DAV TECH DAS 30 Product manual

SPRAY VALVE DAS 30

DAV TECH SRL

Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY

Tel. 0039 0444 574510 - Fax 0039 0444 574324

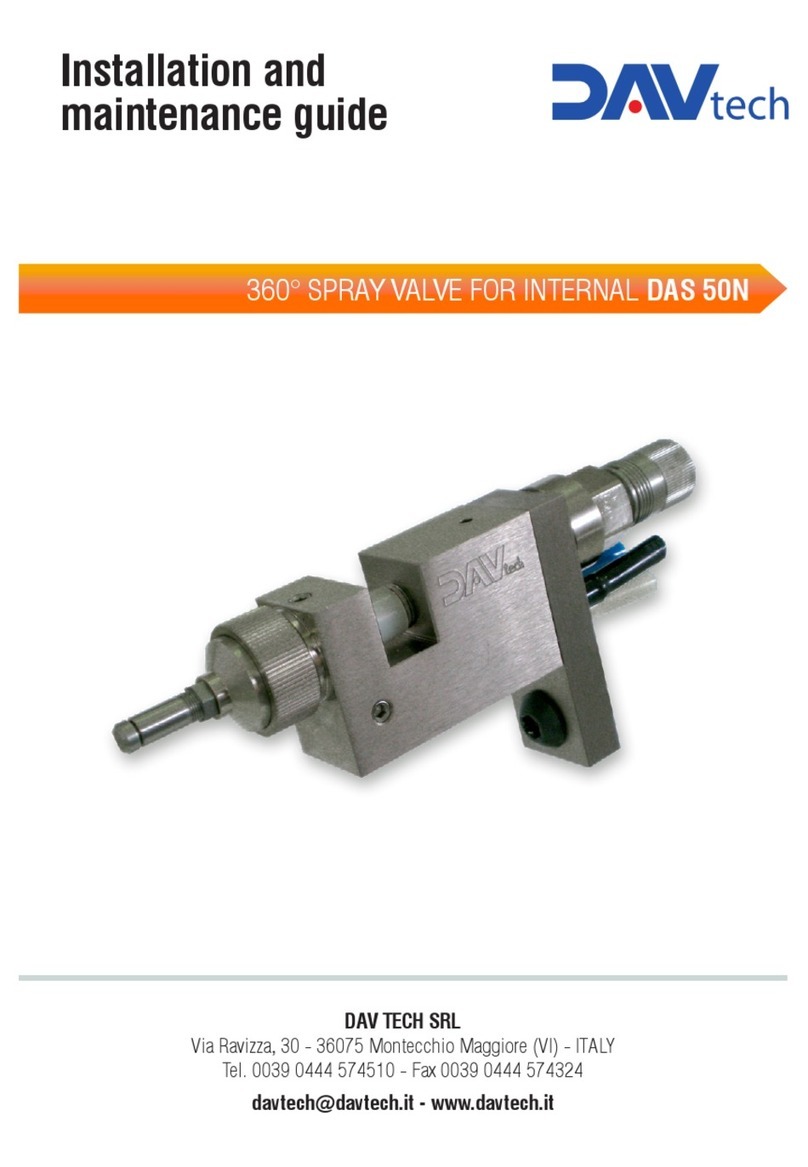

Installation and

maintenance guide

Index

1 INTRODUCTION pag. 3

1.1 The manual

1.2 Warranty

1.3 Goods receiving

2 TECHNICAL DESCRIPTION pag. 3

2.1 Valve operation

2.2 Technical specifications

2.3 Connection diagram

3 INSTALLATION pag. 4

3.1 Mounting in the machine

3.2 Drive the valve

3.3 Fluid connection

3.4 Setting of the dispensed shot

3.5 Amount of the shot

3.6 Screw regulation

4 MAINTENANCE pag. 7

4.1 General rules

4.2 Valve Disassembly and Re-assembly

5 TROUBLESHOOTING pag. 8

5.1 Problems and solutions

6 SIZE pag. 8

7 BREAKDOWN AND DIMENSIONS pag. 9

7.1 Spare parts DAS-30

7.2 Spare parts list DAS-30

7.3 Needle

7.4 Nozzle

7.5 Air cap

7.6 Valve extender

8 SPECIAL VERSION pag. 13

Installation and maintenance guide

SPRAY VALVE DAS 30

pag.3

1 INTRODUCTION

1.1 The manual

The user guide is the document that accompanies the valve from the time of its construction and throughout the period of

use, it is therefore an integral part of the valve. It requires reading the manual before taking any action involving the valve. The

manual must be readily available for use by staff and maintenance of the valve. The user and the attendant use are required

to know the contents of this manual.

Reproduction of any part of this manual, in any form, without the express written permission of DAV Tech. The text and

illustrations in this manual are not binding, the DAV tech reserves the right, at any time and without notice, the right to make

any changes to improve the product or for reasons of character manufacturing or commercial.

1.2 Warranty

The warranty is valid for a period of 12 months from the date of commissioning and no later than 15 months from the

date delivery. The interventions carried out during the warranty period does not extend in any way the validity period of the

guarantee. The seller is not liable for defects caused by normal wear of parts which by their nature are subject to wear.

1.3 Goods receiving

The original configuration of the valve must never be changed.

Upon receipt of the goods, check that:

• The packaging is intact

• The exact correspondence of the material ordered.

