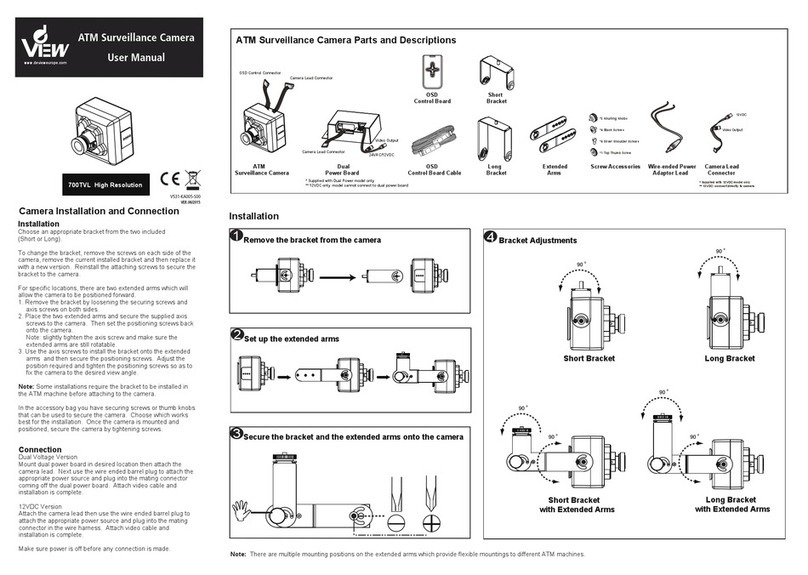

DeView VDM Series User manual

VDM Series

Metal Vandal Dome

Enclosure Installation Guide

RoHS

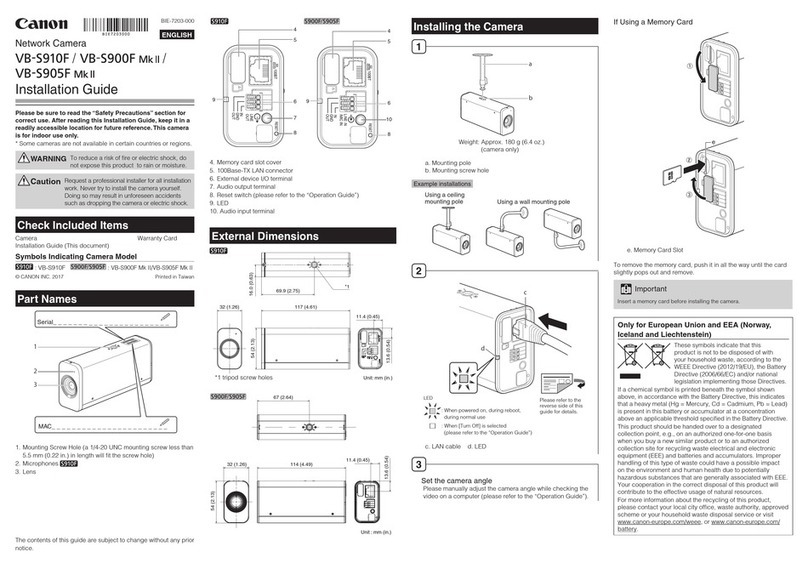

Regulatory Compliance

Emissions

Immunity

FCC part 15 Class B

CE: EN55011

ICES-003

EN55022

CISPR 11

CISPR22

ANSI C63.4

CE: EN50130-4

FCC COMPLIANCE:

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio / TV technician for help.

CISPR 22 WARNING:

This is a Class B product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

POWER SUPPLY REQUIREMENTS:

For use with listed Audio / Video product and only connected to 15W or less power

supply.

*Power supply should be a NEC Class 2/LPS supply.

EQUIPMENT MODIFICATION CAUTION:

Equipment changes or modifications not expressly approved, the party responsible for

FCC compliance, could void the user’s authority to operate the equipment and could

create a hazardous condition.

