Delta Controls HIR User manual

HIR Model

Installation, Operation and Maintenance Manual

Doc No.: 00-HIR

0

Revision: N6

Date:

16 October 2019

Approved:

LTK

Firmware Rev 3. 0N

Doc 00-HIR03 rev N8

Firmware 3.0N8

7 Jan 2022 LTK

2 of 15

MODEL HIR

HIGH TEMPERATURE INFRARED PYROMETER

1. THEORY OF OPERATION ........................................................................................................................................ 3

1.1 Considerations when using Infrared Pyrometry to measure Claus Thermal Reactor Temperature .... 3

2. INSTALLATION ......................................................................................................................................................... 4

2.1 Mounting the Hot Lens Assembly ......................................................................................................... 4

2.1.1 Steam Supply ................................................................................................................................ 4

2.1.2 Lens Purge .................................................................................................................................... 5

2.2 Thermal Insulation ................................................................................................................................ 5

2.3 Installing the Electronics Housing ......................................................................................................... 5

2.3.1 Remote Sensor Mounting – Option RS ........................................................................................ 6

2.3.2 Flameproof Installation.................................................................................................................. 7

2.4 Connecting the Fiber Optic Cable......................................................................................................... 8

2.5 Optical Alignment .................................................................................................................................. 9

3. OPERATION ............................................................................................................................................................ 10

3.1 Setup Parameters ............................................................................................................................... 10

3.2 Initial Startup ....................................................................................................................................... 11

3.3 Two Color Sensing .............................................................................................................................. 12

3.4 Preventive Maintenance ..................................................................................................................... 12

3.5 Calibration ........................................................................................................................................... 13

4. SPECIFICATIONS ................................................................................................................................................... 15

