Derbi GP1 50 cc Instruction manual

GP150 cc

WORKSHOP MANUAL

1

DERBI - NACIONAL MOTOR, S.A., manufacturer of DERBI motorcycles and mopeds, has produced this

manual with the aim of documenting and simplifying as much as possible the work you need to do to in dis-

mantling and assembling the GP1 50 c.c.

The intention is to provide as much assistance as possible to mechanics working for our brand’s dealers and

sub-dealers.

Due to its constant commitment to improving its products, DERBI - NACIONAL MOTOR, S.A. Sociedad

Unipersonal reserves the right to introduce any modifications it deems fit, without prior warning.

All the information included in this manual is based on the latest data available at the time of its publication.

The drawings and photographs in this manual are for reference purposes only, and may therefore not be

exactly the same as the corresponding parts of the current model itself.

NACIONAL MOTOR, S.A.

3

INTRODUCTION

GENERAL INFORMATION

GENERAL TECHNICAL DATA

RECOMMENDED TOOLS

REGULAR MAINTENANCE

DISMANTLING

SEAT SIDE TRIM

COWLING

COWLING BOTTOM COVER

WATER-OIL TANK COVER

SIDE COVERS

SHIELD BOTTOM COVER

PETROL TANK COVER

HELMET HOLDER

FOOTRESTS

SIDE COVERS

SHIELD

DIRECT ACCESS TO THE BOTTOM OF THE CARBURETTOR

DISMANTLING FOOTRESTS

EXTRACTING COMPLETE AIR FILTER BOX

DISCONNECTING SECONDARY AIR PIPE

EXTRACTING CARBURETTOR AIR INTAKE PIPE

EXTRACTING CARBURETTOR

THE MACHINE’S ENGINE

DISMANTLING THE ENGINE

TRANSMISSION COVER

DISMANTLING DRIVEN PULLEY SHAFT SUPPORT BEARINGS

FITTING DRIVEN PULLEY SHAFT SUPPORT BEARINGS

DISMANTLING DRIVEN PULLEY

CHECKING CLUTCH BELL HOUSING

DISMANTLING CLUTCH

CHECKING CLUTCH

BRAKE RETAINING RING

DISMANTLING DRIVEN PULLEY HALF BEARINGS

CHECKING FIXED DRIVEN HALF PULLEY

CHECKING MOBILE DRIVEN HALF PULLEY

FITTING DRIVEN HALF PULLEY BEARINGS

CHECKING VARIATOR SPRING

Page 1

Page 8

Page 9

Page 18

Page 24

Page 35

Page 35

Page 36

Page 36

Page 36

Page 37

Page 37

Page 38

Page 39

Page 39

Page 39

Page 40

Page 40

Page 40

Page 40

Page 41

Page 43

Page 43

Page 44

Page 44

Page 45

Page 45

Page 45

Page 46

Page 46

Page 47

Page 47

Page 48

Page 49

Page 49

4

ASSEMBLING CLUTCH

FITTING DRIVEN PULLEY

TRANSMISSION BELT

DISMANTLING DRIVING PULLEY

MIXER GEARING AND BELT

CHECKING ROLLER CONTAINER

FITTING DRIVING PULLEY

FINAL REDUCTION

DISMANTLING ENGINE PINION

DISMANTLING HUB COVER

DISMANTLING OUTPUT PINION SHAFT

DISMANTLING OUTPUT PINION SHAFT BEARING

DISMANTLING DRIVEN PULLEY SHAFT BEARING

CHECKING THE HUB SHAFTS

CHECKING THE HUB COVER

FITTING DRIVEN PULLEY SHAFT BEARING

FITTING WHEEL PULLEY SHAFT BEARING

FITTING THE HUB COVER

MAGNETO COVER

DISMANTLING THE ENGINE

FITTING THE STATOR

FITTING THE MAGNETO COVER

MAGNETO AND STARTING

DISMANTLING THE STARTER MOTOR

DISMANTLING THE MAGNETO

CHECKING THE MAGNETO COMPONENTS

FITTING THE MAGNETO

FITTING THE STARTER MOTOR

CYLINDER UNIT AND TIMING

DISMANTLING THE SUCTION COLLECTOR

DISMANTLING THE CYLINDER HEAD

DISMANTLING THE PISTON CYLINDER

CHECKING THE CONNECTING ROD BIG END

CHECKING THE GUDGEON PIN

CHECKING THE PISTON

CHECKING THE CYLINDER

Page 49

Page 50

Page 50

Page 51

Page 51

Page 51

Page 52

Page 53

Page 53

Page 54

Page 54

Page 54

Page 55

Page 55

Page 55

Page 56

Page 57

Page 57

Page 57

Page 58

Page 58

Page 58

Page 59

