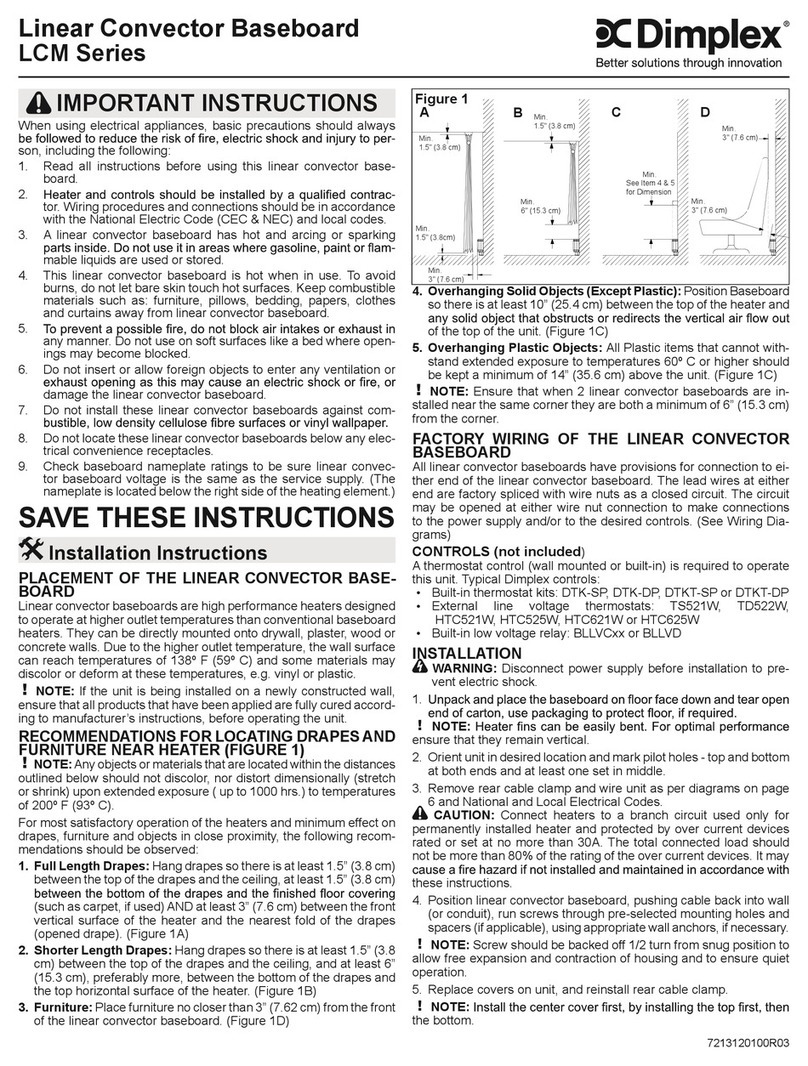

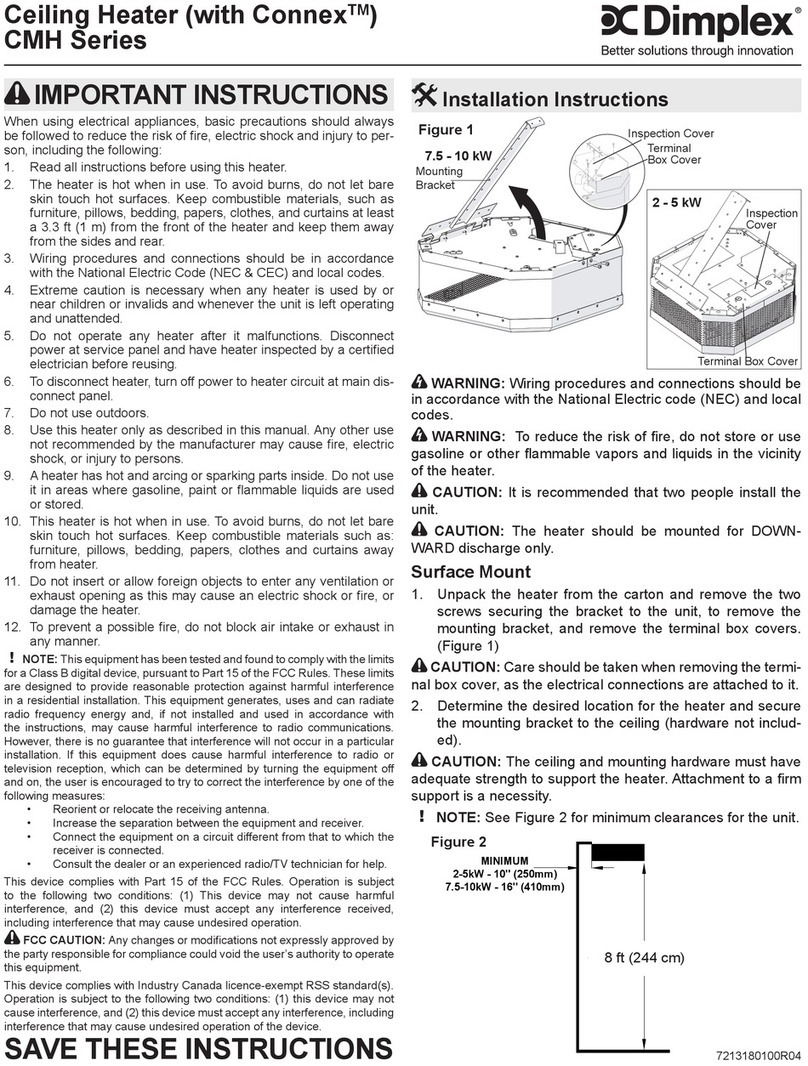

246

146

246

9.5mm dia. holes

9.5mm dia. holes

FXPH 2 Range

FXPH 1 Range

'A'

'B'

centres

143

centres

197

centres

95

182

143

146

'A'

centres

'B' 182

Tapped 20mm

Tapped 20mm

THESE INSTRUCTIONS SHOULD BE READ CAREFULLY AND RETAINED FOR FUTURE REFERENCE.

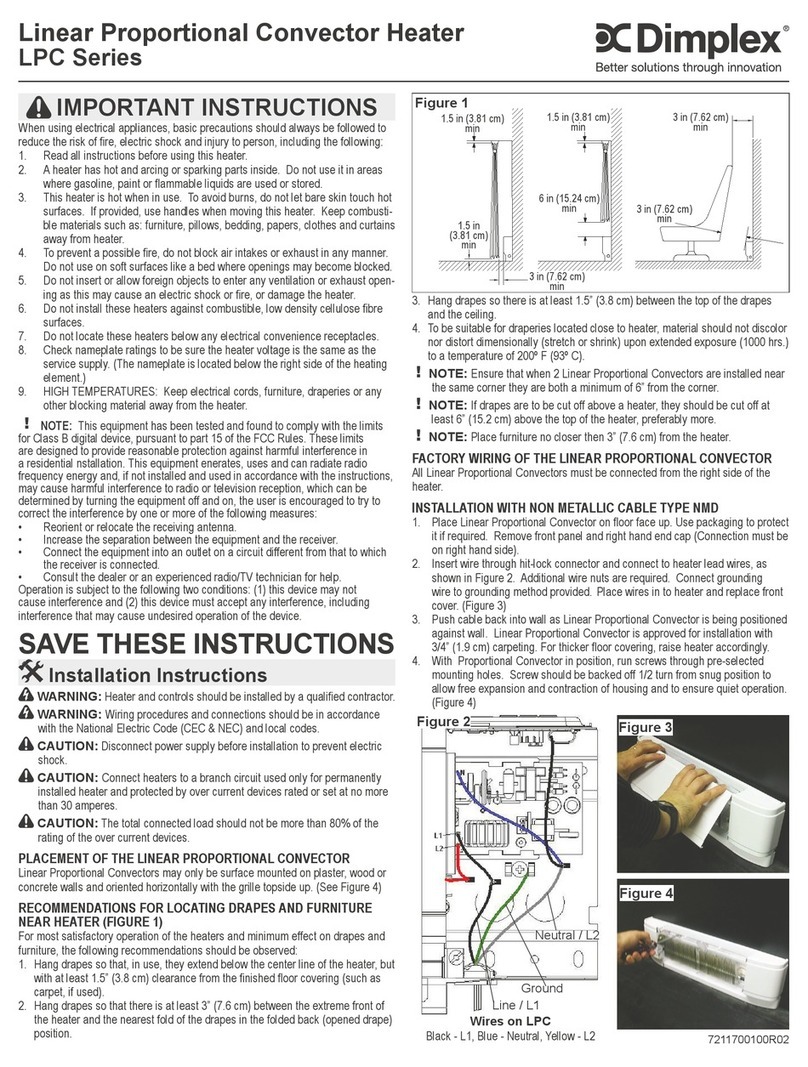

Dimensions

(millimetres)

Model(s)Specification

Watts Volts ‘A’ ‘B’ Weight Temp

FXPH1/42/750 750 240V 1067mm 870mm 14.7kg T2

FXPH1/42/750/110 750 110V 1067mm 870mm 14.7kg T2

FXPH1/60/1000 1000 240V 1524mm 1327mm 16.4kg T2

FXPH2/42/1500 1500 240V 1067mm 870mm 20.3kg T2

FXPH2/42/1500/110 1500 110V 1067mm 870mm 20.3kg T2

FXPH2/60/2000 2000 240V 1524mm 1327mm 23.6kg T2

FXPH Flameproof Heaters

Models : FXPH1/42/750, FXPH1/42/750/110, FXPH1/60/1000 - Single Element

FXPH2/42/1500, FXPH2/42/1500/110 & FXPH2/60/2000 - Double Elements

Installation and Operating Instructions

Fig. 1

08/18799/4 Issue 4

Electrical connection

WARNING – THIS APPLIANCE MUST BE EARTHED

Verify that the electrical supply cable is sufficient for the rated loading.

