DAV TECH DAV 300 MAN Product manual

DISPENSING VALVE WITH HAND-GRIP

DAV 300 MAN - DAV 400 MAN

Installation and

maintenance guide

DAV TECH SRL

Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY

Tel. 0039 0444 574510 - Fax 0039 0444 574324

Index

1 INTRODUCTION pag. 3

1.1 The manual

1.2 Warranty

1.3 Goods receiving

2 TECHNICAL DESCRIPTION pag. 3

2.1 Valve operation

2.2 Technical specifications

2.3 Connection diagram

3 INSTALLATION pag. 4

3.1 Drive the valve

3.2 Fluid connection

3.3 Setting of the dispensed shot

3.4 Amount of the shot

4 MAINTENANCE pag. 5

4.1 General rules

4.2 Valve Disassembly

4.3 Valve Re-assembly

5 TROUBLESHOOTING pag. 6

5.1 Problems and solutions

6 ESPLOSO E DIMENSIONI pag. 7

6.1 Breakdown

6.2 Components

Installation and maintenance guide

DISPENSING VALVE WITH HAND-GRIP DAV 300 MAN - DAV 400 MAN

pag.3

1 INTRODUCTION

1.1 The manual

The user guide is the document that accompanies the valve from the time of its construction and throughout the period of

use, it is therefore an integral part of the valve. It requires reading the manual before taking any action involving the valve. The

manual must be readily available for use by staff and maintenance of the valve. The user and the attendant use are required

to know the contents of this manual.

Reproduction of any part of this manual, in any form, without the express written permission of DAV Tech. The text and

illustrations in this manual are not binding, the DAV tech reserves the right, at any time and without notice, the right to make

any changes to improve the product or for reasons of character manufacturing or commercial.

1.2 Warranty

The warranty is valid for a period of 12 months from the date of commissioning and no later than 15 months from the

date delivery. The interventions carried out during the warranty period does not extend in any way the validity period of the

guarantee. The seller is not liable for defects caused by normal wear of parts which by their nature are subject to wear.

1.3 Goods receiving

The original configuration of the valve must never be changed.

Upon receipt of the goods, check that:

• The packaging is intact

• The exact correspondence of the material ordered.

