Page 2 © 2011 Bosch Security Systems, Inc. DS935Z Installation Instructions

- The angle adjust markings are on the mirror. Slide the

mirror forward or back until the angle hash marks are in-

line with the markers on each side of the frame.

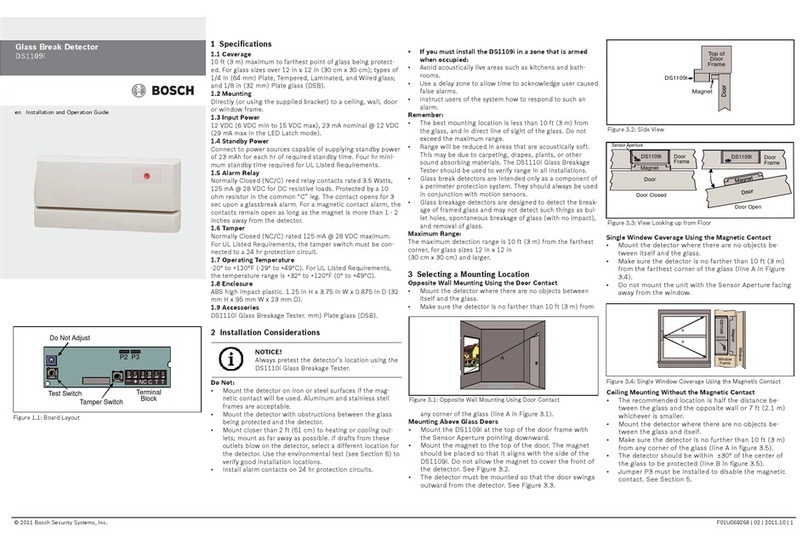

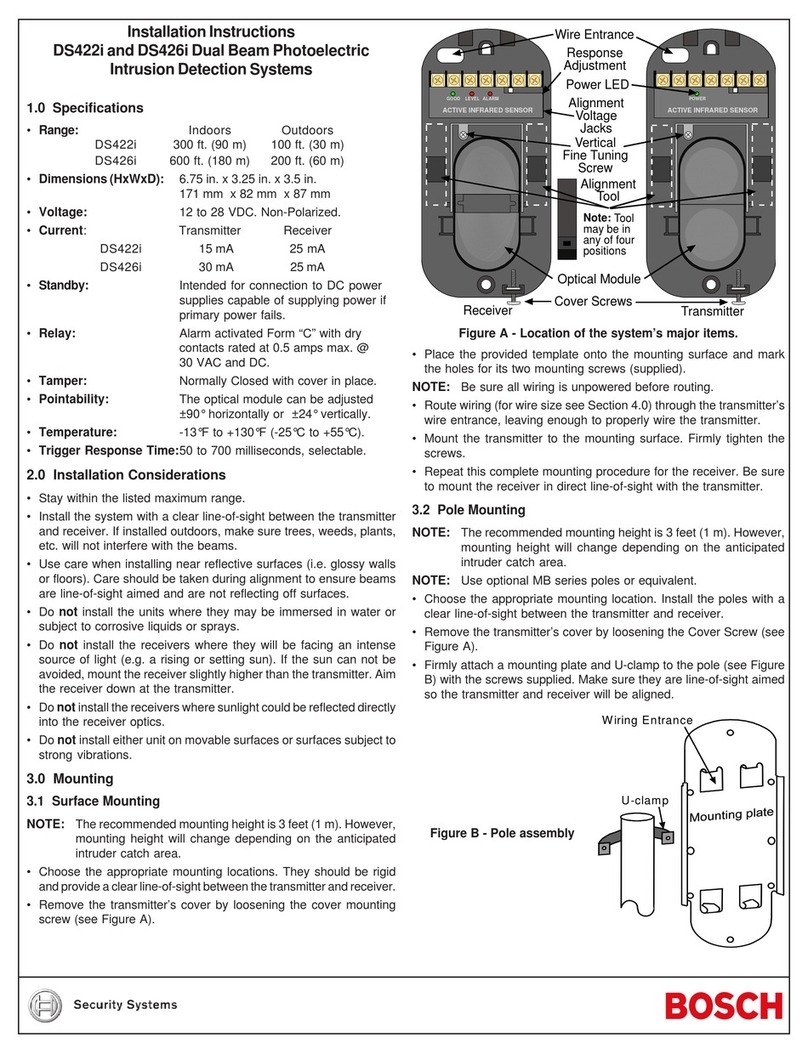

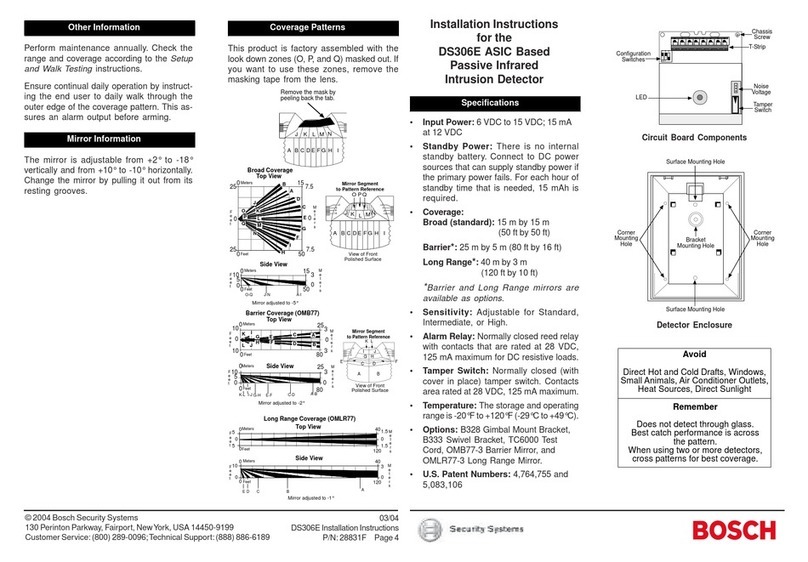

3.0 Wiring

Only apply power after all connections have been

made and inspected.

• Connect wiring as shown.

NOTE: Do not coil excess wiring inside unit.

• Seal the Wire Entrance using the foam plug provided.

Terminal Descriptions

•1 (-) & 2 (+): Input Power. Use no smaller than #22 AWG

(0.8 mm) wire pair.

•3, 4, 5: Form "C" reed relay contacts rated at 3 W, 125 mA,

28 VDC maximum for DC resistive loads and protected by a

4.7 ohm resistor in the common "C" leg of the relay. Do not use

with capacitive or inductive loads.

•6 & 7: Tamper Contact, rated 28 VDC, 125 mA.

•8: Trouble. Solid state open collector; maximum current load is

25 mA. Shorts to ground (-) when the detector is in a Trouble

condition.

5.0 Configuring Detector

1 ON = LED ON

1 OFF = LED OFF

2 ON = Standard

2 OFF = Intermediate

3 ON and 4 OFF = 4 Day Motion Monitor

3 OFF and 4 ON = 30 Day Motion Monitor

3 OFF and 4 OFF = Motion Monitor Disabled

OPEN

12 34

OFF

ON

(ON) 1

(OFF) 0

5.1 S1 - LED Operation

•ON: Allows the LED to operate when activated by alarm.

•OFF: The LED will not operate on alarm.

5.2 S2 - Sensitivity Mode

•Standard Sensitivity: Recommended setting for maximum

false alarm immunity. Tolerates environment extremes on this

setting. Not recommended for Long Range or Barrier type

patterns. The detector is shipped in Standard Sensitivity

mode.

•Intermediate Sensitivity: Recommendedsetting for anylocation

where an intruder is expected to cover only a small portion of the

protected area. Tolerates normal environments on this setting.

This setting will improve your intruder catch performance.

5.3 S3 and S4 - Motion Monitor:

Set for the desired Motion Monitor time (see Supervision

Features). The detector is shipped with the Motion Monitor

feature disabled.

6.0 Setup and Walk Testing

Before walk testing, the system should be fully wired,