Page 59

Page 60

Page 60

Page 60

Page 61

Page 61

Page 61

Page 62

Page 62

5

CHECKING THE OIL SEALS

FITTING THE PISTON

CHECKING TIMING COMPONENTS

CRANKCASE

OPENING THE CRANKCASE

DISMANTLING THE CRANKSHAFT

DISMANTLING THE MAIN BEARINGS

FITTING THE MAIN BEARINGS

CHECKING THE CRANKSHAFT ALIGNMENT

FITTING THE CRANKSHAFT

REJOINING THE CRANKCASE

LUBRICATION

OIL PUMP

DISMANTLING

FITTING

FUEL SUPPLY

FORKS

SEBAC FORKS

MARZOCCHI FORKS

DISMANTLING THE FRONT SUSPENSION

INSPECTING THE FRONT FORKS

SHOCK ABSORBER AND SWINGING ARM

SHOCK ABSORBER AND SWINGING ARM

DISMANTLING

INSPECTION

FRONT WHEEL AND BRAKES

FRONT WHEEL DIAGRAM

DISMANTLING

INSPECTING THE FRONT WHEEL

DISMANTLING THE FRONT DISK CALLIPER

FITTING THE FRONT WHEEL

Page 63

Page 63

Page 64

Page 65

Page 65

Page 65

Page 66

Page 67

Page 67

Page 68

Page 69

Page 70

Page 70

Page 71

Page 72

Page 73

Page 74

Page 76

Page 78

Page 79

Page 79

Page 80

Page 81

Page 81

Page 83

Page 90

6

REAR WHEEL AND BRAKES

REAR WHEEL DIAGRAM

DISMANTLING

DISMANTLING THE REAR DISK CALLIPER

INSPECTING THE REAR WHEEL

REFITTING THE REAR WHEEL

TRANSMISSION

DISMANTLING

INSPECTING THE TRANSMISSION CHAIN

CROWN WHEEL

REFITTING THE CROWN WHEEL AND THE TRANSMISSION CHAIN

COOLING SYSTEM

BLEEDING THE SYSTEM

CHECKING THE WATER PUMP

THERMOSTAT

DISMANTLING

CHECKING

FITTING

ELECTRICAL SYSTEM

GP1 50C.C. WIRING DIAGRAM

GP1 50C.C. WIRING DIAGRAM (SWITZERLAND)

CHECKING CONNECTORS

STEPS FOR THE INSPECTION

DIGITAL INSTRUMENTS UNIT

IGNITION

AUTOMATIC CHOKE AND LIGHTS

BATTERY RECHARGE AND STARTING

LEVEL INDICATORS

TURN INDICATORS AND HORN

CHECKS AND CONTROLS

CHECKING PICK-UP

REFITTING IGNITION

Page 91

Page 92

Page 92

Page 99

Page 99

Page 100

Page 101

Page 101

Page 102

Page 103

Page 103

Page 106

Page 106

Page 106

Page 107

Page 108

Page 109

Page 110

Page 111

Page 111

Page 112

Page 113

Page 114

Page 115

Page 116

Page 117

Page 117

Page 118

7

CHECKING THE STATOR

CHECKING THE VOLTAGE REGULATOR

OPERATIONS

FUSES

DISMANTLING THE BATTERY

BATTERY-INITIAL CHARGE

CAPACITY

INSPECTING THE CHARGING CONDITIONS

RECHARGING

CHECKING THE ELECTRICAL SYSTEM

TROUBLESHOOTING

ENGINE

REAR WHEEL TURNS WITH ENGINE TICKING OVER

DIFFICULTY STARTING

EXCESSIVE CONSUMPTION OF OIL/SMOKY EXHAUST

THE ENGINE TENDS TO STOP AT FULL THROTTLE

THE ENGINE TENDS TO STOP WHEN TICKING OVER

HIGH FUEL CONSUMPTION

EXCESSIVELY NOISY EXHAUST

ENGINE OVERHEATING

FAULTS

TRANSMISSION AND BRAKES PULLING OR ABNORMAL CLUTCH OPERATION

POOR BRAKING POWER

BRAKES OVERHEATING

ELECTRICAL WIRING

STEERING AND SUSPENSION – REAR WHEEL

STIFF STEERING

TOO MUCH PLAY IN STEERING

NOISY SUSPENSION

SUSPENSION LEAKING OIL

Page 118

Page 118

Page 119

Page 122

Page 122

Page 124

Page 124

Page 125

Page 126

Page 127

Page 128

Page 129

Page 129

Page 130

Page 130

Page 130

Page 131

Page 131

Page 131

Page 132

Page 132

Page 133

Page 133

Page 134

Page 134

Page 135

Page 135

Page 135

Page 136

8

REGULATIONS

This section describes the machine’s general safety and maintenance work rules.

SAFETY REGULATIONS

- In the event of having to carry out work on the engine while this is running, ensure that the area is well

ventilated, where possible using extractor fans. Never leave engines running in closed spaces. Exhaust gases

are poisonous.