2 TECHNICAL DESCRIPTION

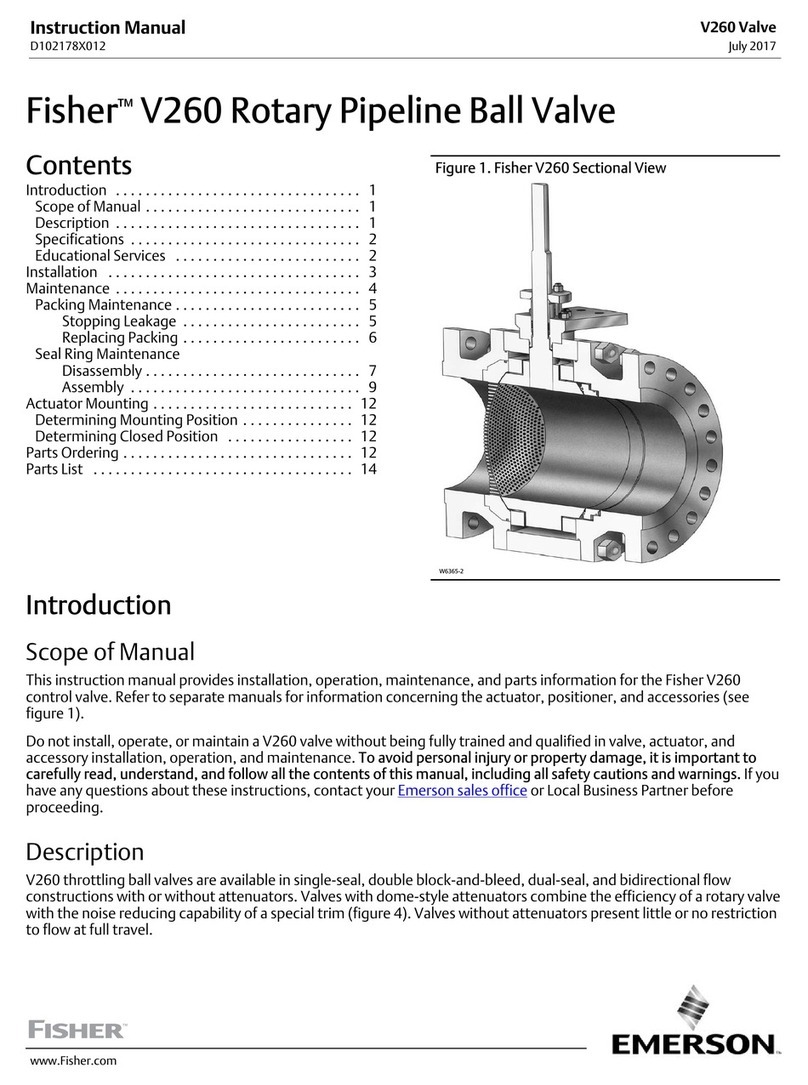

2.1 Valve operation

The dispensing valves with hand grip DAV 300 MAN - DAV 400 MAN are pneumatically drived components, designed for

accurate dispensing of lubricants at low, medium or high viscosity.

The exchange of the compressed air, at a pressure equal to or greater than 6 bar, will result in the emptying of the volumetric

chamber and the relative dispensing of a quantity of fluid constant and adjustable.

2.2 Technical specification

Model DAV 300 MAN - DAV 400 MAN

Operation mode Double Acting

Weight 1.270 g (DAV 300 MAN-O) 1.540 g (DAV 300 MAN-V)

Fluid pressure inlet Min 20 bar - Max 200 bar

Quantity dispensable DAV 300 MAN: 0,1 cm³ - 2,0 cm³ - DAV 400 MAN: 1,0 cm³ - 6,0 cm³

Actuating air pressure 5 - 7 bar

Inlet air M5 for ø 6 mm hose

Inlet fluid thread 1/4 BSP

Outlet fluid M5 threaded with luer lock holder or fitting 1/8 BSP female

Speed Up to 60 cycles / min

Adjusting the amount dosed Micrometric with block screw

Used materials Stainless steel, anodized aluminum

Fluids to be dispensed Greases and lubricants up to NLGI 3-1000000 mPa s

We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this datasheet. The illustrations are not binding.

FEEDING PUMPS FOR GREASE

DAV Tech pumps are ideal to feed grease and lubricants,contained in cans or drums, to the valve DAV 400 MAN.

Pumps are available for cans from 0.5 up to 5 kg and for 5 to 200 kg drums.

NOZZLES FOR VALVE DAV 400 MAN

The valve DAV 400 MAN is equipped with luer lock nozzle holder or alternatively with a threaded nozzle 1/8 BSP

female. We can also design and build special nozzles (multi-point, radial, etc.) to meet the customer needs.

DRIVE THE VALVE DAV 400 MAN

The valve DAV 400 MAN have to be kept constantly fed with air at a pressure between 5 and 7 bar.

The pneumatic switch valve is integrated in the hand-grip. The quantity dispensed is independent of time for which

the operator presses the trigger (in addition to the minimum time required for dosage).

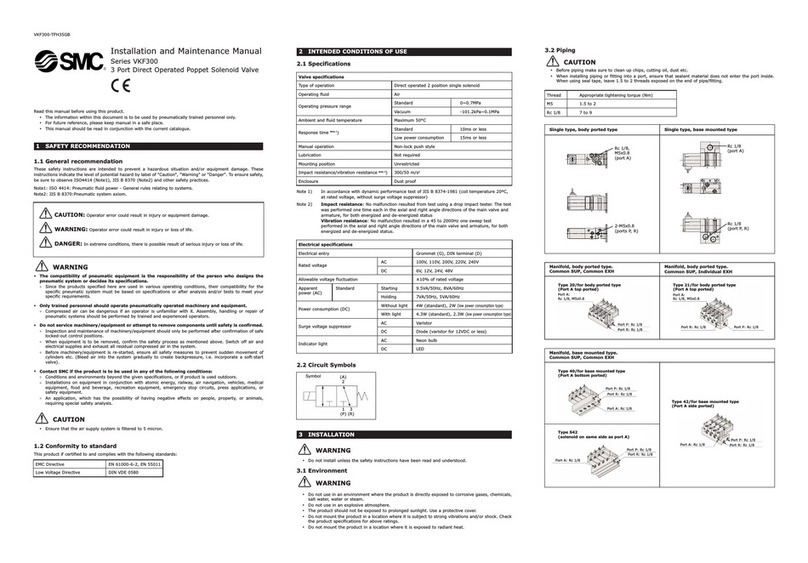

Connection diagram

DISPENSE

SWITCH

(OPTIONAL)

LUBRICANT

(PRESSURE 20-200 bar)

PNEUMATIC

PUMP FLUID INLET POSSIBLE

BOTH UNDER OR BEHIND

THE HAND-GRIP

2.3 Connection diagram

3 INSTALLATION

3.1 Drive the valve

The DAV 300 MAN and DAV 400 MAN valves operate pneumatically with a double effect, by pressing the trigger on

the handle.