This class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

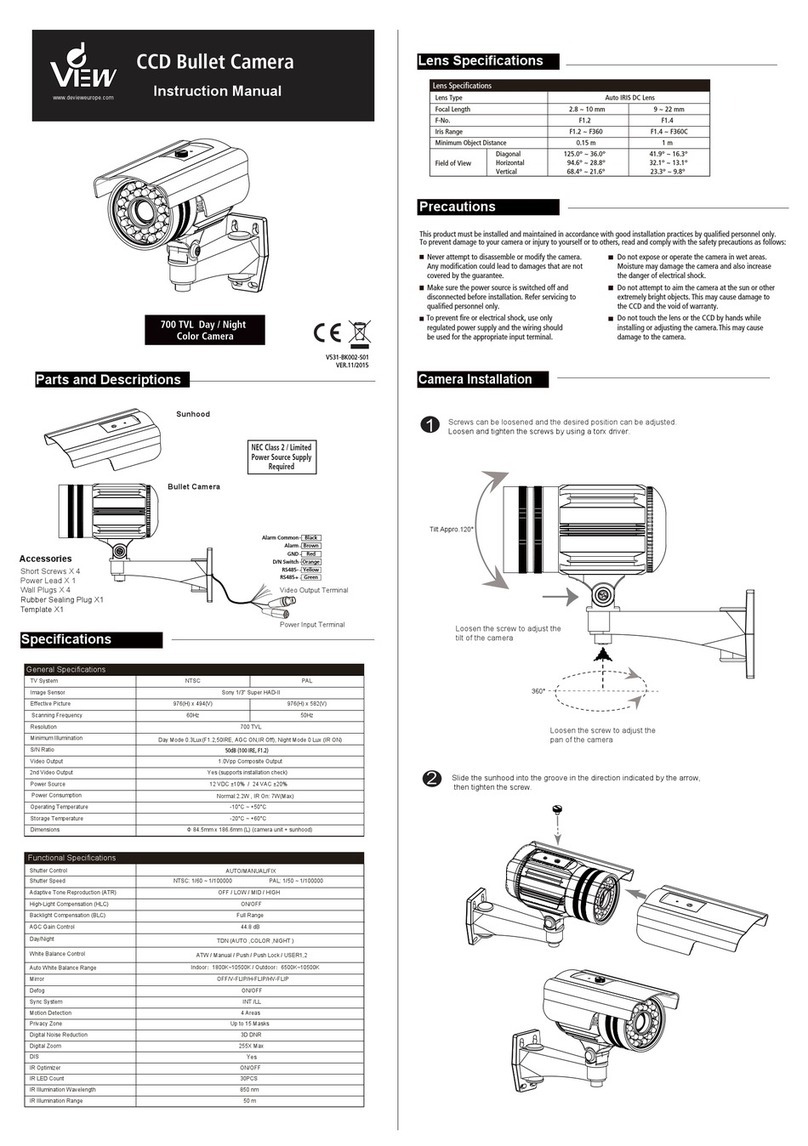

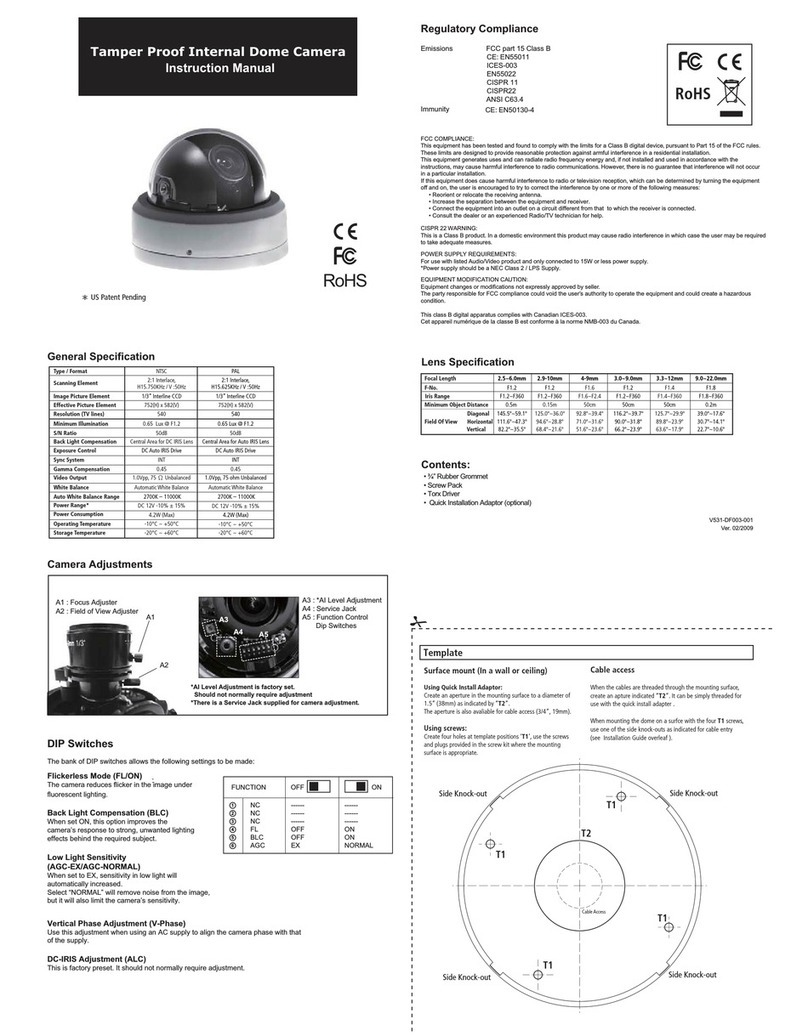

Hardware Kit Contents

• 3/4” Rubber Grommets x 2

• Screw Packs x 2

• M4 Torx Screw Driver x 1

• M2 Allen Key x 1

• Wire-ended Power Adaptor Lead x 1

Template

Surface Mount

Create four holes of diameter ¼” (7mm) at template positions ‘T3’.

