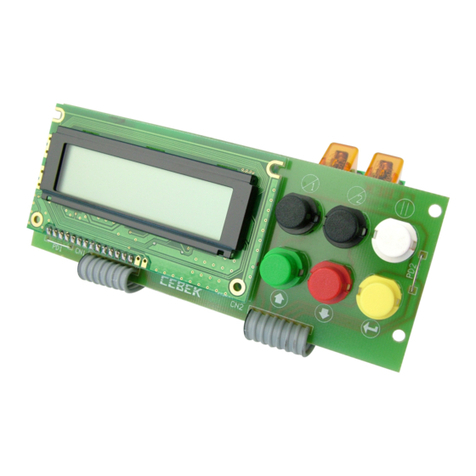

Definox ICS Operation and maintenance manual

Other manuals for ICS

1

Table of contents

Other Definox Control Unit manuals

Definox

Definox DPAX User manual

Definox

Definox DPX EBC User manual

Definox

Definox DCX3 User manual

Definox

Definox Sorio Operation and maintenance manual

Definox

Definox VEOX SP 3 BODY Operation and maintenance manual

Definox

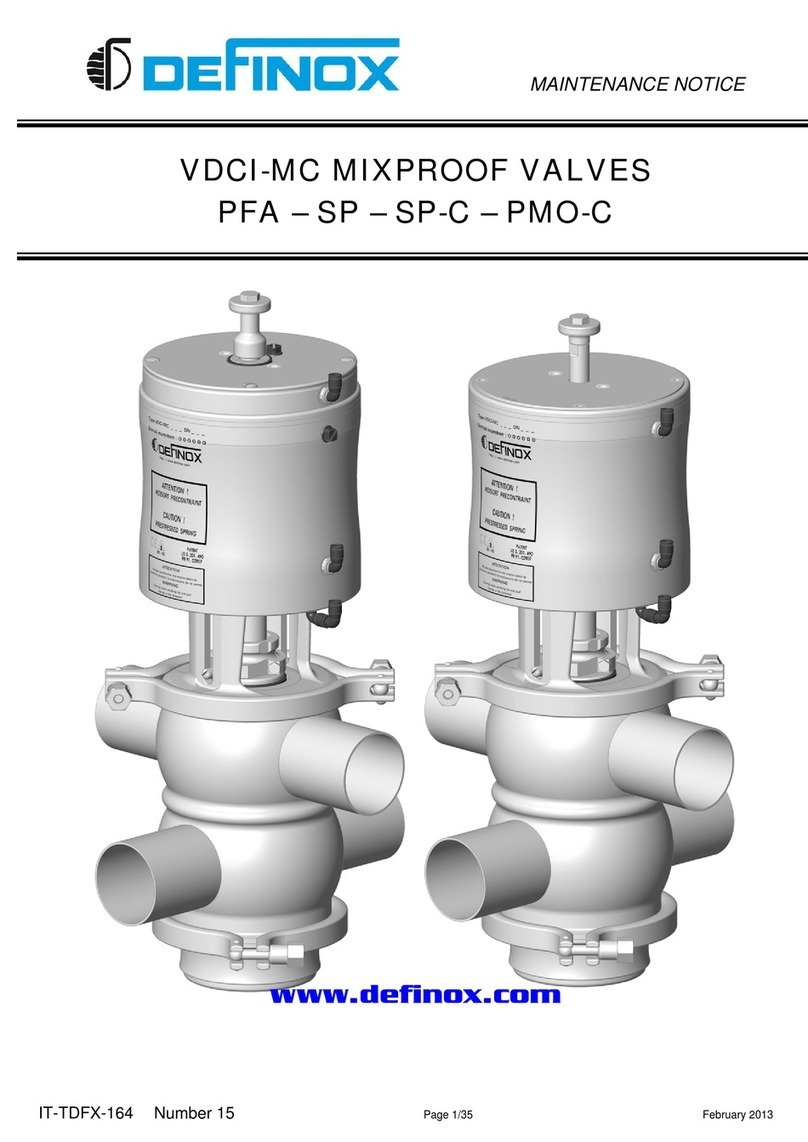

Definox VDCI-MC PFA User manual

Definox

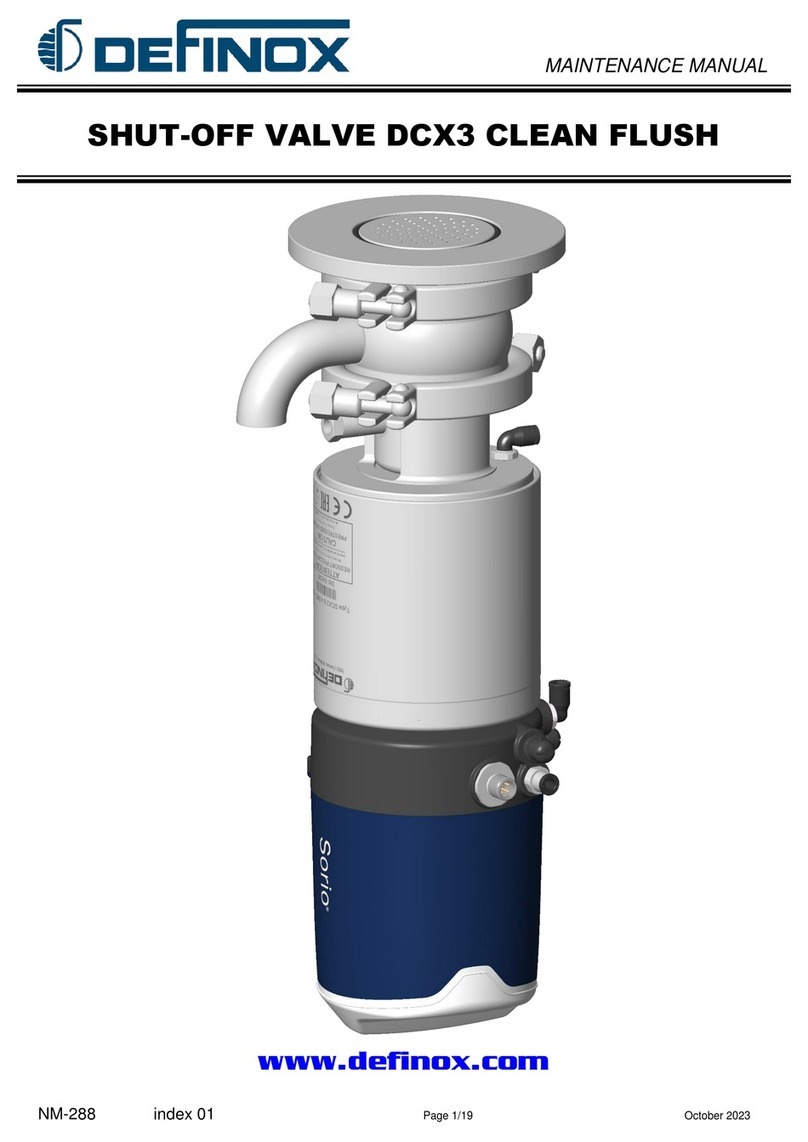

