Definox DPAX User manual

Other Definox Control Unit manuals

Definox

Definox VEOX PMO Operation and maintenance manual

Definox

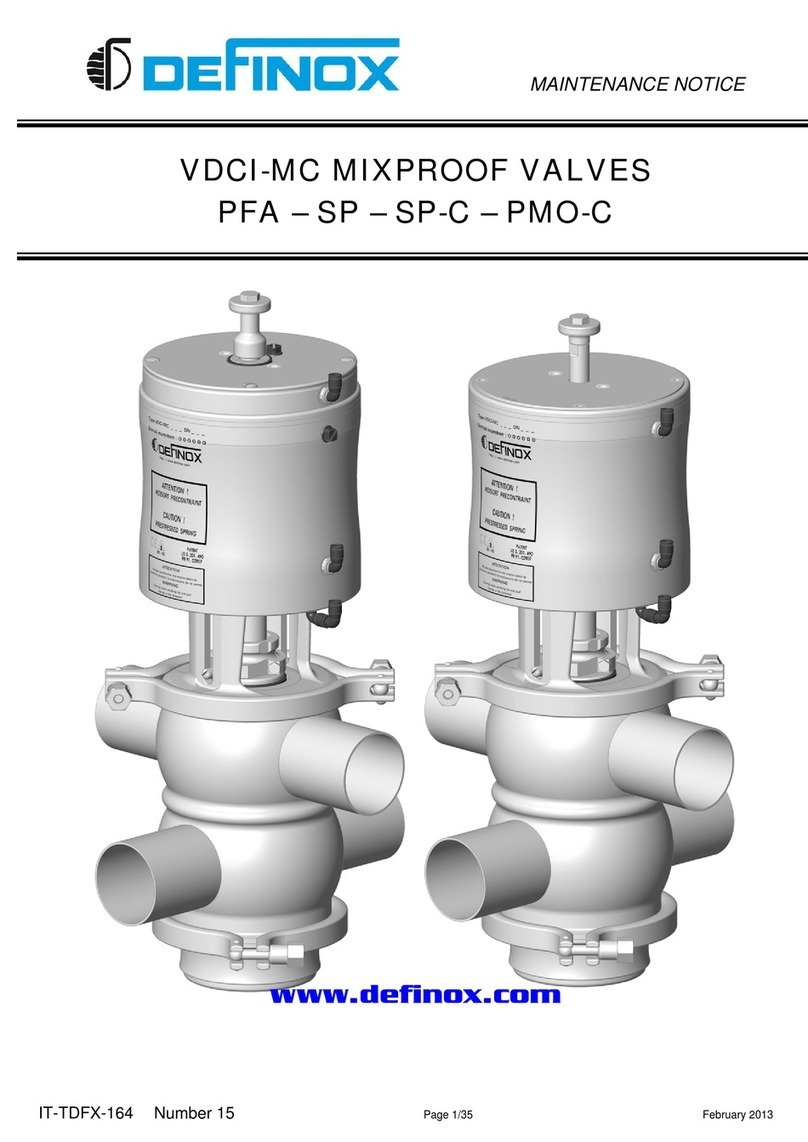

Definox VDCI-MC PFA User manual

Definox

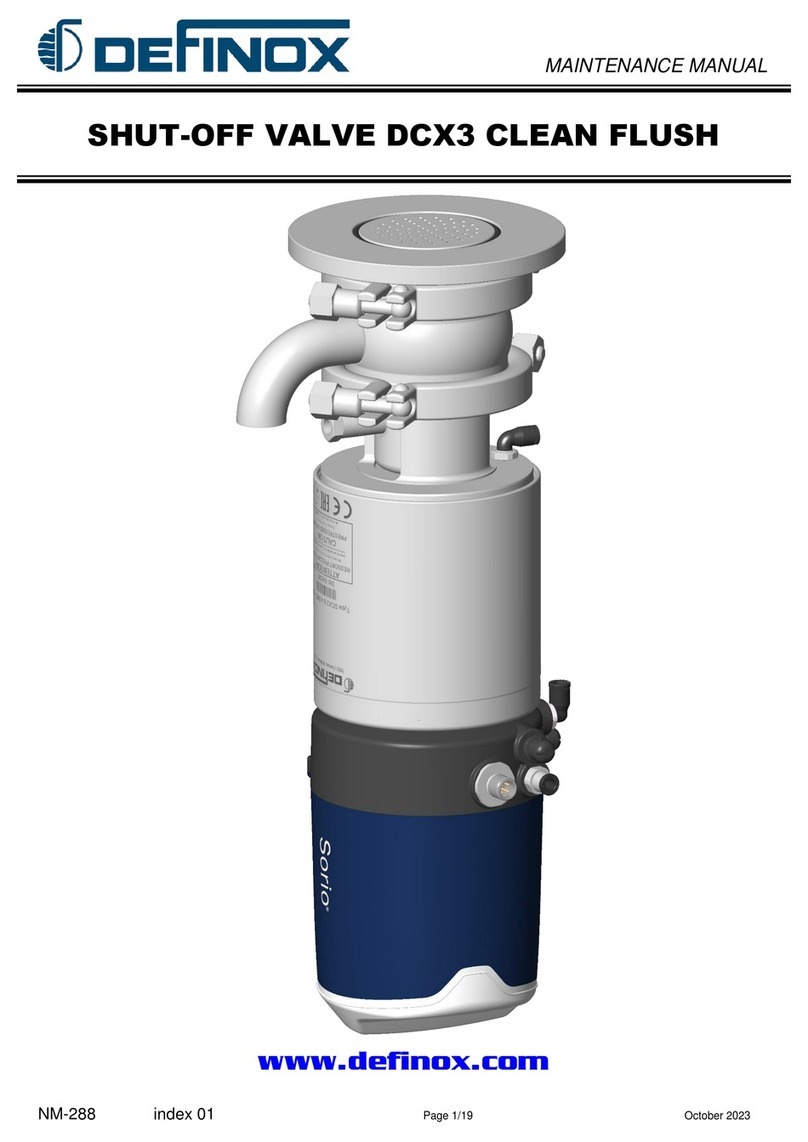

Definox DCX3 Operation and maintenance manual

Definox

Definox DCX3 User manual

Definox

Definox DCX3 User manual

Definox

Definox DPX1EBC Operation and maintenance manual

Definox

Definox DPAX GEN 2 User manual

Definox

Definox VDCI-MC-FC Operation and maintenance manual

Definox

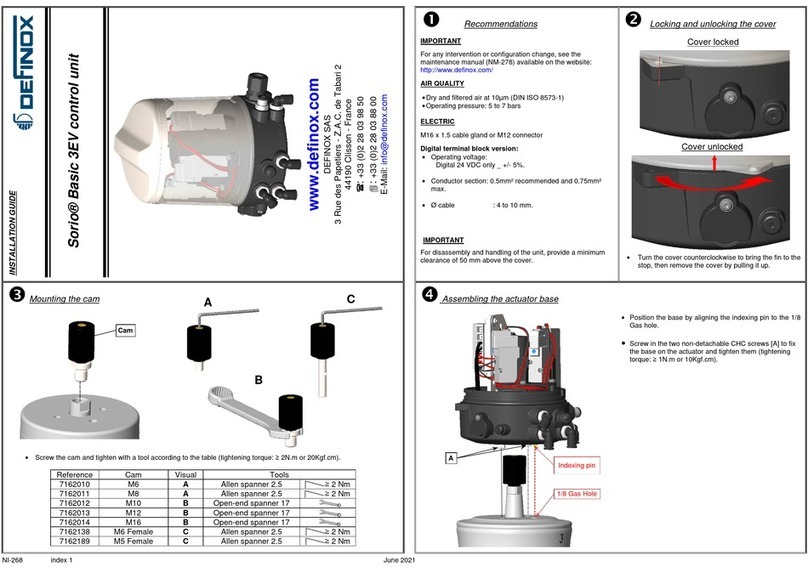