3 of 15

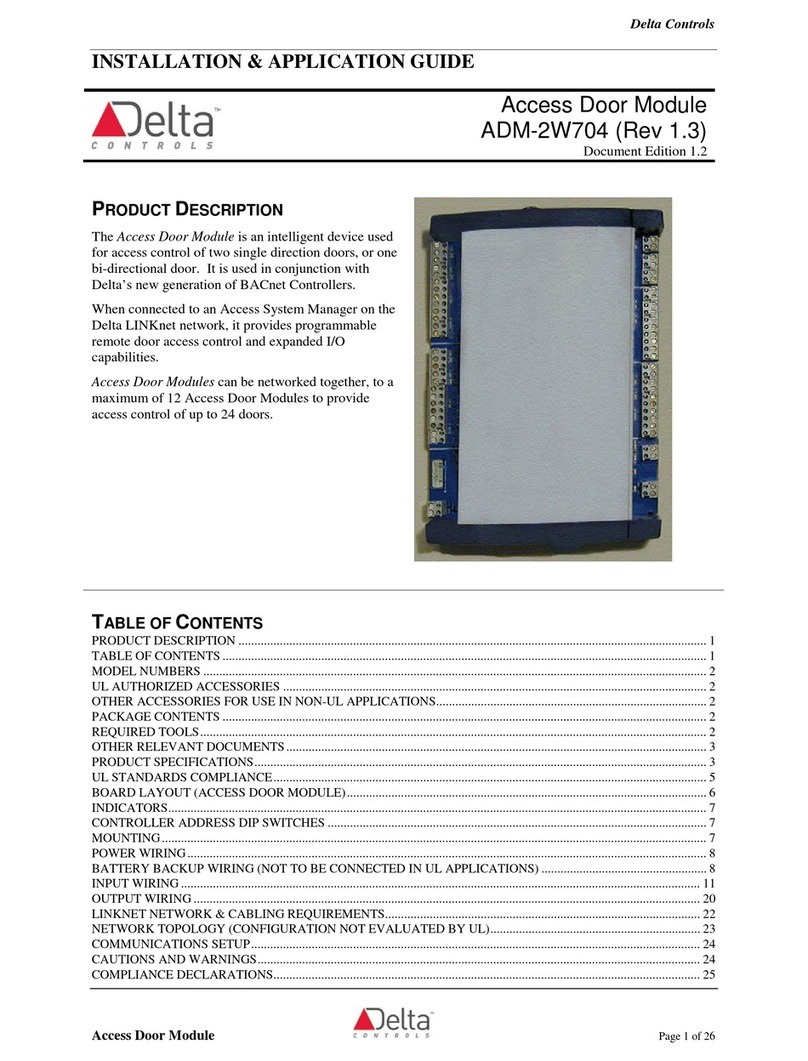

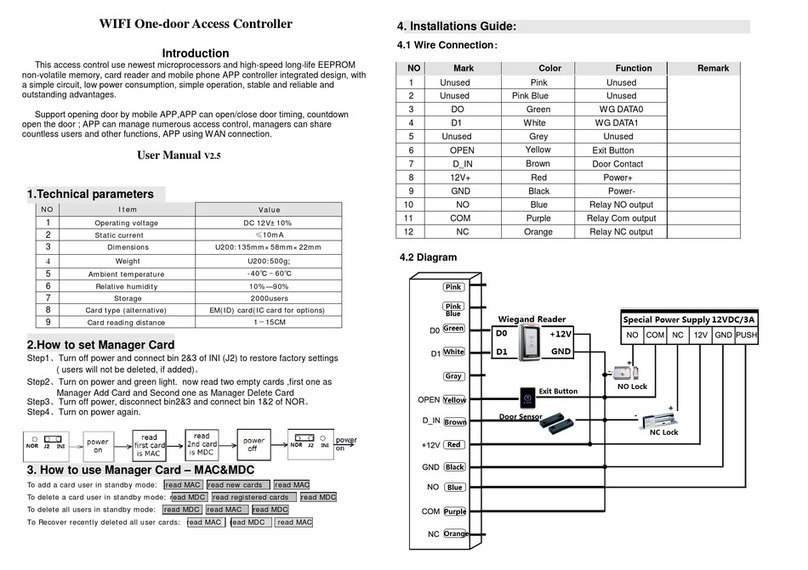

Reaction

gas

Infrared Energy

Lens

Assembly

Claus

Thermal

Reactor

Thermal

Insulation System

Rain

Shield

Isolation

Valve

Purge

Supply Steam

Supply

Steam

Outlet

Thermal

Insulation

System

Delta Controls Model HIR is an infrared temperature pyrometer specifically designed to measure the refractory

temperature of Claus Process thermal reactors.

1. THEORY OF OPERATION

Model HIR uses infrared pyrometry to measure temperature. All materials radiate energy as a function of their absolute

temperatures. Model HIR “looks” into the reactor and senses the amount and spectrum (wavelengths) of the infrared

energy being emitted by the hot face of the refractory. The sensed energy is converted into a signal, which can be used to

accurately display the refractory operating temperature.

1.1 Considerations when using Infrared Pyrometry in Claus Thermal Reactors

To effectively measure temperature, the instrument needs a clear, unobstructed view into the vessel. The infrared energy

must pass through the reacting gases without being absorbed by them. The instrument must “look” through those same

gases without seeing them or sensing their high temperatures. This is accomplished by using optical bandpass filters. The

selected sensing spectrums avoid errors due to absorption, reflection, etc.

A potential problem using infrared pyrometry in a Claus thermal reactor is that sulfur or other solids can accumulate on the

lens or in the nozzle which blocks the infrared radiation, and requires expensive maintenance to clean the lens and optical

path. Model HIR is designed to be nearly maintenance free. When properly installed and operated, it maintains the lens,

sighting window, and nozzle at a sufficiently high temperature to avoid sulfur buildup and reduces frequency of periodic

cleaning.

