80-9395-9521-020 Rev/1 (06-16)

ASSA ABLOY

Norton is a brand associated with Yale Security Inc., an ASSA ABLOY Group company.

Copyright © 2016, Yale Security Inc. All rights reserved. Reproduction in whole or in part

without the express written permission of Yale Security Inc. is prohibited.

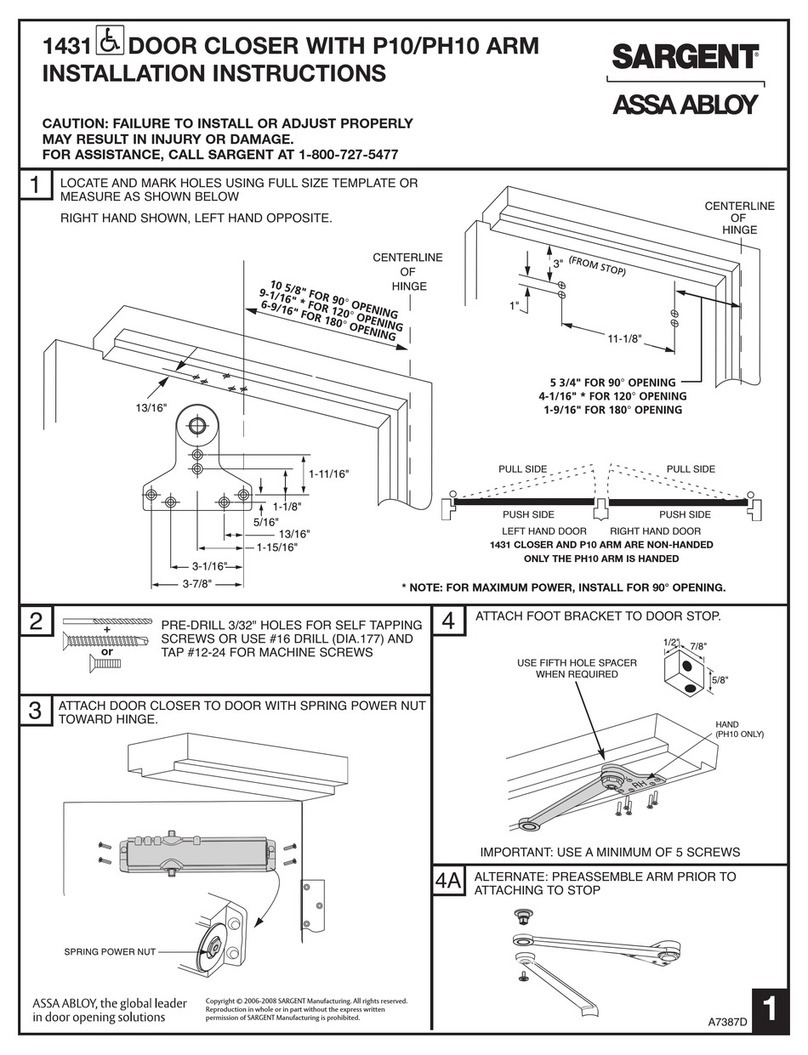

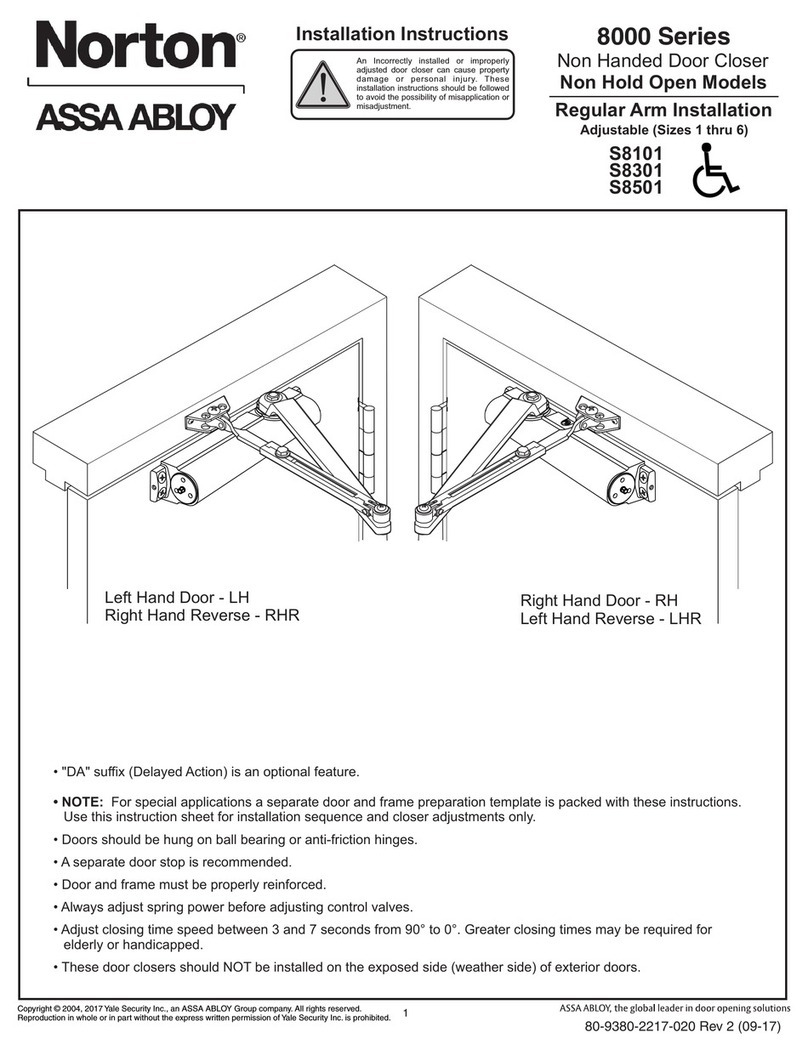

Left Hand Door

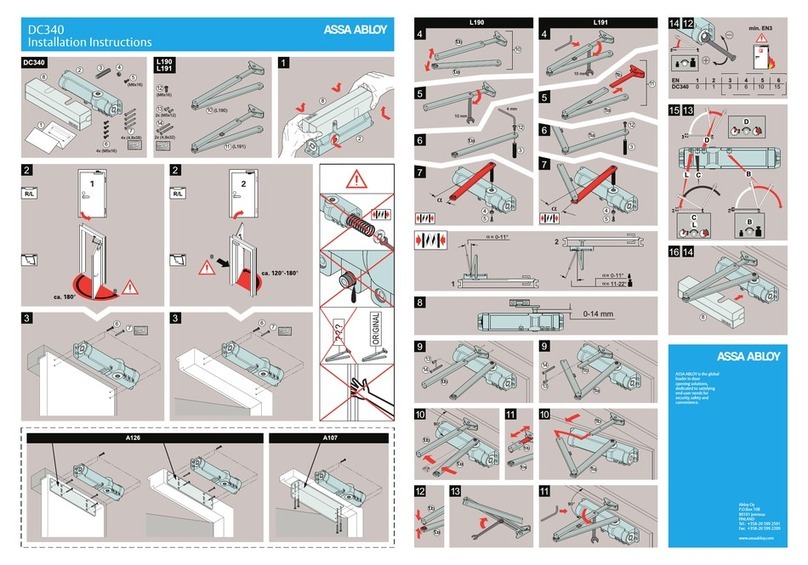

Figure 7.4

(4) #12-24 x 5/8"

Screws to mount

closer body to

mounting bracket

Figure 7.2

90°

Adjusting Rod

Main arm

Figure 7.3

90°

Regular Arm Installation Sequence

1. Remove existing LCN arm assembly, closer body and

supporting mounting hardware. If existing drop plate is

present, replace with Norton drop plate part number 9540-18.

See page 3, figure 3.2 of this instruction.

NOTE: The existing LCN drop plate must be replaced with

the proper Norton drop plate for the 9540 to perform

correctly.

2. Inspect existing mounting holes in door and frame for damage.

Consult templates listed below to confirm existing holes are

located in the proper position:

Page 5: 9540 Regular Arm Mount

Page 6: 9540 Regular Arm Mount with 9540-18 drop plate.

Improperly templated door or frame may affect door

closer performance.

3. IMPORTANT: Using template on Page 5, locate and prepare

two (2) additional holes for #12 screws for closer mounting

plate. Screws will be located under the spring adjust end of

closer when installed. See fastener chart page 4.

(If installing closer body on Norton’s Drop Plate page 6, these

additional holes are already present on drop plate)

4. Secure drop plate (if required) and/or closer mounting plate to

face of door with hardware provided.

Note: See templates on page 5 and 6 for proper orientation

of these plates in both Left Hand and Right Hand

applications.

5. Fasten the closer body, spring adjust end TOWARD hinge