Use 4 x wall plugs and 4 x (no.12 x 1½”) screws.

When mounting externally, use a rubber o-ring at each mounting hole

in the base to ensure moisture resistant seals.

Cable Entry (in base cable entry case)

When use the base cable entry, create a hole of diameter 3/4”NPT (19mm)

at template positions ‘T4’.Cable is threaded out the base.

Using screws to install out ring:

Create three holes at template positions ‘T1’ of diameter 1/5” (5.2mm) and

insert a wall plug into each.Use three screws.

Flush Mount

Create an aperture in the mounting surface to a diameter of 5.5” (140mm) as

indicated by ‘T2’.

Using locking arms (see Installation Method B overleaf) :

Place the enclosure (with the locking arms retracted) into the opening.

Use a cross-head screwdriver to rotate the locking screws until the locking

arms, firstly splay out, and then tighten against the inner face of the mounting

surface.

Tighten the screws sufficiently to compress the o-ring moisture seals located

underneath the screw heads, however:

DO NOT OVERTIGHTEN.

T3

T3

T3

T4

T1

T2

Outer Ring T1

T1

T3

• Handle the camera with care. Do not abuse the camera. Avoid striking or

shaking it. Improper handling or storage could damage the camera.

• Irrespective of whether the camera is in use or not, never faces it towards

the sun. Use caution when operating the camera in the vicinity of spotlights

or other bright lights and light reflecting objects.

Do not operate the camera beyond its temperature, humidity or power

source ratings. Please refer to the environmental information provided

overleaf.

