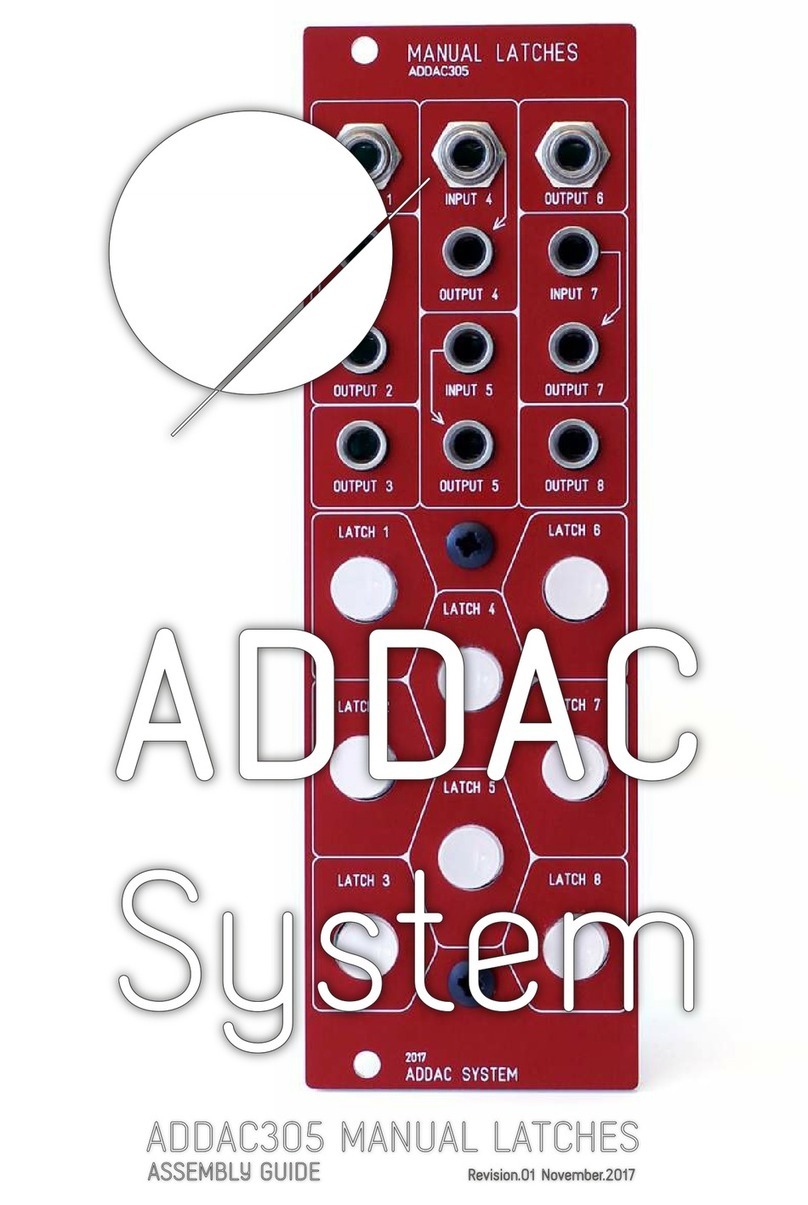

DEEP SEA ELECTRONICS DSE8910 User manual

TYPICAL WIRING DIAGRAM

NOTE: Larger versions of the Typical Wiring Diagrams are available in the products’ operator manuals, refer to DSE

Publication: 057-310 DSE8910 Operator Manual & 057-311 DSE8920 Operator Manual, both available from

www.deepseaelectronics.com.

Deep Sea Electronics Ltd.

Tel: +44 (0)1723 890099

Web: www.deepseaelectronics.com

Deep Sea Electronics Inc.

