Delta Controls DSC-1616 User manual

INSTALLATION GUIDE

DSC-1616 Installation Guide

Document Edition 3.

8SGDWHG1RYHPEHU

Document Edition 3.4

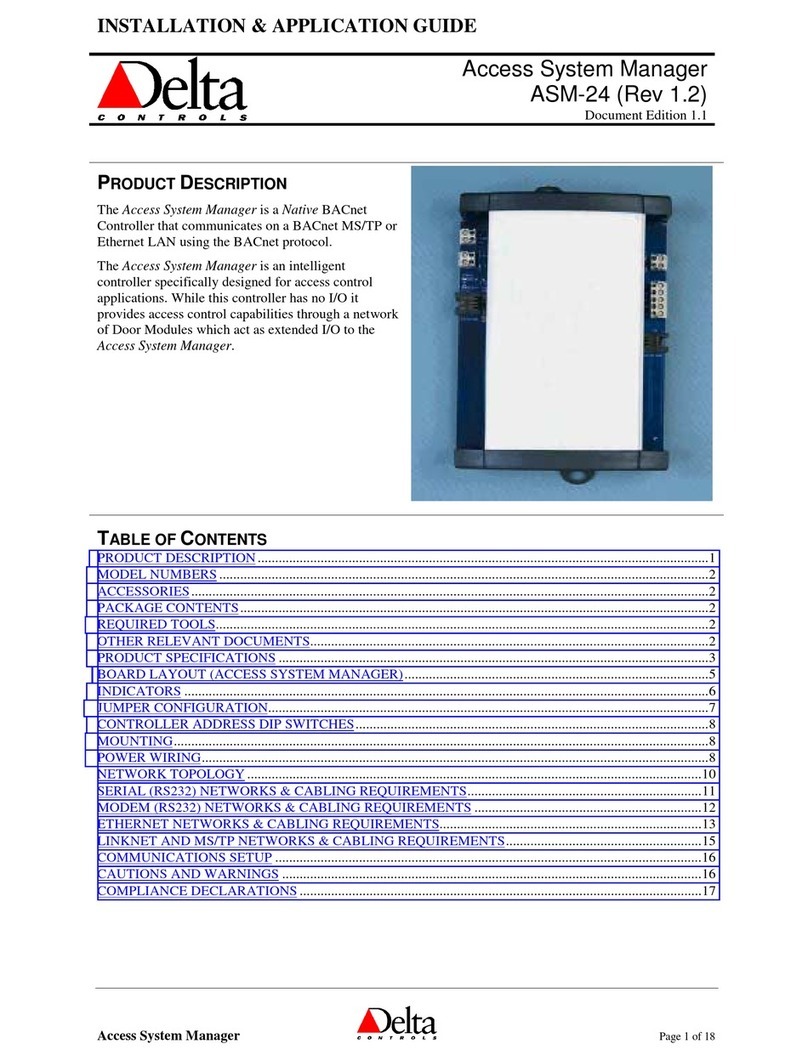

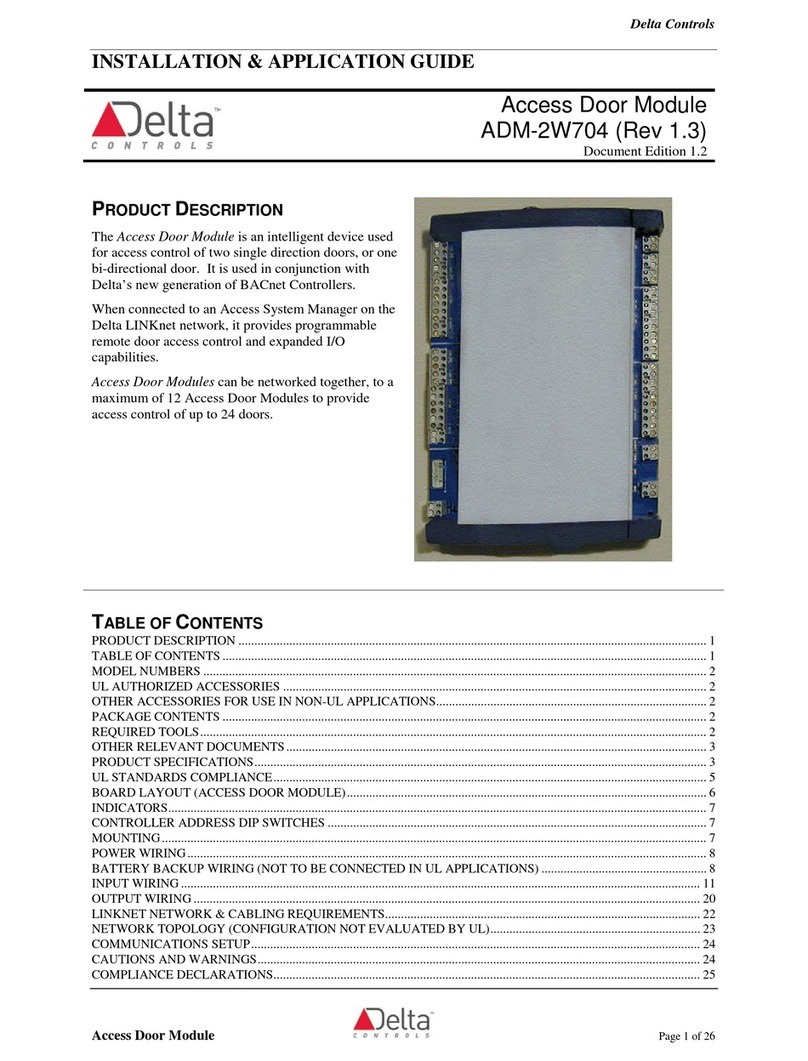

Product Description

The DSC-1616 is a fully programmable, Native BACnet

Building Controller that communicates on Twisted Pair

Ethernet 10-BaseT using BACnet IP and BACnet over

Ethernet, or on an RS-485 LAN using the BACnet MS/TP

protocol.

The controller includes an easy to mount enclosure and is

designed for a wide range of applications requiring no more

than 16 inputs and 16 outputs, including but not limited to Roof

Top Units, Air Handlers, Boilers or Chillers, etc. A second RS-

485 port may be configured as an MS/TP SubLAN or a

LINKnet network that supports up to 12 Delta BACstats or

other Delta LINKnet controllers.

The 16 universal inputs are jumper configurable and the 16

analog outputs have an option of coming with monitored Hand-

Off-Auto switches.

Important Information

ORCAview OWS and controller firmware must all be of the same version number to

be compatible. When upgrading any of these products from older versions (i.e. 3.22 or 3.30),

you must upgrade all the remaining products. Exception: UL 864 model, DSC-1616E-UL864

can be used with V3.33

Package Contents

Product: DSC-1616

DSC-1616 Installation Guide

Related Documents

Delta Controls Wiring Guidelines

ORCAview Operator Guide

ORCAview Technical Reference Manual

Release Notes for related Firmware

and V3.40 firmware.

Delta Controls

Page 2 of 12

UL864 Specific Considerations

Wiring to and from the device shall be through power-limited circuits.

Use only Core Components transformer, Model No. 120-024-100-2TF-CB, by Lectro

Components Inc. to power the device. (Delta Part # 440008)

Use only UL Listed Class 2 Power Supplies for auxiliary field devices.

Use only UL Recognized Ethernet Switch, 571-580, by Siemens for Smoke Control Systems

that utilize Ethernet communications.

Impedance value for which ground faults are detected is zero ohms.

Cautions or Warnings

This controller is an Electro-statically sensitive device. Proper ESD protection (ground strap)

should be used when installing this product so that damage to the product does not occur.

Danger of explosion if the battery is incorrectly replaced. Replace only with the same or equivalent

type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions. Replace the battery with type CR2032.

Equipment damage or loss of data may occur if these procedures are not followed as specified.