Precautions

Please visit our website for more information

www. deview.com

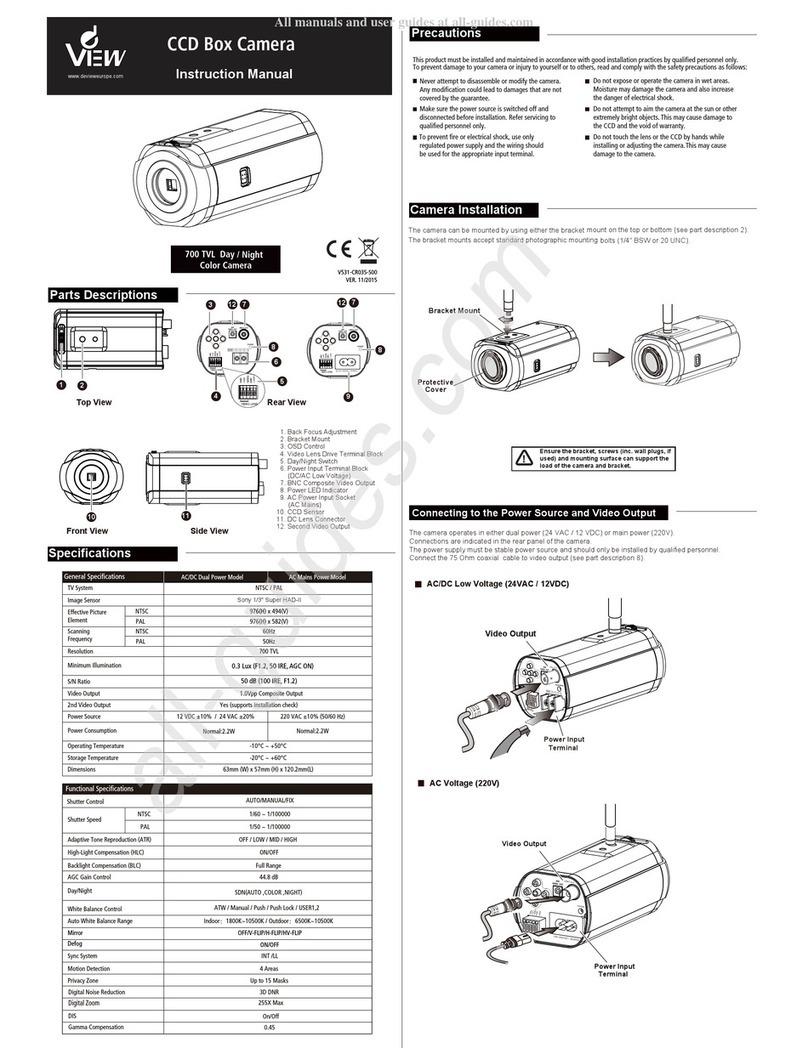

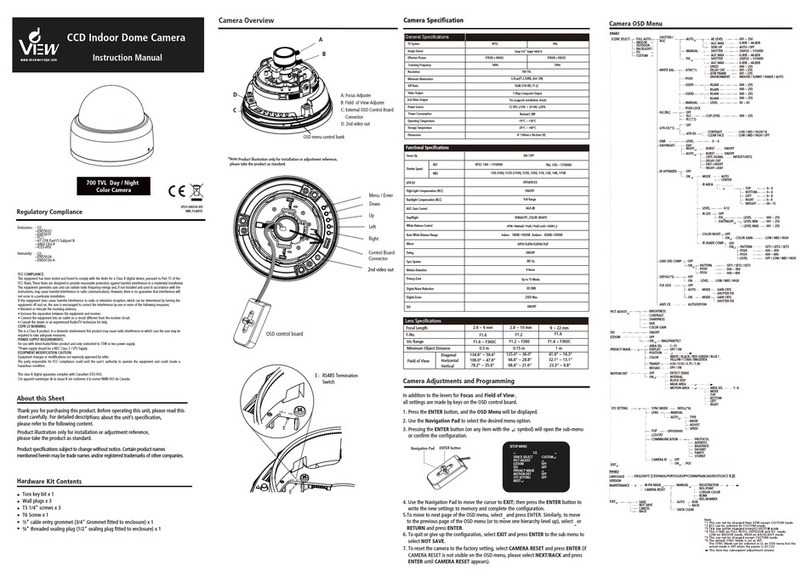

Large Rubber Gasket

Dome Cover

Outer Ring

Cable Entry

Secure Screws

Dome Base

Rubber o-rings to

maintain moisture

seal when fixing

externally.

Rubber o-rings to

maintain moisture

seal when fixing

externally.

Video-Power Cables

Power Input

Video Output

Create an aperture in the mounting surface to

a diameter of 5.5” (140mm) as indicated by

“T2” (see template overleaf ).

Turn silver-colored screws counter-clockwise

by half a turn to extend the locking arms and

then clockwise to tighten them against the

mounting surface (see image B1).

In case of dust and moisture ingress, always

use the large rubber gasket on the dome base

befor installing the dome base (see image B2).

Tighten the screws sufficiently to compress the

o-ring moisture seals located underneath the

screwheads.

Note: Do Not Overtighten.

Flush Mount using Locking Arms.

B3

Locking Arm

Locking Arm Base Cable Entry

Side Cable Entry

Method B:

Flush Mount Using Locking Arms

Locking Screw

Extending the Lock Arm

with Screw Driver

Mount Large Rubber Gasket on

Dome Base before Installation

Large Rubber Gasket

Locking Arms

B1

B2

Allen Head

Locking Screw

Allen Key

D3

Rubber Grommet

Methods for Mounting the Enclosure

There are two main ways to mount and fix the dome enclosure:

A: Surface mount using the outer ring.

B: Flush mount using locking arms.

Note: Always use the template provided.

When mounting externally using the four base holes, use the supplied rubber o-rings

within the mounting holes to ensure moisture resistant seals. Ensure that the cable

entry through either conduit point is suitably sealed against moisture ingress.

Regardless of whether the locking arms are used for installation or are folded away

(in favor of another installation method), always ensure that the locking arm screws

are tight enough to compress the rubber o-rings to maintain the moisture seal.

Method A : When Mounting Externally

Base Cable Entry

Side Cable Entry

Use either the base cable entry (see image D1)

or side cable entry (see image D4) as required.

Carefully remove the appropriate cable entry

sealing plug before installation.

If mounting indoors and conduit is not used,

cables should be passed through a slotted

rubber grommet to prevent dust ingress

(see image D3).

Note: If the side conduit entry is not used, make

sure that the cable entry point is secured with

the outer ring sealing plug (see image D2).

Do Not Overtighten the Locking Screws.

D1

D2

Video-Power Cables

Select Proper Cable Entry

Using Side Cable Entry

When surface mounting and using the

side cable entry (see image D4), first

remove the cable entry sealing plug in

the dome base.

Pull out the outer ring sealing plug so

that the video-power cables can pass

through the outer ring (see image D4).

D5

Outer Ring

Sealing Plug

Outer Ring

D4

C

Torx

Screw

Driver

Cover Screws

Remove the Dome Cover

Use the supplied large torx driver to

loosen, if required, (but not remove)

the four cover screws.

The screws are captive and will be

retained in the lid.

E1

Make all connections is complete before

mounting Camera Module on Dome Base

Fit the Camera Assembly

Gimbal Securing Screws

Camera

Assembly

GCDNH/GCDPH Day/Night Cameras:

Plug the multi colored wire from the camera directly

into the wire that is attached to the power supply

(see image E1).

GCDNH/GCDPH Wide Dynamic Range versions

Cameras:

Connect the white wire with the red stripe to the center

connector on the service jack (see image E3).

Remove the multi color wire that is plugged into the

power control board (6 wire) and replace with the

(5 wire) lead that comes with the camera, then proceed

to plug the camera into this lead (image E3).

E4

E2

Connecting GCDNH/GCDPH

Day/Night Camera

Connecting GCDNH/GCDPH

Wide Dynamic Range Camera

Installing the Camera Module on Dome Base

Place the complete camera

assembly onto the three

mounting pillars.