Petrol is extremely inflammable and in certain conditions may explode. Smoking must not be allowed in the

work area, nor should there be naked flames or sparks.

MAINTENANCE REGULATIONS

- Use genuine DERBI spare parts and lubricants recommended by the manufacturer. Non-genuine or unau-

thorised parts may damage the engine.

Always use new gaskets and oil seals during re-assembly.

After dismantling, clean the components with solvents that are non-inflammable or with a high flammability

point. Lubricate all working surfaces before assembling, excluding tapered joints.

After assembly, check that all components have been correctly fitted and that they are functioning perfectly.

For dismantling, checking and assembly operations, use only tools with metric measurements. Metric screws,

nuts and bolts are not interchangeable with imperial measurement joining devices. Using unsuitable tools

and joining devices may damage the engine.

- In the case of work on the engine involving the electrical circuitry, check that electrical connections have

been correctly fitted.

N.B.

Indicates a note that gives key information to make the procedure easier and clearer.

ATTENTION

Indicates specific procedures that must be carried out to avoid damage to the machine.

WARNING

Indicates specific procedures that must be followed to avoid possible accidents to the person repairing the

machine.

GU O S

SGUOS

MAINTENANCE

REGULATIONS

9

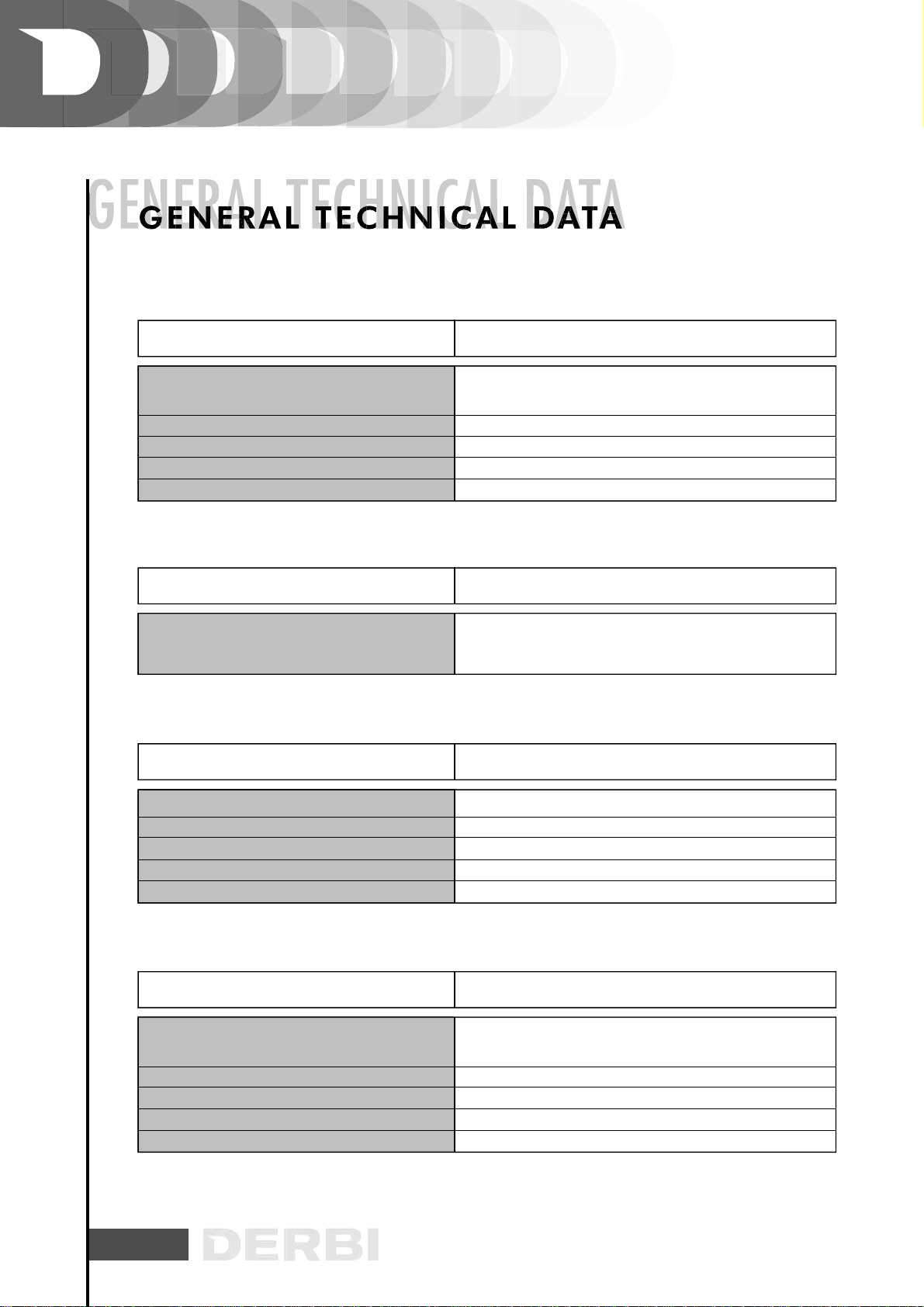

CHARACTERISTIC DIMENSION/VALUE

Maximum length

Maximum height

Length between axles

Handlebar width

Handlebar height

Total weight of machine

GP1 50 c.c. C451M

GP1

50

c.c.