2 TECHNICAL DESCRIPTION

2.1 Valve Operation

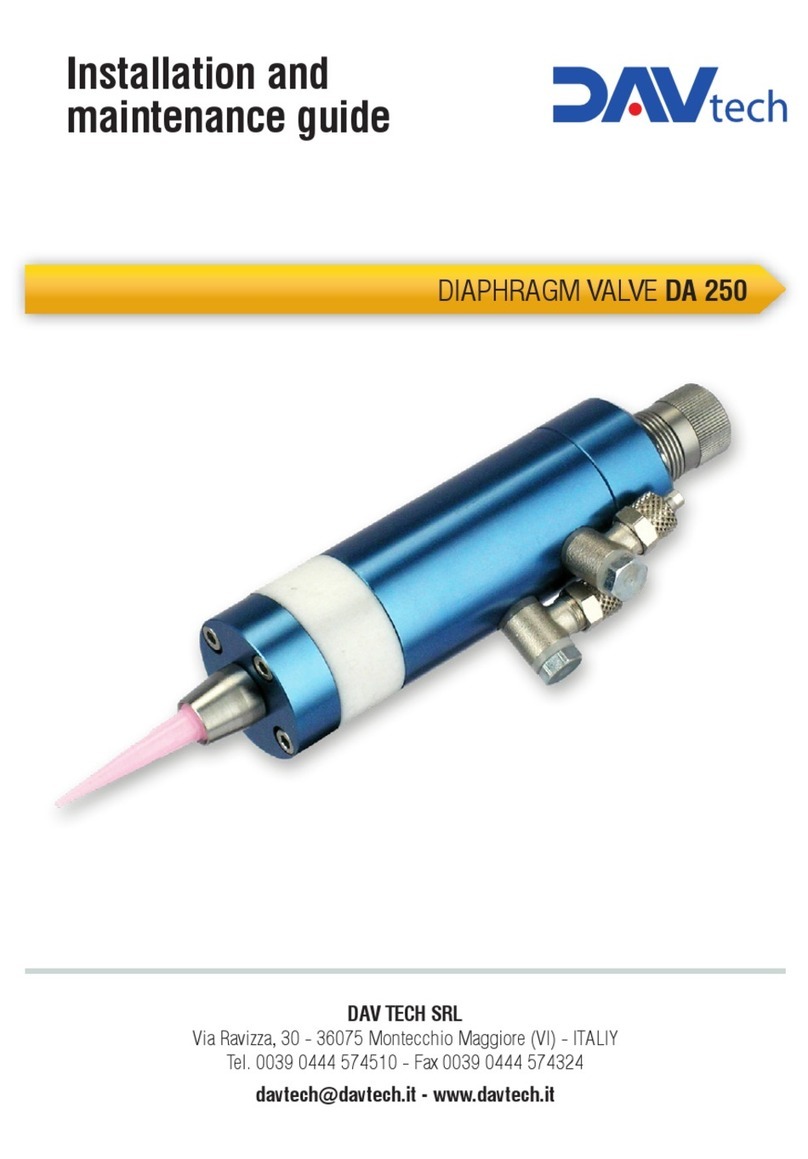

The micro-spray valve DAS 30 is designed to obtain micro-spraying of various types of fluid.

The miniaturized size is perfect for compact layouts, and its design and strenght make it ideal for who is looking for a real

cost-effective solution.

The spray valve DAS 30 can be equipped with various kind of extensions, to fit perfectly any different application.

2.2 Technical Specification

Model DAS 30

Drive Single acting

Weight 140g

Dimensions 40x25x25 mm

Max fluid pressure Max 3 bar - HP version until 12 bar

Actuating air pressure 5-6 bar

Atomizing air pressure 0,1 - 6 bar

Type inlet air Tube 6x4mm

Type inlet fluid Tube 6x4mm

Air cap For round or flat spray (various angle)

Speed Until 200 cycle/min

Adjusting Micrometric - Optionally available with opening sensor

Used materials Stainless steel

Fluids to be dispensed Oil, lubrificants, release agents, thread-lockers (PEEK Version) etc

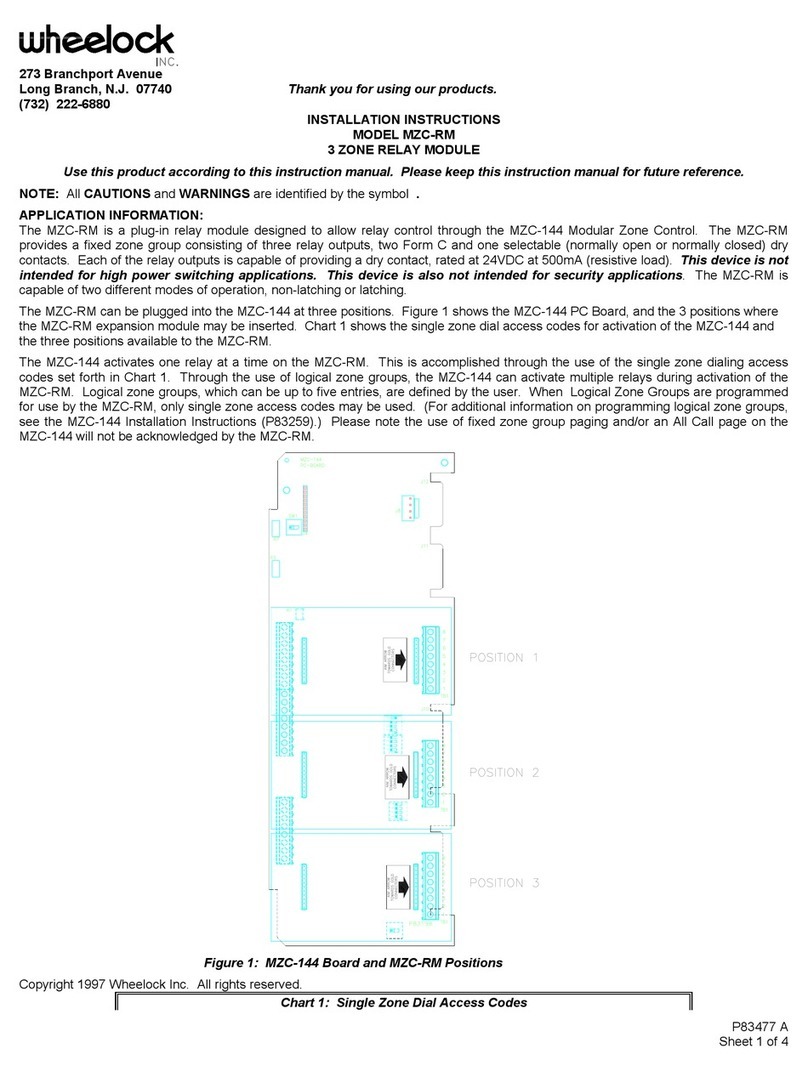

AIR PRESSURE

REGULATOR

FLUID

PLCPLC

E.V.

3/2

E.V.

3/2

E.V.

3/2

PRESSURIZED

TANK

3 INSTALLATION

3.1 Mounting in the machine

The valve can be mounted with any orientation, using the 2 M5 holes on its

body. The distance between the valve and the point of application results in

different results. It is important that the valve is protected from dirt, shocks and

vibrations, which could impair its smooth operation. The inputs on the valve are

marked with letters: M Fluid inlet (max. 3 bar) - Z Atomizing air (0.1 - 6 bar) - S

Air command (5-6 bar).

The inputs can be moved to the back of the valve, replacing the grains (see exploded 12) assembled and going to fix

them on the inputs left free with an anaerobic sealant.

Fastening hole

2.3 Connection

diagram

Installation and maintenance guide

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH,

2022. All rights reserved.

21

Doc-ID 0326

4 Installation

Assembly

The spray valve KA-2 can be installed in any position.

