28

3 TECHNICAL DATA

ADVANCE ADVANCE XL

Motor power supply voltage (V) 24 V

Absorbed power (W) 100 180

Max Thrust (N) 600 1200

Work cycle (cycles/hour) 20 25

Maximum n° of operations in 24 60 75

Operating temperature range (°C) -20÷50 °C

Opening speed (cm/s) 17 16

Weight of product with package (Kg) 4

Sound pressure emitted (dBA) < 70

Protection degree IP X0

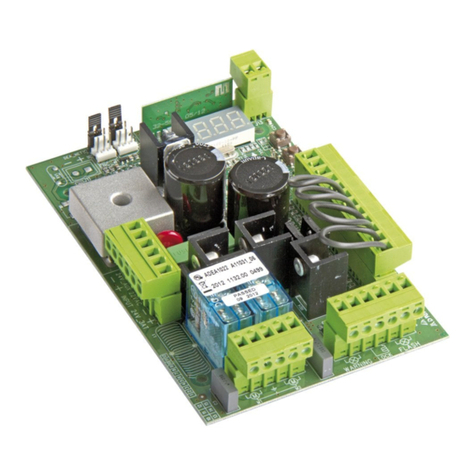

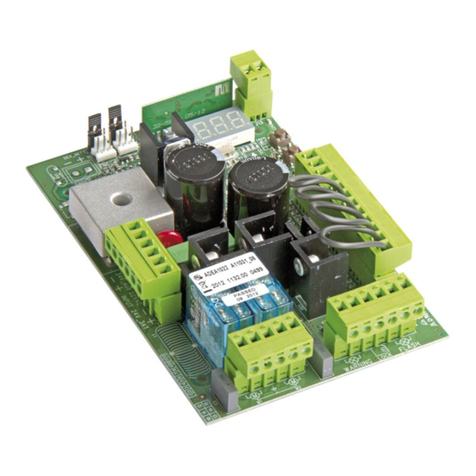

NET724N NET724NXL

Power supply (V) 220 - 240 V ~ ±10% (50/60 Hz)

Rated power transformer (VA) 150 VA (230/25V)

Fuse F1 (A) T2A 250V (retarded)

Auxiliaries power supply output -24 V

(24V_AUX + 24V_ST = max 200mA)

Stabilized power supply output for safety devices 24 V max 200mA

Configurable Output 1 24 V max 5 W

Configurable Output 2 24 V max 5 W

Receiver frequency 433,92 MHz

Transmitters type of coding HCS fix-code - HCS rolling code - Dip-switch - DART

Max remote controllers managed 100

CONTROL BOARD

OPERATOR

4 INSTALLATION AND ASSEMBLY

4.1 For a satisfactory installation of the product is important to:

• The drive unit can only be mounted on garage doors that are in perfect mechanical condition:

The door must be thoroughly inspected (with particular regard to the springs, wheels/wheel supports, ropes, and hinges) in order

to check for any wear and/or damage. Furthermore, check to make sure that all the fastening screws have been tightened in a

secure and stable manner.

• Check the door’s balance and smoothness of movement:

The door must be easy to manoeuvre manually along its entire stroke;

The door must maintain its position without moving when stopped in its open or closed positions, or at any intermediate position.

If any damage is encountered prior to installing the drive unit (wear or difficulties moving the door), stop using the door immediately

and have it repaired by qualified personnel!

• Check to make sure that the encumbrance of the drive unit/ track (Fig. 8a - d) is compatible with the selected installation zone.

• The device requires a 230V power outlet. This must be installed at about 50 cm from the control unit by a qualified electrician.

NOTE: The standard installation of the “ADVANCE” drive unit has been designed with the motor head towards the side of the

door in order to ensure a minimal distance for the connection to the control unit. If the installation conditions do not allow for

the standard attachment to be performed, the automation unit can be turned 180° with the motor head towards the centre of the

garage. In this case, follow the directions below.

Notice: Standard Installation (Fig. 5a)

The standard installation of the “ADVANCE” drive unit has been designed with the motor head towards the side of the door, and the track

towards the centre of the garage.

Notice: Non-Standard Installation (Fig. 5b)

If the installation site does not allow the unit to be mounted in the Standard position, the automation will have to be turned and installed

in the “traditional” method.

In this case, while holding the release lever in the working position (locked), raise the lever, rotate it by 180° (Fig. 5) and return it to its

original position. At this point, the track can be installed with the chain tensioning part in the jamb of the door. Once this has been done,

continue the installation process from point 4.2.