Installation and Operating Instructions

Dimplex Wall-mounted Fan Convector 08/18724/0 Issue 0

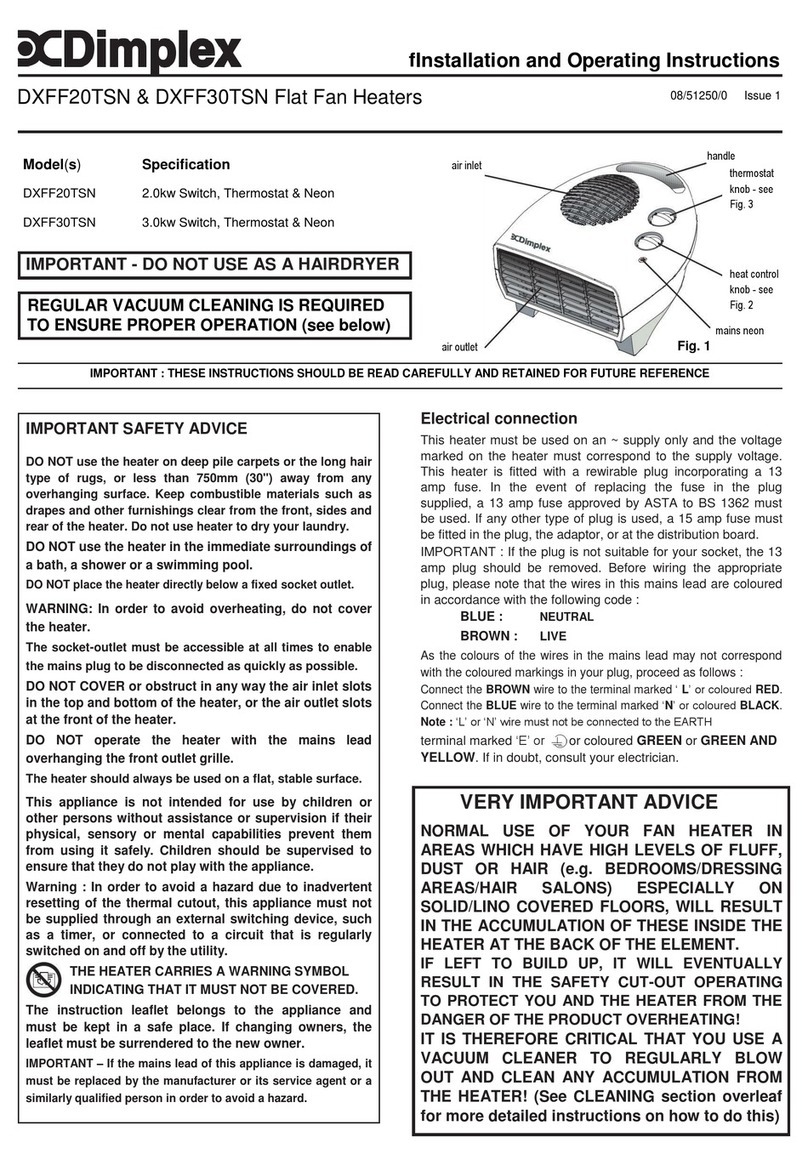

Models : WFC 3NB and WFC 3NS

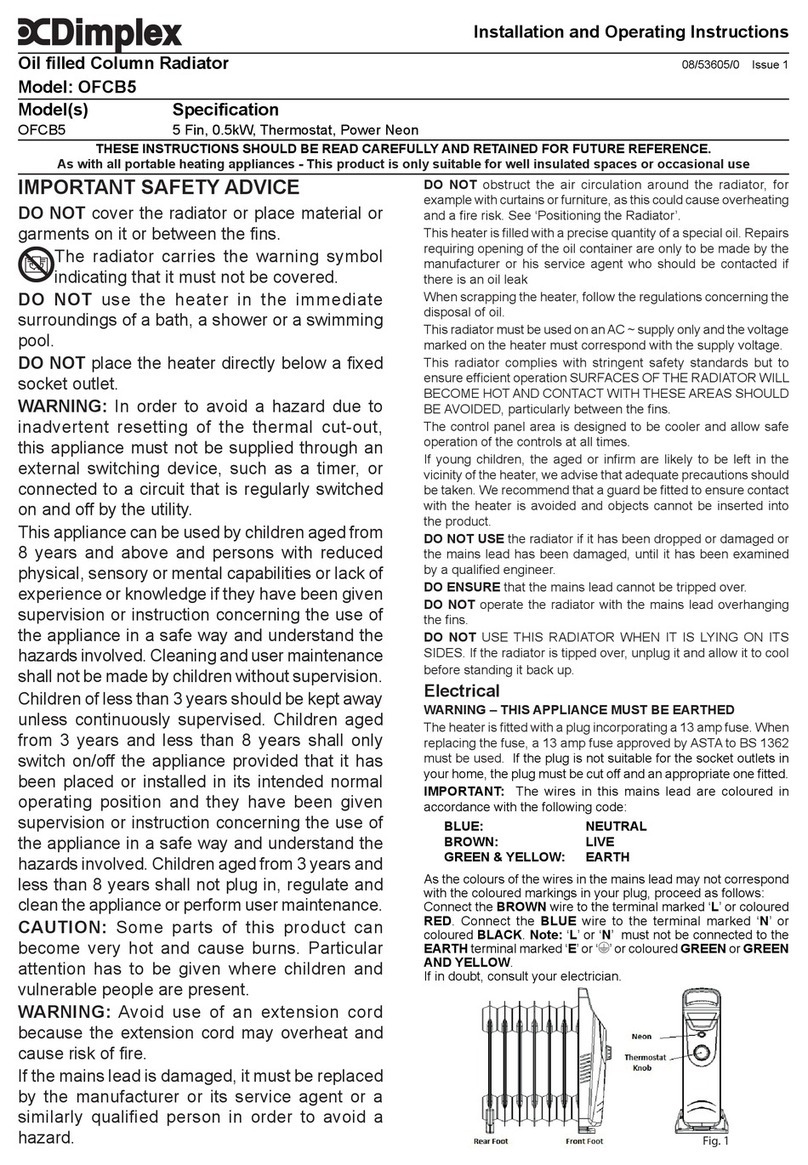

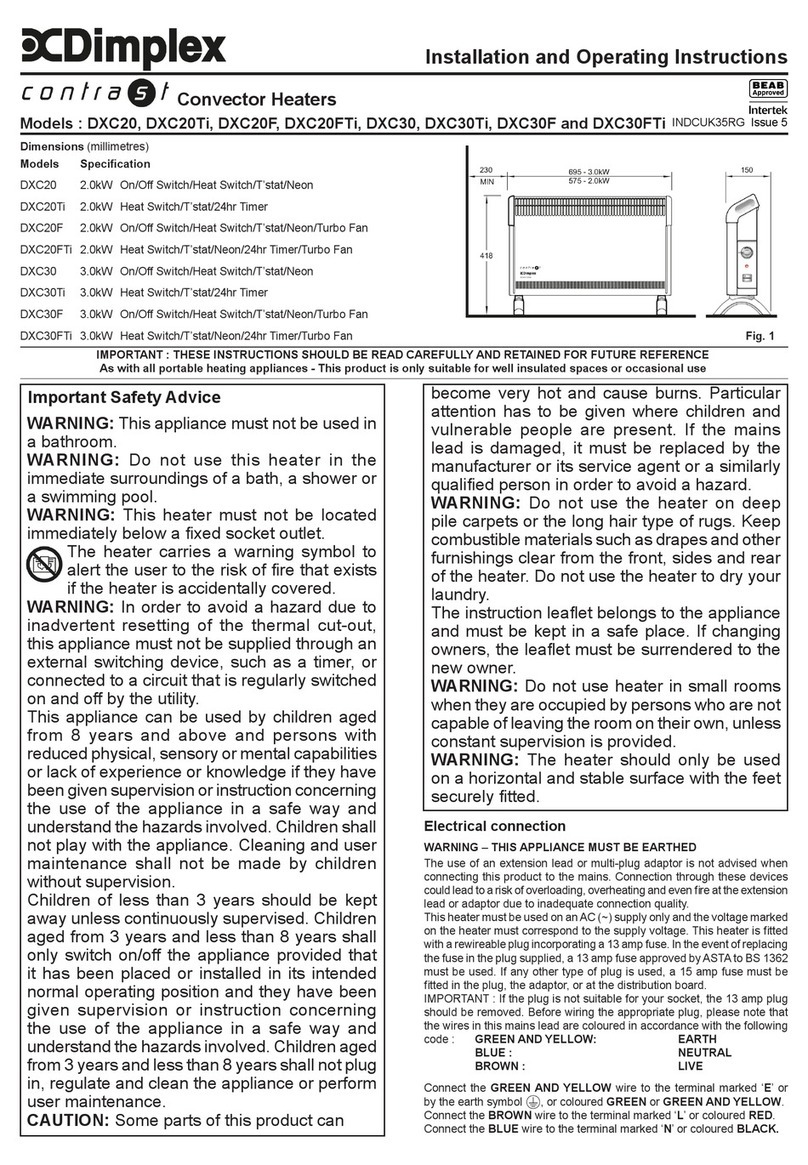

350mm min

571mm 120mm

350mm

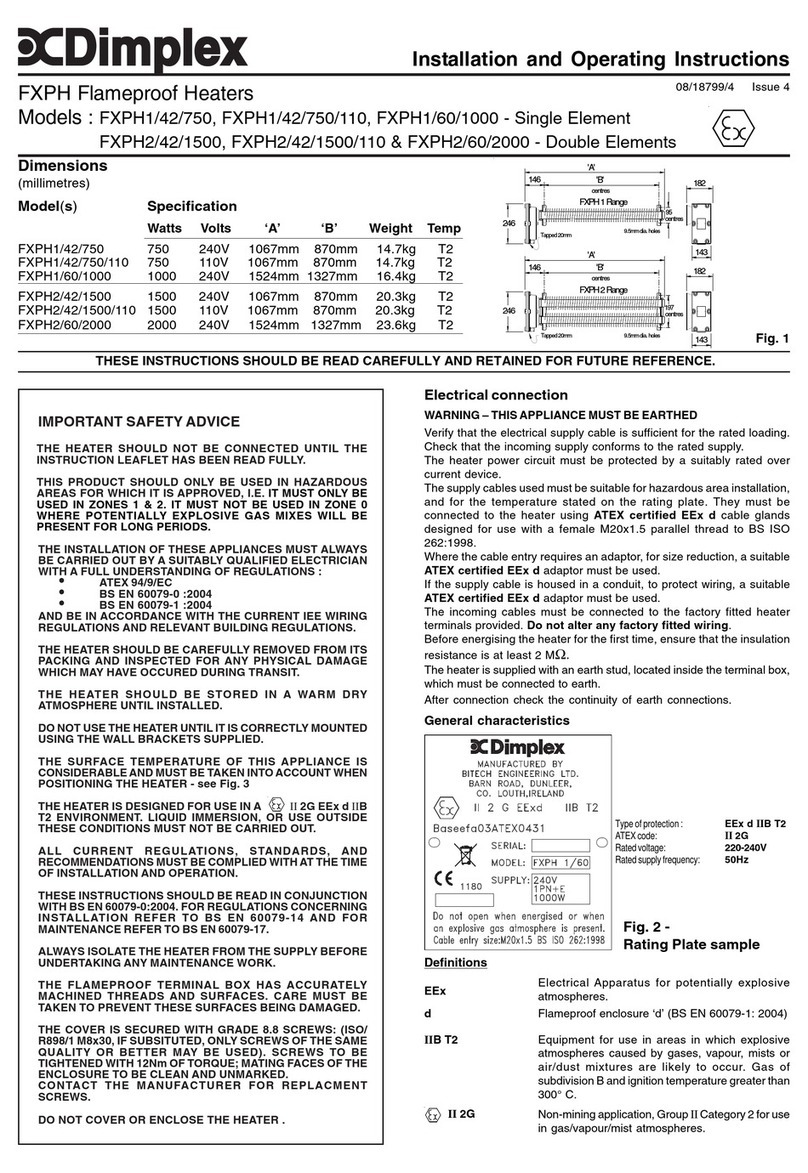

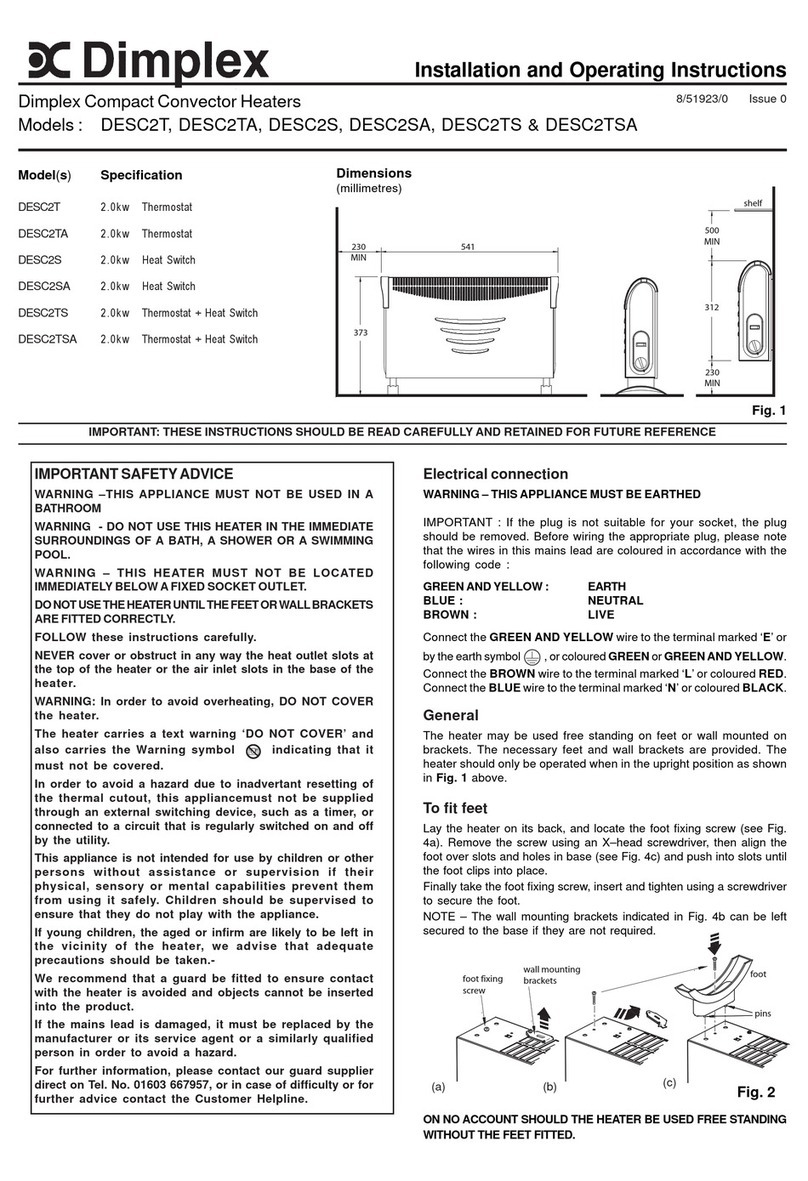

Dimensions

Model(s) Specification

WFC 3NB 3kW, Switch, Thermostat & Neon - Black

WFC 3NS 3kW, Switch, Thermostat & Neon - Silver

Fig. 1

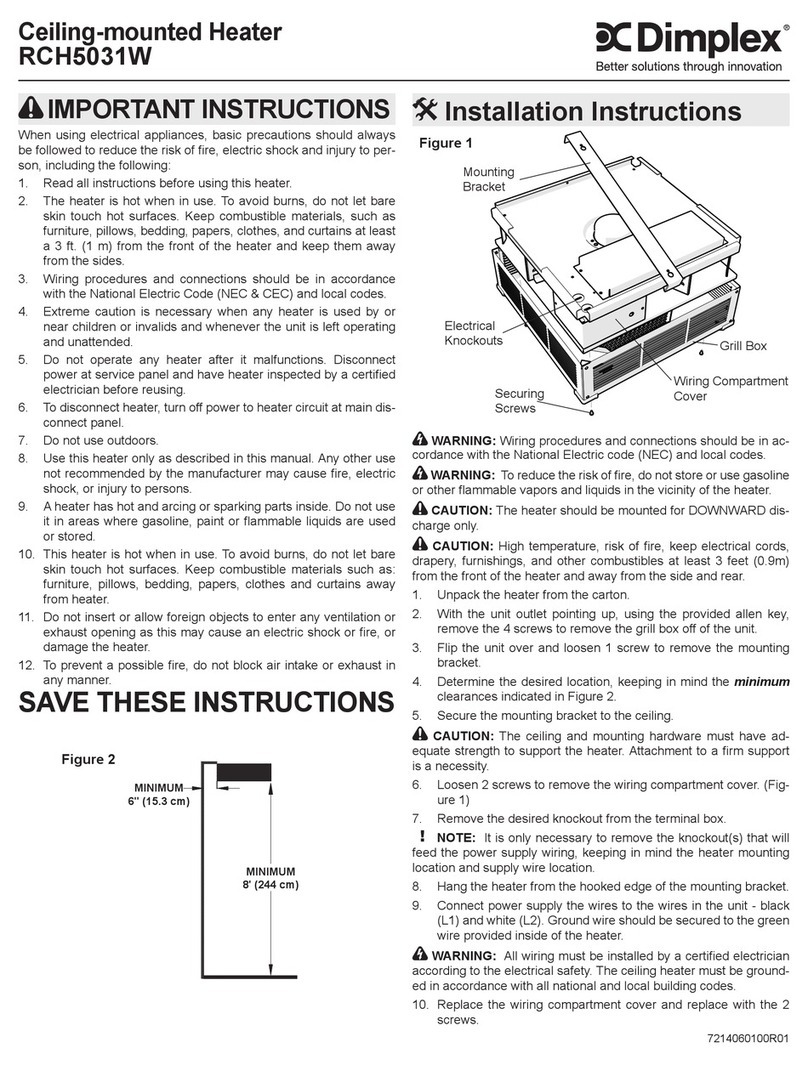

Installation

Before undertaking installation work, ensure the electricity supply

is disconnected from any relevant fixed wiring.

Supply cable is not provided with this appliance, and a competent

electrician should therefore install it.