The distance between nozzle opening and application level depends on the required application

width of the material. The greater the distance between nozzle opening and application level, the

greater the application width of the material.

Securely and tightly screw the spray valve to the arm or machine!

Natural oscillation occurs in intermittent operation.

To achieve clean application, it is essential to avoid the transmission of natural oscillation both from

the machine to the spray valve and from the spray valve to the machine.

Hose installation

Control air, atomising air and material are supplied to the spray valve via three separate

connections. The connection ports are differentiated as follows (see Fig. 4.2/1):

•Atomising air (blue)

Connection Z: to 2/2-way solenoid valve

•Control air (black)

Connection S: to 3/2-way solenoid valve

•Material (transparent or white)

Connection M: to pressure tank or pump

Fig. 4.2/1

WARNING! Risk of injury!

The pneumatic energy can cause severe injury. If a component is damaged, high-pressure

materials can escape and cause injury and damage!

Rear connection

Lateral connection

SIDE

CONNECTION

BACK

CONNECTION

pag.5

3.2 Drive the valve

The DAS 30 spray valve must be actuated by two separate solenoid valves; A 3/2 way to drive and a 3/2 way to spray.

The drive pressure must be between 5 and 6 bar.

Spraying pressure between 0.1 ... 6 bar. To achieve an ideal result, the spraying air must be activated first and closed

after the drive air, to prevent dripping.

It is possible, but not advised, to control the air for opening and additional air through the same solenoid valve.

3.3 Fluid connection

The valve must be connected to a fluid supply unit (pressure tank or diaphragm pump).

3.4 Setting of the dispensed shot

The stroke stroke can be adjusted by acting on the micrometric screw located on the back of the valve body. Each

screw stroke corresponds to a 0.025 mm movement of the pin stop block. It is important not to reduce the passage

excessively by forcing the stop block to prevent needle and nozzle damage. By acting anti-clockwise on the block, the

stroke of the needle (and thus the dosed amount) increases, acting in the opposite direction the dispensed quantity

decreases.

3.5 Amount of the shot

Adjusting the amount of material (fluid) is determined by:

> Diameter of the nozzle(0.3 - 0.5 - 0.8 - 1.0 - 1.5 - 2 - 2,5 mm)

> Fluid pressure

> Pin stroke adjustment

Acting on these factors, you can adjust the amount of material you want.

Do not tighten the needle setting too firmly to avoid damaging the needle and nozzle.

Manuale DAS 90

3 INSTALLAZIONE

3.1 Montaggio della Valvola

La Valvola DAS 90 deve essere montata

utilizzando la piastra di fissaggio presente

sulla Valvola.

Deve essere garantito un buon fissaggio della

Valvola sulla macchina, stabile senza

vibrazioni e con una buona accessibilità per

la regolazione, la pulizia e la manutenzione.

3.2 Azionare la Valvola

La Valvola spray DAS 90 deve essere azionate da due elettrovalvole

separate; una da 3/2 vie per il pilotaggio (tubo nero) e una da 3/2 vie per

la nebulizzazione (tubo blu).

La pressione di azionamento deve essere compresa tra 5 e 7 bar.

La pressione di nebulizzazione tra 0,1…2.5 bar.

L’aria di nebulizzazione deve essere attivata prima e chiusa dopo l’aria di

azionamento, questo per impedire che la colla possa sporcare l’ugello e il

cappuccio.

3.3 Collegamento del materiale

La Valvola deve essere collegata ad un gruppo di alimentazione colla

(fusto sotto pressione o pompa a membrana).

Il tubo del materiale è quello trasparente di diametro 6x4.

DAV Tech Sas Via S. Pio X 6/a 36077 Altavilla Vicentina (VI) 0039 0444 574510 www.davtech.it davtech@davtech.it 6

Foro di fissaggio

Tempo aria di nebulizzazione

Tempo aria di apertura

SPRAY VALVE DAS 30

Spraying air time

Opening air time

Installation and maintenance guide

3.6 Screw regulation

The spray valve can be used with continuous or intermittent operation. In intermittent operation, the control air pressure

must be adapted to the switching frequency and material supply pressure. Under ideal operating conditions (specially

calibrated material pressure, control air pressure, needle stroke, short lines) up to 30 cycles per second are possible.

• The operating air pressure (S) must be 6 bar.

• The additional air (Z) must be adjusted so that it is turned on before the needle retracts and is turned off only after the

nozzle closes (reduces the need for maintenance).

• If the material is kept under pressure without contact with outside air, it can remain in the valve for long periods

without the valve being used.

• Use only clean, filtered material. Ideally, the control air supplied to the valve should be lightly lubricated (line air).

The additional air pressure (Z) and the material pressure (M) are closely related to each other.

The atomizing air pressure should not be significantly greater than the material pressure, otherwise back pressure could

develop which would push the material back into the nozzle.

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH ,

2022. All rights reserved.

25

Doc-ID 0326

Operating instructions

➔The spray valve may be used in continuous or intermittent operation. In intermittent operation

the control air pressure must be matched to the switching frequency and the material feed

pressure. In ideal operating conditions (material pressure, control air pressure, needle

stroke, short lines) up to 30 cycles per second are possible.

➔The control air pressure should be 6 bar.

➔The atomising air has to be regulated so that it is switched on before the needle retracts,

and is switched off only after the nozzle closes (reduces the need for maintenance).

➔If the material is kept pressurised with no contact with the outside air, it can remain in the

valve during long periods without operation.

➔Only clean, filtered material, atomising air and control air may be used. The control air

supplied to the spray valve should ideally be lightly oiled.

➔Only for the adhesive version:

The atomising air pressure and material pressure are closely related to each other. The

atomising air pressure should not be significantly greater than the material pressure, since

otherwise back pressure can develop, pushing the material back into the nozzle.

Fig. 5.2/1

NOTE!

The flow of material can be adjusted to suit individual requirements by turning the regulating

screw (Fig. 5.2/1):

Turn screw to the right: to reduce the material flow

Turn screw to the left: to increase the material flow

NOTE!

The illustrations in these instructions may differ slightly from the actual version of the device.

Incorrect handling can damage the nozzle and nozzle needle. Only reduce the material flow (by

turning the regulating screw to the right) while the material is being dispensed. Once the nozzle

closes, do not turn the regulating screw any further to the right.

NOTE! The illustrations in these

instructions may differ slightly from the

actual version of the device. Incorrect

handling can damage the nozzle and

nozzle needle. Only reduce the material

flow (by turning the regulating screw

to the right) while the material is being

dispensed. Once the nozzle closes, do

not turn the regulating screw any further

to the right.

