving inspection, proceed as follows:

• Notify the carrier (shipper etc.)

• Record the damage

• Inform the supplier

Storage

Operation and interim storage in aggressive, damp environments or outdoors may lead to corrosion and other damage.

Maintain the storage temperature in the range of -20 °C to +40 °C.

• Re-tighten the locking screw (Figure A/No. 4).

CAUTION

Do not aim the jet at people. Wearing eye protection is highly recommended.

Depending on the material conveying pressure, the spraying process may be accompanied by noise.

Hearing protection should be worn if needed.

CAUTION

Do not aim the jet at people. Wearing eye protection is highly recommended. Depending on the material

conveying pressure, the spraying process may be accompanied by noise. Hearing protection should be worn

if needed.

VOLUMETRIC DISPENSING VALVE DAV 150

FAULT POSSIBLE CAUSE REMEDY

The needle metering

valve switches but no

lubricant is ejected

The feed pump is not supplying

lubricant

Consult the operating manual for the

feed pump

The needle metering

valve switches but no

lubricant is ejected

Material pressure too low Increase pump pressure

The dispensing valve is

leaking

The control air pressure/counter-

pressure of the spring is too low

Increase the control air pressure,

reduce the material pressure, install

a stronger spring

The dispensing valve is

leaking Defective seals Replace seals

Air in the system Air pockets in the grease container

Air pockets in the hoses

Loosen supply hose. Bleed system.

Reconnect supply hose.

Leaky valve Defective seals Replace seals

Irregular dispensing No constant grease and air Upstream installation of optional material

pressure regulator MDR

WHEN WHAT HOW WHO

Weekly Check valve for tightness

Visual Qualified

personell

Weekly Check all threaded connections and fittings

for leaks

Monthly Check seals for damage and wear

Annually Complete maintenance Dismantle, clean and

replace seals

TRAINING OF PERSONNEL

Only trained and instructed personnel who have read and understood all points in the operating instructions may work on

the product. The personnel must also be able to control the operating states, and identify and implement the interrelated

safety aspects. Personnel in training may only work on the product under the supervision of qualified personnel.

5 TROUBLESHOOTING, FAULT RESOLUTION

6 MAINTENANCE

Needle metering valves are precision instruments that are not susceptible to faults, given proper handling, and operate

largely without maintenance, assuming that the application material is generally processed in clean condition, not

contaminated by foreign particles. We recommend the following maintenance intervals to optimise the service life:

The specified maintenance intervals are for single shift operation. Maintenance has to be carried out more often

depending on the field of application, medium and in case of operation in more than one shift.

CAUTION

All of the faults described below may only be resolved by trained, qualified personnel.

CAUTION All work on the system is basically only to be carried out when it is at a standstill. The pneumatic

and hydraulic systems have to be de-pressurised. The pressure gauges have to show 0 bar.

Installation and maintenance guide

pag.9

Shutdown

Short interruptions:

In case of short interruptions (15 minutes or more), the product has to be shut off and completely de-pressurised.

No residual pressure is permitted to remain in the system.

Longer interruptions:

For longer interruptions (more than one day), note the following points:

• The main switch/pump must be turned off

•No residual pressure is permitted to remain in the system (check the indicators)

Drawings and replacement parts

Accessories, drawings, dimension sheets, data sheets and spare parts can be found at www.davtech.it.

Decommissioning and disposal

Observe the following points for decommissioning the product/taking it out of operation:

• Turn the master switch (if any) off

• Disconnect the mains plug (if any) from the network

• No residual pressure is permitted to remain in the system.

•The medium must be removed and properly disposed of.

© Publisher’s copyright

The duplication, translation or dissemination to third parties of this document requires the express consent of the

publisher.

Resale

This operating manual is part of the product and must be included in the scope of delivery in case of resale.

Customer service/support

DAV Tech Srl

Via Ravizza, 30 - 36075 Montecchio Maggiore - VICENZA - ITALY

Tel. +39 0444 574510

CAUTION Risk of accidents and environmental damage: Grease/oil on floors increa-ses the risk of

accidents. Properly dispose of grease/oil according to the applicable national regulations (special

waste).

ENVIRONMENTAL HAZARD The various materials/liquids have to be handled properly and disposed

of separately according to the respective applicable national regulations. Lubricants are considered

special waste.