MACHINE ENGINE PREFIX FRAME PREFIX

VTHPR1A1A

DIMENSIONS AND WEIGHT

1875 mm.

1212 mm.

1338 mm.

705 mm.

1050 mm.

117 kg.

CHARACTERISTIC DIMENSION/VALUE

Engine type

Diameter per stroke

Cubic capacity

Compression ratio

Carburettor

CO regulation

Tick over

Air filter

Ignition system

Lubrication

ENGINE

Single cylinder 2-stroke

40 x 39.3 mm

49.40 cm3

11.3 ÷ 12.8 :1

DELL’ORTO PHVA 17,5 ID

3.5%±0.5

1800 ÷ 2000 rpm

Sponge soaked in oil for filters.

Electric starter motor.

Carried out using the mixture oil, and variable depen-

ding on the engine revs and the throttle butterfly valve

aperture by means of a pump driven by the crankshaft

by way of a toothed belt.

10

Fuel tank capacity

Fuel reserve capacity

Oil tank capacity

Oil reserve capacity

Cooling system capacity

7.7 l

2.7 l

1.75 l

0.25 l

1.0 l

CHARACTERISTIC DIMENSION/VALUE

Alimentación

Sistema de refrigeración

Embrague

Piñón salida cambio

Plato de arrastre

ENGINE

By forced circulation of liquid.

Dry automatic centrifugal

Z 19

Z 45

Depression fuel pump supplying lead free petrol via the

carburettor.

CHARACTERISTIC DIMENSION/VALUE

Transmission

TRANSMISSION

Automatic speed variator with expandable pulleys, tra-

pezoidal belt, automatic clutch, gear reducer.

CHARACTERISTIC DIMENSION/VALUE

CAPACITY

CHARACTERISTIC DIMENSION/VALUE

Ignition system

Ignition advance (before T.D.C.)