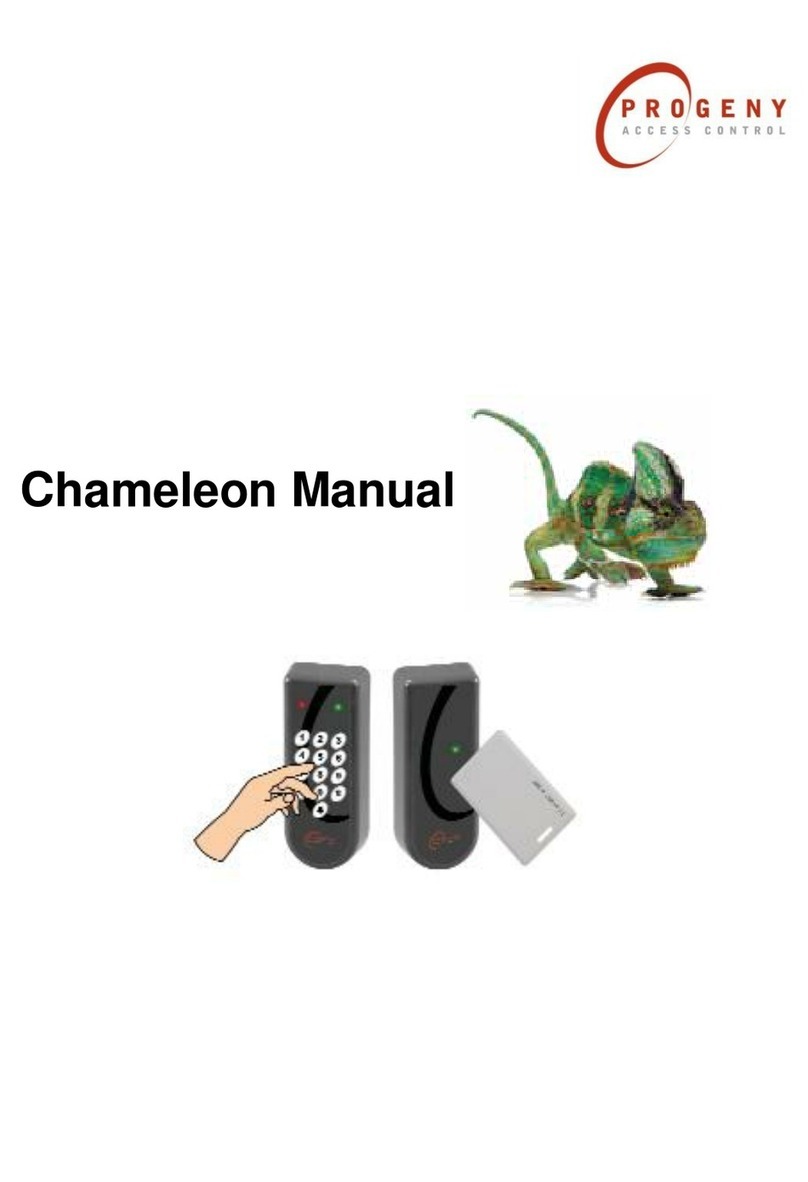

Figure 1

4 of 15

2. INSTALLATION

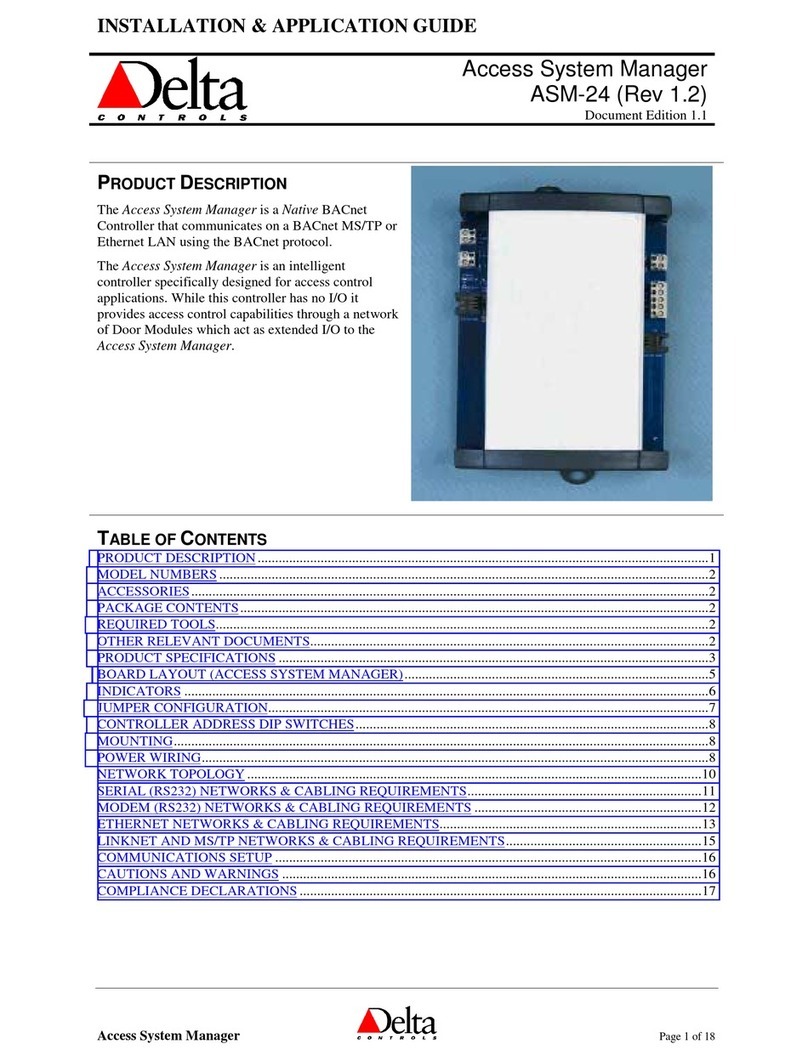

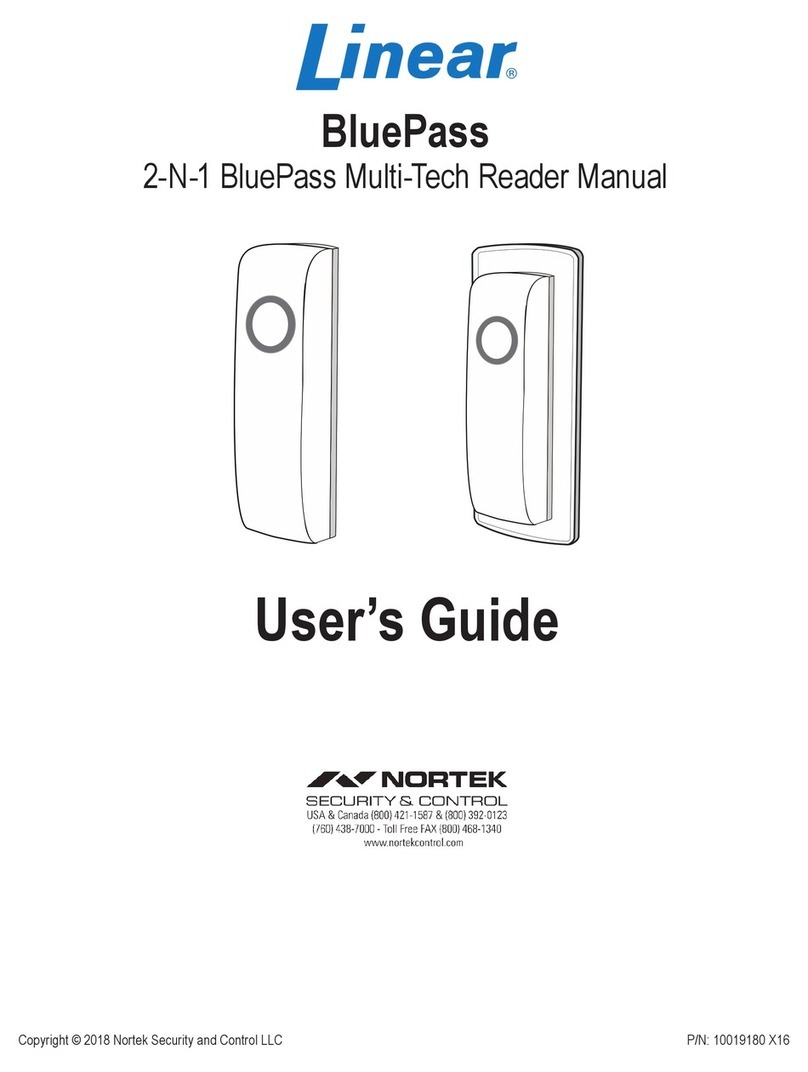

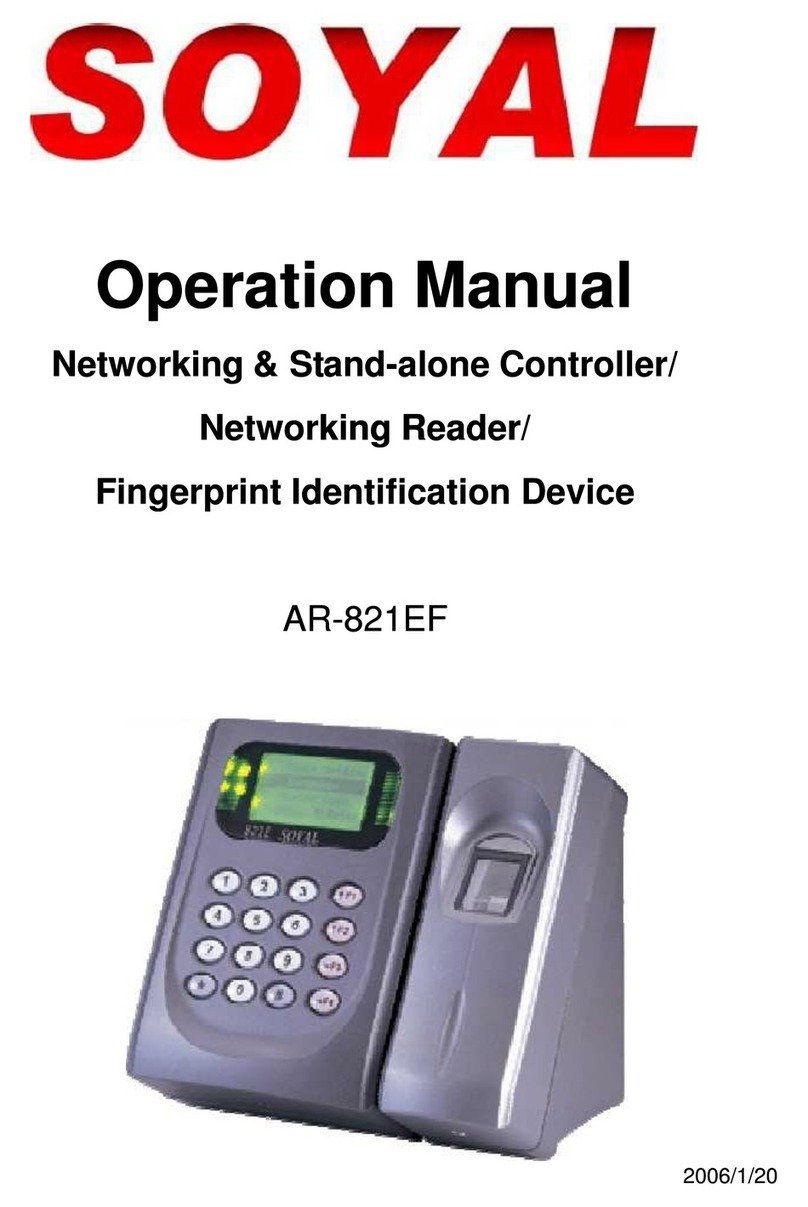

Figure 2 shows a typical installation. The HIR features a unique Steam Jacketed Lens Assembly that is mounted

directly to the isolation valve, which is mounted on the vessel nozzle flange. The Steam Jacketed Lens Assembly

is normally furnished in either a 2 inch or 3 inch flanged process connection size. Ensure the size and type flange

on the nozzle isolation valve matches the Steam Jacketed Lens Assembly mounting flange received. If the

connections do not match, contact Delta Controls to secure a unit with the necessary nozzle connection size and

type.

2.1 Mounting the Steam Jacketed Lens Assembly

While the unit is down, check the isolation valve mounted on the vessel to ensure it operates properly and

properly. Replace the valve if it appears to bind or if, there is any indication that it may leak. Close the valve (it will

be opened after the reactor reaches operating temperature of over +572 F (+300 C).

Bolt the flange of the Steam Jacketed Lens Assembly to the valve flange with the 1/8” NPT purge port at the top.

2.1.1 Steam Supply

Long-term reliability of this instrument requires the use of steam to maintain the temperature of the window and

nozzle above the melting point of sulfur. Failure to maintain a high enough temperature can allow sulfur to solidify

and build up on the window and nozzle surfaces, blocking the light and causing inaccurate temperature readings.

Connect the steam lines (in accordance with the best practices of your plant) to the upper (inlet) port and connect

a bucket type steam trap to the lower (outlet) port of the assembly. The standard steam port connections are

1/4” NPT. Insulating the steam lines is recommended, though not shown in Figure 1.

Clause

Thermal

Reactor

Steam Outlet

Fiber Optic Cable

Cable Tray Wiring Conduit

Electronics

Module

Wiring

Conduit

Figure 2 – Typica l Installation

(Thermal insulation not shown)

Purge Supply

Steam Supply

Isolation Valve

5 of 15

2.1.2 Lens Purge

A 60 SCFH (28 L/min) flow of purge gas to the Steam Jacketed Lens Assembly is required.