NOTE! The flow of material can be adjusted

to suit individual requirements by turning the

regulating screw:

Turn screw to the right:

to reduce the material flow

Turn screw to the left:

to increase the material flow

pag.7

SPRAY VALVE DAS 30

4 MAINTENANCE

4.1 General rules

The DAS 30 spray valve, thanks to the construction methods and materials used, is easy to maintain.

Minimal, simple, accurate, and constant maintenance allow for long-lasting and smooth operation in valve time, while

maintaining performance unchanged.

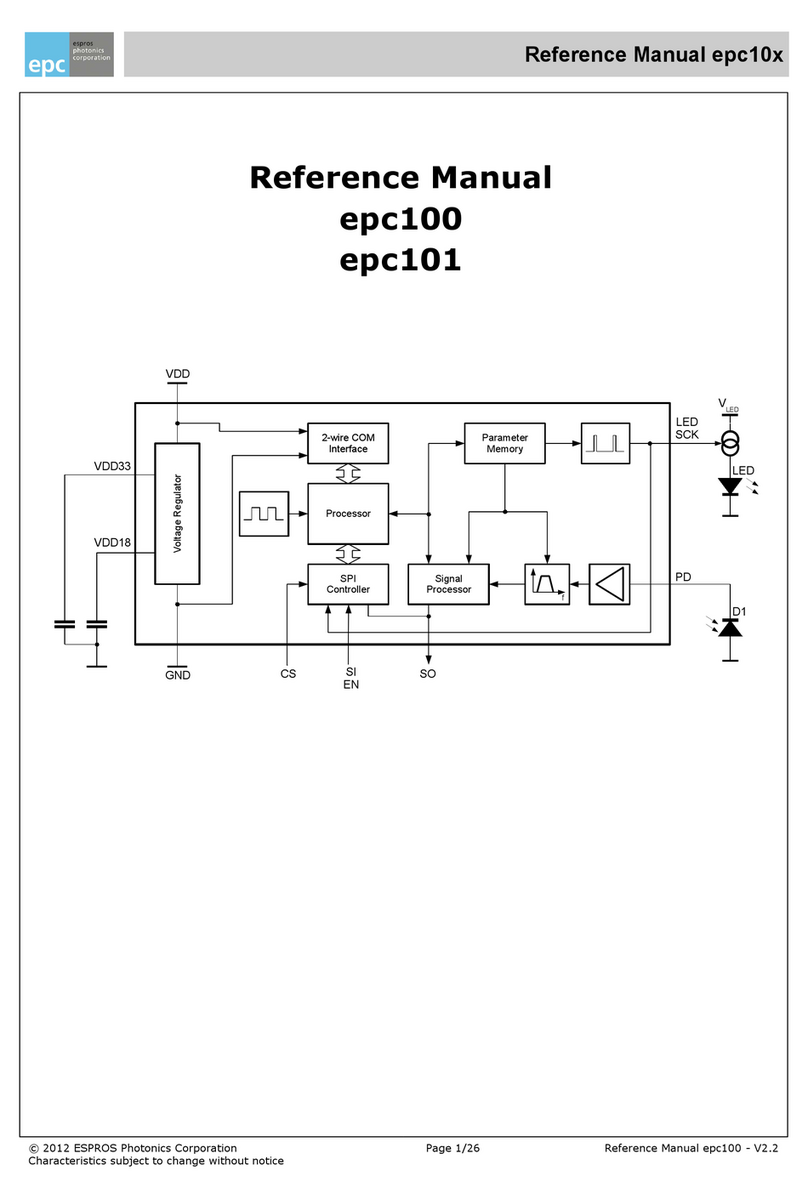

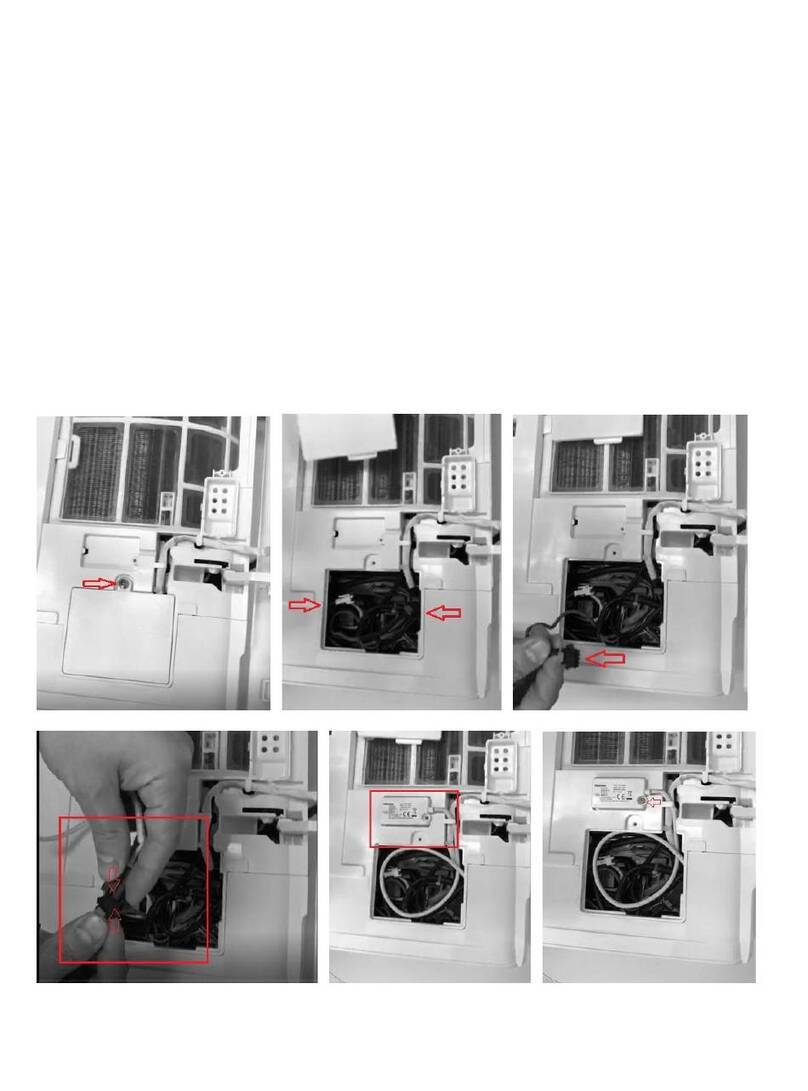

4.2 Valve Disassembly and Re-assembly

Before disassembling the valve:

• Clean the valve

• Disconnect it from the entire circuit

• Remove the screws (10)

• Remove the pneumatic body (9), being careful not to lose the O-rings (8)

• Remove the spring, the needle (6) and the O-ring (5)

• Unscrew the ring nut (1) from the main body (4), and together with it also the air cap (2)

• Unscrew, using a wrench, the nozzle (3)

• Clean and replace all damaged gaskets (in red) and any other parts

• Reassemble in the reverse order.