Installations requiring CE conformance: All wiring for CE rated products must use an extra low

voltage (SELV) or protective extra low voltage (PELV) transformer. Use safety-isolating

transformers, (Class II transformer) per EN61558. The transformer must be rated for 100% duty

cycle.

Document Edition 3.4

Page 3 of 12

Mounting

The DSC-1616 includes a plastic enclosure that can be quickly mounted with two screws (not provided). This

controller should be mounted in an appropriate location within packaged equipment or another enclosure that

meets code requirements.

Delta Controls

Page 4 of 12

Board Layout

Document Edition 3.4

Page 5 of 12

Controller Configuration

Controller Type

Various products have the capability of being configured as one of several

possible controller types, which represents the network level that it will reside

on in the network architecture (Area, System, Subnet). Other than the one

controller acting as a router, all other controllers on the same network segment

must be configured the same.

Area - Configures the controller as an Area level controller on a network. This

is an option only on the Ethernet model and is the setting when the controller is

connected to an Ethernet network (typically between buildings) and is acting as

a router from one LAN to either a network of System controllers or Subnet

controllers.

System - Configures the controller as a System level controller on a network of

System controllers. This is the setting when the controller is connected to an

Ethernet or BACnet MS/TP network with other System controllers or is a single

head-end controller for a network of Subnet controllers.

Subnet - Configures the controller as a Subnet level controller on a Subnet of

similar controllers. This is the setting when the controller is connected to a

BACnet MS/TP network with other Subnet controllers.

Note: This also determines where the DIP or MAC address is mapped into the

controllers BACnet address and which other portions of its BACnet address are

inherited when DNA is enabled.

AREA

SYSTEM

SUBNET

Derived Network Addressing

The DNA jumper comes ON by default. This allows the controller to

automatically configure a BACnet controller address. This should NOT be

removed unless you are assigning a BACnet controller number through

software. The BACnet controller number should not be confused with the DIP

switch setting, and each controller must still have a unique dip switch address

even when using software to define the controller number.

DNA

Controller Addressing

The Dip Switch is a binary switch. Each individual DIP switch represents a

unique value, which forms the controller address when added together.

To set the address, simply move the switches that add up to the controllers

desired address to the ON position.

Example: If the controller is to be address 5 on the network, set the switch

numbered 4 and the switch numbered 1 (equals 5) to the On position.

Note: Each controller on the same MS/TP segment must have a unique DIP

switch address.

Delta Controls

Page 6 of 12

Wiring General

All wiring must conform to NEC and local codes and regulations. Use earth ground isolating step-down Class 2

transformers. Do not use autotransformers. Determine supply transformer rating by summing total VA of product

and output loads.

Risk of Electric Shock or Fire

More than one disconnect switch may be required to de-energize the

equipment before servicing.

Input Class 2 Power Supplies are interconnected. Use only Class 2

sources suitable for interconnections.

All terminals are acceptable for Class 2 Circuit connections only

Use copper conductors only

Apply minimum 6.0 lb-in torque for tightening field wires into the terminal

blocks

Power

This product is designed to use a 24 VAC, Class 2 power supply. The proper specified cabling must be used.

(18 –16 AWG, 2-conductor wire)

A single transformer may be used to power multiple controllers and/or auxiliary field devices (actuators, etc.)

provided the following conditions are met:

All devices MUST be ½ wave rectified. Mixing power between ½ wave and full wave rectified devices

will damage both the transformer and connected equipment.

The transformer is properly sized, including line losses for the total VA requirements.

Polarity is observed between controllers (with respect to 24~ and Gnd).

Each controller is grounded as shown in the diagram below. This is important to protect equipment and

ensure a common ground reference for RS-485 communications.

The transformer secondary is fused for its maximum rated load (4A max for Class 2 circuits).

Make sure to ground the controller using the ground lug that is available on the

controller.