Spark plug

Battery

Main fuse

ELECTRICAL SYSTEM

17º a 4000 rpm

CHAMPION RN1C

12 V 6 Ah

7.5 A

Electronic 12v 88 W with central intermittence unit +

check control

11

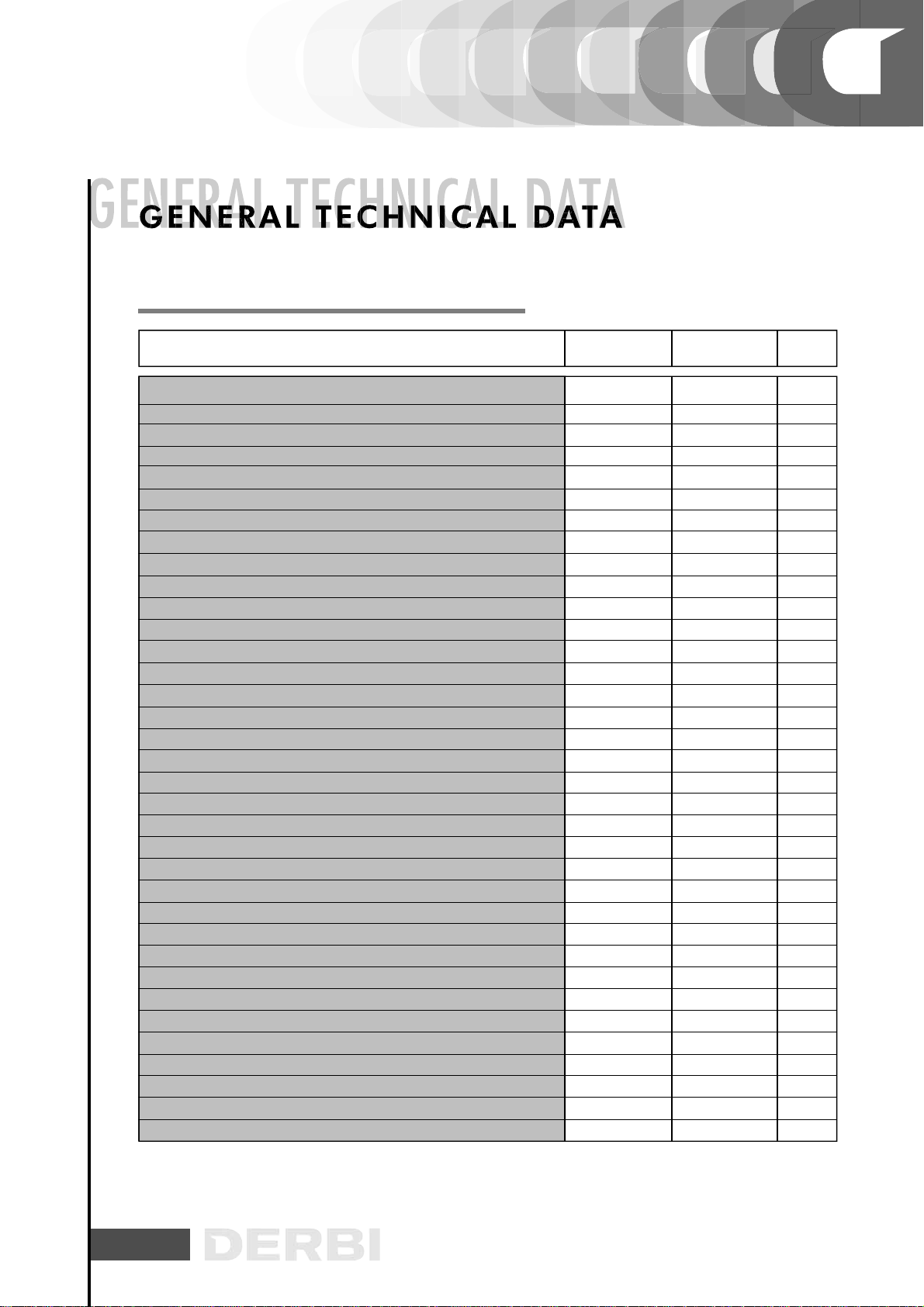

Frame

Front suspension

Diameter / Travel

Oil capacity

Oil type

Rear suspension

Travel

Aluminium, Delta Box type

Telescopic forks with inverted bars

35 mm / 80 mm

95 c.c.

SAE 7,5 W

Swinging arm with single shock absorber.

80 mm

CHARACTERISTIC DIMENSION/VALUE

FRAME AND SUSPENSIONS

Front brake

Front disk diameter

Rear brake

Rear disk diameter

Brake fluid type

Hydraulically operated disk

245 mm

Hydraulically operated disk

180 mm

DOT 4

CHARACTERISTIC DIMENSION/VALUE

BRAKING SYSTEM

Front wheel type

Front tyre inflated pressure.

Rear wheel type

Rear tyre inflated pressure

120 / 70 x 14in (tubeless)

190 kPa / 200 kPa (with pillion passenger)

140 / 60 x 14in (tubeless)

200 kPa / 220 kPa (with pillion passenger)

CHARACTERISTIC DIMENSION/VALUE

WHEELS AND TYRES

Type

Diameter of diffuser

Main jet

Minimum air jet

Carburettor needle setting

Needle position (slots from above)