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH ,

2022. All rights reserved.

29

Doc-ID 0326

Changing the nozzle and nozzle needle

Fig. 6.2/1

1. Depressurise all connections and stop the supply of energy and material!

2. Undo the retaining ring (1) and remove the air cap (2).

3. Unscrew the cylinder-head screws (10) and remove the end plate (9).

(Caution: the end plate is under spring tension)

4. Take care not to lose the O-rings (8) or the pressure springs (7).

5. Withdraw the nozzle needle (6) and unscrew the nozzle (3). Ensure that the O-ring (5)

stays in the main body (4); when pulling out the nozzle needle, it sometimes gets stuck on

the needle.

6. Lightly grease the new nozzle needle (6) and push it into the main body (4). Then remove

any remaining grease from the needle tip.

7. Screw the new nozzle (3) into the main body (4).

8. Only now should the end plate (9) be screwed back onto the main body (4). At this stage,

make sure that the pressure springs and O-rings are positioned correctly, as described in

point 4.

9. Screw the air cap (2) with the retaining ring (1) back onto the main body (4).

10. Perform a functional test of the device after changing the nozzle and needle!

IMPORTANT!

Always install a new nozzle (3) and nozzle needle (6) at the same time.

NOTE!

When replacing nozzles and nozzle needles that have already been in use, rinse the nozzle with

the appropriate solvent in such a way that no material residues remain. The shaft of the needle

must also be cleaned of any residual particles. Needle shafts with hardened material residues

can lead to damage of the sealing element.

PROBLEM POSSIBLE CAUSE SOLUTION

Nothing or little fluid Valve does not receive the command Check valve (solenoid valve) control. Perform

a manual test.

The pressure of the fluid is too low

or absent. Check the fluid supply pressure and, if

necessary, increase it.

The nozzle is clogged

Unscrew and clean the nozzle.

The filter is dirty (if present) Wash or replace the filter.

A tube is bent Check the status of the fluid supply pipes

Insufficient drive pressure Check drive pressure (5-7 bar)

Fluid residues present in the system Clean the system with water

Fluid out of the compass O-ring or shaped gasket on the damaged

valve body Replace O-ring or shaped gasket

Fluid flow between valve

body and fixing plate O-ring on the damaged dam reservoir Replace the O-ring of the hub

The nozzle dries even if

the valve is not piloted Presence of dirt in the nozzle Clean or replace the nozzle.

The valve opens late Insufficient drive pressure Check drive pressure 5-7 bar

O-ring on the damaged spike Replace the O-ring on the pin

Splashed irregularly Insufficient spraying pressure Check spraying pressure

(0,1…2,5 bar)

Dirt in the air cap Clean the air cap

5 TROUBLESHOOTING

5.1 Problems and solutions

The search for defects in the operation should be performed only by personnel qualified respecting the safety rules

in force.

6 DIMENSIONS

Installation and maintenance guide

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH ,

2022. All rights reserved.

17

Doc-ID 0326

Dimensions

Fig. 3.3/1

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH ,

2022. All rights reserved.

17

Doc-ID 0326

Dimensions

Fig. 3.3/1

7.2 Lista componenti DAS-30

STANDARD VERSION HIGH PRESSURE (HP) VERSION (25 bar)

