Derbi GPR 125 Racing Instruction manual

WORKSHOP MANUAL

GPR 125 4-stroke

INTRODUCTION ...................................................................

SAFETY REGULATIONS ......................................................

MAINTENANCE REGULATIONS .......................................

SPECIAL TOOLS FOR THE ENGINE ..................................

SPECIAL TOOLS - CHASSIS ..............................................

TECHNICAL DATA ...............................................................

TIGHTENING TORQUES .....................................................

PDI (Pre-delivery inspection) .................................................

LOCATION OF ELEMENTS .................................................

REMOVING BODYWORK ELEMENTS ................................

PERIODICAL MAINTENANCE TABLE .................................

LUBRICATION POINTS .......................................................

INSPECTION AND MAINTENANCE ..................................

INSPECTION AND MAINTENANCE .................................

IDENTIFICATION OF SETS ...................................................

REMOVING THE ENGINE FROM THE FRAME ...................

DISMANTLING THE ENGINE ...............................................

INSPECTING THE ENGINE ELEMENTS ...............................

ASSEMBLING THE ENGINE ..................................................

FITTING THE ENGINE INTO THE FRAME ...........................

DISMANTLING THE CARBURETTOR ...................................

ASSEMBLING THE CARBURETTOR ......................................

CHECKING LEVEL OF THE FLOAT CHAMBER ...................

CHECKING THE VACUM VALVE AND TAPERED NEEDLE

...........

CHECKING THE AUTOMATIC CHOKE ..............................

ENGINE

4

9

10

13

16

17

26

31

34

36

48

51

52

83

85

89

91

104

119

150

155

160

164

164

166

FUEL

SYSTEM

CONTENTS

4

5

MAINTENANCE

3

1

GENERAL

INFORMATION

0

2

COOLING

SYSTEM

CHASSIS

BRAKE SYSTEM

CONTENTS

DIAGRAM OF THE SYSTEM ..................................................

DESCRIPTION OF THE SYSTEM AND CHECKING OF ELEM

....

RENEWING THE WATER PUMP OIL SEAL

..........................

DIAGRAM OF THE SYSTEM ..................................................

DESCRIPCIÓN OF THE LUBRICATION SYSTEM ................

INSPECTING THE WHEELS ...................................................

FRONT WHEEL .......................................................................

FRONT SUSPENSION ...........................................................

STEERING ................................................................................

REAR WHEEL ...........................................................................

REAR SUSPENSION ...............................................................

FRONT BRAKE ........................................................................

REAR BRAKE ............................................................................

GENERAL INDICATIONS ......................................................

LOCATING ELECTRICAL COMPONENTS ..........................

WIRING DIAGRAM ................................................................

CHARGING SYSTEM .............................................................

IGNITION SYSTEM ................................................................

STARTER MOTOR SYSTEM ....................................................

INSTRUMENT PANEL .............................................................

LIGHTING AND INDICATING .............................................

FITTING NEW COMPONENTS ............................................

INSPECTING THE BATTERY AND FUSES ............................

6

7

8

9

10

169

171

175

179

181

185

187

189

195

198

200

203

211

221

223

224

225

226

227

228

235

241

245

LUBRICATING

SYSTEM

ELECTRICAL SYSTEM

4

0

- INTRODUCTION

Particularly important items of information in this manual are distinguished by the following annota-

tions:

Indicates a serious possibility of suffering SEVERE PERSONAL INJURIES OR DEATH if the instructions are

not followed.

Indicates the possibility that the ELEMENT WILL BE DAMAGED if the instructions are not followed.

Presents USEFUL INFORMATION.

This manual has been produced by Nacional Motor, S.A.U. for use by DERBI dealer and sub-agency works-

hops. It is assumed that those using this publication for training purposes and for repairing DERBI machines

have a basic knowledge of mechanics and of the methods inherent in the technique of vehicle repair. Signifi-

cant variations in the characteristics of the machines or in the specific repair operations will be communicated

by means of updates to this manual.

Completely satisfactory work cannot however be carried out without the availability of suitable facilities

and tools, which is why we ask you to consult the pages of this manual referring to special tools and imple-

ments.