DELL’ORTO PHVA 17.5 ID

Ø 17.5 mm

53

Ø 1.5 mm

A22

1

CHARACTERISTIC DIMENSION/VALUE

CARBURETTOR

12

Emulsifier

Idle jet

Minimum air jet

Secondary minimum air orifice

Minimum mixture screw initial opening

Choke jet

Choke air jet

Choke needle travel

Fuel entry orifice

209HA

32

Libre

Ø 2.5 mm

1 1/2

50

Ø 1.5 mm

11 mm

Ø 1.0 mm

CHARACTERISTIC DIMENSION/VALUE

CARBURETTOR

13

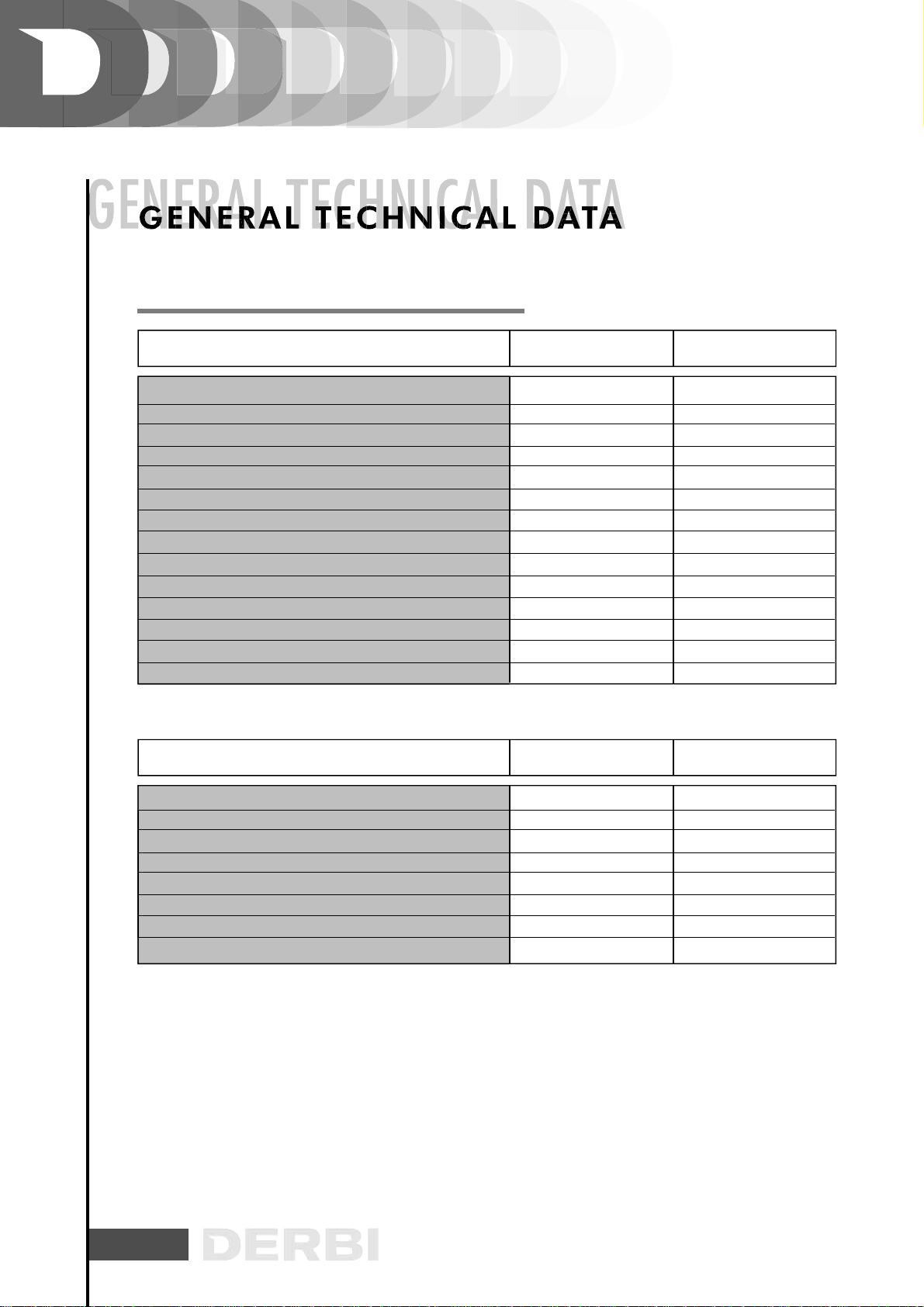

CHASSIS TIGHTENING TORQUES

Top shock absorber - chassis securing device M10x150 8.8

Bottom shock absorber – engine securing device M10x150 8.8

Engine Silent bloc – chassis securing device M10x150 8.8

Engine support securing bolt M10x150 8.8

Engine rear – support securing device M8x125 8.8

Engine rear support - chassis securing device M10x150 8.8

Engine rear Silent bloc clamp securing device M6x100 8.8

Swinging arm securing device M14x200

Change output pinion bush securing device M16x125

Change output pinion securing device M35x100

Filter box – engine securing device M6x100

Horn – chassis securing device M6x100

Steering forks – chassis securing device M24x100

Exhaust pipe –cylinder securing device M6x100 8.8

Exhaust pipe –crankcase securing device M8x125 8.8

Steering lock – chassis securing device M6x100 8.8

Handlebars – steering forks securing device M6x100 8.8

Handlebar clamp securing device M8x125 8.8

Counterweight- handlebars securing device M5x80 8.8

Front wheel – forks securing device M14x200

Fork arm lock securing device M8x125

Brake disk – front wheel securing device M6x100

Brake disk calliper – forks securing device M10x1.5

Rear wheel securing device M14x200

Drag plate – wheel securing device M6x100 10.9

Brake disk – rear wheel securing device M8x125 10.9

Prop stand – chassis securing device M8x125

Brake puller securing device M10x150 10.9

Gripper – chassis securing device M8x125 8.8

Radiator - chassis securing device M6x100

Various metal elements to chassis securing device M5x80

Various metal elements to chassis securing device M6x100

Various metal elements to chassis securing device M8x125

Various plastic elements to chassis securing device M6x100

Various plastic elements to chassis securing device M6x100

30 ÷ 40

30 ÷ 40

30 ÷ 40

20 ÷ 30

17 ÷ 19

30 ÷ 40

8 ÷ 10

70 ÷ 80

115 ÷ 125

115 ÷ 125

8 ÷ 10

8 ÷ 10

90 ÷ 130

9 ÷ 12

17 ÷ 19

8 ÷ 10

17 ÷ 19

17 ÷ 19

3.5 ÷ 4.5

35 ÷ 50

15 ÷ 19

8 ÷ 10

35 ÷ 40

70 ÷ 80

10 ÷ 12

25 ÷ 29

15 ÷ 19

35 ÷ 40

17 ÷ 19

8 ÷ 10

3.5 ÷ 4.5

8 ÷ 10

15 ÷ 19

1 ÷ 2

2 ÷ 3.5

DESCRIPTION TORQUES (N.M)