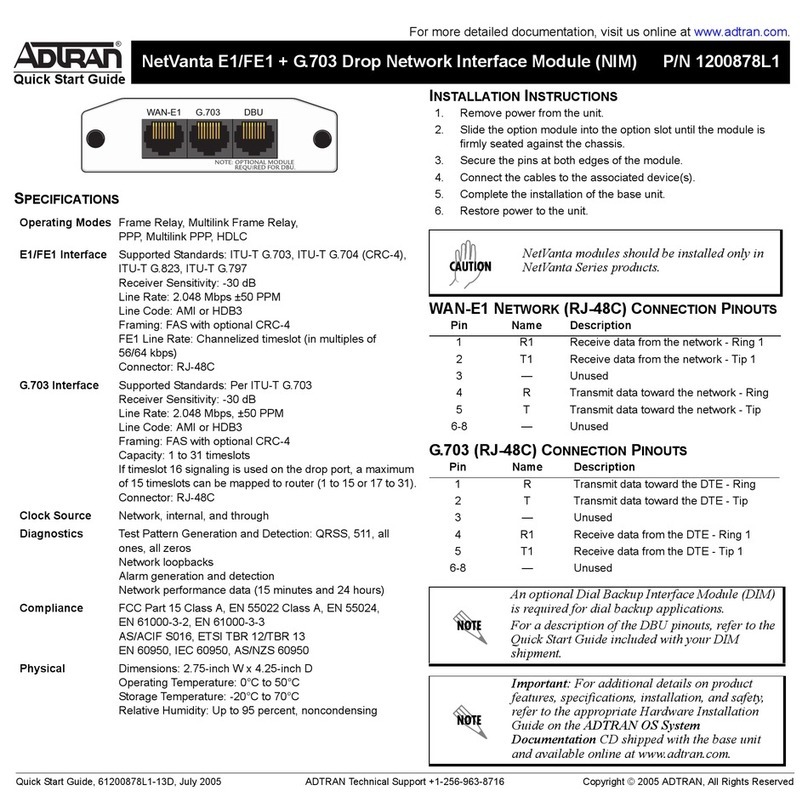

3.2 Connection of the fluid

The valve must be connected to a power supply unit, which guarantees a pressure between 20 and 200 bar.

A flexible hose, resistant to high pressures, must be connected to the fitting placed in the smallest part of the valve.

In the case of the model DAV 300 (400) MAN there is only one product input, in the case of the model DAV 300 (400)

MAN O there are 2 inputs for both the control air and the grease. In one case they are placed at the base of the grip while

in the other case (to be used alternatively), on the back of the handle.

Installation and maintenance guide

Possible material

and air input

Possible material

and air input

pag.5

3.3 Adjusting the amount of material

The amount of product is dispensable functional to fill volume of the room, set by turning the adjustment, mounted

on valve head displacement.

A grain then allows you to lock the adjustment and prevent tampering.

3.4 Quantity dispensable

Being valves volumetric quantity is dispensable only functional to the volume of the chamber set.

In any case it is necessary consider the minimum time required for charging and discharging of the valve, the times

that vary with the pressure of the incoming fluid, its viscosity, and depending on the type of applicator connected

to the nozzle valve.

DISPENSING VALVE WITH HAND-GRIP DAV 300 MAN - DAV 400 MAN

4 MAINTENANCE

4.1 General rules

Le valvole DAV 300 MAN e DAV 400 MAN, thanks to construction methods and materials used are easy to

maintain. Minimal maintenance , simple, accurate and allow a steady long-term operation and regular time of the

valve, maintaining unchanged performance.