edge of door and valve oriented as stated below to mounting

plate with hardware provided (Figure 7.1).

Right hand door: Valves facing UP.

Left hand door: Valves facing DOWN.

See templates on page 5 or 6 for illustrations of closer

orientation.

6. Fasten arm shoe of the adjusting rod assembly to frame face

with hardware provided. Fasten with pivot point of shoe away

from hinge. For additional 15% increase in closing force,

position arm shoe with pivot point towards hinge edge of door

as shown below. See figure 7.1 below; illustration shows left

hand door.

7. Attach main arm to closer pinion as shown below (Figure 7.2) with

main arm positioned 90° to door face. Secure to pinion with arm

screw provided.

8. Pre-load closer unit:

ŸRemove rod screw from adjusting rod. Insert adjusting rod into

rectangular tube of main arm assembly (open door slightly if

needed).

ŸWith door in closed position, rotate main arm until adjusting rod is

90° with respect to door face as shown below (Figure 7.3).

ŸRe-install adjusting rod screw and tighten to maintain closer pre-

load. Reference illustration below (Figure 7.4) for left hand door.

Figure 7.1

Left hand shown Shoe pivot point

9. Closer Adjustments: See page 16 for more information.

A) Adjust closing force using the spring adjust screw.

Rotate screw clockwise (CW) to increase force.

Rotate screw counter-clockwise (CCW) to decrease closing

force. Use hex wrench provided.

B) Adjust closing speed and latching speed of door using

valves identified (Figure 16.1).

Rotate valve clockwise (CW) to decrease speed.

Rotate valve counter-clockwise (CCW) to increase door

closing speed.

C) Adjust backcheck intensity.

Rotate (CW) to increase backcheck intensity.

Rotate (CCW) to de-crease backcheck intensity.

D) Delayed Action: (If equipped)

Rotate valve (CW) to increase close delay time.

Rotate (CCW) to de-crease close delay time

Spring Adjust End

Page 7