Ensure that the supply of purge gas is clean, oil free and dry. Any moisture or hydrocarbons in

this purge gas may cause the inside of the lens window to coat. A coating will prevent some of

the infrared energy from reaching the sensor, causing a low temperature reading to occur, and

window cleaning to be required. Use a flow meter with a needle control valve suitable for a

flow rate of approximately 10 SCFH to 90 SCFH air (0.5 L/min to 41.7 L/min). Connect the

purge gas supply to the 1/8” NPT fitting on the top of the Steam Jacketed Assembly. Regulate

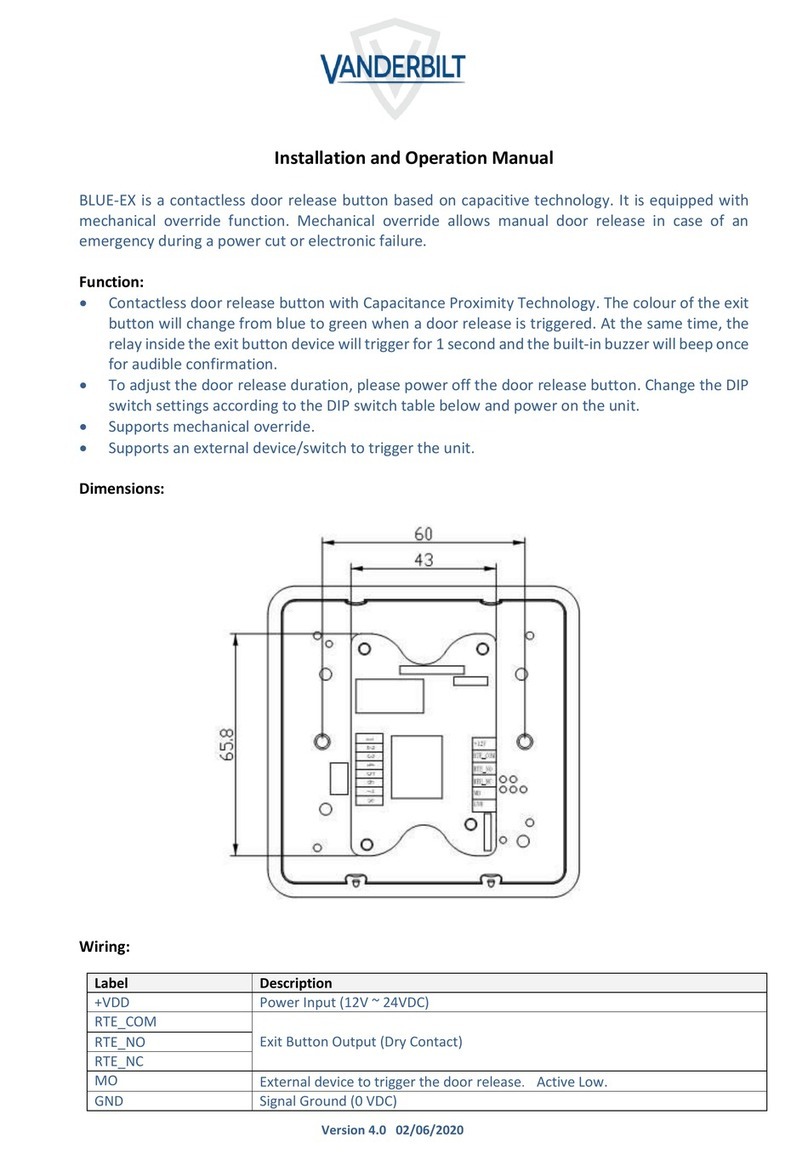

the purge supply to 15 psig (1 bar). Delta Controls recommends using Model HFI Flush Gas

Station (Figure 3) as it provides a conveniently packaged assembly of the necessary purge

supply components. Connection of the Model HFI is shown in Figure 4.

2.2 Thermal Insulation

To prevent sulfur from plugging the optical path, it is important that a temperature above +250 F (+121 C) be

maintained on the nozzle, isolation valve, and Steam Jacketed Lens Assembly. In most cases, the heat from the

reactor and steam body are not sufficient to keep the temperature of the valve and lens assembly above this

temperature unless they are insulated. It is important, therefore, that insulation be installed around the nozzle,

valve, and lens assembly, as shown in Figure 1, in accordance with the best practices of your plant. Adequacy of

the insulation should be tested by verifying that the lens assembly flange and the isolation valve body are above

+250 F (+121 C) under the most unfavorable conditions (wind, rain, snow, etc.)

2.3 Installing the Electronics Housing

A mounting location must be provided nearby for the electronics module.

Choose a location that is protected from the heat of the reactor, such that

the maximum ambient temperature of the electronics is not exceeded. For

convenience in performing optical alignment, the electronics display

should be visible to an operator standing at the Steam Jacketed Lens

Assembly.

To Flush Gas Supply

Purge

Inlet

Model HFI

Flush Gas Station

(Rear View)

Model HIR Steam

Jacketed Assembly

To Steam Trap

To Steam Supply

Figure

4

Purge Connections

Figure 3

Model

HFI Flush

Gas

Station

½” NPT

6 in (150 mm)

Terminal

Block

Fiber

Optic Adapter

Figure

5

Fiber Optic Adapter

6 of 15

2.3.1 Remote Sensor Mounting – Option RS

Under some circumstances, it is impractical to mount the electronics close to the lens body. Extending the fiber

optic cable is not possible, due to losses that would occur in a longer fiber. However, it is possible to mount the

electronics housing farther from the lens body by mounting the fiber optic adapter (Figure 5) at the end of the

10 feet (3 meters) fiber optic cable, and extending the sensor wires back to the remotely mounted electronics

housing, as shown in Figure 6.