Document Edition 3.4

Page 7 of 12

Network Communication

The controller communicates on Twisted Pair Ethernet 10-BaseT using BACnet IP and BACnet over Ethernet,

or on an RS-485 LAN using the BACnet MS/TP protocol. Refer to Delta Controls Wiring Guidelines for further

details.

MS/TP (RS-485) Wiring

For detailed information on MS/TP and LINKnet wiring refer to Delta Controls Wiring Guidelines.

The proper specified cabling must be used to ensure reliable communications. (22 AWG twisted

pair, 100-120 ohms impedance, 17 pF/ft or lower capacitance, with a braided or aluminum foil

shield.)

Controllers should always be wired together in a daisy-chain fashion. Attempting to connect them

using a starred or bus configuration will cause problems on the network.

Networks with a total length greater than 4000 ft or with more than 50 controllers require a

repeater (RPT-768).

LINKnet networks that have only 1-2 controllers, and have less then 100 ft of cable length do not

require network terminators.

Delta Controls

Page 8 of 12

Input and Output Wiring

Inputs and outputs on the DSC-1616 controller follow the same general wiring requirements as other Delta

Controls products. Recommended cable types should be used as listed below. Refer to the Delta Controls

Wiring Guidelines for more details.

Recommended Cable Type

Where to Use

2 Conductor, 18 AWG, Unshielded

All outputs and 4-20mA, 10KΩ, and 10V input types

2 Conductor, 22 AWG, Shielded

Inputs configured for 5V

Input Configuration

The input must be configured to accept the signal used by

the input device. Place the jumper for each input in the

correct location on the Input Type Selector Block. The

diagram to the right shows the factory default selection of

10 K.

4-20mA For sensors that use a 4 to 20 mA signal.

10K For 10 KThermistor temperature

sensors, as well as Dry Contact binary

inputs.

5V For sensors that use a 0 - 5 VDC signal.

10V For sensors that use a 0 -10 VDC signal.

Output Configuration

Each HOA switch is HAND, OFF, AUTO from right to left.

The HAND position allows a user to manually force the

output on, the OFF position allows a user to manually force

an output off, and the AUTO position allows the output to

be controlled automatically by the controller.

AUTO

OFF

HAND

Document Edition 3.4

Page 9 of 12

Indicators

LED

Function

Description

Power

Controller Power

Indicator

This yellow LED turns on to indicate that the controller has power

applied.

Scan

CPU Scan Indicator

This red LED flashes at a rate relative to the CPU scan rate.

Network

(Ethernet)

Ethernet

Communication

Status Indicators

The green LNK LED is turned on when a link is established

between two Ethernet devices. (for example, controller, computer,

switch, etc.) The green ACT LED flashes when communications

are active.

Network

(NET1)

MS/TP (RS485)

Communication

Status Indicators

The green LED flashes to indicate when the controller is

transmitting out the port, and the red LED flashes to indicate when

the controller is receiving data through the port. If communication

is good, both LEDs will flash at a high rate.

Network

(NET2)

MS/TP (RS485)

Communication

Status Indicators

The green LED flashes to indicate when the controller is

transmitting out the port, and the red LED flashes to indicate when

the controller is receiving data through the port. If communication

is good, both LEDs will flash at a high rate.

Inputs

(IP1 –IP16)

Input Status

Indicators

A corresponding red LED varies in intensity and is brightly lit when

the associated input is receiving a low voltage input signal (i.e. a

closed contact, 0 VDC, 0mA or a high temperature reading or low

resistance).

Outputs

(OP1 –OP16)

Output Status

Indicators

A tri-color LED is used. Under automatic control, the

corresponding output LED is green and is on or off to match the

status of an associated binary output. The LED will also vary in

intensity relative to the output signal for an analog output. With

HOA switches, the output LED is red in the OFF position and

yellow in the HAND position.