Insert and tighten the three

gimbal securing screws

(see image E4).

Note:

Do Not Overtighten

the Screws.

Service Jack

Board

Power Control Board

E3

WDR Camera Module

Connector to

Service Jack Board

Connector to

Power Control Board

Adjust the Camera Position

Remove the camera liner and adjust the camera

position (image F1).On the two sides of the module has

positioning screws.

Slightly loosen the positioning screws if the module is

too tight to rotate (image F2).

Rotate and pan the camera chassis to the required

position. Slightly tighten the positioning screws on the

both sides (see image F3).

Note: Do Not Overtighten the Positioning Screws.

Replace the camera liner when the camera is correctly

positioned.

Replace the Dome Cover

Replace the dome cover and use the supplied torx

screw driver to tighten the four cover screws

Install the camera liner

on the camera module

Camera Liner

Positioning Screw

F1

F2

F3

90°

360°

360°

Adjusting the camera position

Positioning Screw

Installing the Dome on the Mounting Area

All mounting access positions should be

sealed until they are ready to be used.

For example, when externally mounting the

housing with the outer ring, first remove the

base cable entry sealing plug that

correspond to the template marks “T4”.

This can be accomplished by using a

cross-point screw driver.

Open three holes correspond to the

template mark “T1” for the outer ring.

Then open four holes at template

positions “T3” for installing the dome base.

The template is in page overleaf.

Note: Ensure the large rubber gasket is always placed under the lip of the dome

when mounting.

