9

Step 4: Install the Monitor Light

Note: If the vehicle has a “dead” brake-light switch when in the towed position (the brake

lights are inoperable with the key in the tow position) or the vehicle’s battery is disconnected

while in tow, the Red wire below should be attached to the blue wire that goes between the

breakaway switch and the operating unit. Most 2009+ GM’s use a multiplex wiring system

and cannot be tapped into. Some newer vehicles (e.g. 2011-13 Chrysler products) have

a functional brake switch even though the brake lights don’t come on in the towed position.

2014+ Chryslers are only functional for five minutes.

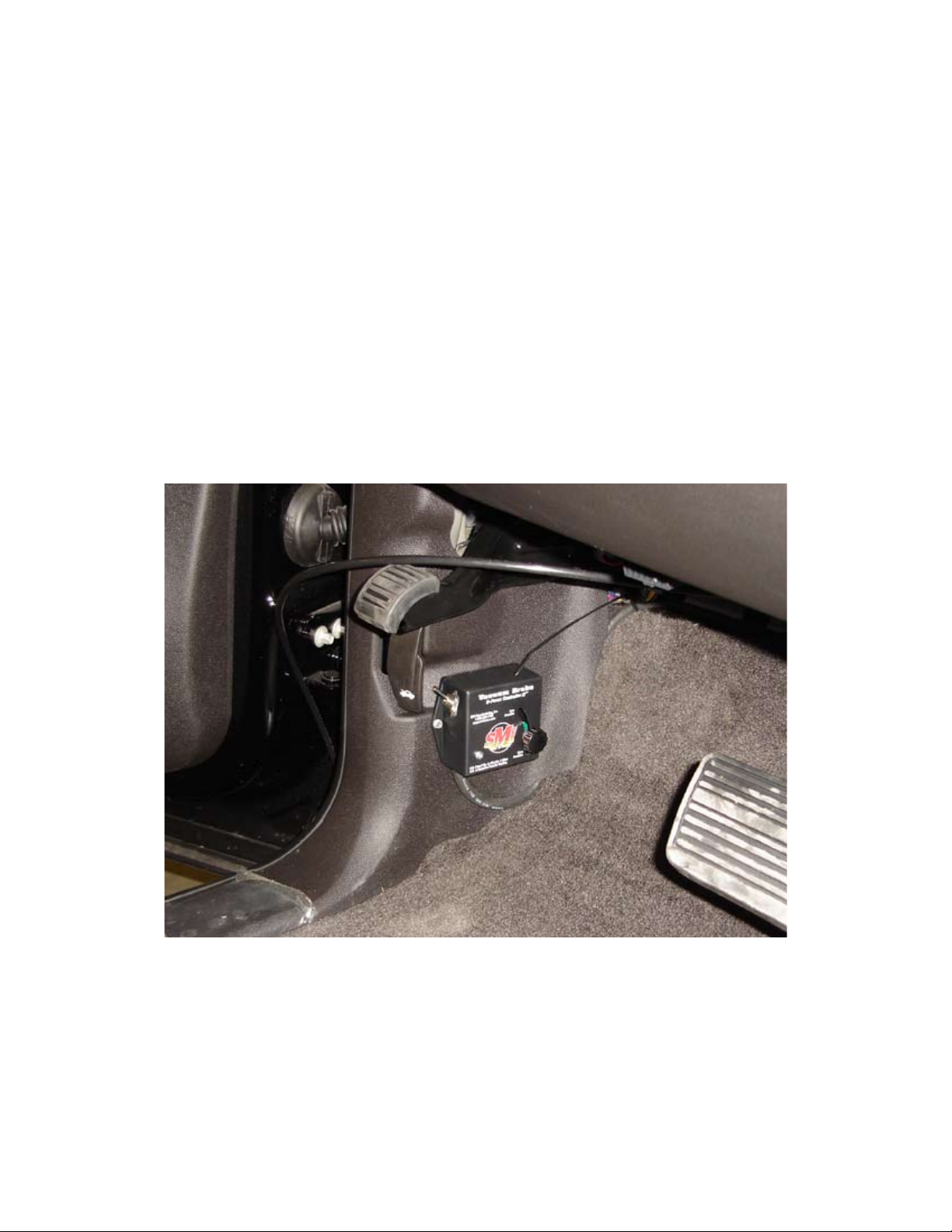

The following instructions are written with a labor-saving installation method of the monitor

light. At the customer’s preference the monitor light may be installed on the dash of the

coach. A wireless radio set is also available (PN 9599005). Contact the Help Line for

specifics.