Pos Code Q.ty Description

1See next table 1 Air cap

2See next table 1 Nozzle

3410028 1 Collar

4510025 1 Main body

5640006 1 O-ring

6220089 3 M5 tting

7640026 1 Seal

8See next table 1 Needle

9640366 1 O-ring

10 820017 1 Pressure spring

11 610090 1 Regulation block

12 640000 3 O-ring

13 510028 1 Pneumatic body

14 610021 3 Grub screws

15 610008 3 Screws

16 650004 1 Conical element

17 820077 1 Spring

18 610017 1 Grub screw

19 220089 3 Fitting

GASKETKIT-DAS30

GASKET KIT COMPLETE

Pos Code Q.ty Description

1See next table 1 Air cap

2See next table 1 Nozzle

3410028 1 Collar

4510938 1 Main Body HP

5640006 1 O-ring

6220089 3 M5 Fitting

7640026 1 Seal

8See next table 1 Needle

9640366 1 O-ring

10 820014 1 Pressure spring HP

11 610090 1 Regulation block

12 640000 3 O-ring

13 510028 1 Pneumatic body

14 610021 3 Grub screws

15 610008 3 Screws

16 650004 1 Conical element

17 820077 1 Spring

18 610017 1 Grub screw

19 220089 3 Fitting

20 320564 1 Needle guide HP

21 640045 1 Quad ring HP

GASKETKIT-DAS30HP

GASKET KIT COMPLETE

air cap nozzle needle

3

1

5

4

19

8

2

7911

12

13 15

14

16 17

18

10

ONLY HP VERSION

20

21

pag.9

7.1 Spare parts DAS 30

7 SPARE PARTS

SPRAY VALVE DAS 30

ONLY HP VERSION

Installation and maintenance guide

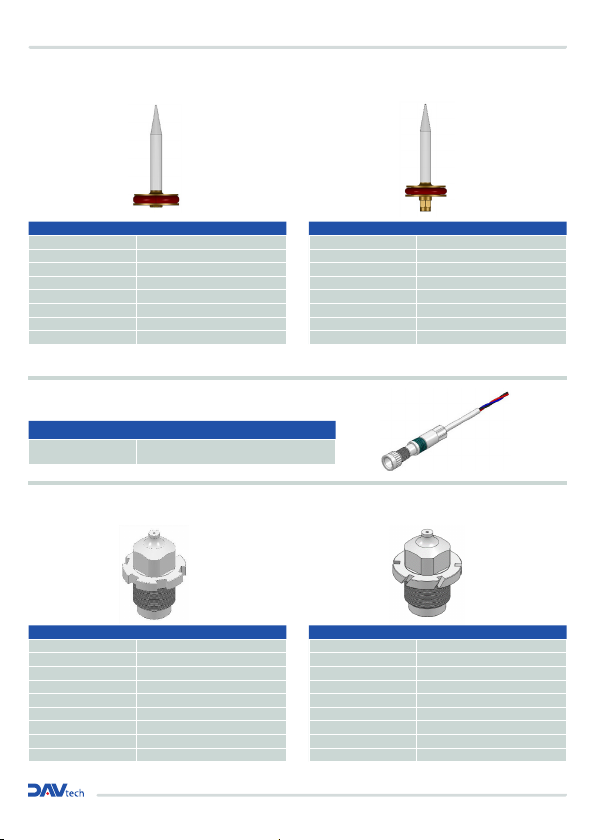

7.3 Needle

7.4 Ugello

STANDARD NEEDLE NEEDLE FOR SENSOR

Code Description

110155 NEEDLE 0,2-0,3 MM

110156 NEEDLE 0,5 MM

110157 NEEDLE 0,8 MM

110158 NEEDLE 1,0 MM

110159 NEEDLE 1,2 MM

110160 NEEDLE 1,5 MM

110161 NEEDLE 2,0 MM

110162 NEEDLE 2,5 MM

Code Description

110696 NEEDLE 0,2-0,3 MM

111062 NEEDLE 0,5 MM

111930 NEEDLE 0,8 MM

111931 NEEDLE 1,0 MM

111932 NEEDLE 1,2 MM

111933 NEEDLE 1,5 MM

111934 NEEDLE 2,0 MM

111935 NEEDLE 2,5 MM

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH ,

2022. All rights reserved.

43

Doc-ID 0326

Nozzle needles

8.4.1 Standard version

Nozzle needle, stainless steel, dia. 3 x 27 mm (7)

Item no.

Description

110155

Nozzle needle, 0.2 / 0.3 mm, complete, Viton®

110156

Nozzle needle, 0.5 mm, complete, Viton®

110157

Nozzle needle, 0.8 mm, complete, Viton®

110158

Nozzle needle, 1.0 mm, complete, Viton®

110159

Nozzle needle, 1.2 mm, complete, Viton®

110160

Nozzle needle, 1.5 mm, complete, Viton®

110161

Nozzle needle, 2.0 mm, complete, Viton®

110162

Nozzle needle, 2.5 mm, complete, Viton®

8.4.2 Standard V4A version

Nozzle needle, V4A, dia. 3 x 27 mm (7)

Item no.

Description

114777

Nozzle needle, 0.2 / 0.3 mm, V4A, complete, Viton®

111758

Nozzle needle, 0.5 mm, V4A, complete, Viton®

111926

Nozzle needle, 0.8 mm, V4A, complete, Viton®

8.4.3 Adhesive version

Nozzle needle, adhesive, stainless steel, dia. 3 x 27 mm (7)

Item no.

Description

110169

Nozzle needle, adhesive, 0.2/0.3 mm, complete, Viton®

110170

Nozzle needle, adhesive, 0.5 mm, complete, Viton®

110171

Nozzle needle, adhesive, 0.8/1.0 mm, complete, Viton®

110172

Nozzle needle, adhesive, 1.2 mm, complete, Viton®

110173

Nozzle needle, adhesive, 1.5 mm, complete, Viton®

110174

Nozzle needle, adhesive, 2.0 mm, complete, Viton®

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH ,

2022. All rights reserved.

45

Doc-ID 0326

8.5.2 Connecting the sensor

For information on the electrical connection of the needle sensor, please refer to the enclosed

documentation for the sensor in the appendix (Chapter 12 "Appendix").

8.5.3 Nozzle needle for sensor

When using a raster needle sensor, one of the following nozzle needles is needed.

8.5.3.1 Standard version

Nozzle needle, stainless steel, dia. 3 x 31 mm (7)

Item no.

Description

110969

Nozzle needle, 0.2/0.3 mm, complete, NA, Viton®

111062

Nozzle needle, 0.5 mm, complete, NA, Viton®

111930

Nozzle needle, 0.8 mm, complete, NA, Viton®

111931

Nozzle needle, 1.0 mm, complete, NA, Viton®

111932

Nozzle needle, 1.2 mm, complete, NA, Viton®

111933

Nozzle needle, 1.5 mm, complete, NA, Viton®

111934

Nozzle needle, 2.0 mm, complete, NA, Viton®

111935

Nozzle needle, 2.5 mm, complete, NA, Viton®

8.5.3.2 Adhesive version

Nozzle needle, adhesive, stainless steel, dia. 3 x 31 mm (7)

Item no.

Description

112406

Nozzle needle, adhesive, 0.2/0.3 mm, complete, NA, Viton®

112405

Nozzle needle, adhesive, 0.5 mm, complete, NA, Viton®

112163

Nozzle needle, adhesive, 0.8/1.0 mm, complete, NA, Viton®

112513

Nozzle needle, adhesive, 1.2 mm, complete, NA, Viton®

112514

Nozzle needle, adhesive, 1.5 mm, complete, NA, Viton®

112515

Nozzle needle, adhesive, 2.0 mm, complete, NA, Viton®

WARNING! Electrical hazard!

Work on the electrical equipment must only be carried out by qualified personnel in accordance

with the safety regulations.

Before beginning work, the electrical supply must be switched off, and secured against being

switched back on.

Special custom versions available on request.

Code Description

210110 NOZZLE 0,2 MM

210111 NOZZLE 0,3 MM

210112 NOZZLE 0,5 MM

210113 NOZZLE 0,8 MM

210114 NOZZLE 1,0 MM

210115 NOZZLE 1,2 MM

210116 NOZZLE 1,5 MM

210117 NOZZLE 2,0 MM

210118 NOZZLE 2,5 MM

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH,

2022. All rights reserved.

38

Doc-ID 0326

8.2.4 Special round spray pattern version

Air cap, round spray pattern, special swirl valve

Item no.

Description

310197

Air cap, round spray pattern, special swirl valve, 0.2–

1.0 mm

Nozzles (3.0)

8.3.1 Standard version

Nozzle, stainless steel, dia. 12 x 18 mm, AF size 6

Item no.

Description

210110

Nozzle, 0.2 mm, stainless steel, 12 x 18 mm, AF size 7

210111

Nozzle, 0.3 mm, stainless steel, 12 x 18 mm, AF size 7

210112

Nozzle, 0.5 mm, stainless steel, 12 x 18 mm, AF size 7

210113

Nozzle, 0.8 mm, stainless steel, 12 x 18 mm, AF size 7

210114

Nozzle, 1.0 mm, stainless steel, 12 x 18 mm, AF size 7

210115

Nozzle, 1.2 mm, stainless steel, 12 x 18 mm, AF size 7

210116

Nozzle, 1.5 mm, stainless steel, 12 x 18 mm, AF size 7

210117

Nozzle, 2.0 mm, stainless steel, 12 x 18 mm, AF size 7

210118

Nozzle, 2.5 mm, stainless steel, 12 x 18 mm, AF size 7

The appropriate nozzle needles and air caps can be found in Chapter 8.4.1 and Chapter 8.2.1.