NACIONAL MOTOR, S.A.U.

CAUTION

The DERBI logo is the registered trademark and property of DERBI - Nacional Motor, S.A.U.

The total or partial reproduction of any photograph, graphical image or text inserted in this manual is prohibited.

© 2009 DERBI - Nacional Motor, S.A.U.

Created by: www.ciandisseny.com

WARNING

N.B.

5

0

-

I

NTRODUCTION

The aim of this manual is to provide the mechanic with a handy and easy to use reference source. It contains

comprehensive explanations of all the installation, extraction, dismantling, assembly, repair and checking

procedures organized step by step in sequence.

Each chapter is divided into sections whose titles appear at the top of each page.

The titles of the subsections appear in a smaller format than the section titles.

Each operation is accompanied by photographs or illustrations.

Numbering corresponding to the chapter.

1

2

3

4

4

3

1

2

6

0

- INTRODUCTION

LEFT-HAND SIDE (facing forwards)

RIGHT-HAND SIDE (facing forwards)

VIEWS OF THE MACHINE

Whenever Right-hand or Left-hand Side are specified in this manual, it

is understood as meaning facing forward (i.e. in the riding direction).

N.B.

7

0

-

I

NTRODUCTION

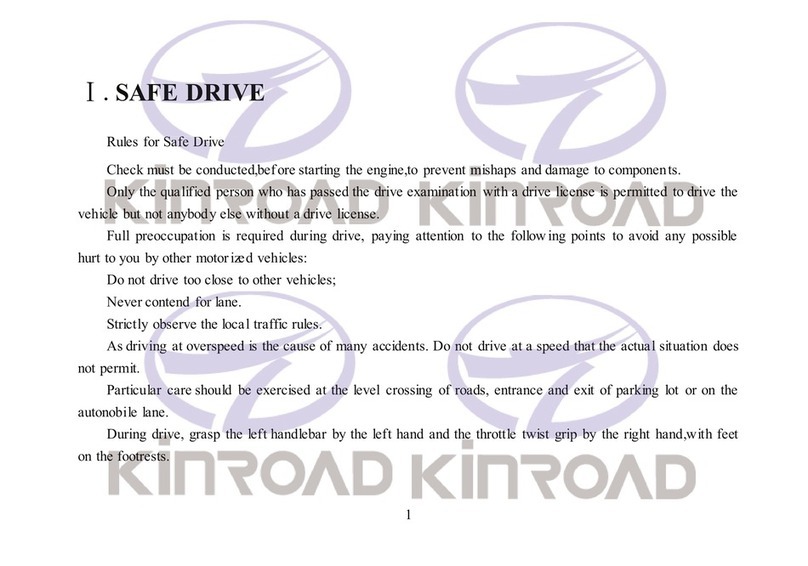

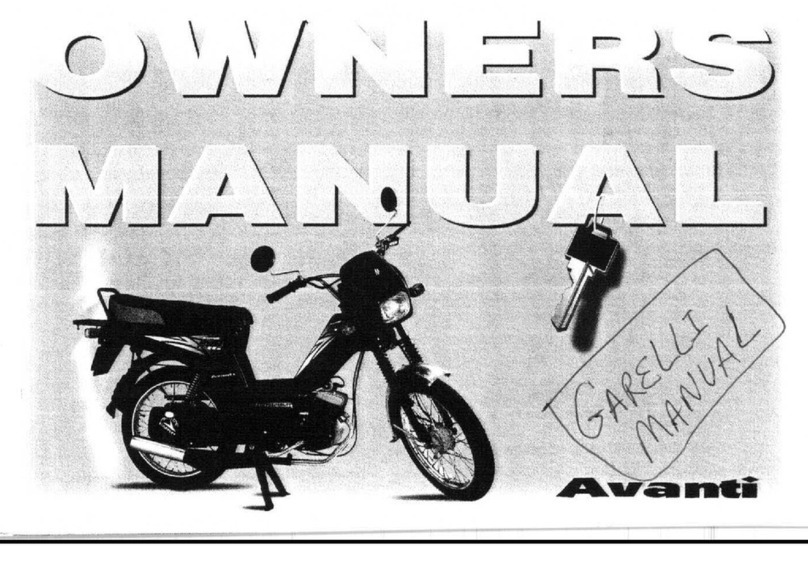

IDENTIFICATION OF THE MACHINE

FRAME SERIAL NUMBER

VTHRG1A1Axxxxxxxx

The frame serial number is located to the right

of the steering column.