Definox Sorio Basic 3EV User manual

Definox

Definox DPX EBC User manual

Definox

Definox DCX4 HP User manual

Definox

Definox VEOX SP 3 BODY Operation and maintenance manual

Definox

Definox Sorio Basic 1EV User manual

Definox

Definox ICS Operation and maintenance manual

Definox

Definox DCX3 Operation and maintenance manual

Definox

Definox DCX3 Operation and maintenance manual

Definox

Definox Sorio Operation and maintenance manual

Definox

Definox DCX3 Operating and maintenance instructions

Popular Control Unit manuals by other brands

Goodwe

Goodwe Wi-Fi/LAN Kit Quick installation guide

Intermatic

Intermatic K4621 installation manual

TP-Link

TP-Link kasa smart KE100 quick start guide

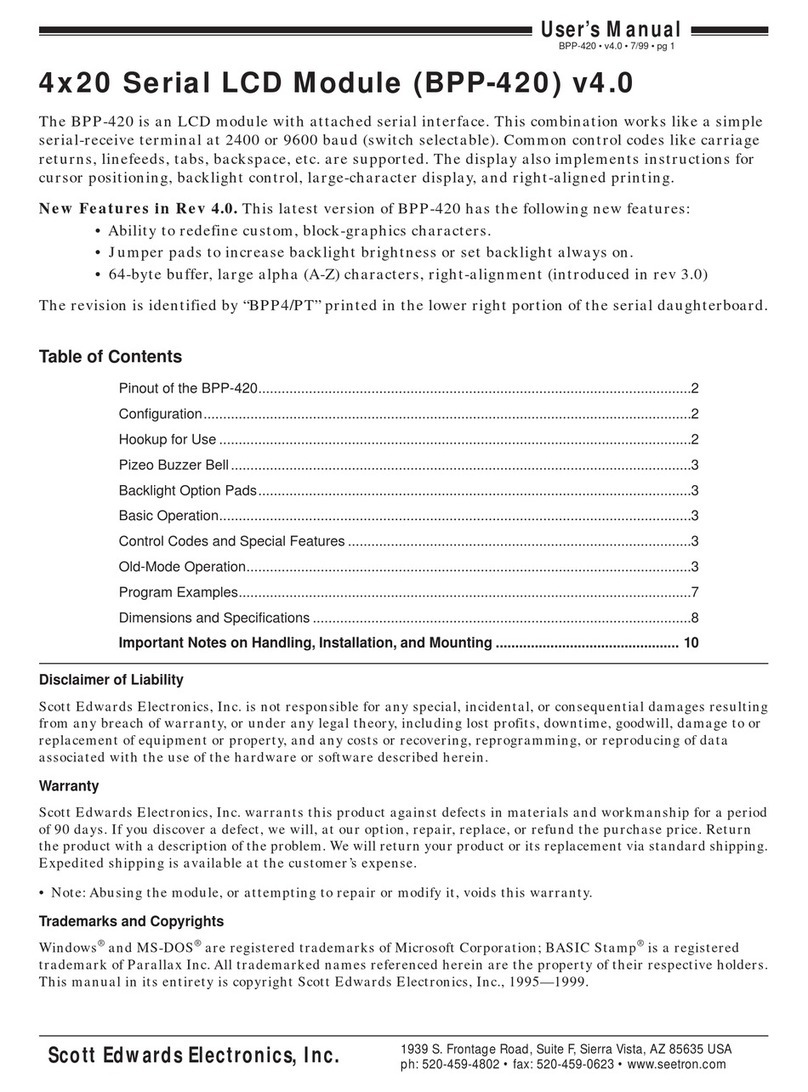

Scott Edwards Electronics

Scott Edwards Electronics BPP-420 user manual

Honeywell

Honeywell 804973 Installation instruction

O&O

O&O LOG-BC Installation and operation manual

emmeti

emmeti Gerpex INSTRUCTIONS AND SUGGESTIONS FOR CORRECT UTILIZATION

Bticino

Bticino LN4574CWI quick start guide

Texas Instruments

Texas Instruments AM437x user guide

Dyna-Flo