VOLUMETRIC DISPENSING VALVE DAV 150

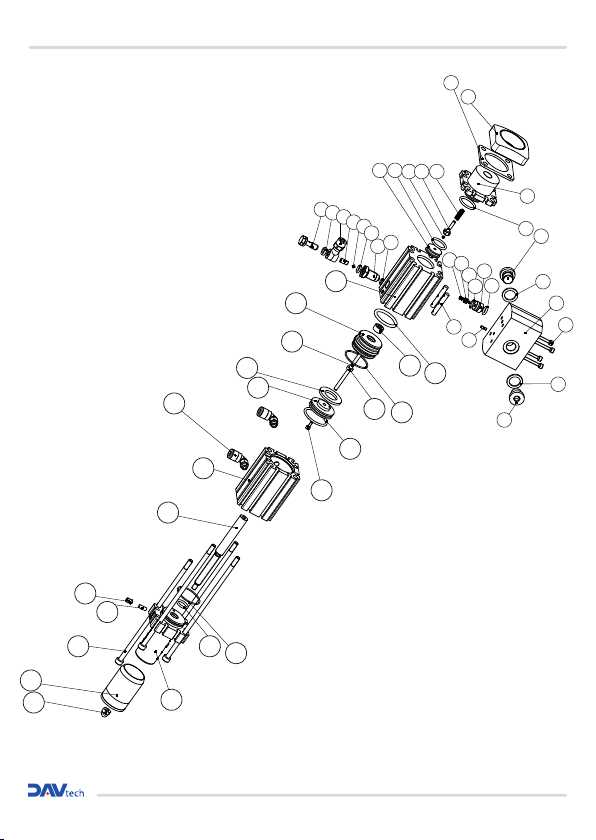

7. BREAKDOWN

28

39

37

30

38

40

47

27

35

10

33

36

19

21

20

13

29

20

14

46

9

49

314567

82

45 16 23 43 24

42

41

44

17

25 32

23

18

34

26

22

15

11

12

48

12

31

11

Installation and maintenance guide

pag.11

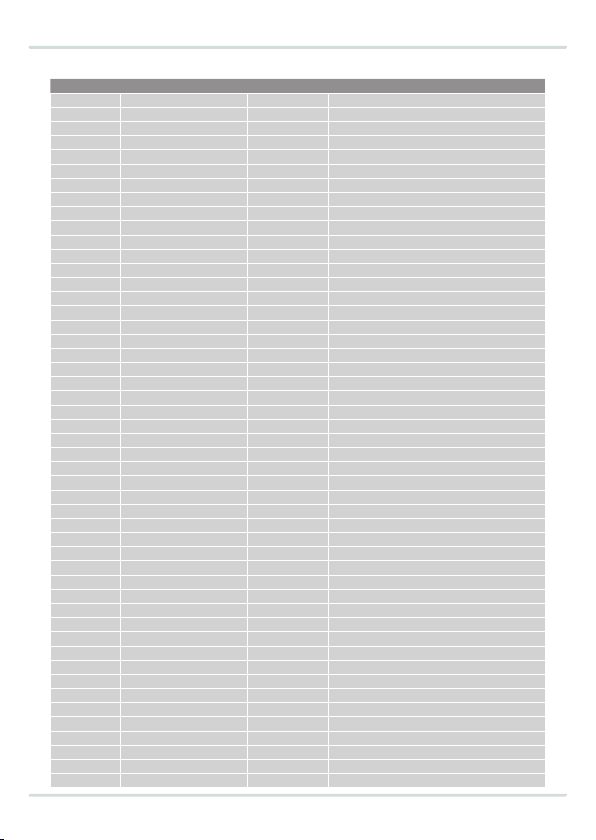

7.1 Components

POS. CODE QUANTITY DESCRIPTION

1011286 1 Gasket

2220900 1 O-Ring

3010025 1 Hydraulic component

4010026 1 Hydraulic component

5010105 1 Sleeve

6 206600 1 Ball

7221801 1 O-Ring

8010106 1 Case

9010031 1 Rod seal

10 001528 1 Magnet

11 430001 2 Screw plug

12 259300 2 Screw seal

13 001590 1 O-Ring

14 223500 1 O-Ring

15 005047 1 O-Ring

16 226800 1 O-Ring

17 227300 1 O-Ring

18 007775 1 O-Ring

19 005121 1 O-Ring

20 232100 2 O-Ring

21 353502 1 Slot ring

22 460002 1 Spring pin

23 007776 2 Ball

24 009349 1 Compression spring

25 007777 1 Compression spring

26 002213 2 Slot nut

27 634200 2 Connection pneumatic

28 411000 1 Cap nut

29 0001226 1 Socket head screw

30 8512700 1 Set screw

31 001593 4 Socket head screw

32 008608 1 Valve housing

33 011573 1 Needle

34 008602 1 Valve seat

35 008601 1 Piston

36 009071 1 lntermediate unit

37 010174 4 Socket head screw

38 001589 1 Pin

39 010173 1 Metering sleeve

40 008598 1 Metering screw

41 005068 1 Threaded plate C 3/C 4

42 008597 1 Housing

43 010108 1 Valve casing

44 008595 1 Connection piece

45 011292 1 Valve seat

46 008592 1 End piece

47 008591 1 Air cylinder

48 008590 1 Connection błock

49 008588 1 Grease cylinder

VOLUMETRIC DISPENSING VALVE DAV 150

Declaration of Incorporation