Tel: +1 (815) 316 8706

Email: USAsupport@deepseaelectronics.com

Web: www.deepseaelectronics.com

D E E P S E A E L E C T R O N I C S

DSE8910 & DSE8920 Installation Instructions

053-248

ISSUE: 2

ACCESSING THE MAIN CONFIGURATION EDITOR

NOTE: The available parameters within the Main Configuration Edtior differ depending if the DSE8910 or DSE8920 software

application is selected. For a list of available configuration parameters, refer to DSE Publication: 057-310 DSE8910 Operator

Manual & 057-311 DSE8920 Operator Manual, both available from www.deepseaelectronics.com.

•Ensure the engine is at rest and the module by pressing the Stop/Reset Mode

button.

•Press the Stop/Reset Mode and Tick buttons together to enter the main

configuration editor.

•If a module security PIN has been set, the PIN request is then shown.

•Press the Tick button, the first ‘#’ changes to ‘0’. Press the Up or Down buttons to adjust it to the correct value.

•Press the Right button when the first digit is correctly entered. The digit previously entered now shows as ‘#’ for security.

•Repeat this process for the other digits of the PIN number. Press the Left button to move back to adjust one of the previous

digits.

•When the Tick button is pressed after editing the final PIN digit, the PIN is checked for validity. If the number is not correct, the

PIN must be re-entered.

•If the PIN has been successfully entered (or the module PIN has not been enabled), the editor is displayed.

ACCESSING THE RUNNING CONFIGURATION EDITOR

•The Running Configuration Editor is accessible without stopping the generator. All protections remain active whilst the ‘Running

Configuration Editor is accessed.

•Press and hold the Tick button to enter the Running Configuration Editor.

EDITING A PARAMETER

NOTE: If the editor is left inactive for the duration of the Page Timer, it is automatically exited to ensure security.

•Enter either editor as described above.

•Press the Up or Down buttons to select the section to view/change. The current selected section highlights in green.

•Press the Left or Right buttons to select the Subsection/Parameter to be edited. The current selected item highlights in

green.

•To edit the parameter, press the Tick button to enter the edit mode. The parameter is no longer highlighted green to indicate

editing.

•Press the Up or Down buttons to change the parameter to the required value.

•Press the Tick button to save the value. The parameter highlights green to indicate that it has been saved.

•To exit the editor and save the changes, press and hold the Tick button.

SELECTING THE DSE8910 OR DSE8920 SOFTWARE APPLICATION

•Ensure the generator is at rest and the module by pressing the Stop/Reset Mode button.

•Enter the Running Configuration Editor as described above.

•Press the Up or Down buttons to navigate to the MODEL TYPE section. The section highlights in green when selected.

•Press the Right button to select the MODEL SELECTION parameter. The parameter highlights in green when selected.

•To edit the parameter, press the Tick button to enter the edit mode. The parameter is no longer highlighted green to indicate

editing.

•Press the Up or Down buttons to change between DSE8910 and DSE8920, by default DSE8920 is selected.

•Press the Tick button to change the software application, a confirmation box appears.

•Press the Left or Right buttons to select YES to confirm software application change. When prompted, remove the power

supply to the module and then reapply the power supply. The module powers up in the newly selected software application.

RUNNING CONFIGURATION EDITOR PARAMETERS

Section

Sub Section

Parameter

Value

Model Type

Model Selection

8910 / 8920

Display

Backlight

Backlight Level

0 %

Language

Lang File Selection

English

Run Load

Priority

Load Priority (DSE8910 Only)

1 to 32

Screen

Selection

Home Selection

DSE8910: Home / Engine / Generator / Bus / I/O / PLC / Status

DSE8920: Home / Engine / Generator / Mains / I/O / PLC / Status

Commissioning Screen

Enable / Disable

Tier 4 Screen

Enable / Disable

Display

Options

Page Timer

0 m 0 s

Graphics

Bars / Meters

Bar Selection

DEF Level / Coolant Temp

Options

Starting Alarms

Enable / Disable

Mains Decoupling Test Mode

Enable / Disable

External Alarm Alert

Enable / Disable

Adjustments

Frequency Adjust

0 %

Voltage Adjust

0 %

Units

Pressure

kPa / Bar / PSI

Temperature

°C / °F

Volume

Litres / Imp Gal / US Gal

Logging

Safe Removal

Edit Up to Remove

Engine

Governor Gain

0.0 %

Frequency Adjust Offset

0.0 %

DPF Auto Inhibit

Enable / Disable

DPF Manual Regen

Enable / Disable

Power

Levels

Control Mode

Power Control Mode

Const Power / Frequency Power / Voltage Power

kVAr Control Mode

Const Reactive / Voltage-Reactive Power / Power-Power Factor

Mains (DSE8920 only)