Dyna-Flo 350 Operation, Parts, and Instruction Manual

Quectel

Quectel AG35 SMTP AT Command manual

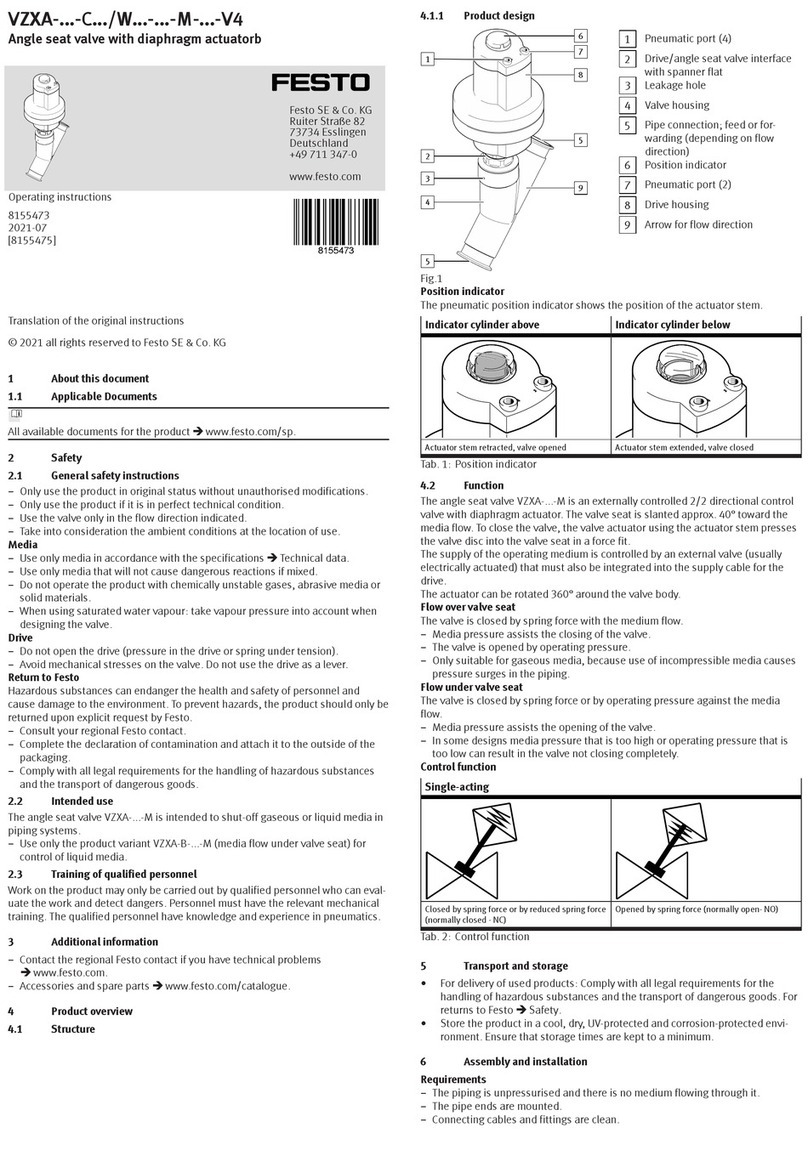

Festo

Festo VZXA-C/W-M-V4 Series operating instructions

TESTO

TESTO 0560 5600 quick start guide

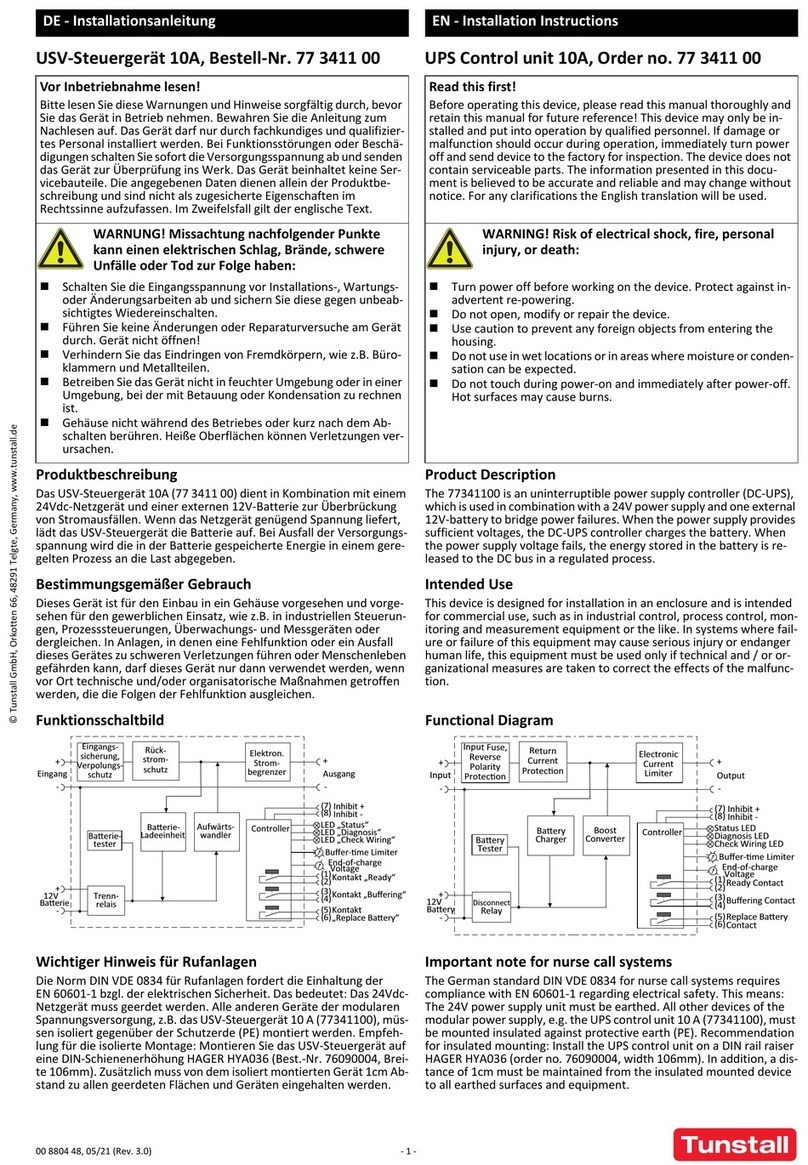

Tunstall

Tunstall 77 3411 00 installation instructions

White Rodgers

White Rodgers 50T35-743 installation instructions

SMC Networks

SMC Networks VOA325 Series Operation manual

Albalá Ingenieros, S.A.

Albalá Ingenieros, S.A. HLI3000C01 manual

Woodward

Woodward 8280-464 product manual