according to the EU Machinery Directive 2006/42/EG, Annex II, 1.B for partly completed machinery

Manufacturer:

DAV Tech Srl

Via Ravizza, 30 - 36075 Montecchio Maggiore

VICENZA - ITALY

Person residing within the Community authorised to compile the relevant technical documentation:

Andrea Grazioli

DAV Tech Srl

Via Ravizza, 30 - 36075 Montecchio Maggiore

VICENZA - ITALY

Description and identification of the partly completed machinery:

Type: Volumetric valves

Model: DAV 100, DAV 150, DAV 200, DAV 300, DAV 400, DAV 100 MAN, DAV 200 MAN, DAV 300 MAN, DAV 400 MAN.

It is also declared that the relevant technical documentation has been compiled in accordance with part B of

Annex VII.

It is expressly declared that the partly completed machinery the machinery fulfils all relevant provisions of the

following EU Directives:

• 2006/42/CE

• 2006/42/EG

• 95/16/EG

The manufacturer or his authorised representative undertakes to transmit, in response to a reasoned request by the

national authorities, relevant information on the partly completed machinery. This transmission takes place:

This does not affect the intellectual property rights!

Important note! The partly completed machinery may be put into service only if it was determined, where

appropriate, that the machinery into which the partly completed machinery is to be installed meets the provisions

of this Directive.

Andrea Grazioli

We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this manual.

The illustrations are not binding.

DAV TECH SRL Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY - Tel. 0039 0444 574510 - Fax 0039 0444 574324