Delta Controls

Page 10 of 12

Product Specifications

Power Requirements

24 VAC, 60Hz, Class 2

Power Consumption

30 VA

Ambient Ratings

32° to 131°F (0° to 55°C), 10 to 90% RH (non condensing)

Communication Ports

Ethernet

10 BaseT @ 10Mbps

BACnet IP, BACnet over Ethernet

NET1

BACnet MS/TP (RS-485)

Communication: 9600, 19200, 38400, 76800 bps (Default)

Maximum of 99 controllers

OR

LINKnet

Communication: 76800 bps

Maximum of 12 LINKnet controllers including up to two DFM

controllers

NET2

BACnet MS/TP (RS-485)

Communication: 9600, 19200, 38400, 76800 bps (Default)

Maximum of 99 controllers

OR

LINKnet

Communication: 76800 bps

Maximum of 12 LINKnet controllers including up to two DFM

controllers

Serial

RS-232

BACnet PTP

Communication: 9600, 19200, 38400 (default)

Service

Port

RJ-11 Jack

Used with Delta Controls service tool devices (for example, CON-768)

Inputs

16 Universal Inputs (10 bit), jumper configurable for the following input types:

0-5 VDC

0-10 VDC

10 KThermistor

Dry Contact (using 10 KThermistor jumper setting

4-20 mA

Outputs

16 Universal Outputs c/w LED status indication (including HOA status)

0-10 VDC @ 20 mA maximum per output

Software configurable as binary or analog

Hand/Off/Auto Switches (c/w position feedback)

Technology

32 bit processor

2 MB (16 megabit) Flash Memory

512 KB SRAM memory

Listings

UL 916 Listed

BTL Listed

UL 864 Listed (DSC-1616E-UL864 model only)

Compliance

CE

FCC

Page 11 of 12

CE - DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer's Name: Delta Controls

Manufacturer's Address: 17850 56th Avenue

Surrey, British Columbia

Canada

V3S 1C7

declares that the product (s):

Product Name: 16 x 16 Controllers

Model Numbers: DSC-1616, DFM-1616

Product Options: All

conforms to the following Product Specifications:

EN 50081-1:1992

Generic Emission Standard Part 1: Residential

EN 55022:1998

Radiated and Conducted Emissions

Class A

EN 61000-3-2:1999

Power Line Harmonics

Class A

EN 61000-3-3:1998

Power Line Fluctuations

Pst < 1, Plt < 0.65

EN 50082-1:1997

Generic Immunity Standard Part 1: Residential

EN 61000-4-2:1995

ESD Immunity

Level B

EN 61000-4-3:1996

RF Electromagnetic Field Immunity

Level A

ENV 50204:1995

RF Electromagnetic Field Immunity (Keyed Carrier)

Level A

EN 61000-4-4:1995

EFT/Burst Immunity

Level B

EN 61000-4-5:1995

Surge Immunity

Level B

EN 61000-4-6:1996

Conducted Immunity

Level A

EN 61000-4-11:1994

Voltage Dips / Interruptions

Level A/B/B/B

Supplementary Information

The product(s) herewith comply with the requirements of the EMC Directive 89/336/EEC. The

product(s) were tested in a typical configuration.

Lee Dickson

Quality Assurance Manager

Delta Controls

Page 12 of 12

FCC Compliance Information

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

Industry Canada Compliance Statement

ICES-003 This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations

Cet appareil numérique de la Classe A Respecte toutes les exigences du Règlement sur le matérial

brouiller du Canada.

This product conforms to the following UL requirements:

UL916: Energy Management Equipment

UL864*: Control Units and Accessories for Fire Alarm Systems, 9th Edition

* - Applicable to DSC-1616E-UL864 model only

Table of contents

Other Delta Controls IP Access Controllers manuals

Popular IP Access Controllers manuals by other brands

Vicon

Vicon VAX-PCR-35L Quick installation guide

Dorset

Dorset Trovan Access Guard installation manual

Easy Clocking

Easy Clocking XENIO 200 Instruction guide

jablotron

jablotron JA-113E quick start guide

DMP Electronics

DMP Electronics 1134 Installation and programming guide

Visionis

Visionis VIS-3103 installation manual