Outer Ring

Large

Rubber Gasket

Dome Base

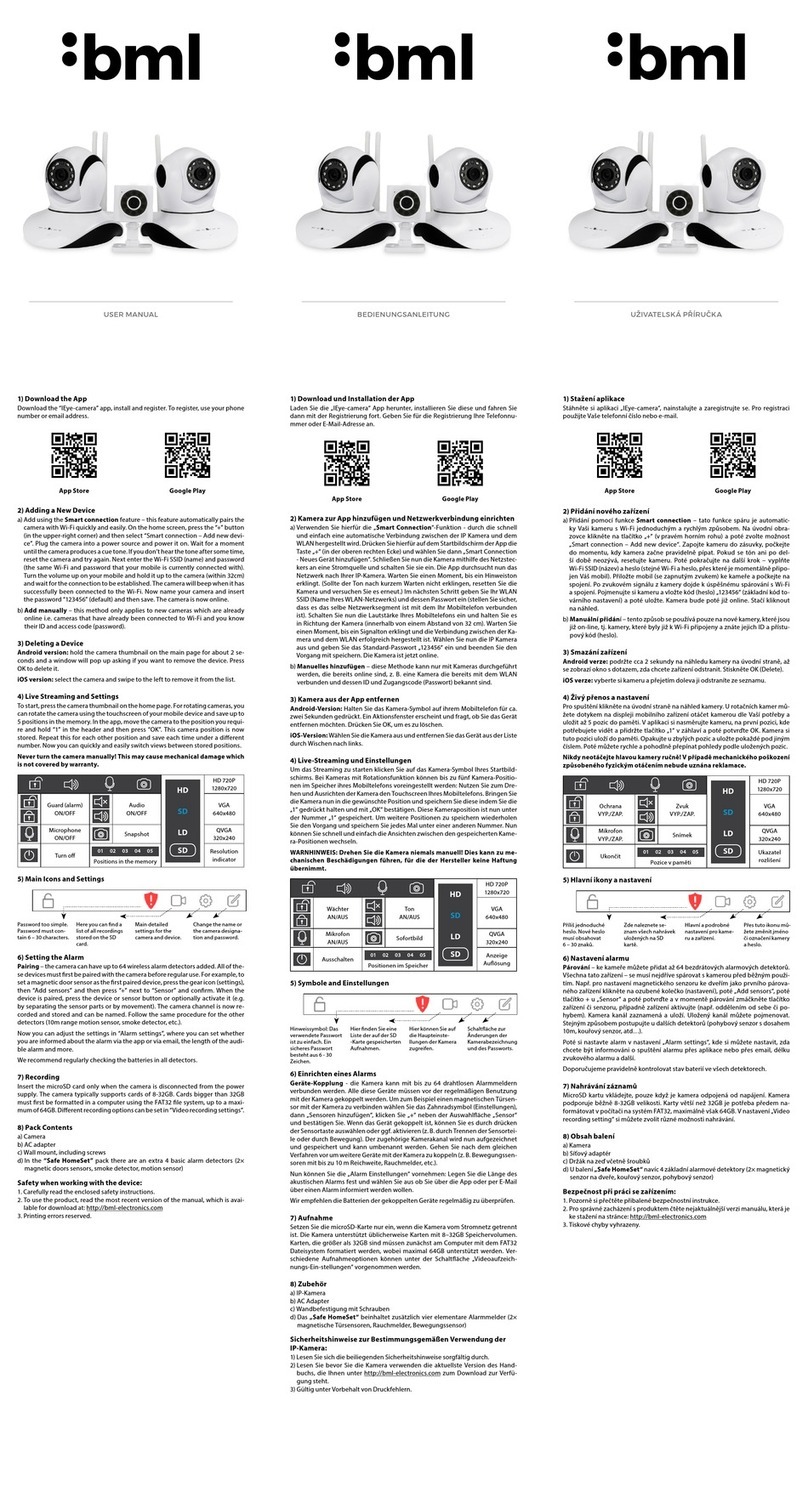

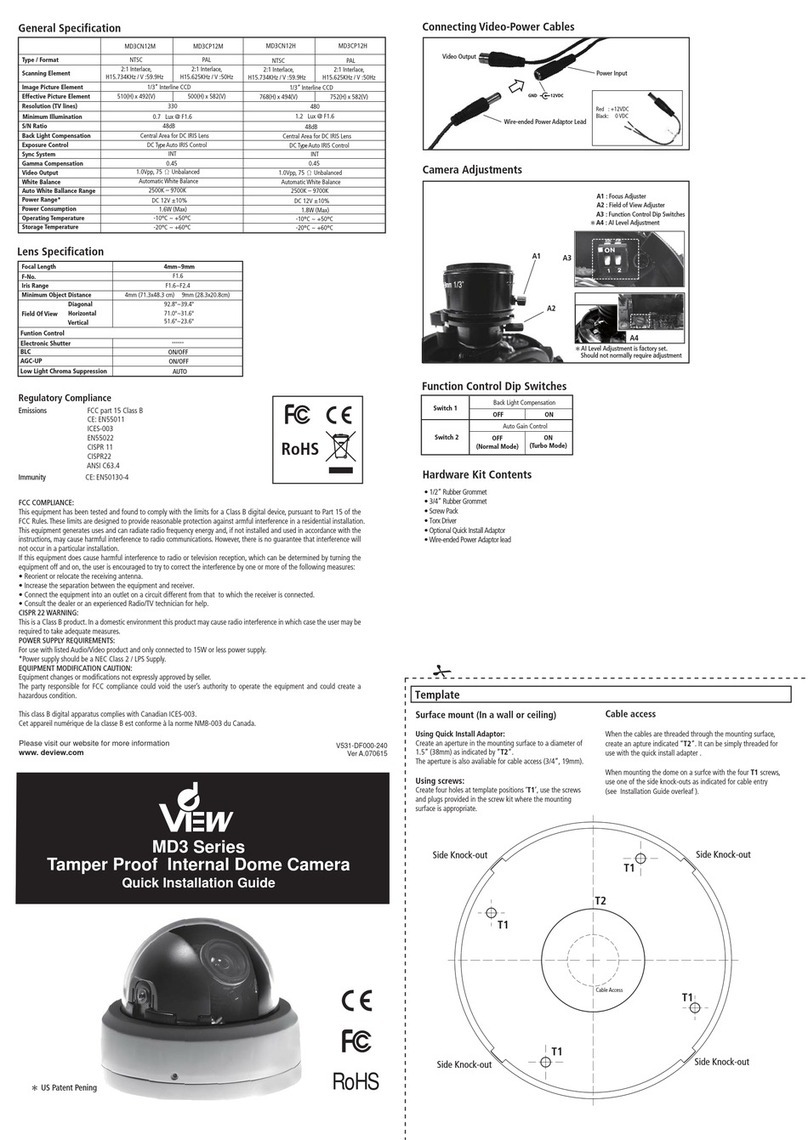

Other DeView Security Camera manuals

DeView

DeView ATMP7W User manual

DeView

DeView Tamper Proof User manual