Table of contents

Other DAV TECH Control Unit manuals

DAV TECH

DAV TECH DA 400 EV Product manual

DAV TECH

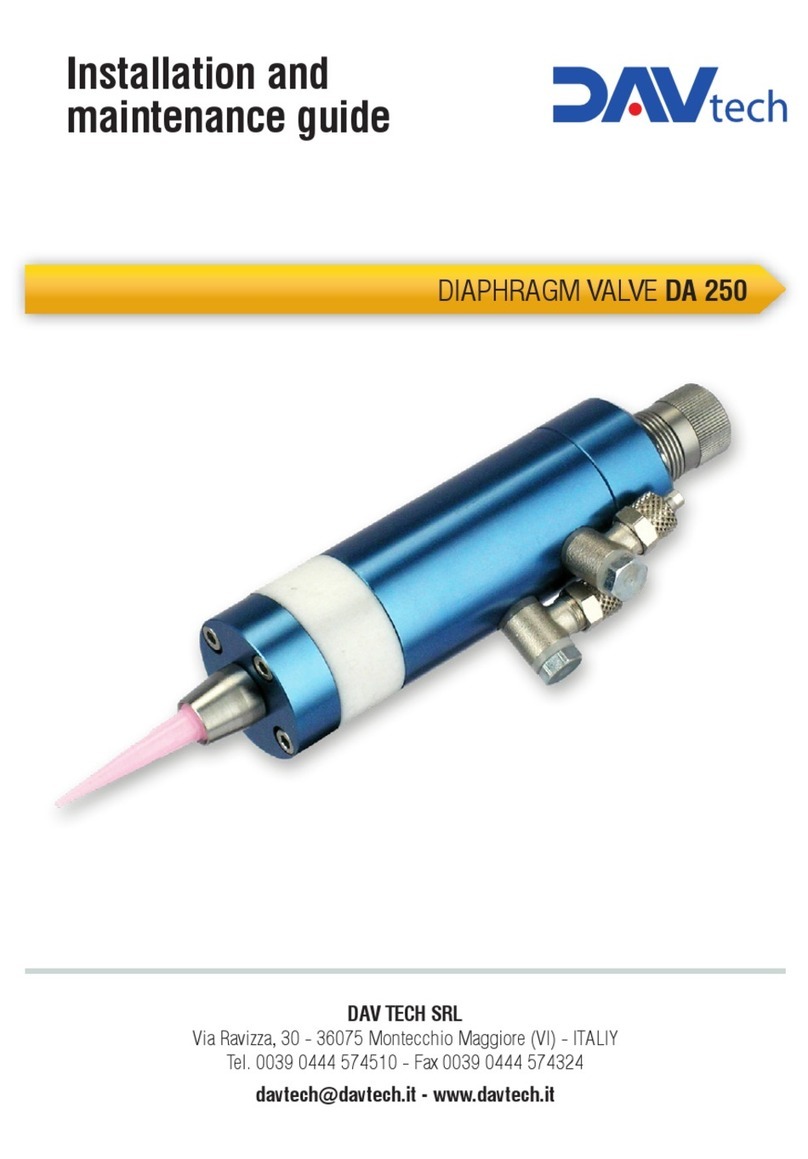

DAV TECH DA 250 Product manual

DAV TECH

DAV TECH DAS 30 Product manual

DAV TECH

DAV TECH DA 400 Product manual

DAV TECH

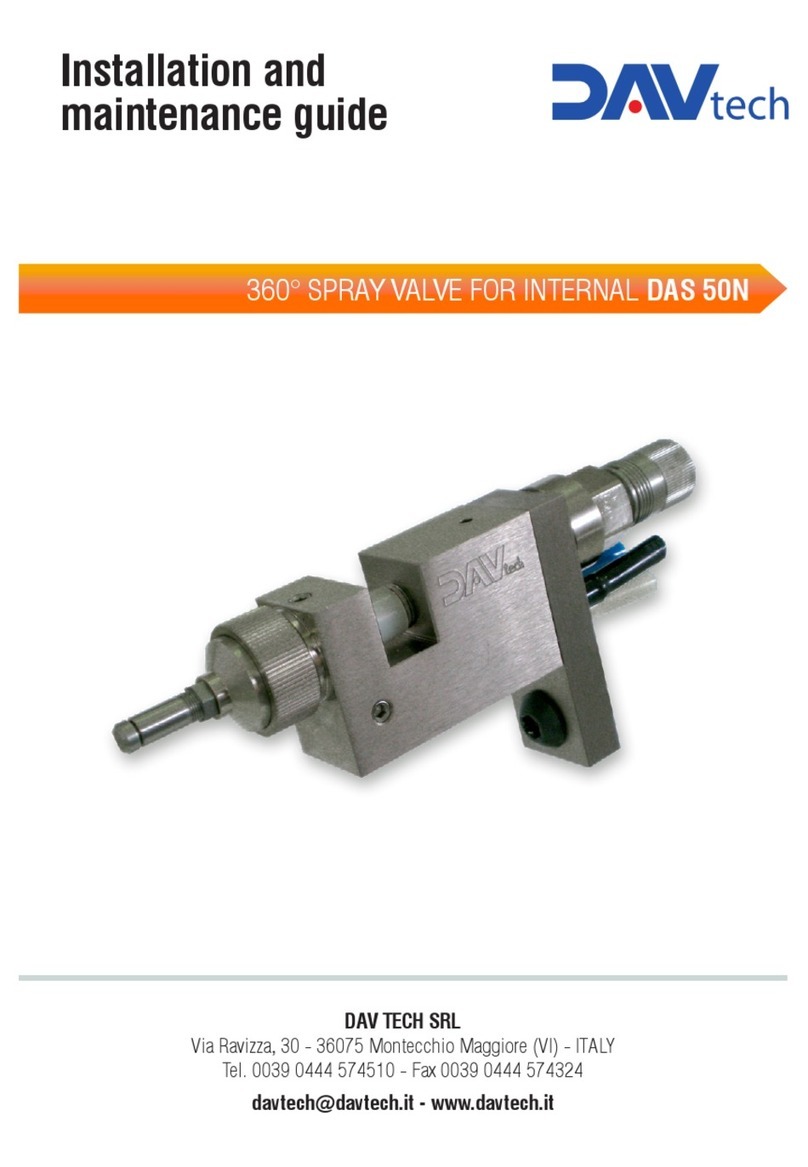

DAV TECH DAS 50N Product manual

DAV TECH

DAV TECH DAV 300 MAN Product manual

DAV TECH

DAV TECH DA 400 EVO Product manual

DAV TECH

DAV TECH DAS 90 Product manual