The following considerations should be observed when remotely mounting the fiber optic adapter:

The fiber optic adapter must be mounted in a location with an ambient temperature of 0 F to +185 F

(-18 C to +85 C).

The recommended maximum extension is 25 feet (7.6 meters).

Install twisted cable pair between the fiber optic adapter and the electronics housing. The twisted pair

MUST be run through metallic conduit. Note that F-range models use two twisted pairs (4 wires total).

Other models use a single twisted pair.

Do not install other wires in the same conduit with the sensor wires.

Conduit should be appropriate for the area classification. Seals should be installed near the electronics

housing, in accordance with governing code.

The loop wiring conduit connection on Model HIR is ¾” NPT. Unless the ‘RS’ (remote sensor) option is specified,

the fiber optic adapter is normally factory installed in the ½” NPT opening in the housing.

Wire the electronics module in accordance with local governing code.

A green external earthing screw is located near the threaded conduit entry. An internal green earthing screw is

also provided inside the housing. To connect to the internal earthing screw, you must first move the electronics

module by removing the two screws holding the module down. Replace the module and hold-down screws after

connecting the earth ground conductor.

Note: If, for any reason, the fiber optic adapter must be unscrewed from the

electronics housing, first make sure the fiber optic adapter sensor wires are

disconnected from the electronics module terminals.

Model HIR

Electronics

Housing

Conduit Seal*

* Provided by user

Conduit Outlet Body

½” NPT

ex Conduit*

Fiber Optic Adapter

½” NPT

Fiber Optic Cable

Figure 6 Typical Installation of Remote Fiber Optic Adapter

7 of 15

2.3.2 Flameproof Installation

When type ‘d’ flameproof protection is employed, wire the HIR as shown in Figure 7 or Figure 8. Use certified

cable glands and conduit seals for all flameproof installations.

Figure 7

Typical Wiring

Note: F-range shown; other ranges use a two-wire fiber optic adapter

Figure 8 Typical Wiring - Option RS (Remote Sensor)

Note: F-range shown; other ranges use a two-wire fiber optic adapter

8 of 15

2.4 Connecting the Fiber Optic Cable

Use care in handling the fiber optic cable. Even though it is armored, sheathed, and sealed for durability,

individual glass fibers within the cable can be damaged by mishandling. Avoid dropping, shocking, kinking,

pulling, or sharply bending the cable. When routing the fiber optic cable, it is important to observe the

minimum bend radius specification of 3 inches (7.6 cm). Bending the fiber optic cable more sharply than

specified radius can result in low temperature readings due to excessive infrared energy losses in the cable.

The fiber optic cable is connected to a sensor in the fiber optic adapter as shown in Figure 9.

1. Insert the cable into the fiber optic adapter. The cable must be inserted all the way to the bottom of the

adapter hole for the cable grip to seat and to avoid calibration errors.

2. Tighten the cable grip to seal the cable against moisture.

Model HIR Electronics

Housing

2. Tighten cable grip

1. Insert cable

Note: Do not unscrew this ½” NPT

connection without first

disconnecting the sensor wires.

Otherwise, damage to internal

wiring could result.

¾” NPT

Conduit

Connection

Figure 9

– Inserting the Fiber Optic Cable

9 of 15

2.5 Optical Alignment

The fiber optic lens is aligned at the factory to look straight down the nozzle’s bore. The alignment should be

visually checked prior to using the instrument. This alignment check is only possible when there is light inside the

reactor vessel, either with the vessel opened and lighted prior to operation, or from the light from the reaction after

startup.

To view the optical path:

1. Unscrew the lens cover quick disconnect and remove the lens top cover as shown in Figure 10. Be

careful not to allow the weight of the cover to damage the fiber optic cable.

2. Open the isolation valve.

3. Sight down the Alignment Tube, through the process window and into the reaction chamber.

The light from the reaction vessel should appear centered in

the Alignment Tube. If it is not, the Alignment Tube should

be aligned as follows:

4. Loosen the three alignment clamp screws using a

9/64” hex wrench (Figure 11).

5. Manually adjust alignment tube until light is

centered.

6. Tighten the three alignment clamp screws.

7. Re-check the alignment to make sure the alignment

tube did not move while tightening the clamp

screws.

8. Replace the Lens Top Cover, making sure that the

Lens Body is inserted into the Alignment Tube, and

tighten the Lens Cover Quick Disconnect.

Lens

Top

Cover

Lens Body

Alignment Tube

Figure

10

Lens Cover Quick Disconnect

Alignment

Clamp

Screws (3)

Figure 11

Alignment

Tube

10 of 15

3. OPERATION

Caution: When used with type ‘d’ flameproof protection, do not open cover when

circuits are energized nor when hazardous gasses might be present.

Model HIR user interface consists of an LCD display and 4 setup pushbuttons. The temperature characteristics of

the display are such that you should only calibrate the unit when the ambient temperature is between 0 F and

+140 F (-18 C through +60 C). Outside this temperature range, the transmitter will operate properly, but the

display may be difficult to read.

Pushbuttons:

Pressing the UP button causes the value displayed to be incremented. Holding the button down causes

the value to continue upward at an ever-increasing rate.

