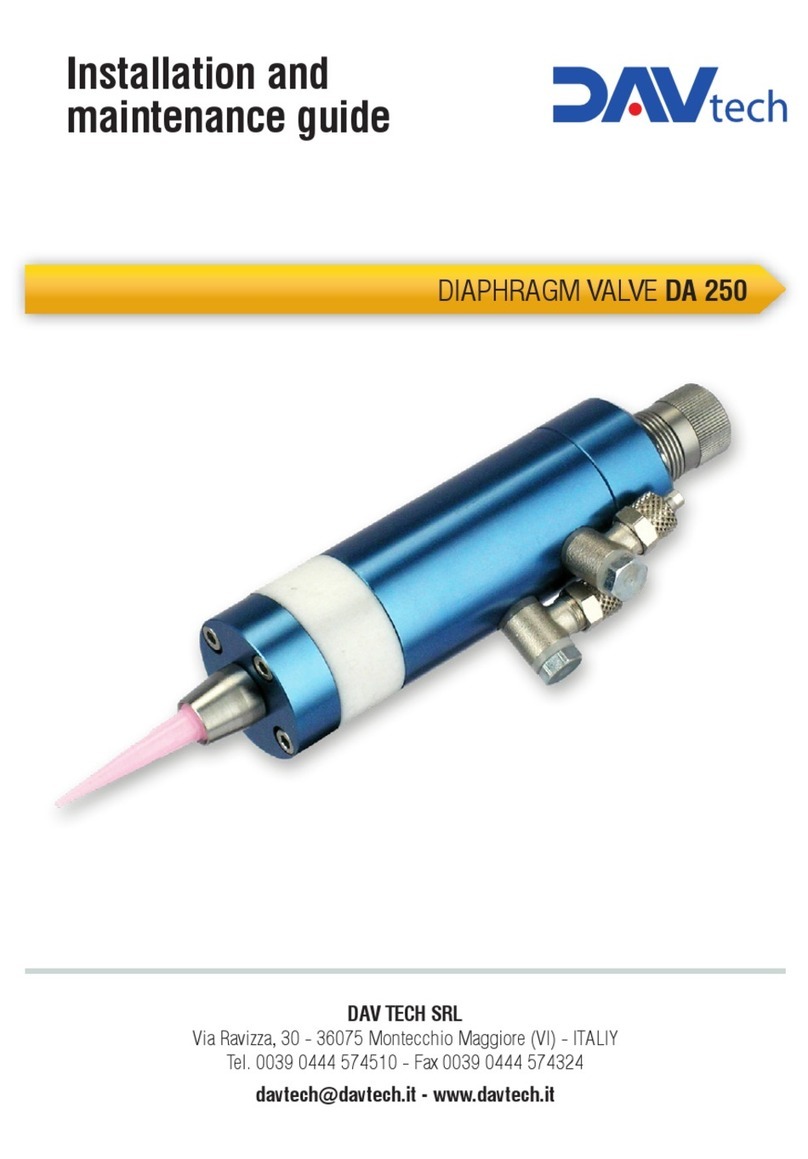

DAV TECH DAS 50N Product manual

360° SPRAY VALVE FOR INTERNAL DAS 50N

DAV TECH SRL

Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY

Tel. 0039 0444 574510 - Fax 0039 0444 574324

Installation and

maintenance guide

Index

1 INTRODUCTION pag. 3

1.1 The manual

1.2 Warranty

1.3 Goods receiving

2 TECHNICAL DESCRIPTION pag. 3

2.1 Valve operation

2.2 Technical specifications

2.3 Connection diagram

3 INSTALLATION pag. 4

3.1 Mounting in the machine

3.2 Drive the valve

3.3 Fluid connection

3.4 Setting of the dispensed shot

3.5 Amount of the shot

4 MAINTENANCE pag. 5

4.1 General rules

4.2 Cleaning and replacing the nozzle

4.3 Valve Disassembly

4.4 Valve Re-assembly

5 TROUBLESHOOTING pag. 6

5.1 Problems and solutions

7 BREAKDOWN AND DIMENSIONS pag. 6

6.1 Overall dimensions

6.2 Spare parts DAS 50 N

6.3 Spare parts list DAS 50 N

Installation and maintenance guide

360° SPRAY VALVE FOR INTERNAL DAS 50N

pag.3

1 INTRODUCTION

1.1 The manual

The user guide is the document that accompanies the valve from the time of its construction and throughout the period of