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH ,

2022. All rights reserved.

39

Doc-ID 0326

8.3.2 Standard/swirl version

Nozzle, swirl, stainless steel, 12 x 18 mm, AF size 6

Item no.

Description

210776

Nozzle, swirl, 0.2 mm, stainless steel, 12 x 18 mm, AF

size 7

210777

Nozzle, swirl, 0.3 mm, stainless steel, 12 x 18 mm, AF

size 7

210778

Nozzle, swirl, 0.5 mm, stainless steel, 12 x 18 mm, AF

size 7

211024

Nozzle, swirl, 0.6 mm, stainless steel, 12 x 18 mm, AF

size 7

211025

Nozzle, swirl, 0.7 mm, stainless steel, 12 x 18 mm, AF

size 7

210779

Nozzle, swirl, 0.8 mm, stainless steel, 12 x 18 mm, AF

size 7

210780

Nozzle, swirl, 1.0 mm, stainless steel, 12 x 18 mm, AF

size 7

210781

Nozzle, swirl, 1.2 mm, stainless steel, 12 x 18 mm, AF

size 7

210782

Nozzle, swirl, 1.5 mm, stainless steel, 12 x 18 mm, AF

size 7

210783

Nozzle, swirl, 1.8 mm, stainless steel, 12 x 18 mm, AF

size 7

210784

Nozzle, swirl, 2.0 mm, stainless steel, 12 x 18 mm, AF

size 7

The appropriate nozzle needles and air caps can be found in Chapter 8.4.1 and Chapter 8.2.1.

STANDARD NOZZLE SPIN NOZZLE

Code Description

210776 NOZZLE 0,2 MM

210777 NOZZLE 0,3 MM

210778 NOZZLE 0,5 MM

210779 NOZZLE 0,8 MM

210780 NOZZLE 1,0 MM

210781 NOZZLE 1,2 MM

210782 NOZZLE 1,5 MM

210783 NOZZLE 2,0 MM

210784 NOZZLE 2,5 MM

COMPLETE SENSOR DAS-30

Code Description

320314 NEEDLE OPEN/CLOSE DETECTING SENSOR

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH,

2022. All rights reserved.

44

Doc-ID 0326

Raster needle sensing

In the KA-2, a raster needle sensor can optionally be installed, the inductive sensor can be used to

monitor whether the needle is open.

Important: If damaged, use a different nozzle needle!

Sensor spindle, KA-2, complete

Item no.

Description

320314

Sensor spindle, KA-2, complete

In conjunction with the appropriate nozzle needle (see Chapter: 8.5.3).

8.5.1 Adjusting the sensor

Fig. 4.5/1

1. Glue the M4 x 0.5 screw sensor (2) into the sensor receptacle (1) over an installation

length of 14.5 mm using a high-strength threadlocker. (See drawing)

2. Screw the regulating spindle (5) in until the needle is closed and no more material

emerges from the nozzle.

3. Connect the sensor to a control device in order to adjust it.

4. Then push the spring (3) and the spindle guide (4) onto the sensor and insert them

together into the regulating spindle until a signal appears.

5. Unscrew the regulating spindle until the signal disappears (up to at most 6 clicks). If the

signal from the sensor has still not disappeared, finely adjust the sensor using the

spindle guide until the signal disappears.

6. Perform the fine adjustment by pushing the spindle guide back against the spring, so

that the sensor can be turned in the regulating spindle until the signal disappears.

7. Allow the spindle guide to latch back into the groove of the regulating spindle.

pag.11

SPRAY VALVE DAS 30

7.5 Air cap

7.6 Valve extender (Standard)

FLAT AIR CAP

60° (STANDARD)

RADIAL DISPENSING VALVE EXTENDER 360° - L:100 mm

FLAT AIR CAP

ROUND AIR CAP

ROUND AIR CAP

15°

FRONTAL DISPENSING VALVE EXTENDER - L:100 mm

Code Description

310032 FOR NOZZLE 0,2-1,0 MM

310033 FOR NOZZLE 1,2-1,5 MM

310079 FOR NOZZLE 1,8-2,0 MM

310090 FOR NOZZLE 2,5 MM

Codice Description

310034 FOR NOZZLE 0,2-1,0 MM

310035 FOR NOZZLE 1,2-1,5 MM

310080 FOR NOZZLE 1,8-2,0 MM

310091 FOR NOZZLE 2,5 MM

90°

Code Description

310036 FOR NOZZLEO 0,2-1,0 MM

310037 FOR NOZZLE 1,2-1,5 MM

310166 FOR NOZZLE 1,8-2,0 MM

310167 FOR NOZZLE 2,5 MM

Ø 4 mm Ø 4 mm

45°

Code Description

310038 FOR NOZZLE 0,2-1,0 MM

310039 FOR NOZZLE 1,2-1,5 MM

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH ,

2022. All rights reserved.

33

Doc-ID 0326

8 Spare parts and accessories

General and safety instructions for use

When ordering nozzle sets as spare parts (nozzle needle, air cap and nozzle), please state required

size. Nozzle sets should always be replaced together!

Available nozzles, air caps and needle sizes (dia.):

0.2 mm / 0.3 mm / 0.5 mm / 0.8 mm / 1.0 mm / 1.2 mm / 1.5 mm / 2.0 mm / 2.5 mm

Special nozzles, needles and air caps can be developed for your particular application upon

request!

Only use swirl nozzles in combination with the matching round spray cap!

Air caps

8.2.1 Standard version

Air cap, flat spray pattern, dia. 20 x 14.5 mm, 45°

Item no.

Description

310038

Air cap, flat spray pattern, 0.2–1.0 mm, 20 x 14.5 mm

310039

Air cap, flat spray pattern, 1.2–1.5 mm, 20 x 14.5 mm

Air cap, flat spray pattern, dia. 20 x 14.5 mm, 60°, standard version

Item no.

Description

310032

Air cap, flat spray pattern, 0.2–1.0 mm, 20 x 14.5 mm

310033

Air cap, flat spray pattern, 1.2–1.5 mm, 20 x 14.5 mm

310079

Air cap, flat spray pattern, 1.8–2.0 mm, 20 x 14.5 mm

310090

Air cap, flat spray pattern, 2.5 mm, 20 x 14.5 mm

Air cap, flat spray pattern, dia. 20 x 14.5 mm, 90°

Item no.