4.2 Valve disassembly

Before disassembling the valve:

1) Clean the outside

2) Release the pressure from the system

3) Disconnect the power supply of lubricant to the valve

4) Key 4mm remove the 4 tie rods present in the head and foot valve

5) Remove various aluminum bodies

6) Remove the needle and the volumetric chamber

7) If necessary, unscrew the air piston needle from the spool.

4.3 Valve reassembly

After it has been cleaned thoroughly and have replaced all the damaged parts (especially the seals,scrapers etc.),

reassemble in reverse order of disassembly little lubrication parts and seals with grease fittings.

Be careful not to overdo the tightening of the 4 tie rods, to avoid damage.

5 TROUBLESHOOTING

5.1 Problems and solutions

The search for defects in the operation should be performed only by personnel qualified respecting the safety rules in force.

PROBLEM POSSIBLE CAUSE SOLUTION

The lubricant does not

come out The valve does not receive the command Check the control (solenoid) of valve. Perform

a manual test.

The pressure of the grease is too low or

absent.

Check the pressure of the power supply fluid

and possibly increase in range 20/200 bar

The nozzle is clogged Remove and clean the nozzle.

The filter is dirty (if any) Clean or replace the filter.

A tube is bent Check the fluid supply pipe

Actuating pressure tire Ensure sufficient pressure to drive (5-7 bar)

The lubricant has a viscosity too high

The valves can DAV 100 and DAV 200

dispense lubricant viscosity max. 1,000,000 m

Pa s and NLGI 3

Lubricant leakage retired Molded seals or gaskets Replace the damaged needle or needle shaped