MANUFACTURER’S PLATE

The manufacturer’s plate is located to the right

of the steering column.

It includes information about the exhaust

system’s noise emissions (useful in MOT inspec-

tions).

ENGINE SERIAL NUMBER

*xxxx*

The frame serial number is on the rear of

the chassis.

1

-

G

ENERAL INF

O

RMATI

O

N

8

1 - GENERAL INFORMATION

SAFETY REGULATIONS ............................................................

MAINTENANCE REGULATIONS .............................................

SPECIAL TOOLS FOR THE ENGINE .......................................

SPECIAL TOOLS FOR THE CHASSIS .......................................

TECHNICAL DATA ....................................................................

TORQUE TIGHTENING VALUES .............................................

9

10

13

16

17

26

1.1 -

1.2 -

1.3 -

1.4 -

1.5 -

1.6 -

1

-

G

ENERAL INF

O

RMATI

O

N

9

1.1 - SAFETY REGULATIONS

- In the event of having to carry out work on the machine while the engine is running, ensure that the work

area is well ventilated, where possible using suitable extractor fans. Never leave engines running in closed

spaces. The exhaust gases produced contain CO (carbon monoxide) which can cause loss of consciousness

and can lead to death when inhaled.

- The battery electrolyte contains sulphuric acid. Protect eyes, clothing and skin. Sulphuric acid is highly co-

rrosive; in the event of contact with the eyes or skin, wash with copious amounts of water and seek medical

attention immediately. If electrolyte is swallowed accidentally, drink copious amounts of water or milk and seek

medical attention immediately.

- The battery produces hydrogen, a gas that can be highly explosive. Do not smoke, and avoid flames or sparks

close to the battery, especially during battery charging operations.

- Avoid prolonged contact of used engine oil with the skin. Either wear gloves or wash your hands on finishing

handling used oil.

- Petrol is extremely inflammable, and in certain conditions can be explosive. Do not smoke, and avoid sparks

or other points of ignition in the work area.

- Clean brake pads in a well-ventilated place. DO NOT use compressed air to clean brake pads or brake calli-

pers. Although the dust does not contain asbestos, its inhalation can cause respiratory illnesses.

- Brake liquid attacks painted surfaces very aggressively. Protect painted elements with a clean cloth when

performing operations with brake fluid. Wear gloves if possible, since contact of brake fluid with the skin is not

advisable.

- Prevent coolant from spilling onto hot elements, since it produces an “invisible flame” which may lead to a

person receiving burns as a result of not seeing the flame.

- Do not remove the radiator cap when the engine is hot, since the coolant is under pressure and at a high

temperature, and may cause severe burning.

- If coolant enters the eyes, they must be washed immediately with cold water and medical attention sought.

- During normal functioning, the exhaust system and the engine are at a high temperature.

If work has to be carried out on these, either wait until they have cooled down or wear suitable gloves to avoid

being burnt.

WARNING

1

-

G

ENERAL INF

O

RMATI

O

N

10

1.2 - MAINTENANCE REGULATIONS

- Use genuine DERBI spare parts and lubricants recommended by DERBI. Non-genuine or unauthorised parts

may damage the machine.

- Only use the specific tools intended for this machine.

- During re-assembly, always use new oil seals, gaskets, piston rings and grommets.

- After dismantling, clean the components with solvents that are non-inflammable or that have a high flam-

mability point. Grease all working surfaces before assembling, excluding tapered joints.

- After assembly, check that all components have been correctly fitted and that they are functioning perfectly.