DAV TECH

DAV TECH DA 600 Product manual

Popular Control Unit manuals by other brands

Eaton

Eaton Vickers CG-03 Series Overhaul manual

resideo

resideo RV283P installation instructions

Nav TV

Nav TV MFT F-CAM installation manual

CALEFFI

CALEFFI 5231 Series Installation and commissioning manual

Panasonic

Panasonic CF-BAH0256U operating instructions

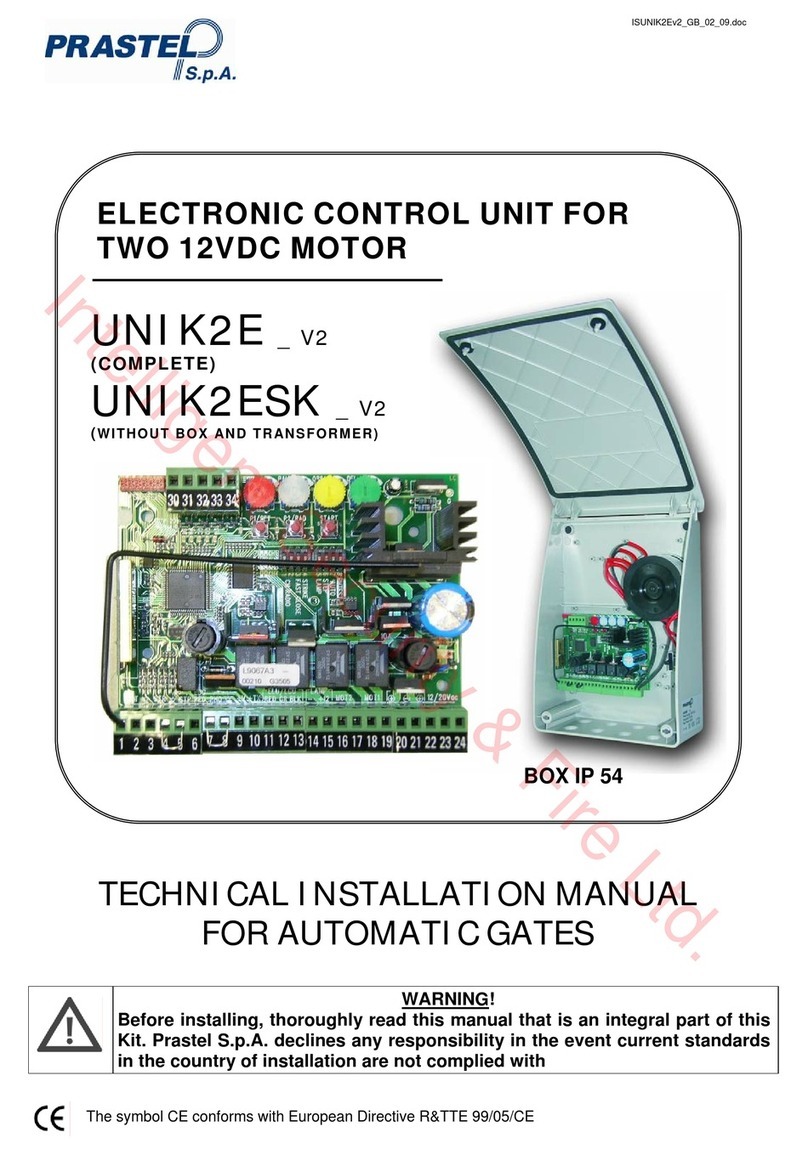

PRASTEL

PRASTEL UNIK2E-V2 Technical installation manual