use, it is therefore an integral part of the valve. It requires reading the manual before taking any action involving the valve. The

manual must be readily available for use by staff and maintenance of the valve. The user and the attendant use are required

to know the contents of this manual.

Reproduction of any part of this manual, in any form, without the express written permission of DAV Tech. The text and

illustrations in this manual are not binding, the DAV tech reserves the right, at any time and without notice, the right to make

any changes to improve the product or for reasons of character manufacturing or commercial.

1.2 Warranty

The warranty is valid for a period of 12 months from the date of commissioning and no later than 15 months from the

date delivery. The interventions carried out during the warranty period does not extend in any way the validity period of the

guarantee. The seller is not liable for defects caused by normal wear of parts which by their nature are subject to wear.

1.3 Goods receiving

The original configuration of the valve must never be changed.

Upon receipt of the goods, check that:

• The packaging is intact

• The exact correspondence of the material ordered.

2 TECHNICAL DESCRIPTION

2.1 Valve Operation

DAS 50N spray valve have been designed and manufactured to be used in a variety of applications.

Their design and versatility make them suitable for any application requiring the use of spraying valves.

DAS 50N valves is low and medium viscosity fluid dispensers.

The valves are pneumatically controlled by means of external solenoid valves.

2.2 Technical Specification

Model DAS 50N

Drive Single acting

Weight 440 g

Max fluid pressure Max 10 bar

Actuating air pressure 5 - 7 bar

Atomizing air pressure 0,1 - 2 bar

Input type air Tube 6x4mm

Inlet type fluid Tube 6x4mm

Extension length 15, 20, 30, 50, 100, 200 mm

Speed Up to 200 cycles / min

Adjusting the passage Micrometric

Used materials Stainless steel, nickel-plated brass

Fluids to be dispensed Oils, lubricants, greases up to NLGI 2, primers

We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this datasheet. The illustrations are not binding.

TANKS FOR FLUID FEEDING

The PT series DAV Tech tanks are ideal to feed in the best way the valves

DAS 50 and DAS 50N. They are available in 3 sizes 2, 5 and 10 liters and in

different variations. Made of mirror polished stainless steel and aluminum,

all tanks can be equipped on request with an electrical minimum level sensor.

DRIVE THE VALVES DAS 50 AND DAS 50N

The valves DAS 50 and DAS 50N have to be drived with a 3/2 solenoid valve, timed by the customer. The atomizing

air, necessary for the spraying,have to be drived with another 3/2 solenoid valve with a precision pressure regulator

mounted on the line. This allows to keep separate the timing of dosing and spraying, and allow to have the greatest

possible results.

EXTENSIONS FOR VALVES DAS 50 AND DAS 50N

The valves DAS 50 and DAS 50N may be provided with extensions of different lengths. 15mm, 30mm and 50mm are

standard sizes, and upon request can be constructed with higher lengths or different positions of the spraying holes.

20 mm

30 mm

50 mm

100 mm

200 mm

DAS 50 _ _

EXTENSIONS

Special versions available on request.

Length

Connection diagram

Valve configurations

AIR PRESSURE

REGULATOR

BLUE TUBE

BLACK TUBE

FLUID

PLC

PLC

E.V.

3/2

E.V.

3/2

E.V.

3/2

PRESSURIZED

TANK

2.3 Connection

diagram

3 INSTALLATION

3.1 Mounting in the machine

The DAS 50 / DAS 50N valve must be mounted using the fixing plate

on the valve.