3 ÷ 4

3 ÷ 4

3 ÷ 4

2 ÷ 3

1.7 ÷ 1.9

3 ÷ 4

0.8 ÷ 1

7 ÷ 8

11.5 ÷ 12.5

11.5 ÷ 12.5

0.8 ÷ 1

0.8 ÷ 1

9 ÷ 13

0.9 ÷ 1.2

1.7 ÷ 1.9

0.8 ÷ 1

1.7 ÷ 1.9

1.7 ÷ 1.9

0.35 ÷ 0.45

3.5 ÷ 5

1.5 ÷ 1.9

0.8 ÷ 1

3.5 ÷ 4

7 ÷ 8

1 ÷ 1.2

2.5 ÷ 2.9

1.5 ÷ 1.9

3.5 ÷ 4

1.7 ÷ 1.9

0.8 ÷ 1

0.35 ÷ 0.45

0.8 ÷ 1

1.5 ÷ 1.9

0.1 ÷ 0.2

0.2 ÷ 0.35

TORQUES (M.KG)

•

•

•

•

•

•

SEALER

14

12 ÷ 13

8 ÷ 9

1 ÷ 2

3.5 ÷ 5

3 ÷ 4

4 ÷ 5

3 ÷ 4

12 ÷ 13

ENGINE TIGHTENING TORQUES

Clutch bell housing nut

Clutch locking nut

Nut for locking the driving pulley on the crankshaft

Kick start lever bolt

Magneto nut

Magneto fan bolts

Crankcase halves joining bolts

Bolts for securing exhaust pipe to the crankcase

Bolts for securing the filter box to the crankcase

Cylinder head nuts

Starter motor bolts

Spark plug

Oil sump drain plug

Rear hub cover bolts

DESCRIPTION TORQUES (N.M) TORQUES (M.KG)

40 ÷ 44

55 ÷ 60

40 ÷ 44

12 ÷ 13

40 ÷ 44

3 ÷ 4

12 ÷ 13

22 ÷ 24

4 ÷ 5

10 ÷ 11

12 ÷ 13

25 ÷ 30

3 ÷ 5

12 ÷ 13

4 ÷ 4.4

5.5 ÷ 6

4 ÷ 4.4

1.2 ÷ 1.3

4 ÷ 4.4

0.3 ÷ 0.4

1.2 ÷ 1.3

2.2 ÷ 2.4

0.4 ÷ 0.5

1 ÷ 1.1

1.2 ÷ 0.3

2.5 ÷ 3

0.3 ÷ 0.5

1.2 ÷ 1.3

DESCRIPTION TORQUES (N.M) TORQUES (M.KG)

