HJ26141 Page 7

Place wheel chocks on both sides of trailer1.

wheels.

Lower trailer jacks to ground and extend un-2.

til load is level with truck suspension. If on soft

ground, place support under jack feet to pre-

vent trailer from settling.

Lower tailgate on truck.3.

Disconnect power cable and break away switch.4.

Remove lock pin and pull handle out. If handle5.

will not stay out, install safety pin in second han-

dle hole just outside of frame handle bushing.

Drive truck slowly away from trailer.6.

Inspect all fasteners for tightness at least every1.

2,000 miles of operation.

Inspect jaw and jaw bar for freedom of move-2.

ment and proper operation before each use.

Replace all damaged or worn parts.

Keep all moving parts of hitch well lubricated.3.

It is recommended to use grease or a 3/16”4.

maximum Teflon disc to help prevent wear on

top plate surface.

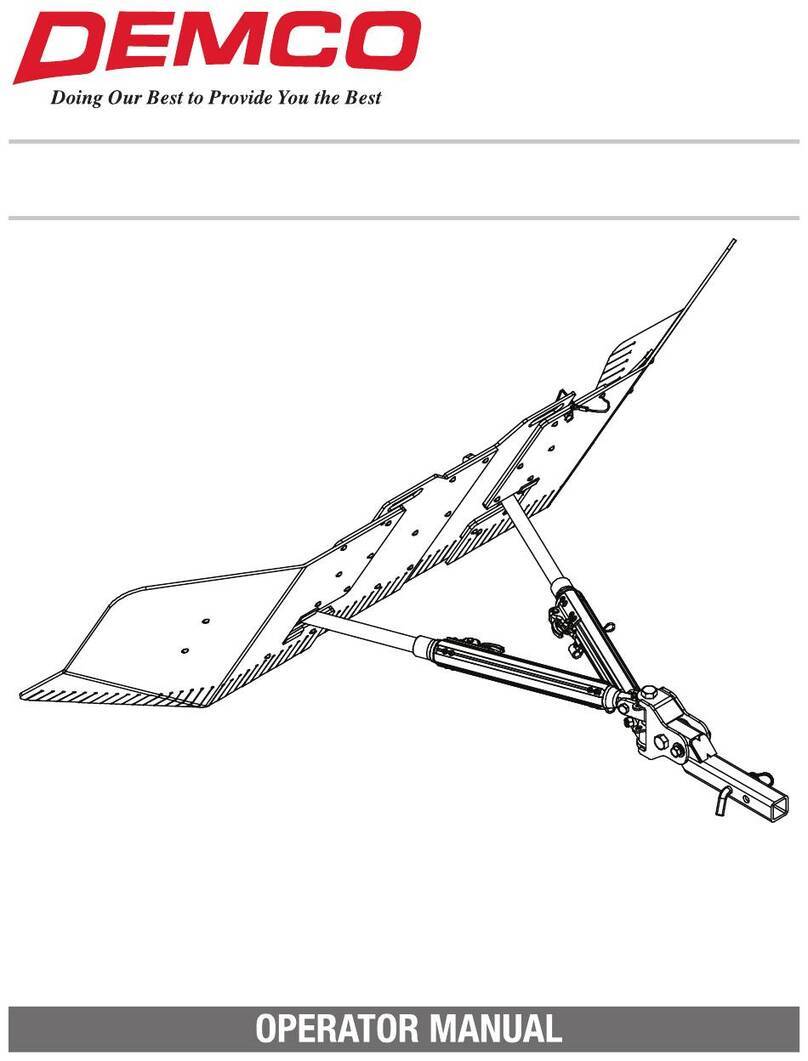

COUPLING PROCEDURE UNCOUPLING PROCEDURE

VERY IMPORTANT

MAINTENANCE INSTRUCTIONS

VERY IMPORTANT WARNINGS

Know your vehicle and trailer GVWR and CVWR.1.

DO NOT exceed capacity of hitch.

Hitch is for use with only a standard 2” king pin.2.