Pressing the DOWN button causes the value displayed to be decremented. Holding the button down

causes the value to continue downward at an ever-increasing rate.

NEXT Pressing this button shifts the display to the next setup parameter.

SAVE Pressing the SAVE button saves all calibration values and setup parameters. The display will indicate

"Saving..." to verify that the values are being saved.

3.1 Setup Parameters

IR Temp This parameter displays the temperature as measured by the infrared sensor. When

displaying this parameter, the signal strength is also displayed. (Refer to section 3.4

Preventative Maintenance: Signal Strength.)

LOOP mA Loop current transmitted in milliamperes

LOOP % Loop current as a percentage where 0 % = 4 mA and 100 % = 20 mA

Units This parameter sets the units of measure for temperatures. Use the up or down arrows to

toggle between degrees Fahrenheit and Celsius.

4mA = Zero scale temperature, i.e., the temperature corresponding to 4.00mA loop current.

20mA Full scale temperature, i.e., the temperature corresponding to 20.00 mA loop current.

Lo Alarm Low alarm setpoint – If the measured temperature falls below this setpoint, the Low Alarm

bit will be set in the HART Device Status and an exclamation (!) will appear next to the

displayed temperature.

Hi Alarm Hi alarm setpoint – If the measured temperature rises above this setpoint, the High Alarm

bit will be set in the HART Device Status and an exclamation (!) will appear next to the

displayed temperature.

Sig Alarm Signal level alarm setpoint – If optical occlusions cause the amount of light reaching the

sensor to fall below this level the Signal Alarm bit will be set in the HART Device Status

and ‘LOW!” will appear in the signal display field when displaying the IR TEMP parameter.

Enter a number between 0 and 100 where 0 means light is completely blocked. 100

means no blockage. Typical values would be 50 to 70.

11 of 15

The parameters listed below are normally used only during factory setup. However, they can be

accessed by pressing and holding the NEXT button while simultaneously pressing the UP arrow button.

CAUTION: Accessing these parameters can result in at least momentary

disruption of the transmitted 4-20 mA signal as described below under

Zero Adj and Span Adj.

Version Software/Hardware Revision number

Cal Temp Calibration Temperature

LowCutoff Temperature below which the unit will not read.

HART

ADDR

When using HART in multidrop mode, this parameter sets the HART address on the bus.

LOOP CTL 0 = normal (current follows temperature); 1 = multidrop (loop set to 4.00 mA); 2 = manual.

When set to 2 (manual), current can be set by changing the LOOP mA parameter above.

Note: LOOP CNTRL = 2 is used for testing purposes only and reverts to 0 on

device reset or cycling power.

Zero Adj When accessed, current loop immediately transmits 0 scale or 4 mA. Adjust parameter up

or down until device measuring the output current indicates exactly 4.00 mA.

CAUTION: Accessing this parameter causes the temperature measurement to STOP

transmitting and instead transmits Zero Scale. Be sure that any equipment

connected to this transmitter is prepared for the disruption in the temperature

signal level before accessing this parameter.

Span Adj When accessed, instrument immediately transmits full scale or 20 mA. Adjust parameter

up or down until the device measuring the output current indicates exactly 20.00 mA.

CAUTION: Accessing this parameter will cause the transmitter to transmit Full

Scale Temperature. Be sure that any equipment connected to this

transmitter is prepared for the disruption in the temperature signal level

before accessing this parameter.

ALRM

ACTN

Alarm Action – This controls how current loop responds to a detected diagnostic alarm.

0 = drive high (22.0 mA); 1 = drive low (3.6 mA); 2 = hold; 3 = ignore.

NOTE: This alarm action is based only on internal consistency checks that are

used to detect hardware failures. If a diagnostic alarm is detected, check the

wiring between the fiber optic adapter and the electronics module and/or consult

the factory. The alarm action can be tested by disconnecting the red or green

wire to the fiber optic adapter while the pyrometer is looking at a hot reactor or

other incandescent light source.

DAMPING The measurement time constant in seconds. Higher numbers provide more smoothing.

MemCmd Factory Use Only

3.2 Initial Startup

1. Confirm the nozzle isolation valve is closed. This prevents any foreign matter from collecting on the

viewport window during refractory dry out, curing and hydrocarbon firing.

2. Establish steam flow to the Steam Jacketed Assembly and ensure that the steam trap is functioning

properly. This assures that condensation will not accumulate on the viewport.

3. After verifying that the Steam Jacketed Lens Assembly is up to temperature, open the isolation valve.

Note: It is important to keep the isolation valve closed until operating temperature is

reached in order to prevent sulfur from condensing and solidifying on the window.

12 of 15

4. Turn purge gas pressure on and set the purge flow meter needle control valve to approximately 60 SCFH

(28 L/min).

5. Apply power to the electronics module. “IR Temp” value will be displayed.

6. Press the NEXT button to display the “Units” parameter.

7. Press the UP or Down arrow buttons to toggle between Celsius or Fahrenheit and set as desired.

8. Press the NEXT button to display the “4mA=” parameter.

9. Press the UP or DOWN arrow buttons to set the temperature corresponding to 4.00 mA loop current.

10. Press the NEXT button to display the “20mA=” parameter.

11. Press the UP or DOWN arrow buttons to set the temperature corresponding to 20.00 mA loop current.

12. Press the SAVE button to save all changes. The display will briefly indicate “Saving…”

Note: If you do not press SAVE, the changes you made above will not be

remembered after a power fail.