*All parts needed for this step are located in the “Coach Notification Kit”

Decide on a location for the LED strip. The provided LED strip is extremely bright and can be1.

placed in any location on the towed vehicle that is viewable in the rear camera of the coach.

Many have found that the back side of the rear view mirror provides a good backdrop for the

LED and is easily viewable in the coach’s rear camera. The following steps are written with this

in mind.

Using the provided hook and loop fastener, attach the LED to the rear view mirror of the towed2.

vehicle.

Note: During tow it may be helpful to angle the rear view mirror toward the rear camera of the

coach.

Conceal the wires by routing it along the top of the windshield and3.

down the side of the A-pillar on the driver’s side of the towed vehicle.

The A-pillar can be removed if needed, but exercise caution as some

models have side curtain air bags. Most A-pillar covers are secured

with 1-2 screws (in the handle area) and hidden pop connectors. Re-

move the screws and gently pull the cover away from the pillar.

Note: It may be necessary to extend the wires of the LED.

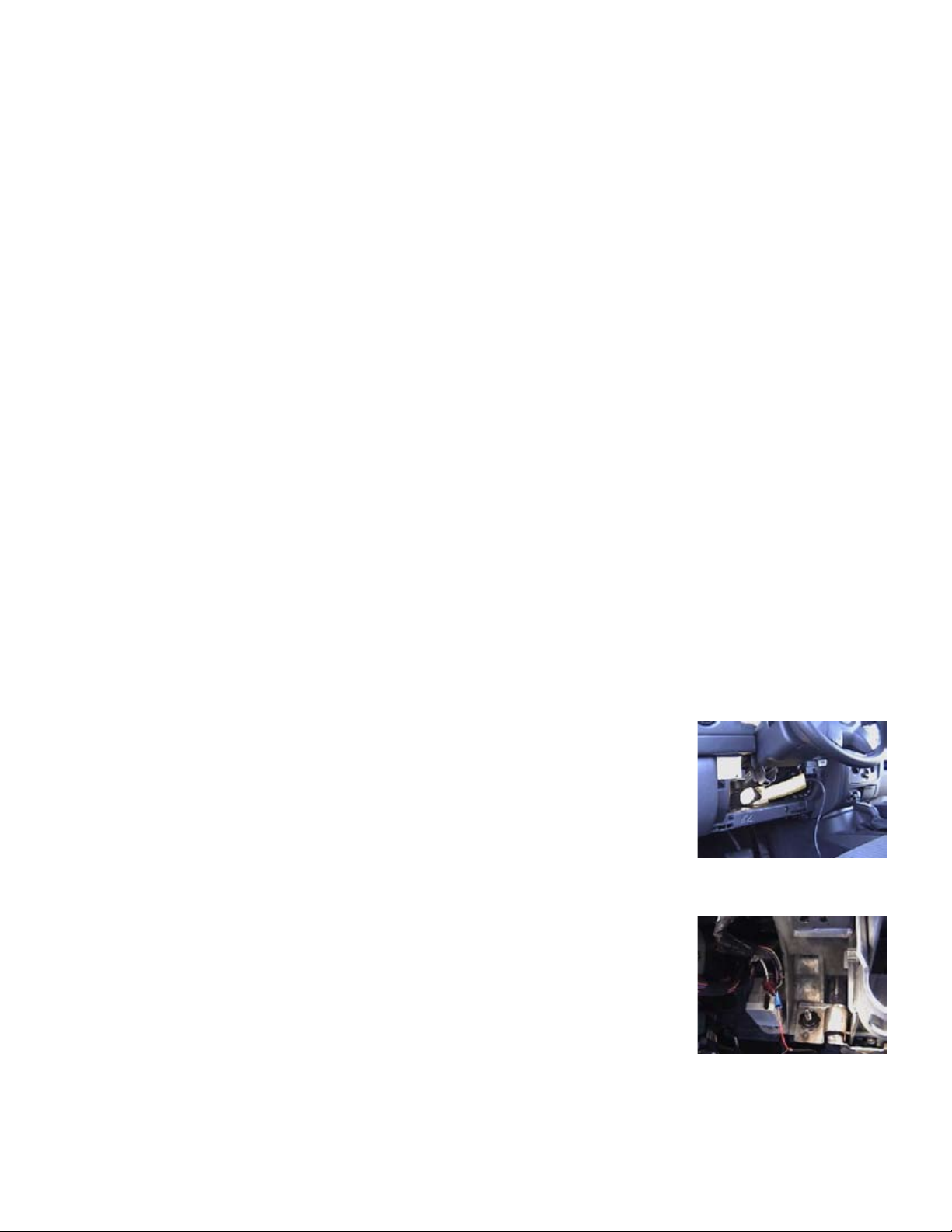

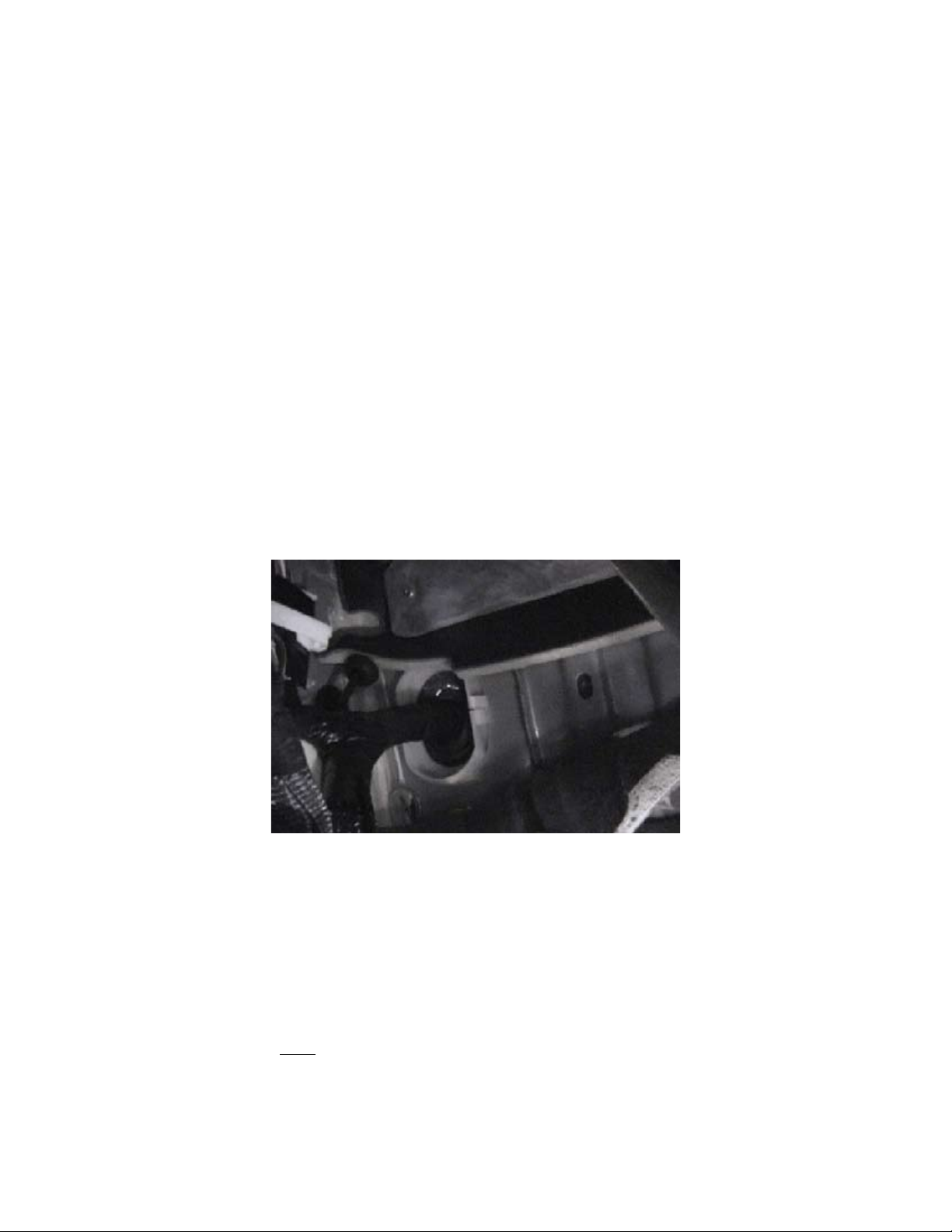

Locate the cold side of the brake light switch (BLS). This is the wire4.

that is normally cold, but has 12v+ when the brake pedal is depressed.

Crimp the spade onto the red wire on the LED and place the spade5.

into the flip-over connector.

Clip the flip-over connector onto the cold side of the brake light switch6.

wire.

Using the provided 3 way crimp connector, connect the Black wire7.

from the LED to the Black wire on the G-Force Controller that was

mounted in Step 3.

* Careful attention must be given to disabling the light before driving the towed vehicle on public

streets. In this configuration, the toggle switch will disable/enable the light.