- For dismantling, checking and re-assembly operations use only tools with metric measurements. Metric

screws, nuts and bolts are not interchangeable with imperial measurement joining devices. Using unsuitable

tools and joining devices may damage the machine.

- In the case of work on the machine’s electrical circuitry, check that electrical connections have been correc-

tly fitted, especially the earth connections.

Use only genuine DERBI spare parts. For all lubrication tasks use

oils and greases recommended by DERBI. Other makes make

seem similar in their function and appearance, but are inferior

in quality.

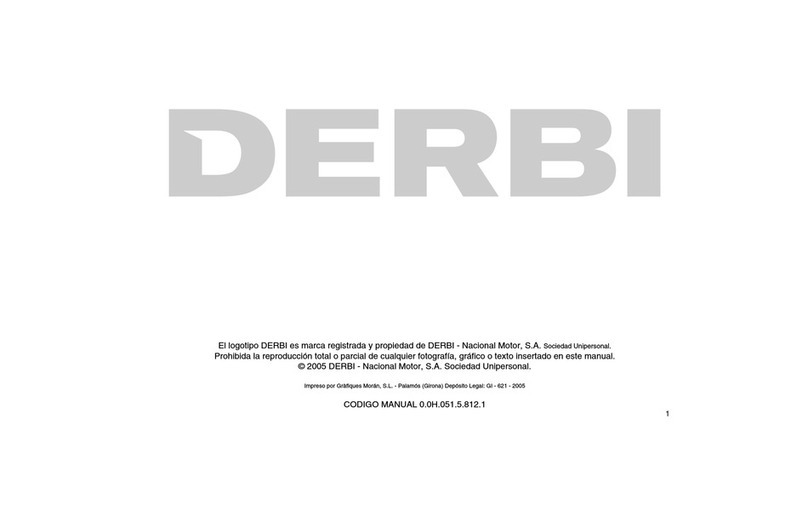

Examine all the locking rings carefully before fitting. Always re-

place the gudgeon pin circlips after every use. Replace distorted

locking rings. On fitting a locking ring (1), ensure that the sharp

edge (2) is on the opposite side to the force (3) to be applied to

it.

See the figure on the side, (4) Axle.

CAUTION

N.B.

1

-

G

ENERAL INF

O

RMATI

O

N

11

Replace all seals, retaining rings and O-rings when servicing the

engine. All surfaces receiving seals, retaining ring edges and O-

rings must be cleaned.

Apply oil to all paired parts and bearing during reassembly.

Apply grease to the retaining ring edges. After removing them,

replace all tab/spacer washers (1) and split pins. Bend the tabs

to fit the flat surfaces of the bolt or nut once they have been

tightened to the specified torque.

WHEN FITTING BEARINGS, EN-

SURE THAT THE SAME PRESSURE

IS APPLIED TO BOTH RACES TO

AVOID DAMAGING THEM.

Fit bearings and retaining rings in such a way that the manufac-

turers marks remain visible. On fitting retaining rings, applying

a thin film of light lithium soap based grease to their edges.

Where appropriate, apply oil generously when fitting bearings.

DO NOT USE COMPRESSED AIR

TO DRY BEARINGS. THIS WILL DA-

MAGE THE BEARING SURFACES.

Remove all the dirt, grime, dust and other foreign material befo-

re removing and dismantling.

N.B.

CAUTION

CAUTION

1

-

G

ENERAL INF

O

RMATI

O

N

12

Use properly cleaned tools and equipment.

See “SPECIAL TOOLS”.

On dismantling parts, always keep paired items together.

This includes gears, cylinders, pistons and other parts submitted

to natural wear in pairs. Paired parts must always be reassem-

bled or replaced together.

While dismantling the motorcycle, clean all the parts and lay

them out on trays in the order dismantled. This speeds up reass-

embly and ensures the correct fitting of all the parts.

KEEP ALL PARTS WELL AWAY FROM

ANY SOURCE OF IGNITION (CIGA-

RETTES, FLAMES, SPARKS, ETC.).

CAUTION

N.B.

