-5 -

CLEANING

1. When you clean the Full-Auto type gun, Rear CYL air should be stopped. In case of Semi-Auto type

gun, you should set the dial to “CLEAN” position.

2. Relieve air pressure from pressure tank. Carefully follow instructions in bulletin sent with tank.

3. Replace material in container with a suitable solvent.

4. Re-pressurize system.

5. Trigger gun (Front CYL air / ON at FULL-AUTO) and repeat procedure until gun and hose are thoroughly

Clean. A SolventSaver™ type hose and gun cleaner which supplies a mixture of air and solvent can be

used to most effectively clean gun and hose internal passages.

See “Accessories” for SolventSaver™. Wipe exterior of gun with a solvent dampened cloth.

6. If a recirculating system is used, it may be necessary to fit a shut off valve in return line to ensure fluid tip

and forward portion of sprayhead passage are properly cleaned when flushed with solvent.

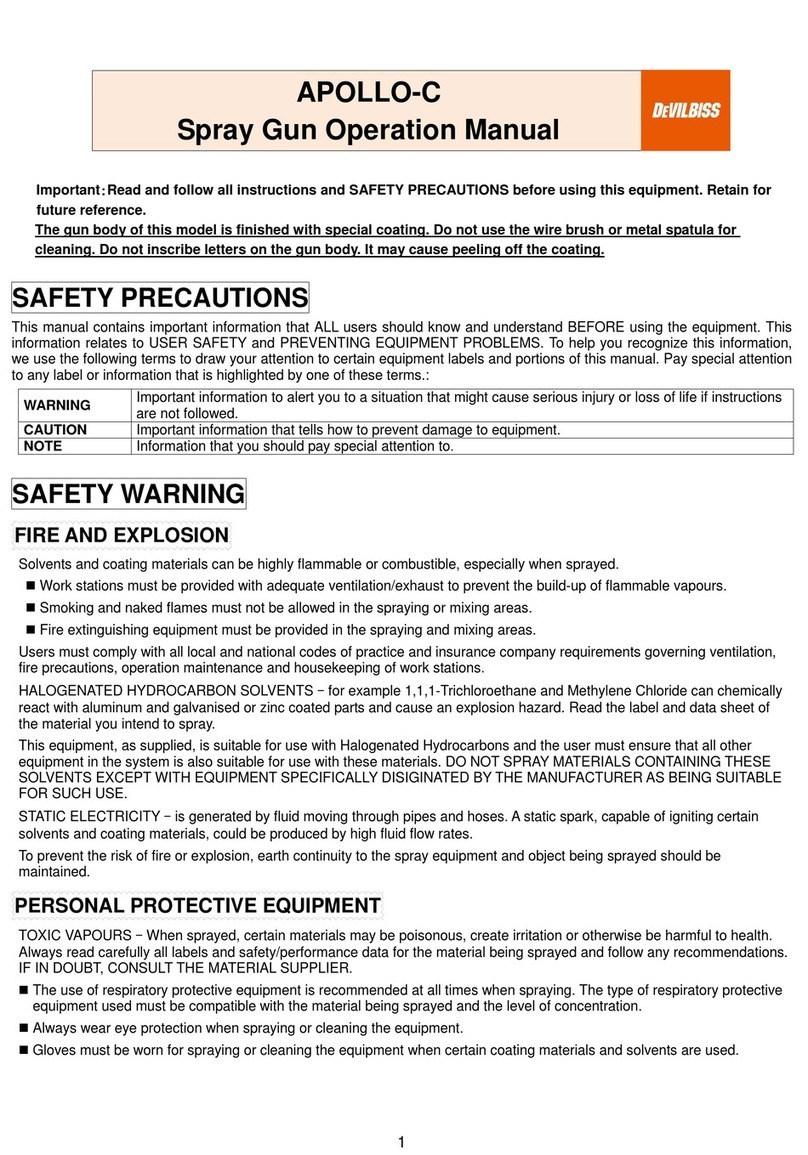

CAUTION

Do not totally submerge gun in solvent. It may damage the inside of the gun with solids.

CAUTION

The air cap can be immersed in solvent for cleaning. If orifices are clogged, use a cocktail stick

or toothpick to remove obstruction. Never use a steel wire or hard instrument. This will damage

air cap and result in a destroyed spray pattern.