13. Press the NEXT button to display the temperature.

3.3 Ratiometric Two-Wavelength Sensing

The HIR ‘F range’ transmitter measures the intensity of light at two different wavelengths to determine the

temperature. This allows the measurement to be accurate even if there is a partial blockage of light due to

material buildup (occlusion) on the window or in the nozzle. In essence, the measurement is based on the light’s

color (wavelength), instead of the intensity, as is usually done with a single wavelength measurement. In addition

to the temperature, the amount of occlusion can also be measured as a Signal Value number from 0 (completely

blocked) and 100 (no blockage). The Signal Value appears on the display in small numbers below the

temperature. If the number falls below the Signal Alarm setpoint, then “LOW!” appears next to the displayed

signal level, and HART Additional Device Status Byte 1, bit 2 is set.

Note that below 1472 °F (800 °C), there is not enough infrared light at both wavelengths to make a two-

wavelength measurement. Therefore, temperatures between 662 °F and 1472 °F (350 °C and 800 °C) are only

measured with a single wavelength. In that case, the amount of blockage cannot be determined.

3.4 Preventive Maintenance

Model HIR is designed to give years of trouble-free operation without the need for service. In most cases, to

achieve this performance, the only requirement is that the optical path (nozzle, valve, window) temperature be

maintained above the freezing point of sulfur, and that the window purge be maintained to keep the window free

of particulates. Thus, a preventive maintenance schedule should include periodic inspections to verify that:

1. The steam supply is on, the steam trap is functioning, and steam is heating the lens body,

2. The lens purge flows at the recommended rate of 60 SCFH (28 L/min), and

3. The thermal insulation as shown in Figure 1 is in place and in good condition.

Signal Strength Indication

Signal strength measurement (Signal=XXX.XX) is located beneath the temperature measurement when

displaying the temperature parameter. This value should read between 0 and 100 and indicates the amount of

light reaching the sensor relative to an unobstructed sight path. A value of ≥ 95 is normal. Values below 95 may

indicate the occurrence of sight path attenuation, possibly due to material build-up on window or inside the nozzle.

The signal strength should be monitored periodically. If it drops significantly or if the optical path temperature or

purge is suspected to be compromised, corrective action should be scheduled. This includes inspecting the

13 of 15

optical sight path and performing any necessary sight glass or lens cleaning and / or nozzle cleanout. Refer to

section 2.5 Optical Alignment for details.

3.5 Calibration

Calibration should be checked any time an anomaly is suspected or annually. The best way to check the

calibration or to recalibrate the instrument is with a CLAUSTEMP® Model HIP Handheld Pyrometer. See

www.claustemp.com.

To calibrate the HIR Pyrometer:

1. Measure reactor temperature using a CLAUSTEMP® model HIP handheld pyrometer or other means.

2. Ensure Model HIR has a clear sight path into the reactor.

3. Press and hold the NEXT button while simultaneously pressing the UP arrow button. Then release both

buttons.

4. Press the NEXT button to display the CAL TEMP parameter.

5. Unlock the calibration feature by pressing and holding the NEXT button while simultaneously, pressing

the DOWN arrow button. Then release both buttons.

6. Use the UP and Down arrow buttons to set the known reactor temperature.

7. Press the SAVE button. Calibration is complete.

00-

HIR05

Fiber Optic Cable

3” Minimum Bend Radius

Figure

12

-

Dimensions

–

Steam Jacketed Lens Assembly

Units: [mm]

inches

14 of 15

Figure 13 - Dimensions – Electronics Housing

4. SPECIFICATIONS

Range:

“C” Range +1472 °F to +3092 °F (+800 °C to +1700 °C)

“D” Range +662 °F to +3092 °F (+350 °C to +1700 °C)

“F” Range

Dual Wavelength

Single Wavelength

+1472 °F to +3092 °F (+800 °C to +1700 °C)

+662 °F to +3092 °F (+350 °C to +1700 °C)

Accuracy 0.5 % of reading or 36 F (±20 C), whichever is greater

Repeatability 0.1 % of full-scale span

Warm-Up Time 60 seconds

Readout High Contrast LCD Display

Output Signal: 4-20 mADC, 2-wire loop-powered

Hazardous Location Rating II 2 G Ex d IIC T6 (When installed per section 2.3.1 Remote Sensor

Mounting — Option RS.)

IP65

Fiber Optic Cable: Flexible PTFE over SS armor

10 feet (3 meters) standard length

Minimum Bend Radius 3 inches (7.6 cm)

Hot Lens Mounting 3” ANSI is standard on a flanged nozzle steam jacketed.

Other types and sizes available

Ports:

Steam Jacket in and out 50 psi to 100 psi (344 kPa to 689 kPa) for steam to heat the lens

assembly

Nitrogen Purge 60 SCFH (28 L/min) typical

Housing Mounting Vertical surface or 2-20 pipe stand with vertical or horizontal

orientation

Housing Conduit Connection ¾” NPT

Ambient Temperature Limits:

Fiber Optics & Lens -20 F to +400 F (-29 C to +204 C)

Fiber Optics Adapter -4 F to +185 F (-20 C to 85 C)

Electronics -4 F to +158 F (-20 C to +70 C)

Maximum Process Pressure 150 psi (1034 kPa)

585 Fortson Street

Shreveport, LA 71107

www.claustemp.com

delta@deltacnt.com

Table of contents

Other Delta Controls IP Access Controllers manuals