Dentsply Sirona Capsule Extruder 2 User manual

Other Dentsply Sirona Dental Equipment manuals

Dentsply Sirona

Dentsply Sirona X-Smart IQ User manual

Dentsply Sirona

Dentsply Sirona DAC Universal User manual

Dentsply Sirona

Dentsply Sirona SmartLite Focus User manual

Dentsply Sirona

Dentsply Sirona SINIUS User manual

Dentsply Sirona

Dentsply Sirona Gutta-Smart Manual

Dentsply Sirona

Dentsply Sirona SiroLaser Blue User manual

Dentsply Sirona

Dentsply Sirona Midwest Stylus Plus User manual

Dentsply Sirona

Dentsply Sirona MIDWEST AUTOMATE User manual

Dentsply Sirona

Dentsply Sirona CEREC Omnicam AC User manual

Dentsply Sirona

Dentsply Sirona inLab Profire User manual

Dentsply Sirona

Dentsply Sirona SiroCam UAF Plus User manual

Dentsply Sirona

Dentsply Sirona X-Smart IQ User manual

Dentsply Sirona

Dentsply Sirona Essix Dual Laminate Plastic Manual

Dentsply Sirona

Dentsply Sirona Eclipse Manual

Dentsply Sirona

Dentsply Sirona Cavitron Select SPS User manual

Dentsply Sirona

Dentsply Sirona Midwest Tradition TB User manual

Dentsply Sirona

Dentsply Sirona X-Smart User manual

Dentsply Sirona

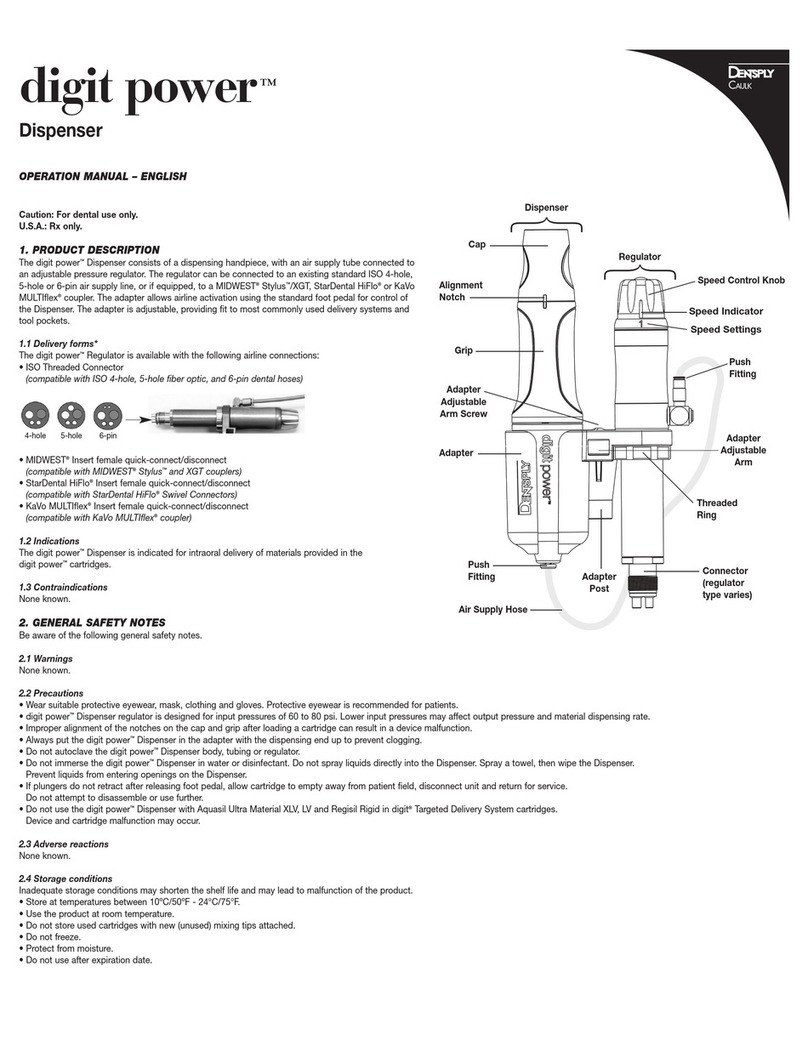

Dentsply Sirona digit Power User manual

Dentsply Sirona

Dentsply Sirona CEREC MC XL User manual

Dentsply Sirona

Dentsply Sirona Midwest Stylus Plus User manual

Popular Dental Equipment manuals by other brands

Vatech

Vatech EzRay Air VEX-P300 user manual

KaVo

KaVo GENTLEpower LUX Contra-angle 25 LP Technician's Instructions

DENTSPLY

DENTSPLY SmartLite Focus Instructions for use

LM

LM ProPower CombiLED quick guide

Owandy Radiology

Owandy Radiology RX-AC user manual

mectron

mectron Piezosurgery Cleaning and sterilization manual