Installation and maintenance guide

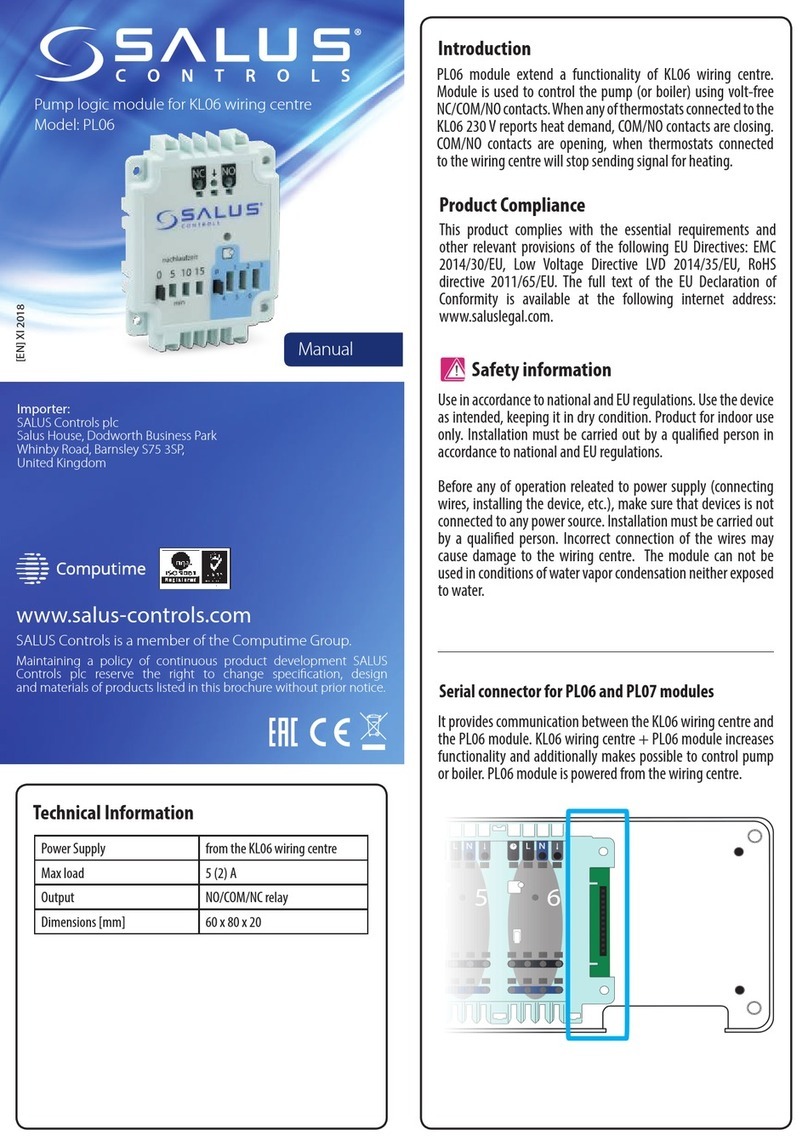

6 BREAKDOWN AND DIMENSIONS

42

43

39

42

47

41

40

10

44

26

31

31

33

34

32

30

34

25

24 38

35 36 37

21

22

23

27

32

28

29

49

11

48

9

15

20

17

19

18

50

14

2

10

1

16

7

4

13

5

49

10

8

6

7

46

45

3

5

6.2 Breakdown DAV- 300/400MANO - HORIZONTAL HANDLE GRIP

pag.7

DISPENSING VALVE WITH HAND-GRIP DAV 300 MAN - DAV 400 MAN

Ref. Description Code

10- RING 10005121

2UPPER LIP SEAL 18365000

3LOWER LIP SEAL 18331100

4MAGNET RING 10001528

50- RING 20001590

60- RING 18223200

7VARISEAL 28223201

8WASHER 10001595

9FLAT HEAD SCREW 18424105

10 0- RING 38232100

11 0- RING 18222500

12 0- RING 18227700

13 VOLUMETRIC CHAMBER DAV-300 10001583

13 bis VOLUMETRIC CHAMBER DAV-400 10001583

14 NEEDLE 10001586

15 PNEUMATIC PISTON 10001591

16 BUSH 10005113

17 FLAT HEAD SCREW 28423900

18 NUT 18400700

19 GOLFARE 18447200

20 FASTENING 10002007

21 0- RING 48223705

22 0- RING 28220900

23 HANDLE SPRING 18135000

24 AIR FITTING 18589300

25 INLET NIPPLEX 12258400

26 0- RING 38221400

27 HANDLE SPRING PIN 18460002

28 HANDLE SCREW COMPLETE 18515504

29 FITTING CAP 28639300

30 SINTERIZED DISC 14222200

31 BALL 38206600

32 FLAT HEAD SCREW 40004734

33 FITTING CAP 18430001

34 SHAPED GASKET 28259300

35 LEVER 14202100

36 HANDLE VALVE PISTON 14222001

37 HANDLE VALVE BODY 14241500

38 HANDLE BODY 10006426

39 SCREW 40005147

40 PIN 10001589

41 GRUB SCREW 18512700

42 NUT 18411000

43 MICROMETRIC REGULATION 10001588

44 STOPPER 10001587

45 FRONTAL PLATE DAV-300/400 10005068

46 FRONTAL BODY 10004922

47 REGULATION BODY 10004918

48 PNEUMATIC BODY 10004919

49 MID BODY DAV-300 10004920

49 bis MID BODY DAV-400 10004920

50 NUT 60002213

HORIZONTAL HANDLE GRIP COMPLETE 0006033

GASKET KIT COMPLETE (HANDLE GRIP GASKET NOT INCLUDED) GASKETKIT-DAV300400

6.3 Components DAV- 300/400MANO

Installation and maintenance guide

6.4 Breakdown DAV- 300/400MANV - VERTICAL HANDLE GRIP

1

1

4

1

1

1

1

1

1

6

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

2

1

1

5

25

6

26

18

53

4

29

51

27

35

56

1

47

44

54

55

19

31

3

57

2

36

37

14

15

12

13

9

8

7

46

51

45

43

41

51

22

52

34

16

32

38

33

42

40

24

23

50

47

39

20

30

21

28

48

10

11

17

49

pag.9

DISPENSING VALVE WITH HAND-GRIP DAV 300 MAN - DAV 400 MAN

Ref. Description Code

1BUSH 10005113

2HANLDE VALVE PISTON 14222001

3HANLDE VALVE BODY 14241500

4FLAT HEAD SCREW 48423900

5FASTENING 10002008

6FIXING PLATE 20002007

7BLACK HOSE 150MM 18589400

8BLACK HOSE 115MM 18589400

9AIR FITTING 28589100

10 AIR FITTING 18589102

11 GRUB SCREW 28461700

12 FLAT HEAD SCREW 18424304

13 SINTERIZED DISC 14222200

14 LEVER 14247300

15 HANDLE FRONTAL BODY 14247200

16 HANDLE BODY 14247100

17 HANDLE HEAD 10002026

18 SCREW 40005147

19 INLET NIPPLEX 10004850

20 SHAPED GASKET 18259500

21 NUT 60002213

22 AIR FITTING 28634201

23 PIN 10001589

24 GRUB SCREW 18512700

25 NUT 18411000

26 MICROMETRIC REGULATION 10001588

27 STOPPER 10001587

28 FRONTAL BODY 10004922

29 REGULATION BODY 10004918

30 PNEUMATIC BODY 10004919

31 SCREW 40001593

32 CONNECTION BODY 10004923

33 MID BODY DAV-300 10004921

33 bis MID BODY DAV-400 10004920

34 FIXING KEY 13234403