Check that the incoming supply conforms to the rated supply.

The heater power circuit must be protected by a suitably rated over

current device.

The supply cables used must be suitable for hazardous area installation,

and for the temperature stated on the rating plate. They must be

connected to the heater using ATEX certified EEx d cable glands

designed for use with a female M20x1.5 parallel thread to BS ISO

262:1998.

Where the cable entry requires an adaptor, for size reduction, a suitable

ATEX certified EEx d adaptor must be used.

If the supply cable is housed in a conduit, to protect wiring, a suitable

ATEX certified EEx d adaptor must be used.

The incoming cables must be connected to the factory fitted heater

terminals provided. Do not alter any factory fitted wiring.

Before energising the heater for the first time, ensure that the insulation

resistance is at least 2 MΩ.

The heater is supplied with an earth stud, located inside the terminal box,

which must be connected to earth.

After connection check the continuity of earth connections.

IMPORTANT SAFETY ADVICE

THE HEATER SHOULD NOT BE CONNECTED UNTIL THE

INSTRUCTION LEAFLET HAS BEEN READ FULLY.

THIS PRODUCT SHOULD ONLY BE USED IN HAZARDOUS

AREAS FOR WHICH IT IS APPROVED, I.E. IT MUST ONLY BE

USED IN ZONES 1 & 2. IT MUST NOT BE USED IN ZONE 0

WHERE POTENTIALLY EXPLOSIVE GAS MIXES WILL BE

PRESENT FOR LONG PERIODS.

THE INSTALLATION OF THESE APPLIANCES MUST ALWAYS

BE CARRIED OUT BY A SUITABLY QUALIFIED ELECTRICIAN

WITH A FULL UNDERSTANDING OF REGULATIONS :

•ATEX 94/9/EC

•BS EN 60079-0 :2004

•BS EN 60079-1 :2004

AND BE IN ACCORDANCE WITH THE CURRENT IEE WIRING

REGULATIONS AND RELEVANT BUILDING REGULATIONS.

THE HEATER SHOULD BE CAREFULLY REMOVED FROM ITS

PACKING AND INSPECTED FOR ANY PHYSICAL DAMAGE

WHICH MAY HAVE OCCURED DURING TRANSIT.

THE HEATER SHOULD BE STORED IN A WARM DRY

ATMOSPHERE UNTIL INSTALLED.

DO NOT USE THE HEATER UNTIL IT IS CORRECTLY MOUNTED

USING THE WALL BRACKETS SUPPLIED.

THE SURFACE TEMPERATURE OF THIS APPLIANCE IS

CONSIDERABLE AND MUST BE TAKEN INTO ACCOUNT WHEN

POSITIONING THE HEATER - see Fig. 3

THE HEATER IS DESIGNED FOR USE IN A II 2G EEx d IIB

T2 ENVIRONMENT. LIQUID IMMERSION, OR USE OUTSIDE

THESE CONDITIONS MUST NOT BE CARRIED OUT.

ALL CURRENT REGULATIONS, STANDARDS, AND

RECOMMENDATIONS MUST BE COMPLIED WITH AT THE TIME

OF INSTALLATION AND OPERATION.

THESE INSTRUCTIONS SHOULD BE READ IN CONJUNCTION

WITH BS EN 60079-0:2004. FOR REGULATIONS CONCERNING

INSTALLATION REFER TO BS EN 60079-14 AND FOR

MAINTENANCE REFER TO BS EN 60079-17.

ALWAYS ISOLATE THE HEATER FROM THE SUPPLY BEFORE

UNDERTAKING ANY MAINTENANCE WORK.

THE FLAMEPROOF TERMINAL BOX HAS ACCURATELY

MACHINED THREADS AND SURFACES. CARE MUST BE

TAKEN TO PREVENT THESE SURFACES BEING DAMAGED.

THE COVER IS SECURED WITH GRADE 8.8 SCREWS: (ISO/

R898/1 M8x30, IF SUBSITUTED, ONLY SCREWS OF THE SAME

QUALITY OR BETTER MAY BE USED). SCREWS TO BE

TIGHTENED WITH 12Nm OF TORQUE; MATING FACES OF THE

ENCLOSURE TO BE CLEAN AND UNMARKED.

CONTACT THE MANUFACTURER FOR REPLACMENT

SCREWS.

DO NOT COVER OR ENCLOSE THE HEATER .

Fig. 2 -

Rating Plate sample

Definitions

General characteristics

Electrical Apparatus for potentially explosive

atmospheres.

Typeofprotection: EEx d IIB T2

ATEXcode: II 2G

Ratedvoltage: 220-240V

Ratedsupplyfrequency: 50Hz

Flameproof enclosure ‘d’ (BS EN 60079-1: 2004)

Equipment for use in areas in which explosive

atmospheres caused by gases, vapour, mists or

air/dust mixtures are likely to occur. Gas of

subdivision B and ignition temperature greater than

300° C.

Non-mining application, Group IICategory 2 for use

in gas/vapour/mist atmospheres.

d

IIB T2

II 2G

EEx