Safety pin MUST be fastened securely before moving vehicle and/or traveling

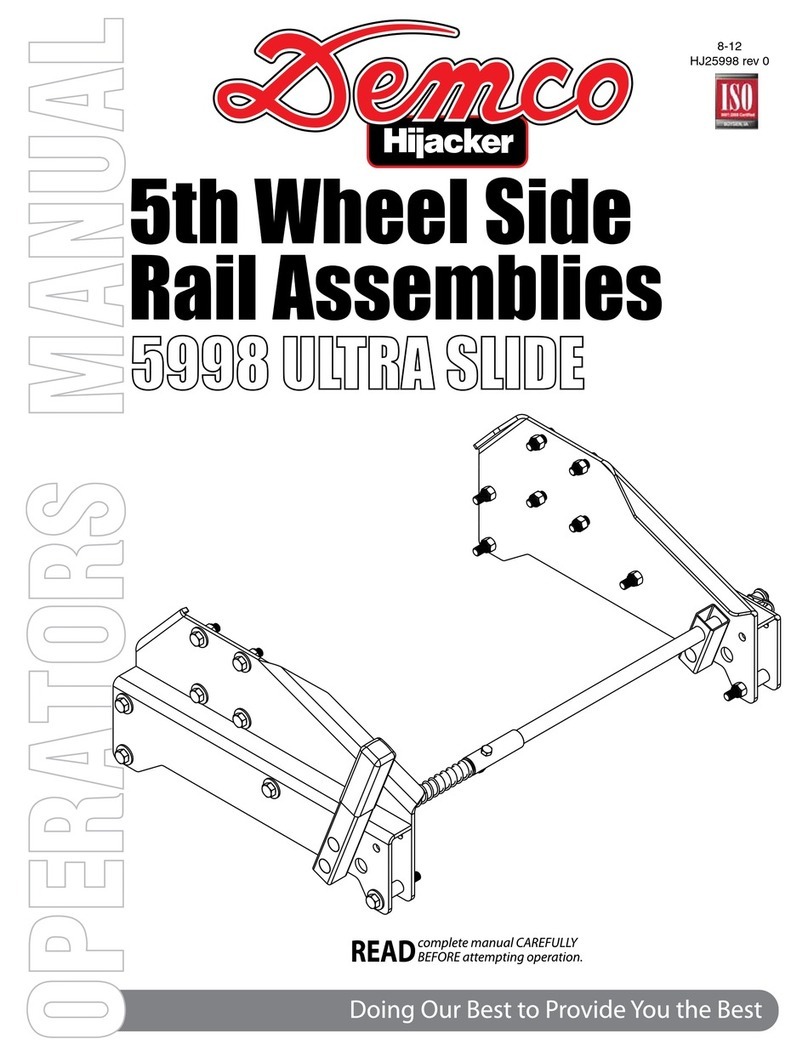

Ready to Couple Coupled and Locked Uncoupled

VISUALLY INSPECT JAW LOCKING MECHANISM BEFORE TRAVELING

Remove safety lock

pin if installed and

pull handle until

jaw locks open.

With handle in "Ready to Couple" position,

back-up tow vehicle to couple trailer and hitch.

Insert safety pin thru tab and hole in handle.

NOTE: Ensure safety lock pin is inserted properly.

Apply trailer brakes before jacks are raised and

wheel chocks are removed.

Place wheel chock on each side of trailer wheels.1.

Adjust trailer jacks until trailer is a height for hook up.2.

King pin plate should contact hitch approximately 1/2”

below level.

Lower tailgate of truck.3.

If hitch is in locked position, remove safety pin and pull4.

handle out to the “Ready to Couple” position.

Line truck so that the hitch will accept king pin. Back5.

truck up slowly towards trailer until king pin engages.

Hitch will lock when king pin is fully engaged.

With the trailer coupled, visually check to see if hitch is6.

completely locked by looking at the handle position, as

well as visually checking to ensure that the jaw bar has

traveled completely across the front of the king pin.

Place safety pin thru the tab and the hole in the handle.7.

This will prevent handle from opening.

Connect power cable and breakaway switch cable be-8.

tween truck and trailer.

Close and latch tailgate.9.

Apply trailer brakes and try to pull forward slowly to10.

double check that hitch is locked. Trailer should pre-

vent truck from moving.

Completely raise trailer jacks. Check for proper clear-11.

ance between truck box and trailer.

Pick up and store wheel chocks. You are now ready to12.

travel.

To uncouple, remove saftey pin,

pull handle straight out until the

jaw locks open. If jaw will not

stay open, install safety pin in

second handle hole just outside

of frame handle bushing.

OPERATION

5TH WHEEL HITCH OPERATION INSTRUCTIONS