Definox DCX3 Operation and maintenance manual

Definox

Definox DCX4 HP User manual

Definox

Definox DPX1EBC Operation and maintenance manual

Definox

Definox VEOX PMO Operation and maintenance manual

Definox

Definox Sorio Basic 1EV User manual

Definox

Definox VDCI-MC-FC Operation and maintenance manual

Definox

Definox DCX3 Operating and maintenance instructions

Definox

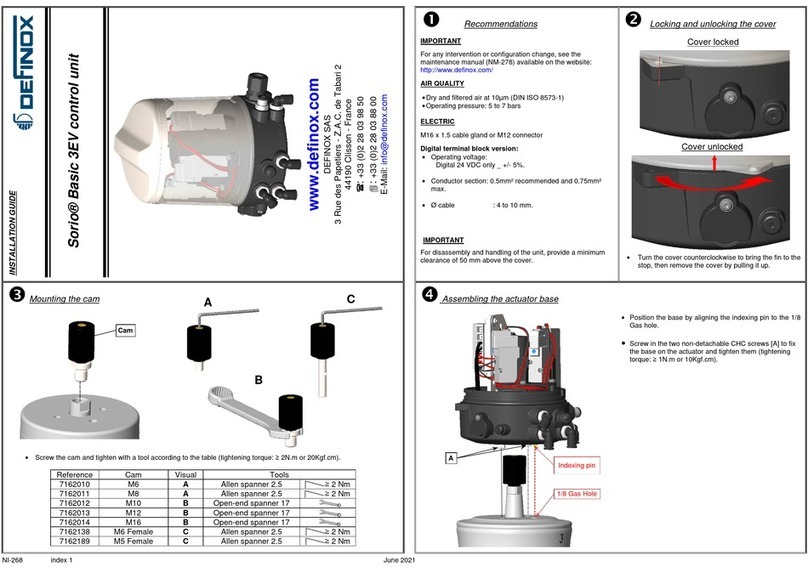

Definox Sorio Basic 3EV User manual

Definox

Definox DCX3 User manual

Definox

Definox DPAX GEN 2 User manual

Definox

Definox DCX3 Operation and maintenance manual