DeView

DeView MD3CN12M User manual

DeView

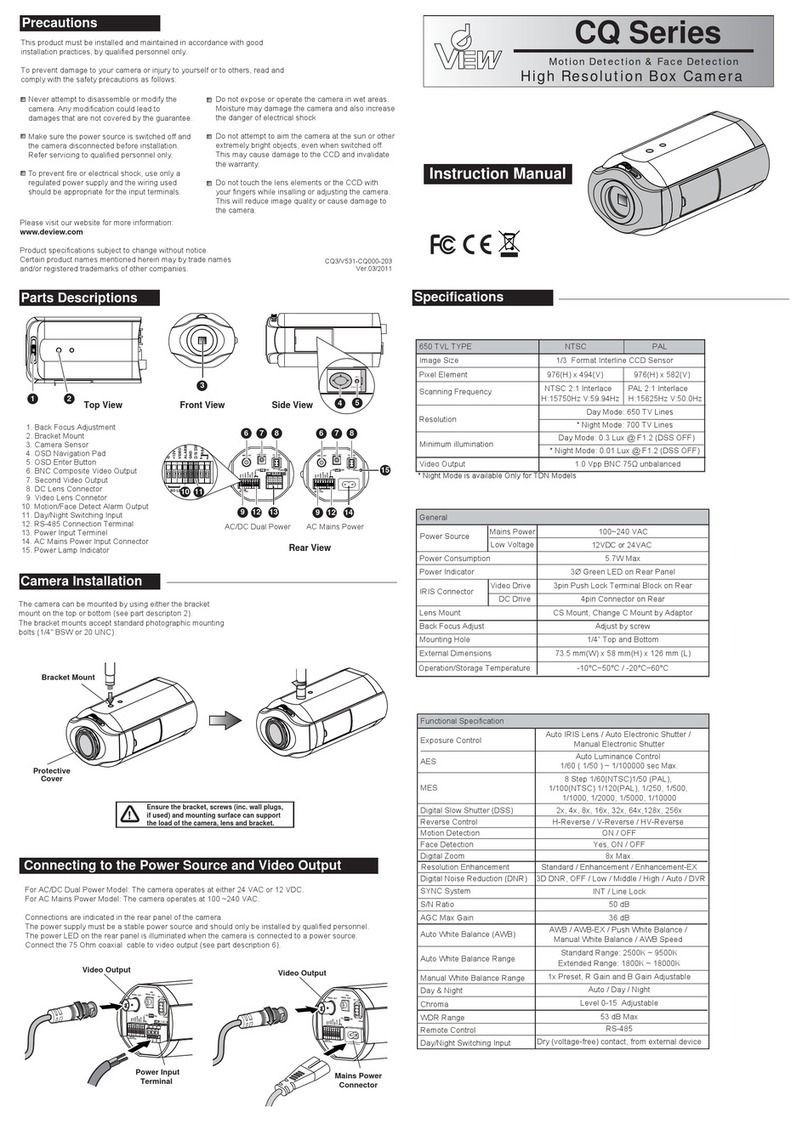

DeView CQ Series User manual

DeView

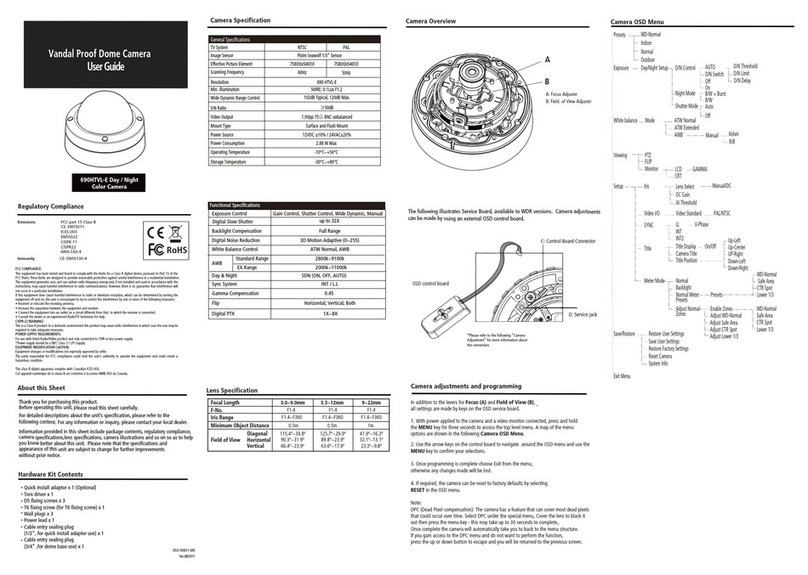

DeView 690HTVL-E User manual

DeView

DeView BTP12H37V12L User manual