Mains Stability Timer

0 s

Out of Sync

Enable / Disable

Sequence Alarm Reset

Enable / Disable

REQUIREMENTS FOR UL CERTIFICATION

WARNING!: More than one live circuit exists, see diagram overleaf for further information.

ATTENTION!: Il existe plusieurs circuits sous tension. Voir le schéma au verso pour plus d'informations.

Specification

Description

Screw Terminal Tightening Torque

•4.5 lb-in (0.5 Nm)

Conductors

•Terminals suitable for connection of conductor size 13 AWG to 20 AWG (0.5 mm² to 2.5

mm²).

•Conductor protection must be provided in accordance with NFPA 70, Article 240

•Low voltage circuits (35 V or less) must be supplied from the engine starting battery or an

isolated secondary circuit.

•The communication, sensor, and/or battery derived circuit conductors shall be separated

and secured to maintain at least ¼ ” (6 mm) separation from the generator and mains

connected circuit conductors unless all conductors are rated 600 V or greater.

Current Inputs

•Must be connected through UL Listed or Recognized isolating current transformers with the

secondary rating of 5 A max.

Communication Circuits

•Must be connected to communication circuits of UL Listed equipment

DC Output Pilot Duty

•0.5 A

Mounting

•Suitable for flat surface mounting in Type 1 Enclosure Type rating with surrounding air

temperature -22 ºF to +122 ºF (-30 ºC to +50 ºC)

•Suitable for pollution degree 3 environments when voltage sensing inputs do not exceed

300 V. When used to monitor voltages over 300 V device to be installed in an unventilated

or filtered ventilation enclosure to maintain a pollution degree 2 environment.

Operating Temperature

•-22 ºF to +122 ºF (-30 ºC to +50 ºC)

DIMENSIONS AND MOUNTING

Parameter

Specification

Dimensions

310 mm X 162 mm X 51.3 mm (12.2 ” X 6.38 ” X 2.02 ”)

Panel Cutout

282 mm X 136 mm (11.10” X 5.35”)

Weight

1.19 kg (2.62 lb)

Operating Temperature

-40 ºC to +70 ºC (-40 ºF to +158 ºF)

Storage Temperature

-40 ºC to +80 ºC (-40 ºF to +176 ºF)

Minimum Cable Size

0.5 mm² (AWG 20)

Maximum Cable Size

2.5 mm² (AWG 13)

Screw Terminal Tightening Torque

0.5 Nm (4.5 lb-in)

Wire Strip Length

7 mm (9/32”)

PANEL FASCIA FIXING CLIPS

NOTE: In conditions of excessive vibration, mount the module on suitable anti-vibration mountings.

The module is held into the panel fascia using the supplied fixing clips:

•Withdraw the fixing clip screw (turn anticlockwise) until only the pointed end is protruding from the clip.

•Insert the three ‘prongs’ of the fixing clip into the slots in the side of the module case.

•Pull the fixing clip backwards (towards the back of the module) ensuring all three prongs of the clip are inside their allotted slots.

•Turn the fixing clip screws clockwise until they make contact with the panel fascia.

•Turn the screw a quarter of a turn to secure the module into the panel fascia. Care must be taken not to over tighten the fixing clip

screws.

This manual suits for next models

1

Other DEEP SEA ELECTRONICS Control Unit manuals

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS DSEE800 User manual

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS 6110 User manual

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS DSEGenset DSE3110 User manual

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS DSEControl DSEE050 User manual

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS DSE8910 User manual

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS DSECONTROL DSE7000 Series User manual

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS DSEGenset DSE6110 MKIII User manual