WARNING

1

-

G

ENERAL INF

O

RMATI

O

N

13

1.3 - SPECIAL TOOLS FOR THE ENGINE

The following special tools are needed for assembly and for com-

plete and exact adjustments. Only use the proper special tools;

thereby avoiding damage caused by the use of unsuitable tools

or improvised techniques.

Ref. 864486

Camshaft sprocket locking tool.

Ref. 864487

Crankshaft sprocket locking tool.

Ref. 864567

Set of camshaft locking keys.

Ref. 864592

TDC measuring tool (must be accompanied by a dial depth gauge).

This is used to calculate the thickness of the cylinder base gasket

to be used.

1

-

G

ENERAL INF

O

RMATI

O

N

14

Ref. 865207

Set of tools for 125cc 4-stroke 4v engine.

THE SET OF TOOLS FOR THE ENGI-

NE DOES NOT INCLUDE TOOL REF.

866380.

Ref. 865259

Camshaft crown wheel locking tool.

Ref. 865260

Magneto flywheel locking tool.

Ref. 865261

Tool for supporting piston.

N.B.

1

-

G

ENERAL INF

O

RMATI

O

N

15

Ref. 866380

Tool kit (A-B-C) for extracting and fitting water pump oil seal.

Ref. 00H05300041

Clutch bell housing locking tool.

Ref. 864868

Magneto flywheel extractor tool.

1

-

G

ENERAL INF

O

RMATI

O

N

16

1.4 - SPECIAL TOOLS - CHASSIS

The following special tools are needed for assembly and for com-

plete and exact adjustments. Only use the proper special tools;

thereby avoiding damage caused by the use of unsuitable tools

or improvised techniques.

Ref. 866714

Tool for adjusting the swinging arm nut.

1

-

G

ENERAL INF

O

RMATI

O

N

17

1.5 - TECHNICAL DATA

GENERAL

MACHINE DIMENSIONS

Distance between wheel shafts

Length

Wide

High

Weight

ENGINE

Diameter x stroke

Cubic capacity

Power

Type

Timing

Compression ratio

Cylinder material

Cylinder head material

Type of lubrication

Cooling

Idling

Gearchange

Final transmission

Polluting emissions reduction system

OTHER PARTS OF THE MOTORCYCLE

Type of chassis

Steering angle

Front suspension

Front suspension travel

Rear suspension

Rear suspension travel

Swinging arm

Front tyre

Rear tyre

Make and model of tyres

Front brake

Rear brake

POWER SUPPLY

Carburettor

TRANSMISSION

Clutch type

Primary transmission ratio

1st gear ratio

2nd gear ratio

3rd gear ratio

4th gear ratio

5th gear ratio

6th gear ratio

Final transmission ratio

Type of chain

1353 mm

1968 mm

720 mm

810 mm

135 Kg

58 mm. x 47 mm

124,2 cm3

15 HP at 9.250 rpm

Single cylinder 4-stroke, 4 valves, Euro 3

Double overhead camshaft (DOHC) chain driven

12:1

Cast iron

Cast aluminium

Semi-wet crankshaft

Liquid

1680 ±50 rpm

Manual, 6 gears

Chain driven

Secondary air system and 2-way catalyser

Double beam of injected aluminium alloy

25º

41 mm Ø inverted hydraulic forks

110 mm

Single shock absorber

135 mm

Double asymmetrical aluminium arm

100/80x17” Tubeless type

130/70X17” Tubeless type

Pirelli Sport Demon

300mm Ø disk

220mmØ disk

Keihin CVK Ø30

Multi-disk in oil bath

(5 driving disks and 4 driven disks).

24/73=1/3,04

11/33=1/3

15/30=1/2

18/27=1/1,5

20/24=1/1,2

25/27=1/1,08

23/22=1,045

14/49=1/3,50

With coupling and 130 links

1

-

G

ENERAL INF

O

RMATI

O

N

18

GENERAL

ELECTRICAL SYSTEM

Spark plug

Gap between electrodes (plug gap)

Charging system

Regulated voltage to battery

Ignition system

Battery

Starting system

CAPACITIES AND TYPES OF FLUIDS

Periodical engine oil change (with oil filter)

Total engine oil (complete dismantling of the engine)

Type of engine oil recommended

Engine oil viscosity

Petrol

Fuel tank capacity

Coolant in radiator

Coolant in expansion chamber (up to max.)