DeView

DeView MD4SP70 User manual

DeView

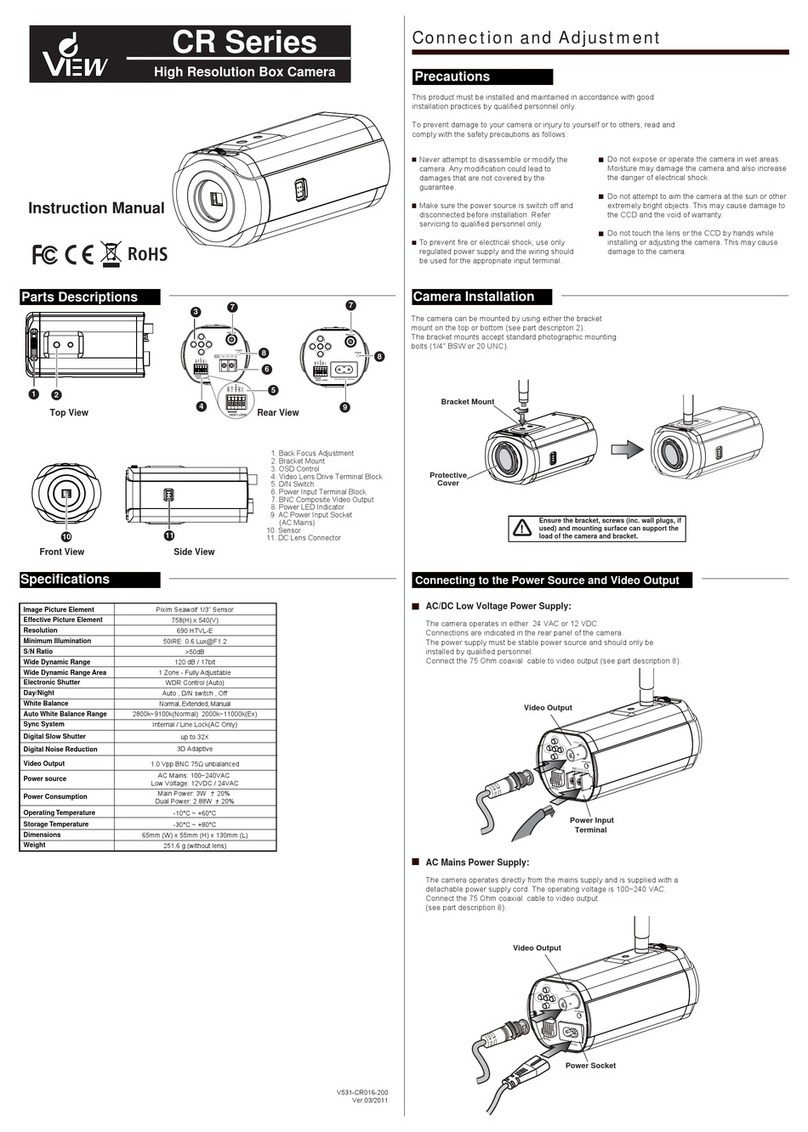

DeView CR Series User manual

DeView

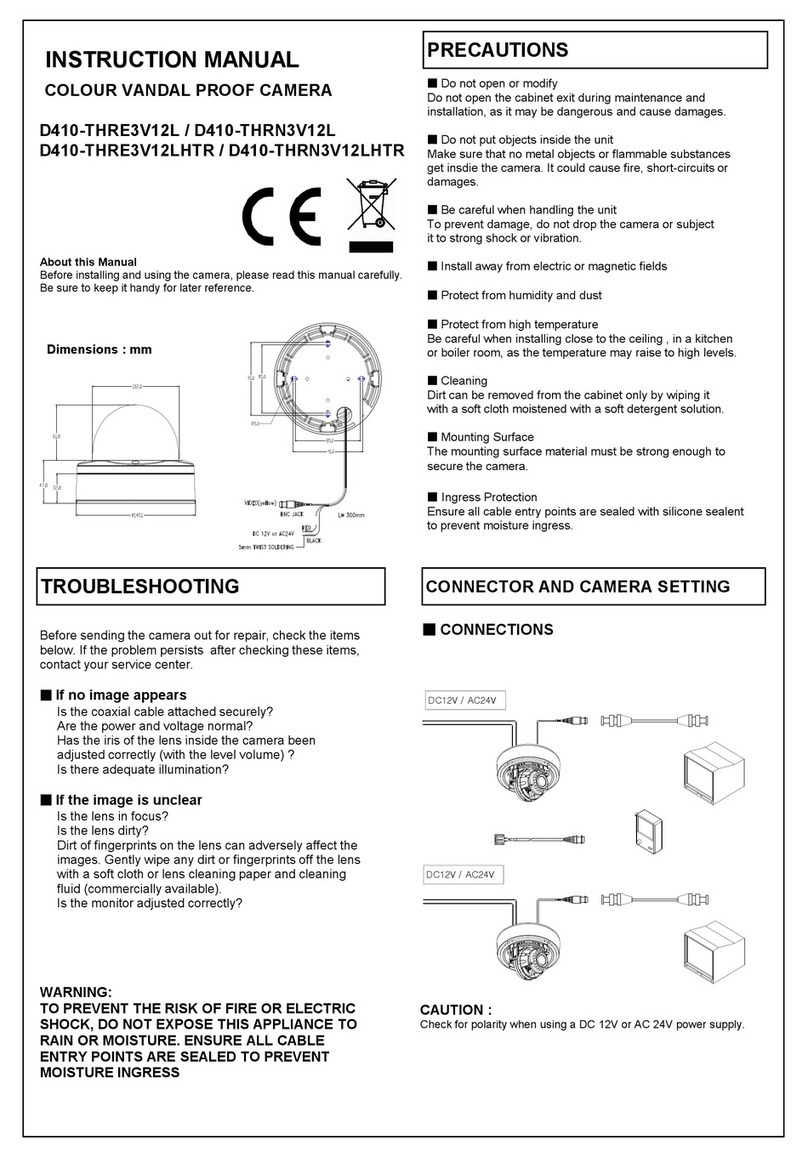

DeView D410-THRE3V12L User manual

DeView

DeView CR Series User manual