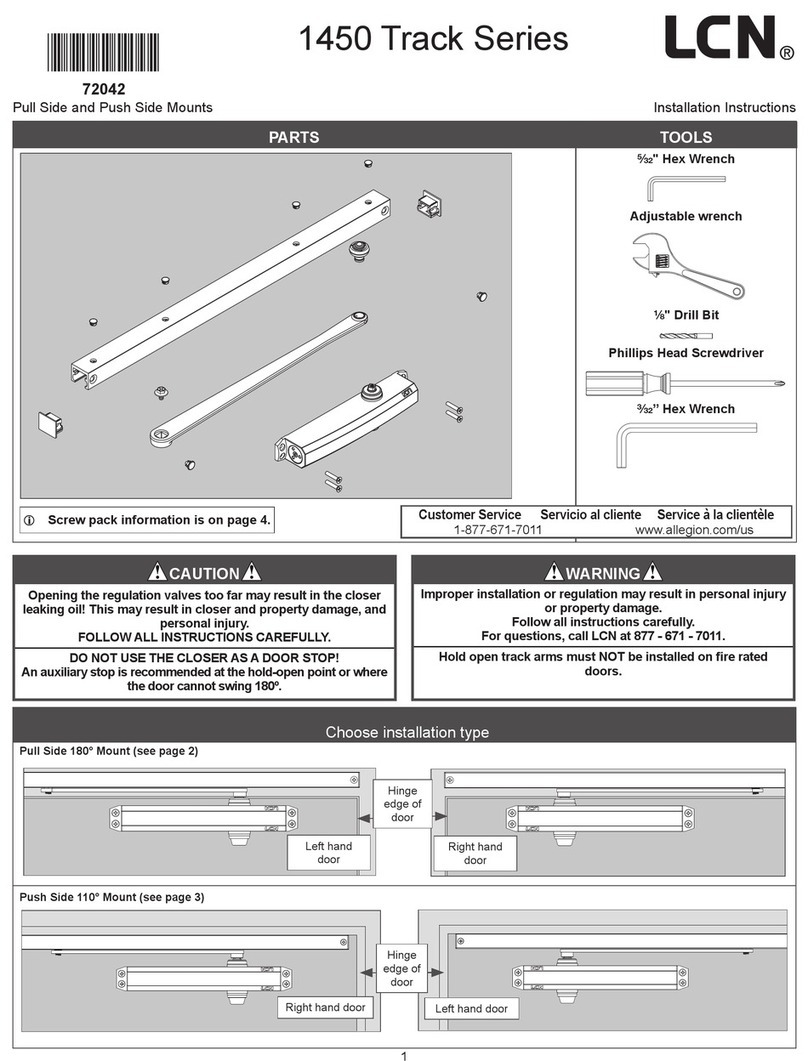

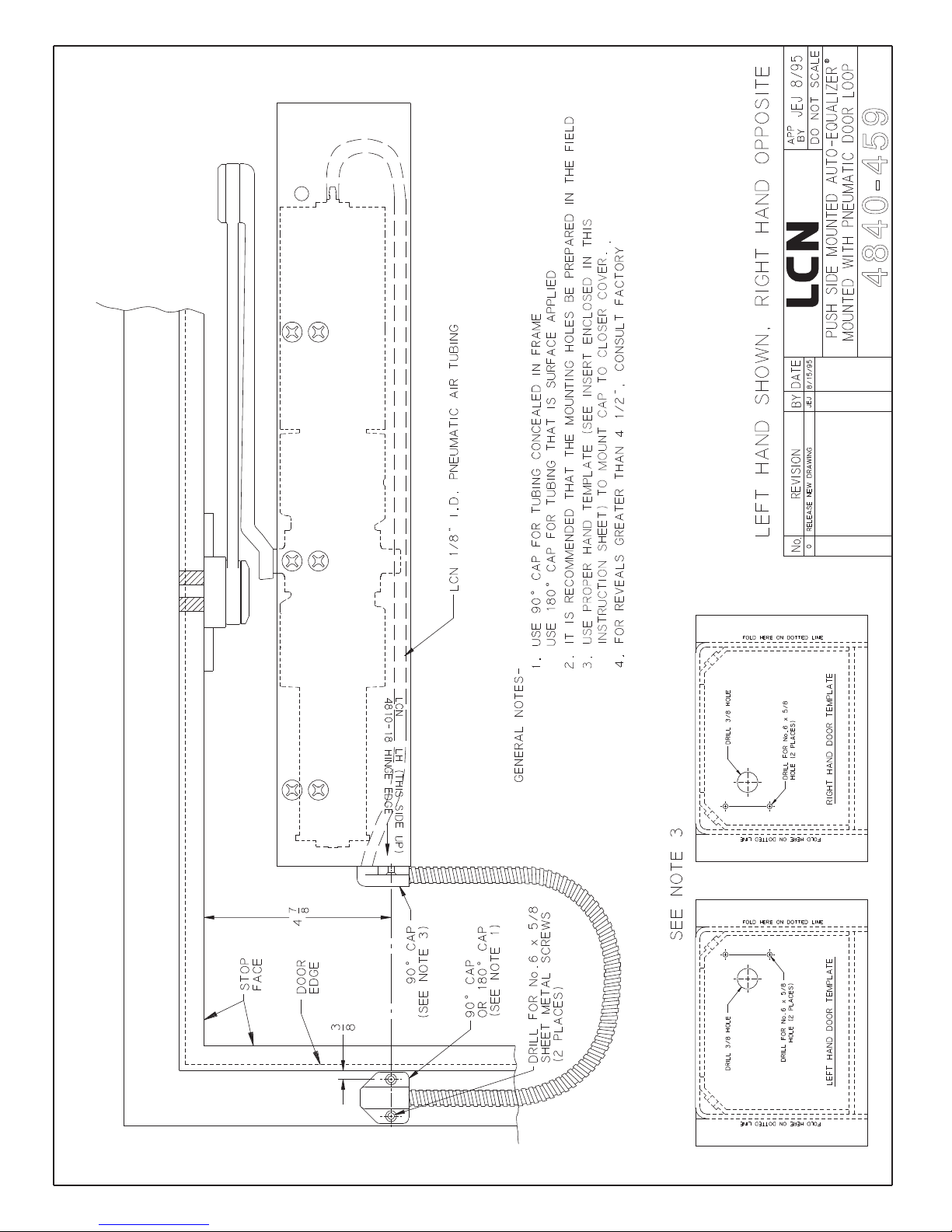

Concealed or Surface Air Transfer Options

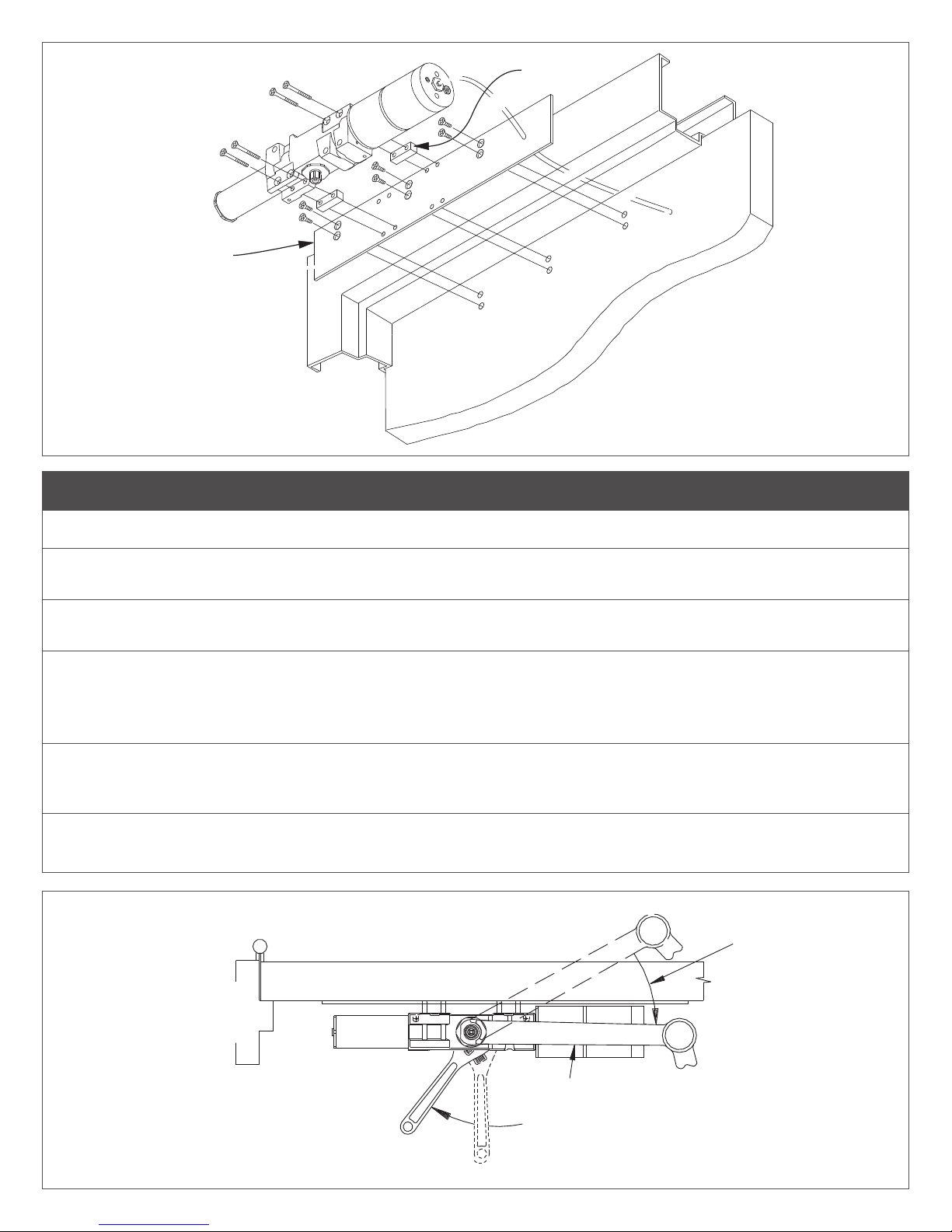

10 Pneumatic Door Loop Installation (see Figure 6)

LSee page 8 for template

LReveal must be less than 4 Z\x”

10a Remove the cover end cap (closest to hinge stile of

door) by removing the (2) Phillips head screws from

inside the cover.

10b Place the proper hand template (see cutouts on page

11) over the end cap and tape down securely.

10c Once the template is in place, drill (1) 3/8” hole, and

(2) 1/16” holes in the proper location.

10d After holes are drilled, remove template and place end

cap back on the cover.

10e Feed 1/4” tubing through the drilled end cap and also

through the 15” aluminum tubing supplied with kit.

10f Place 90° door loop cap on cover end cap (making

sure to line up slots over the ends of the 15” tubing)

and secure with No.6-32 screws provided.

10g Feed the 1/4” tubing (either 180° up the frame, or 90°

into the frame), place the concealed 90° or the surface

180° (depending on the installation) door loop cap

over end of the 15” aluminum tubing and secure to the

frame of the door. (See Figure 6).