Definox

Definox DCX3 Operation and maintenance manual

Popular Control Unit manuals by other brands

Taco Comfort Solutions

Taco Comfort Solutions Geo-Sentry V100C3G1ZA024Q4A2 instruction sheet

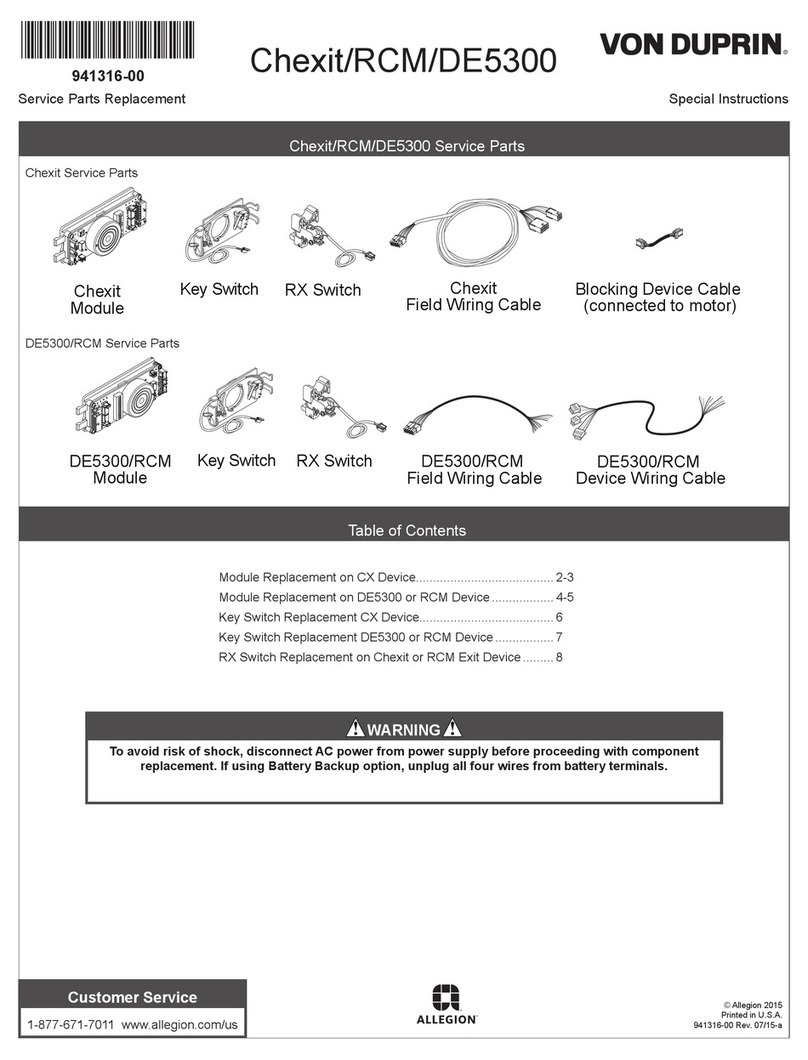

Von Duprin

Von Duprin DE5300 Special instructions

Kohler

Kohler K-304 Installation and care guide

Versum Materials

Versum Materials GASGUARD AP11 BSGS eV Asia Installation, operation & maintenance manual

V2

V2 EASY-BASIC manual

VIA Technologies

VIA Technologies SOM-3000-STK quick start guide