Description

310036

Air cap, flat spray pattern, 0.2–1.0 mm, 20 x 14.5 mm

310037

Air cap, flat spray pattern, 1.2–1.5 mm, 20 x 14.5 mm

310166

Air cap, flat spray pattern, 1.8–2.0 mm, 20 x 14.5 mm

310167

Air cap, flat spray pattern, 2.5 mm, 20 x 14.5 mm

Automatic Spray Valve

KA-2

Copyright ALFRED SCHÜTZE Apparatebau GmbH,

2022. All rights reserved.

34

Doc-ID 0326

Air cap, flat spray pattern, dia. 20 x 14.5 mm, 45°, VA

Item no.

Description

310512

Air cap, flat spray pattern, 0.2–1.0 mm, 20 x 14.5 mm,

VA

311015

Air cap, flat spray pattern, 1.2–1.5 mm, 20 x 14.5 mm,

VA

Air cap, flat spray pattern, dia. 20 x 14.5 mm, 60°, VA, standard version

Item no.

Description

310209

Air cap, flat spray pattern, 0.2–1.0 mm, 20 x 14.5 mm, VA

310420

Air cap, flat spray pattern, 1.2–1.5 mm, 20 x 14.5 mm, VA

310513

Air cap, flat spray pattern, 1.8–2.0 mm, 20 x 14.5 mm, VA

310944

Air cap, flat spray pattern, 2.5 mm, 20 x 14.5 mm, VA

Air cap, flat spray pattern, dia. 20 x 14.5 mm, 90°, VA

Item no.

Description

310584

Air cap, flat spray pattern, 0.2–1.0 mm, 20 x 14.5 mm, VA

Air cap, flat spray pattern, 1.2–1.5 mm, 20 x 14.5 mm, VA

310584

Air cap, flat spray pattern, 1.8–2.0 mm, 20 x 14.5 mm, VA

Air cap, flat spray pattern, 2.5 mm, 20 x 14.5 mm, VA

Air cap, round spray pattern, dia. 20 x 11 mm, 15°

Item no.

Description

310034

Air cap, round spray pattern, 0.2–1.0 mm, 20 x 11 mm

310035

Air cap, round spray pattern, 1.2–1.5 mm, 20 x 11 mm

310080

Air cap, round spray pattern, 1.8–2.0 mm, 20 x 11 mm

310091

Air cap, round spray pattern, 2.5 mm, 20 x 11 mm

Air cap, round spray pattern, dia. 20 x 11 mm, 15°, VA

Item no.

Description

310370

Air cap, round spray pattern, 0.2–1.0 mm, 20 x 11 mm, VA

310366

Air cap, round spray pattern, 1.2–1.5 mm, 20 x 11 mm, VA

310385

Air cap, round spray pattern, 1.8–2.0 mm, 20 x 11 mm, VA

310464

Air cap, round spray pattern, 2.5 mm, 20 x 11 mm, VA

Special custom versions available on request.

Pos Code Description

1 640203 O-RING

2 230747 RADIAL DISPENSING VALVE EXTENDER

3 410028 NUT

Pos Code Description

1 640203 O-RING

2 231515

FRONTAL DISPENSING VALVE EXTENDER

3 410028 NUT

3

1

2

3

1

2

Installation and maintenance guide

Ø 8 mm

Pos Description vers. Code

1

INNER TUBE STD (100 mm)

INNER TUBE HP (100 mm)

INNER TUBE STD (200 mm)

INNER TUBE HP (200 mm)

1.1

1.2

1.3

1.4

850129

851134

850096

854821

2OUTER TUBE (100 mm)

OUTER TUBE (200 mm)

2.1

2.2

850130

850097

3 BELL 220197

4 O-RING 640039

5 O-RING 640366

6

NOZZLE 0,4 mm

NOZZLE 0,6 mm

NOZZLE 0,8 mm

5.1

5.2

5.3

211206

211343

211327

7

NEEDLE STD (100 mm)

NEEDLE VERS. SENSOR

NEEDLE STD (200 mm)

6.1

6.2

6.3

110432

112929

112601

8 COLLAR 410028

Pos Description vers. Code

1

INNER TUBE STD (100 mm)

INNER TUBE HP (100 mm)

INNER TUBE STD (200 mm)

INNER TUBE HP (200 mm)

1.1

1.2

1.3

1.4

850129

851134

850096

854821

2OUTER TUBE COMPLETE (100 mm)

OUTER TUBE COMPLETE (200 mm)

2.1

2.2

850215

850669

3 O-RING 640366

4 NOZZLE 0,5 mm 210348

5

NEEDLE STD (100 mm)

NEEDLE VERS. SENSOR

NEEDLE STD (200 mm)

6.1

6.2

6.3

110432

112929

112601

6 COLLAR 410028

Ø 8 mm

RADIAL DISPENSING VALVE EXTENDER 360° - L:100/200 mm FRONTAL DISPENSING VALVE EXTENDER - L:100/200 mm

1

2

3

4

5

6

1

2

3

4

5

6

7

8

pag.13

SPRAY VALVE DAS 30

8 SPECIAL VERSION :

The DAS 30 valve exists in many special variants:

- PEEK version, for aggressive or reactive products

- Extension extension for radial spraying (draw design) Extensions are available in lengths of 100, 200, 300,

400 and 500 mm and allow to dispense holes and cylinders with low and medium viscosities such as oils

and greases.

- Version with sensor for objectization after valve opening.

- Special versions with extensions and nozzles for spraying in difficult access areas. For example, with tilted

nozzles 45 °, with double spraying nozzles etc.

- Versions with special seals for extremely high temperature working areas (up to 150°).

We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this manual.

The illustrations are not binding.

DAV TECH SRL Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY - Tel. 0039 0444 574510 - Fax 0039 0444 574324

Table of contents

Other DAV TECH Control Unit manuals

DAV TECH

DAV TECH DA 400 Product manual

DAV TECH

DAV TECH DAS 50N Product manual

DAV TECH

DAV TECH DA 400 EV Product manual

DAV TECH

DAV TECH DA 400 EVO Product manual

DAV TECH

DAV TECH DA 250 Product manual

DAV TECH

DAV TECH DA 600 Product manual

DAV TECH

DAV TECH DAV 300 MAN Product manual

DAV TECH

DAV TECH DAS 90 Product manual

DAV TECH

DAV TECH DAV 150 Product manual

Popular Control Unit manuals by other brands

MacDon

MacDon FM100 installation instructions

Emerson

Emerson Varec 5010 Series Installation, operation and maintanance instructions

Bogen

Bogen RIO1S manual

Heinner

Heinner HAC-HS09WH++ installation guide

SOMAS

SOMAS SKV Service and operating instruction

Neptune

Neptune AquaController Apex EnergyBar 4 Setup guide