1.2 ÷ 1.3

0.8 ÷ 0.9

0.1 ÷ 0.2

0.35 ÷ 0.5

0.3 ÷ 0.4

0.4 ÷ 0.5

0.3 ÷ 0.4

1.2 ÷ 1.3

Transmission cover bolts

Suction collector bolts

Magneto cover securing bolts

Cylinder casing securing bolts

Stator securing bolt

Pick-up securing bolt

Mixer securing bolt

Bolt securing brake pedal to shaft in the engine

15

CONECTION PISTON AND CYLINDER

Standard fitting

Standard fitting

Standard fitting

Standard fitting

1st oversize fitting

1st oversize fitting

1st oversize fitting

1st oversize fitting

2nd oversize fitting

2nd oversize fitting

2nd oversize fitting

2nd oversize fitting

NAME PLAY

<⁄>

<⁄>

<⁄>

<⁄>

<⁄>

<⁄>

<⁄>

<⁄>

<⁄>

<⁄>

<⁄>

<⁄>

INITIALS

M

N

O

P

M1

N1

O1

P1

M2

N2

O2

P2

CYLINDER

39,997-40,004

40,004-40,011

40,011-40,018

40,018-40,025

40,197-40,204

40,204-40,211

4,211-40,218

40,218-40,225

40,397-40,404

40-404-40,411

40-411-40,418

40,418-40,425

PISTON

39,943-39,95

39,95-39,957

39,957-39,964

39,964-39,971

40,143-40,15

40,15-40,157

40,157-40,164

40,164-40,171

40,343-40,35

40,35-40,357

40,357-40,364

40,364-40,371

PLAY ON FITTING

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

0,047-0,061

PISTON RINGS

Compression lining

Compression lining 1˚ Greater

Compression lining 2˚ Greater

NAME DIMENSIONS

40

40,2

40,4

INITIALS

A

A

A

QUANTITY

0,10 ÷ 0,25

0,10 ÷ 0,25

0,10 ÷ 0,25

DESCRIPTION

16

END PLAY BETWEEN CRANKCASE, CRANKSHAFT AND CONNECTING ROD

Connecting rod

Packing washer

Half shaft transmission side

Half shaft flywheel side

Spacing between shoulders

Cage

NAME DIMENSIONS

11,750 ÷ 0,05

0,5 ÷ 0,03

13,75 ÷ 0,040

13,75 ÷ 0,040

40,64

11,80 ÷ 0,35

INITIAL

A

G

C

D

H

B

C

onnectin

g

rod

P

ac

ki

ng was

h

er

Ha

lf

s

h

a

ft tr

a

n

s

mi

ss

i

o

n

s

i

de

H

alf shaft fl

y

wheel sid

e

S

pac

i

ng

b

etween s

h

ou

ld

ers

C

a

ge

QUANTITY

Play E=0,25÷0,50

Play F= 2,20÷0,75

DESCRIPTION

Play E=0,25÷0,50

Play F= 2,20÷0,75

Play E=0,25÷0,50

Play F= 2,20÷0,75

Play E=0,25÷0,50

Play F= 2,20÷0,75

Play E=0,25÷0,50

Play F= 2,20÷0,75

Play F= 2,20÷0,75

SLOT PACKING SYSTEM

- Fit the cylinder without positioningthe base gasket

- Position a dial gauge on the special tool and zeri it on rectified surface.

- Fis the tool on the top of the cylinder using two nuts to fix it to the studs and then bring the piston to T.D.C.

- The gasket thickness to be adopted varies with the measurement. For this reason gaskets with three diffe-

rent thicknesses ara available as spares.

Specific tooling

020272Y Tool for checking the piston of the piston.

S

LOT

PACKING

S

YSTEM

17

SISTEMA DE MONTAJE DE ESPESORES

Packing

Packing

Spacing

NAME THICKNESS

0,4

0,6

0,8

MEASURE A

2,80 ÷ 3,04

3,04 ÷ 3,24

3,24 ÷ 3,48

18

PPREPARATION FOR REMOVAL AND DISMANTLING

1. Remove all the dirt, grime, dust and other foreign material

before removing and dismantling.

2. Use properly cleaned tools and equipment.

See “SPECIAL TOOLS”.

3. On dismantling the motorcycle, always keep paired parts

together. This includes gears, cylinders, pistons and other

parts submitted to natural wear in pairs. Paired parts must

always be reassembled or replaced together.

4. While dismantling the motorcycle, clean all the parts and

lay them out on trays in the order dismantled. This speeds up

reassembly and ensures the correct fitting of all the parts.

5. Keep all parts away from any contact with fire.

P

PREPARATION

FOR

REMOVAL

AND

DISMANTLING

19

REPLACEMENT PARTS

1. Use only genuine DERBI spare parts. For all lubrication

tasks use oils and greases recommended by DERBI. Other

makes make seem similar in their function and appearance,

but are inferior in quality.

SEALS, RETAINING RINGS AND O-RINGS

1. Replace all seals, retaining rings and O-rings when servi-

cing the engine.

All surfaces receiving seals, retaining ring edges and O-rings

must be cleaned.

2. Apply oil to all paired parts and bearing during reassem-

bly. Apply grease to the retaining ring edges.

TAB/SPACER WASHERS AND SPLIT PINS

1. After removing them, replace all tab/spacer washers (1)

and split pins Bend the tabs to fit the flat surfaces of the

bolt or nut once they have been tightened to the specified

torque.

BEARINGS AND RETAINING RINGS

1. Fit bearings and retaining rings in such a way that the ma-

nufacturers marks remain visible. On fitting retaining rings,

applying a thin film of light lithium soap based grease to

their edges. Where required, apply oil generously when fit-

ting bearings.

WARNING

DO NOT USE COMPRESSED AIR TO DRY BEARINGS. THIS

DAMAGES THE BEARING SURFACES.

C S

SEALS,

RETAINING

RINGS

AND

O RINGS

/SC SS S S

GS GGS

Table of contents

Other Derbi Motorcycle manuals

Derbi

Derbi GPR 125 Racing Instruction manual

Derbi

Derbi Dirtboy 10 Instruction manual

Derbi

Derbi SENDA R DRD PRO 50 c.c. User manual

Derbi

Derbi GPR 125 Racing Instruction manual

Derbi

Derbi SENDA R/SM 125 4T Baja User manual

Derbi

Derbi RAMBLA 250 i.e. 2008 User manual

Derbi

Derbi SENDA 50 DRD RACING X-TREME User manual

Derbi

Derbi GPR 50 2009 User guide

Derbi

Derbi Senda DRD Evo 50 SM User manual

Derbi

Derbi X-TREME R/SM User manual