Recommended coolant

Brake fluid

NGK CR8 EB

0,7÷0,8 mm

Three-phase magneto

13v-15v at 8.000 rpm

Electronic CDI type

FTX7L-BS, 12v - 6Ah (MF type)

Electric

1150 ml

1200 ml

AGIP TECH 4T

SAE 10W-40

Lead free 95 octane

14,5 litres

780 ml

230 ml

AGIP PLUS 30%

DOT 4

1

-

G

ENERAL INF

O

RMATI

O

N

19

ENGINE

PISTON DIAMETER (D) CAT M

CAT N

CAT O

CAT P

EXT. DIAMETER MEASUREMENT POINT PISTON (C)

DIAMETER OF PISTON GUDGEON PIN ORIFICE (E)

DIAMETER OF PISTON GUDGEON PIN (a)

Standard

Service limit

PISTON RING TYPE

1st compression ring

Type

Dimension (BxT)

2nd compression ring

Type

Dimension (BxT)

3rd oil scraper ring

Dimension (BxT)

PISTON RING GAP

1st compression ring

2nd compression ring

3rd oil scraper ring

57,953-57,960 mm

57,960-57,967 mm

57,967-57,974 mm

57,974-57,981 mm

7,5 mm

15,003-15,008 mm

14,997-15,00 mm

14,995 mm

Tapered

1 x 2,5 mm

Tapered

1,2 x 2,5 mm

2 x 2,5 mm

0,2-0,35 mm

0,2-0,35 mm

0,2-0,7 mm

C

D

B

T

T

B

B

T

E

1

-

G

ENERAL INF

O

RMATI

O

N

20

ENGINE

CYLINDER DIAMETER CAT M

CAT N

CAT O

CAT P

CYLINDER WARP

CYLINDER-PISTON ASSEMBLY

CYLINDER HEAD WARP SET

ENGINE COMPRESSION VALUE

Standard

Minimum

VALVE ADJUSTMENT VALUE

Inlet (engine cold below 35ºC)

Exhaust (engine cold below 35ºC)

MAXIMUM CAMSHAFT WARP

Inlet

Exhaust

MAXIMUM CAMSHAFT AXIAL PLAY

Inlet

Exhaust

CAM SIZE

Inlet “A”

Inlet “B”

Inlet (lifted) “C”

Exhaust “A”

Exhaust “B”

Exhaust (lifted) “C”

TIMING CHAIN

Type

Timing chain tensioner

58,010-58,017 mm

58,017-58,024 mm

58,024-58,031 mm

58,031-58,038 mm

0,05 mm

0,050-0,064 mm

0,05 mm

more than 15 kg/cm2

13 Kg/cm2

0,012 - 0,015 mm

0,015 - 0,020 mm

0,008 mm

0,008 mm

0,4 mm

0,4 mm

31,44-31,54 mm

23,95-24,05 mm

7,49 mm

30,81-30,91 mm

23,95-24,05 mm

6,86 mm

92RH2005 114 links

Automatic (ratchet)

B

A

C

Other manuals for GPR 125 Racing

1

Table of contents

Other Derbi Motorcycle manuals

Derbi

Derbi GP1 50 cc Instruction manual

Derbi

Derbi Dirtboy 10 Instruction manual

Derbi

Derbi GPR 125 Racing Instruction manual

Derbi

Derbi SENDA R/SM 125 4T Baja User manual

Derbi

Derbi SENDA R DRD PRO 50 c.c. User manual

Derbi

Derbi X-TREME R/SM User manual

Derbi

Derbi Senda DRD Evo 50 SM User manual

Derbi

Derbi RAMBLA 250 i.e. 2008 User manual

Derbi

Derbi SENDA 50 DRD RACING X-TREME User manual

Derbi

Derbi GPR 50 2009 User guide