A good valve fixing on the machine must be guaranteed, stable

without vibration and with good accessibility for adjustment, cleaning

and maintenance.

3.2 Drive the valve

The DAS 50 / DAS 50N spray valve must be operated by two separate solenoid valves; a 3/2 way for the pilot (black

tube) and a 3/2 way for the nebulization (blue tube).

The operating pressure must be between 4 ... 6 bar.

Additional air pressure between 0.1 ... 3 bar.

3.3 Fluid connections

The valve must be connected to a fluid supply unit (pressure drum or diaphragm pump).

The material pipe is the transparent 6x4 diameter.

Fastening hole

Installation and maintenance guide

pag.5

3.4 Setting of the dispensed shot

Pin stroke adjustment determines the amount of fluid delivered.

> Version with micrometric adjustment:

To adjust the travel, act on the adjustment knob at the top of the valve.

Rotate clockwise to decrease the stroke and consequently the amount of adhesive.

Turning clockwise, reaching the end of the stroke the valve will be fully closed, so it will not flow fluid.

Rotate counterclockwise to increase the stroke and then the amount of fluid.

3.5 Amount of the shot

Adjusting the amount of material (fluid) is determined by:

> Fluid pressure

> Needle stroke adjustment

> Valve opening time

Acting on these factors, you can adjust the amount of material you want.

Do not tighten the needle setting too firmly to avoid damaging the needle and nozzle.

Adjustment knob

360° SPRAY VALVE FOR INTERNAL DAS 50N

6.1 Overall dimensions DAS 50 / DAS 50N

The size of the enclosure depends on the type of

extender used and its length.

Download 3D models from our web-site.

Dimensions refer to the 15mm extension.

5 TROUBLESHOOTING

5.1 Problems and solutions

The search for defects in the operation should be performed only by personnel qualified respecting the safety rules

in force.

6 SPARE PARTS AND DIMENSIONS

Installation and maintenance guide

PROBLEM POSSIBLE CAUSE SOLUTION

Nothing or little fluid Valve does not receive the command Check valve (solenoid valve) control. Perform

a manual test.

The pressure of the fluid is too low

or absent. Check the fluid supply pressure and, if

necessary, increase it.

The nozzle is clogged

Unscrew and clean the nozzle.

The filter is dirty (if present) Wash or replace the filter.

A tube is bent Check the status of the fluid supply pipes

Insufficient drive pressure Check drive pressure (5-7 bar)

Fluid residues present in the system Clean the system with water

Fluid out of the compass O-ring or shaped gasket on the damaged

valve body Replace O-ring or shaped gasket

Fluid flow between valve

body and fixing plate O-ring on the damaged dam reservoir Replace the O-ring of the hub

The nozzle dries even if

the valve is not piloted Presence of dirt in the nozzle Clean or replace the nozzle.

The valve opens late Insufficient drive pressure Check drive pressure 5-7 bar

O-ring on the damaged spike Replace the O-ring on the pin

Splashed irregularly Insufficient spraying pressure Check spraying pressure

(0,1…2,5 bar)