The appliance must be fitted horizontally with the cable or conduit entry

at bottom right. It should be mounted such that the underside is at least

350mm above the floor and the top of the heater is 150mm below any

overhanging shelf or obstruction.

This heater must be used on an A.C.~ supply only and the voltage

marked on the heater must correspond to the supply voltage.

To comply with the I.E.E. Wiring Regulations, the appliance must be

earthed; the supply circuit must be adequate for the input of the

appliance, and the circuit protected by a suitable 13A fuse. A suitable

termination to the fixed wiring of the premises must be provided adjacent

to the final position of the appliance. In this instance, such a termination

can be a double-pole switch with a contact separation of at least 3mm in

all poles.

The heater must not be located immediately below a socket-outlet.

Electrical

WARNING : THIS APPLIANCE MUST BE EARTHED.

After ensuring the electricity supply is not live, electrical connections can

be made, either to an adjacent double-pole switch having a contact

separation of at least 3mm in all poles or to a plug-top for use in a

standard 13A socket.

If the latter: Connect Green and Yellow wire to plug terminal marked E

or Green or Green and Yellow. Connect Blue wire to plug terminal

marked Nor Black. Connect Brown wire to plug terminal marked Lor

Red.

Refit cover, first hooking top over the back of the unit and then securing

the bottom by refitting the two screws under the bottom edge. The

appliance is now ready for use and the electricity supply can be