powered, and programmed.

• Turn LED Switch ON.

• Replace the front cover.

NOTE: All testing must be performed with the front

cover in place.

• Wait at least two minutes (with no motion in the

coverage area) for the detector to setup.

• Walk test across the coverage pattern.

• The edge of the coverage is determined by activation of the

LED.

• Walk test the unit from both directions to determine the

boundaries.

7.0 Supervision Features

A supervision trouble condition is indicated at the detector by the

LED. The LED indicates the cause of the trouble using coded

pulses. The trouble signal activates the Trouble output available

at Terminal 8, which should be connected to a 24-hour zone.

The supervision features function as follows:

•PIR: PIRoperation is checkedelectronically approximately every

12 hours. If the circuit fails, the LED will pulse four times, the

Trouble output will activate and the unit must be replaced.

•Motion Monitor Supervision: This feature verifies that the

detector has a clear view of the detection area.

- When selected, a supervision timer is activated. A trouble

condition will be indicated if the detector has not alarmed at

least once during the selected time period (this feature can be

disabled by placing both switches [S3 and S4] in the OFF

position). The time period selected should be long enough to

allow adequate time for holiday weekends.

- If the time period selected has elapsed from the last alarm,

the LED will flash two times and the Trouble output will activate.

The following chart displays the LED response to the supervision

features: LED Cause

ON

Two Flashes

Four Flashes

Unit Alarm

Motion Monitor Timeout

PIR Self-Test Failure

(replace detector)

• Trouble Reset: An alarm activation will reset a motion monitor

trouble condition.

8.0 Maintenance

At least once a year, the range and coverage should be checked

in accordance with the Walk Testing section. To ensure continual

daily operation, the end user should be instructed to daily walk

through the outer edge of the coverage pattern and observe the

LED operation (if used). This assures an alarm output prior to

arming.

TR

-+

12345678

NO CNC TT

larm

larm