Dirt in the air cap Clean the air cap

black

air drive

transparent

material

blue

nebulization

pag.7

360° SPRAY VALVE FOR INTERNAL DAS 50N

5.2 Esploso ricambi DAS 50 N

POS CODE DESCRIPTION

10003.36000009 MICROMETRIC REGULATION COMPLETE

20003.000200 PRESSURE SPRING

30003.36000006 FIXING PLATE

40003.010407 BLUE HOSE (ATOMIZING AIR)

50003.050407 CLEAR HOSE (FLUID)

60003.140407 BLACK HOSE (COMMAND AIR)

70003.36000011 HOSE HOLDER

80003.000901N O-RING

9NEEDLE COMPLETE

0003.84150206 9.1 NEEDLE COMPLETE 20 mm

0003.84150306 9.2 NEEDLE COMPLETE 30 mm

0003.84150506 9.3 NEEDLE COMPLETE 50 mm

0003.84151006 9.4 NEEDLE COMPLETE 100 mm

0003.84152006 9.5 NEEDLE COMPLETE 200 mm

10 0003.0004010 NEEDLE NUT

11 0003.36000028 NEEDLE COLLAR

12 0003.36000005 PISTON

13 0003.000015E O-RING

14 0003.000007E O-RING

15 NEEDLE BASIC

0003.84050206 15.1 NEEDLE BASIC 20 mm

0003.84050306 15.2 NEEDLE BASIC 30 mm

0003.84050506 15.3 NEEDLE BASIC 50 mm

0003.84051006 15.4 NEEDLE BASIC 100 mm

0003.84052006 15.5 NEEDLE BASIC 200 mm

16 0003.36000003 BUSH

17 0003.000010E O-RING

18 0003.30570T VARISEAL

19 0003.36000001 BODY VALVE

20 0003.36000029 PLASTIC COLLAR

21 FLUID OUTLET EXTENDER

0003.85811020 21.1 FLUID OUTLET EXTENDER 20 mm

21.2 FLUID OUTLET EXTENDER 30 mm

21.3 FLUID OUTLET EXTENDER 50 mm

21.4 FLUID OUTLET EXTENDER 100 mm

21.5 FLUID OUTLET EXTENDER 200 mm

22 0003.85791003 AIR CAP

23 0003.85792001 COLLAR

24 0003.060X10E O-RING

25 AIR EXTENDER

25.1 AIR EXTENDER 20 mm

25.2 AIR EXTENDER 30 mm

25.3 AIR EXTENDER 50 mm

25.4 AIR EXTENDER 100 mm

25.5 AIR EXTENDER 200 mm

26 0003.85801000 EXTENDER NOZZLE

GASKETKIT-DAS50N-EV

GASKET KIT COMPLETE

5.3 Lista ricambi DAS 50 N

32 LISTINO RICAMBI 2023

codice codicepos. pos.q.tà q.tàdescrizione descrizione€ €

VALVOLA ELETTROPNEUMATICA SPRAY MZF360 lisno ricambi 2023

1

2

3

4

912

16

17

23

24

25

26

18

19

20

21

22

13

14

14

15

11

10

5

6

7

8

1 C36000009 1 Regolazione micrometrica

completa 57,00

2 CCS000200 1 Molla 6,00

3 C36000006 1 Piastra ssaggio 30,00

4 TBP010407 1 Tubo blu (aria di nebulizzazione) 2,00

5 TBP050407 1 Tubo trasparente (uido) 2,00

6 TBP140407 1 Tubo nero (aria pilotaggio) 2,00

7 C36000011 3 Porta tubo 7,00

8 RNG000901N 3 O-ring� 2,00

9

H84150206

H84150306

H84150506

H84151006

H84152006

1

1

1

1

1

Spillo completo 20 mm

Spillo completo 30 mm

Spillo completo 50 mm

Spillo completo 100 mm

Spillo completo 200 mm

95,00

95,00

95,00

100,00

105,00

10 NT0004010 1 Dado spillo 5,00

11 C36000028 1 Ghiera spillo 6,00

12 C36000005 1 Pistone 8,00

13 RNG000015E 1 O-ring� 2,00

14 RNG000007E 2 O-ring� 2,00

15

H84050206

H84050306

H84050506

H84051006

H84052006

1

1

1

1

1

Spillo nudo 20 mm

Spillo nudo 30 mm

Spillo nudo 50 mm

Spillo nudo 100 mm

Spillo nudo 200 mm

75,00

75,00

75,00

80,00

85,00

16 C36000003 1 Bussola 14,00

17 RNG000010E 1 O-ring� 2,00

18 SHS30570T 1 Guarnizione sagomata� 9,00

19 C36000001 1 Corpo valvola 218,00

20 C36000029 1 Protezione in plasca 1,00

21

H85811020

H85811030

H85811050

H85811100

H85811200

1

1

1

1

1

Prolunga prodoo 20 mm

Prolunga prodoo 30 mm

Prolunga prodoo 50 mm

Prolunga prodoo 100 mm

Prolunga prodoo 200 mm

78,00

78,00

78,00

83,00

88,00

22 H85791003 1 Cappuccio aria 48,00

23 H85792001 1 Ghiera 9,00

24 RNG060X10E 1 O-ring� 2,00

25

H85801020

H85801030

H85801050

H85801100

H85801200

1

1

1

1

1

Prolunga aria 20 mm

Prolunga aria 30 mm

Prolunga aria 50 mm

Prolunga aria 100 mm

Prolunga aria 200 mm

33,00

33,00

33,00

38,00

43,00

26 H85801000 1 Terminale prolunga 201,00

KGN000210 1 Kit guarnizioni� 25,00

We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this manual.

The illustrations are not binding.

DAV TECH SRL Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY - Tel. 0039 0444 574510 - Fax 0039 0444 574324