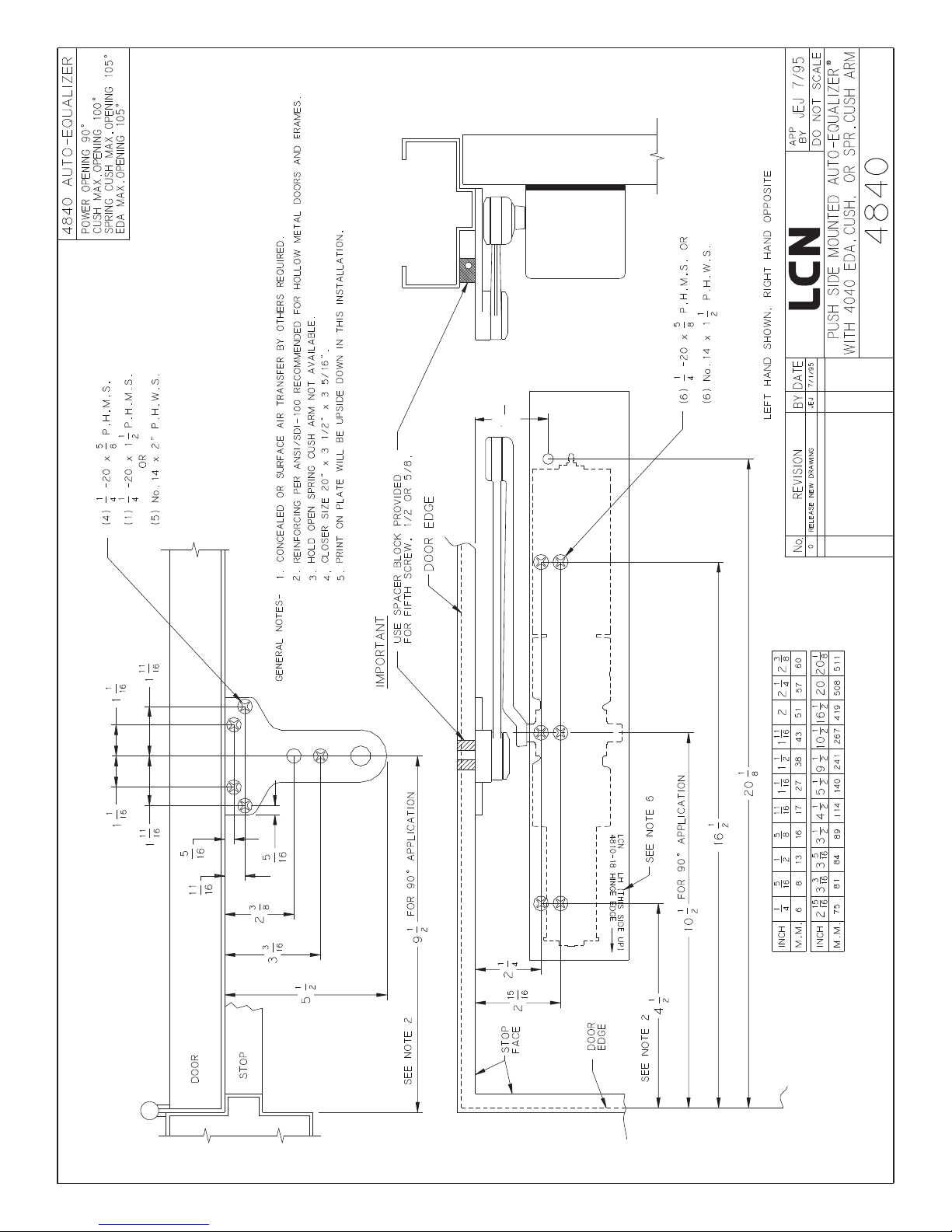

Figure 6

90° Concealed

Cap Shown

180° Surface

Cap Shown

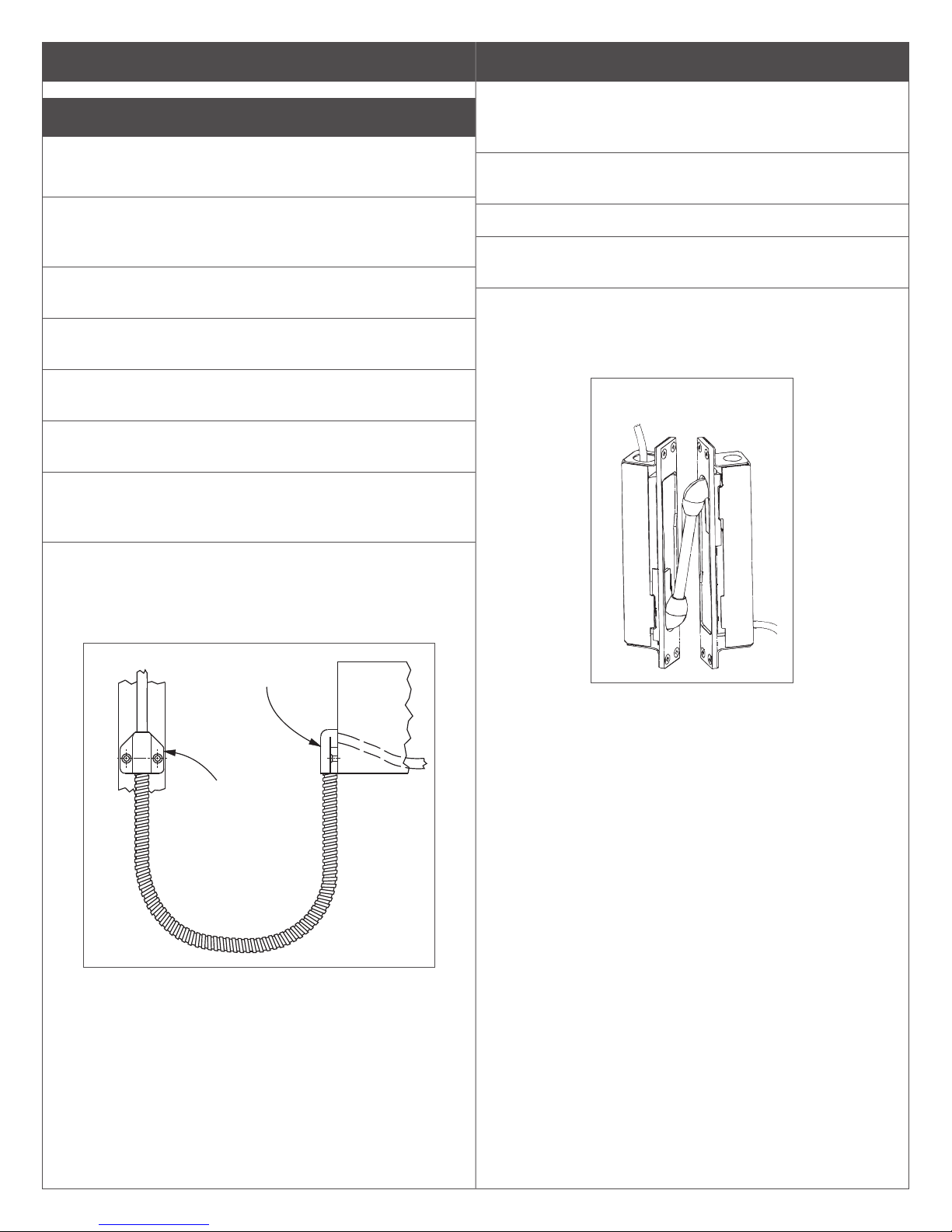

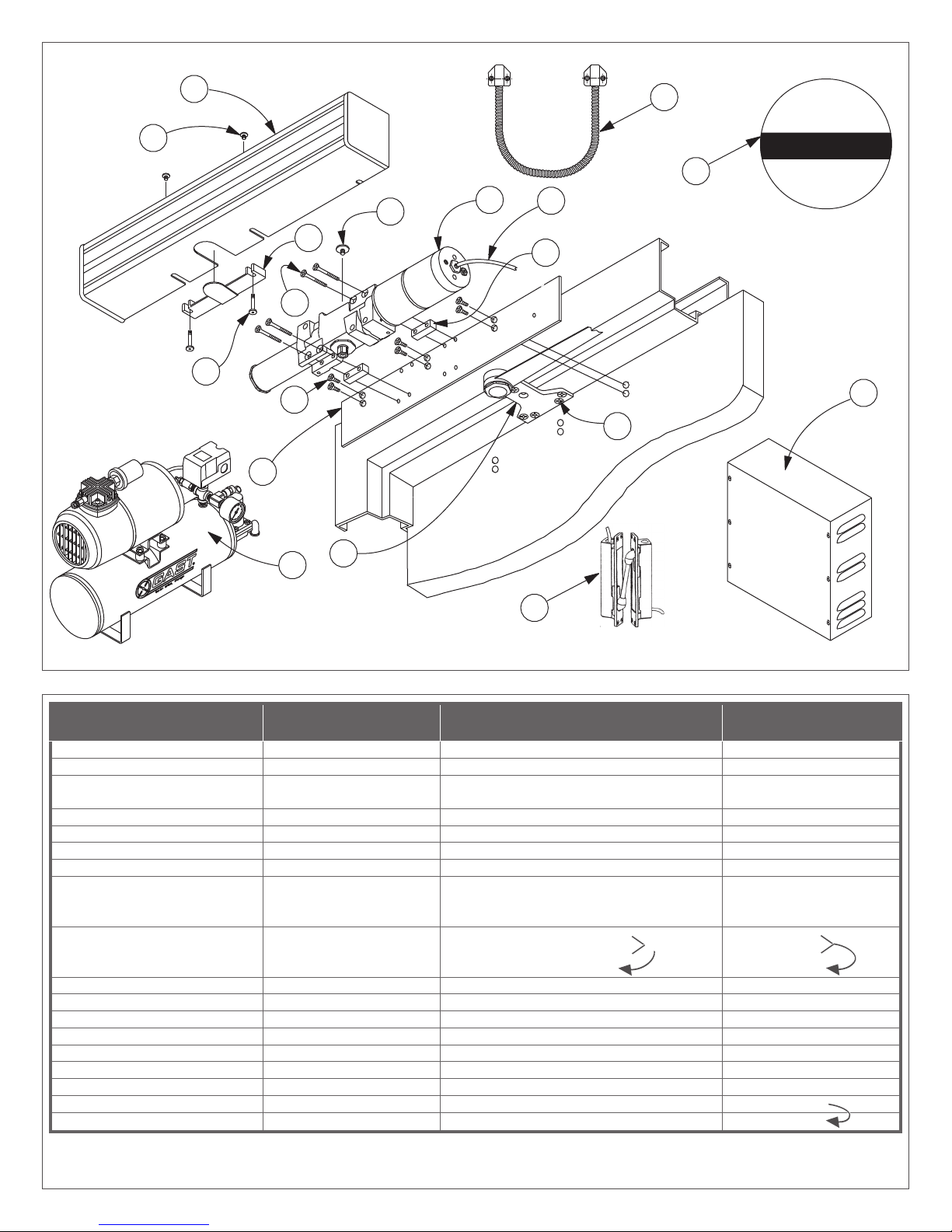

11 Pneumatic Transfer Hinge Installation (see Figure 7)

LA INTERIOR RACEWAY FROM TRANSFER HINGE TO 4840

CLOSER IS REQUIREDTO USE THIS PRODUCT, SEE PAGE

9 FOR TEMPLATE.

11a Apply pneumatic transfer hinge housing using No.

8-32 machine screws provided.

11b Connect tubing using the inline tubing splice provided

11c Apply transfer hinge unit using No.10-24 machine

screws provided.

11d Check operation of pneumatic transfer hinge unit.

LNOT FOR USE WITH SWING CLEAR HINGES OR CENTER

PIVOTS!

Figure 7

90° Concealed

Cap Shown

180° Surface

Cap Shown