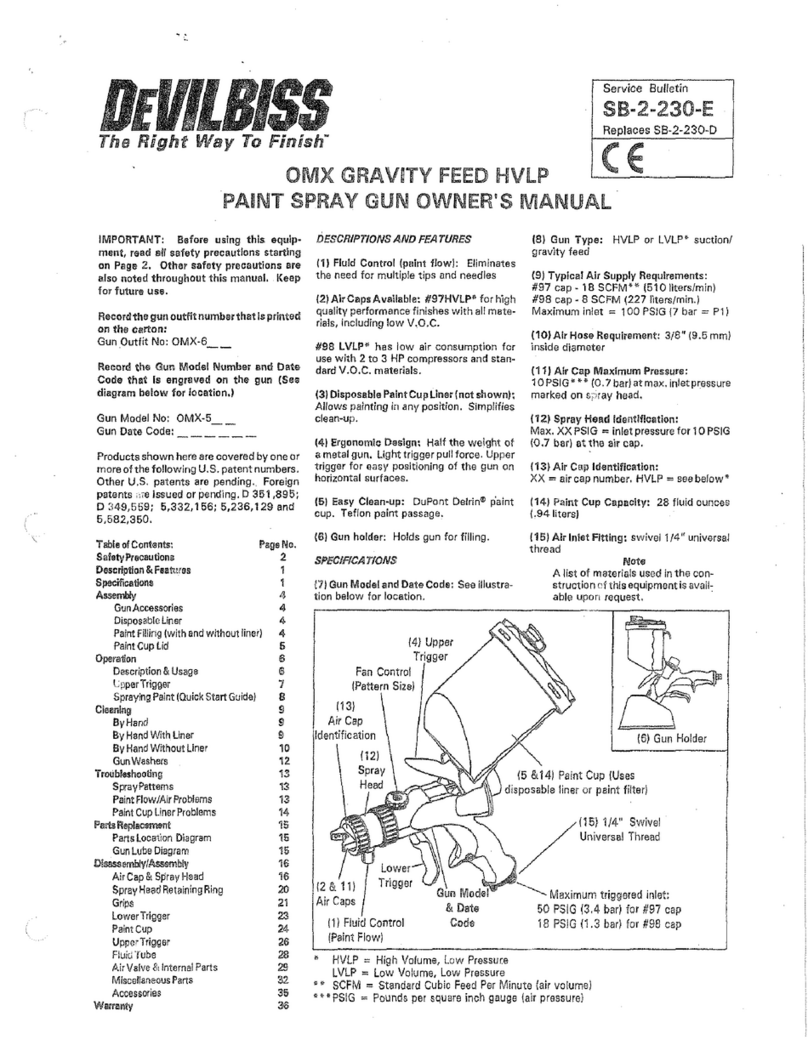

REPLACEMENT

Tools required:

•Special tool for adjusting needle seal kit (for Item No. 5)

•19mm Box Wrench (for Item No. 4)

•2.5mm Hex Wrench (for Item No. 30)

•4mm Hex Wrench (for Item No. 17, 19)

•6mm Hex Wrench (for Item No. 31)

☆Replacing Tip, Needle & Piston Set (4)

1. Relieve all air and fluid pressure in system.

2. It is recommended to remove the Gun from the Manifold (24) by removing Bolt (31) before carrying out

any maintenance.

3. First, remove rear body (13 or 18) with 4mm Hex Wrench, then remove Needle Spring (12). Pull

Needle Assy from Gun body. When pulling out the needle assy., use the bolt Hex (17 or 19) which

could screw into the rear side of piston.

4. Remove Retaining Ring (1) and Air Cap (3).

5. Remove Fluid Tip with 19mm Box Wrench.

6. Reassemble in reverse order.

*Recommended torque for Fluid Tip:12N・m / for M5 Bolt (17, 19, 30): 2.5N・m

* Apply petroleum jelly on cylinder of gun body and MiniY-Packing (11) and insert into gun.

* Apply petroleum jelly (Vaseline) on the rear cylinder, piston and O-Ring (16).

CAUTION

*Please ensure that there is no foreign matter at the tip and the area where the tip will be set at the

gun body.

*It is recommended that Tip, Needle & Piston Set (4) and Needle Seal Kit (5) MiniY-Packing(11) should

be replaced at the same time.

*Tip, Needle & Piston Set (4) is a precision machining part set. Therefore, they should be handled

with care and do not push and rotate the needle to the tip by hand after the tip has been set to the

gun body. It may damage the tungsten part of tip and needle.

☆Replacing Needle Seal Kit (5)

1. Please follow the procedure of above replacing Tip, Neeld & Piston Set (4) until #3.

2. Remove the Needle Seal Kit from the gun body by using special tool for adjusting needle packing

T-AGPZ-34 (33 / optional accessory).

3. Set the Needle Seal Kit (5) to the special tool (option)

Insert and screw it to the gun body until it stops.

A slightly tighten it after it stops. Then the setting is completed.

The special tool is also used for checking the tightness of needle seal. If the needle movement is not

smooth enough, then seal needs to be adjusted (loosen a little).

CAUTION

*It is recommended to use T-AGPZ-34 (33) the special tool for adjusting needle packing when you