Table of contents

Other DAV TECH Control Unit manuals

DAV TECH

DAV TECH DA 400 EV Product manual

DAV TECH

DAV TECH DA 400 Product manual

DAV TECH

DAV TECH DAS 90 Product manual

DAV TECH

DAV TECH DA 400 EVO Product manual

DAV TECH

DAV TECH DAS 30 Product manual

DAV TECH

DAV TECH DA 600 Product manual

DAV TECH

DAV TECH DAV 300 MAN Product manual

DAV TECH

DAV TECH DA 250 Product manual

DAV TECH

DAV TECH DAV 150 Product manual

Popular Control Unit manuals by other brands

FUEL MASTER

FUEL MASTER AIM 2 installation manual

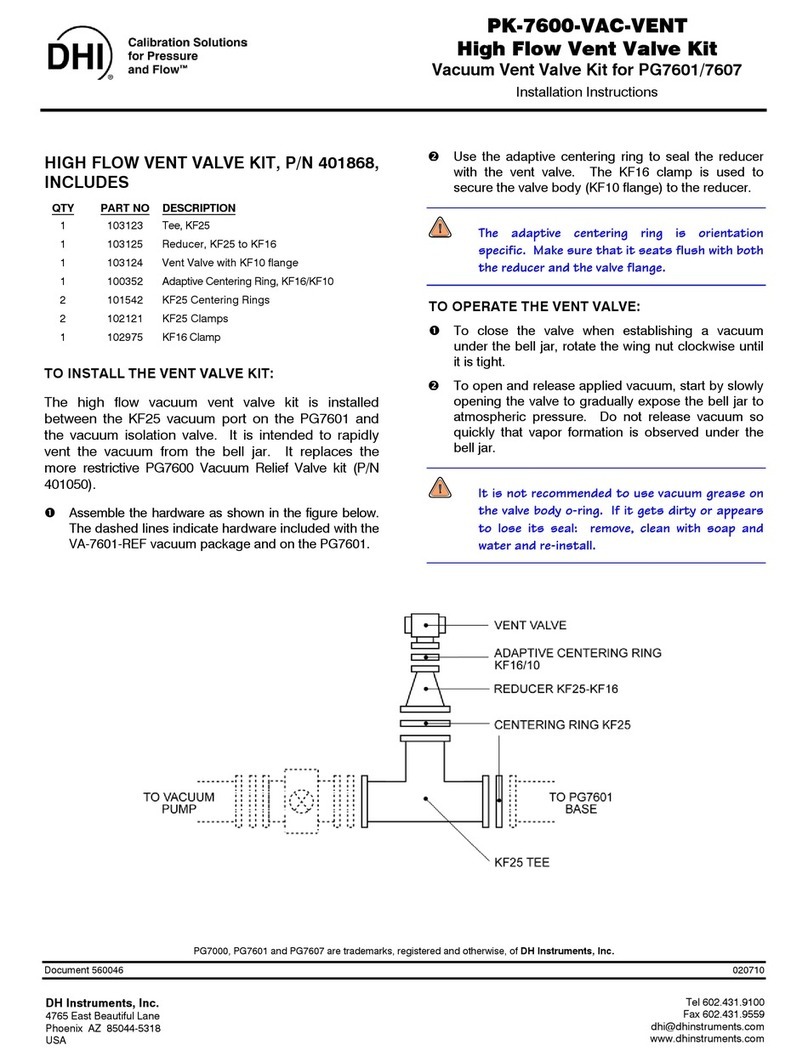

DH Instruments

DH Instruments PK-7600-VAC-VENT installation instructions

Aumuller

Aumuller M-COM Click Assembly and commissioning instructions

CORNING

CORNING EDGE Series manual

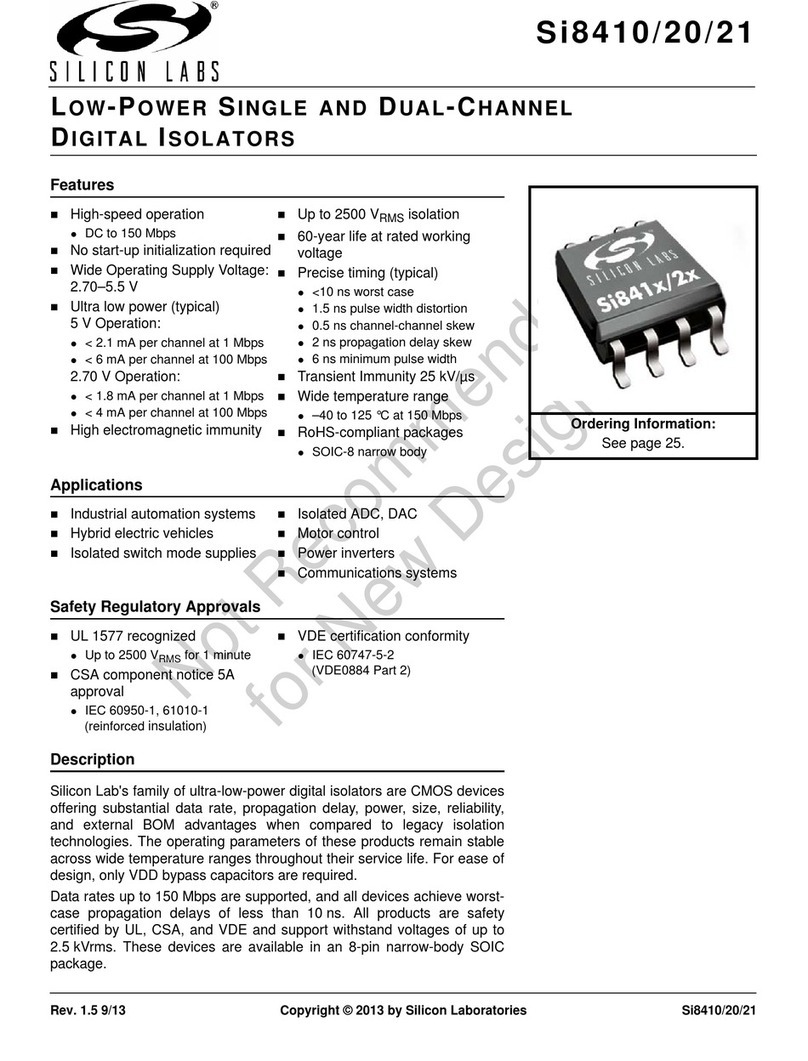

Silicon Laboratories

Silicon Laboratories Si8410 manual

Zator

Zator MZB200 User and maintenance manual