35 FLAT HEAD SCREW 18424105

36 O - RING 28220900

37 HANDLE SPRING 18135000

38 GRUB SCREW 18460002

39 O - RING 18221400

40 O - RING 10001590

41 O - RING 10005121

42 UPPER LIP SEAL 18365000

43 LOWER LIP SEAL 18331100

44 MAGNET RING 10001528

45 O - RING DAV-300 18227302

45 bis O - RING DAV-400 10001590

46 O - RING 18223200

47 VARISEAL 28223201

48 O - RING 18233000

49 O - RING 18229301

50 WASHER 10005384

51 O - RING 38232100

52 O - RING 18222500

53 O - RING 18227700

54 VOLUMETRIC CHAMBER DAV-300 10001584

54 BIS VOLUMETRIC CHAMBER DAV-400 10001583

55 NEEDLE 10001586

56 PNEUMATIC PISTON 10001591

57 O - RING 48223705

VERTICAL HANDLE GRIP COMPLETE 0004576

GASKET KIT COMPLETE (ESCLUSE GUARNIZIONI IMPUGNATURA) GASKETKIT-DAV300400

6.5 Components DAV- 300/400MANV

We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this manual.

The illustrations are not binding.

DAV TECH SRL Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY - Tel. 0039 0444 574510 - Fax 0039 0444 574324

Declaration of Incorporation

according to the EU Machinery Directive 2006/42/EG, Annex II, 1.B for partly completed machinery

Manufacturer:

DAV Tech Srl

Via Ravizza, 30 - 36075 Montecchio Maggiore

VICENZA - ITALY

Person residing within the Community authorised to compile the relevant technical documentation:

Andrea Grazioli

DAV Tech Srl

Via Ravizza, 30 - 36075 Montecchio Maggiore

VICENZA - ITALY

Description and identification of the partly completed machinery:

Type: Volumetric valves

Model: DAV 100, DAV 200, DAV 300, DAV 400, DAV 100 MAN, DAV 200 MAN, DAV 300 MAN, DAV 400 MAN.

It is also declared that the relevant technical documentation has been compiled in accordance with part B of

Annex VII.

It is expressly declared that the partly completed machinery the machinery fulfils all relevant provisions of the

following EU Directives:

• 2006/42/CE

• 2006/42/EG

• 95/16/EG

The manufacturer or his authorised representative undertakes to transmit, in response to a reasoned request by the

national authorities, relevant information on the partly completed machinery. This transmission takes place:

This does not affect the intellectual property rights!

Important note! The partly completed machinery may be put into service only if it was determined, where

appropriate, that the machinery into which the partly completed machinery is to be installed meets the provisions

of this Directive.

Andrea Grazioli

This manual suits for next models

3

Table of contents

Other DAV TECH Control Unit manuals

DAV TECH

DAV TECH DA 400 EVO Product manual

DAV TECH

DAV TECH DA 400 Product manual

DAV TECH

DAV TECH DA 400 EV Product manual

DAV TECH

DAV TECH DAS 50N Product manual

DAV TECH

DAV TECH DAS 30 Product manual

DAV TECH

DAV TECH DAV 150 Product manual

DAV TECH

DAV TECH DAS 90 Product manual

DAV TECH

DAV TECH DA 600 Product manual

DAV TECH

DAV TECH DA 250 Product manual

Popular Control Unit manuals by other brands

REMKO

REMKO Smart WP MANAGER operating manual

Bosch

Bosch Rexroth ctrlX CORE manual

hager

hager RTN710X manual

Rockwell Automation

Rockwell Automation Bulletin 193 E1 PLUS Application and Installation

Genebre

Genebre 2103 Installation, operation and maintenance manual

Swegon

Swegon TBLZ-1-66 installation instructions