reinstated.

THESE INSTRUCTIONS SHOULD BE READ CAREFULLY AND RETAINED FOR FUTURE REFERENCE.

IMPORTANT SAFETY ADVICE

WARNING – THIS APPLIANCE MUST NOT BE USED IN A

BATHROOM.

WARNING – DO NOT USE THIS HEATER IN THE IMMEDIATE

SURROUNDINGS OF A BATH, A SHOWER OR A SWIMMING

POOL.

WARNING – THIS HEATER MUST NOT BE LOCATED

IMMEDIATELY BELOW A FIXED SOCKET OUTLET.

DO NOT USE THE HEATER UNTIL IT IS WALL MOUNTED

CORRECTLY.

The heater carries a warning 'Do Not Cover' to alert the user

to the risk of overheating that exists if the heater is

accidentally covered.

NEVER cover or obstruct in any way the air inlet slots at the

front of the heater or the heat outlet slots in the base of the

heater.

Keep combustible materials such as drapes and other

furnishings clear from the front of the heater. Do not use

heater to dry your laundry.

If young children, the aged, or infirm are likely to be left in

the vicinity of the heater, we advise that adequate

precautions should be taken. We recommend that a guard

be fitted to ensure contact with the heater is avoided and

objects cannot be inserted into the product.

If you use this heater in conjunction with a thermal control, a

programme controller, a timer or any other device which

switches on the heater automatically, remember to observe

all safety warnings at all times.

Do not use where excessive dust or moisture is present.

For further information, please contact our guard supplier

direct on Tel. No. 01603 667957, or in the case of difficulty or

for further advice contact the Customer Helpline.