- 7 -

Commissioning

Upon completion of installation, the stove and ue system should

be tested by a suitably qualied person to make sure it is safe for

normal use. A smoke draw test should be completed to check for

soundness of joints and seals and also that all smoke and fumes

are taken from the appliance up the chimney and emitted safely.

First warm the ue with a blowlamp or similar for about 10 minutes.

Place a lit smoke pellet on the centre of the grate with the air

controls open. Close the door – the smoke should be drawn up the

ue and be seen to exit from the ue terminal. Complete the test

with all windows and doors shut in the room where the appliance

is tted.

If a ceiling fan is present it must be operated on max for the duration

of the test. If there are any extraction fans in adjacent rooms these

too must be operated on maximum setting during the test with the

interconnecting doors open. If any spillage occurs, recheck the

suitability of the ue system making sure there is adequate air

supply to the room (as per Building Regulations).

Light the appliance and slowly increase the temperature to

operating levels. Open the main re door when the appliance

reaches normal operating condition and carry out a spillage test

using a smoke match or pellet around the door opening. If any

spillage occurs, open all windows, allow the re to go out and

recheck the ue system and ventilation.

Operating Instructions

Please read fully these operating instructions and advise any

other users of the correct operating procedures for this stove.

Warning: This appliance and its operating handles become

hot when the stove is in use and the stove will remain hot for

some time afterwards. For your safety use the glove provided.

Initial Firing of Stove

We recommend that you have 3-4 small res before you operate

your stove to maximum heat output. This is to allow the paint to cure

and the castings to relax and consolidate location. We recommend

this ‘running in’ procedure after long idle periods to preserve the

life of the stove. During this you may notice an unpleasant smell

as paint and re cement cures. It is not toxic but for your own sake

we would suggest that during this period you leave all doors and

windows open.

Air Controls

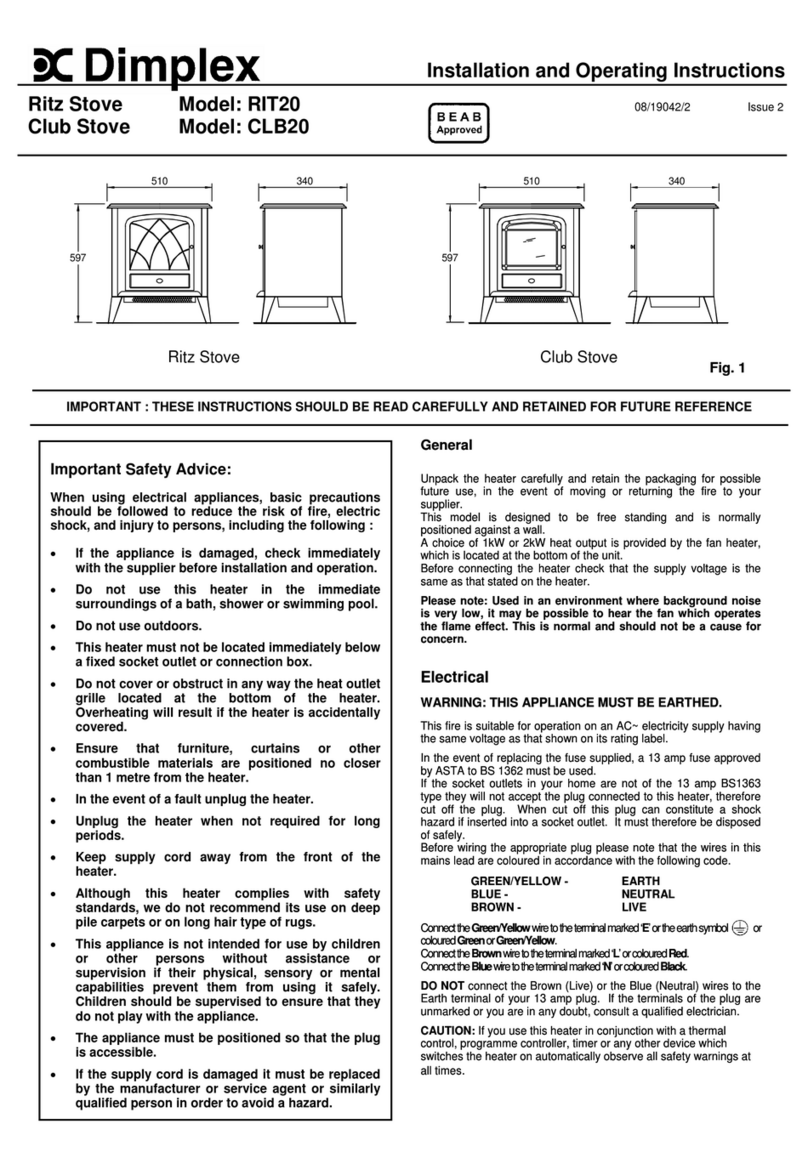

Primary air is controlled via the sliding vent (Fig 9 A) in the bottom

of the door; this provides a conventional air draught to the bed of

the re. Moving the slider to the right increases the air intake, to

the left reduces the air intake.

Secondary air is controlled via the sliding vent (Fig 9 B) above the

door. It is this ‘Airwash’ that keeps a clean and uninterrupted view

of the re, also aiding in good secondary combustion of fuel and

reducing emissions into the chimney and environment.

Lighting the Stove

Place re lighters or paper and 5-6 pieces of dry kindling on the

grate. Light the re at base and allow the kindling to light fully

across the grate. Build the re up gradually using small rells of

fuel until there is a good re bed and the re is well established.

When refuelling with wood, leave both air controls in the fully open

position to the right for 1-2 minutes until the new fuel is burning

brightly. Once the fuel is fully alight and ames are well established,

the primary air (undergrate air) should be closed fully and the

airwash reduced to adjust the stove to the desired heat output.

If refuelling with solid fuel then the airwash should be closed

and the primary air slide should be fully open until the fuel is well

alight. Once the fuel is well alight the primary air may be adjusted

to control the re to the desired heat setting.

Do not operate the stove with both air supplies open for

extended periods, as this will result in overring, causing

excessive running temperatures and premature burnout of

components.

Running the Stove

When your fuel is well alight you can start to restrict the air intake to

the desired setting. Your stove is burning with maximum efciency

when a bright re is achieved using minimum air inlet.

Never leave the stove unattended until the fuel is burning well and

the air supply has been adjusted down to desired level.

Note that refuelling onto a low rebed causes excessive smoke

to occur. Refuelling must be carried out onto a sufcient quantity

of glowing embers to ignite fuel in a reasonable period. If there

are too few embers add kindling rst to get re going again before

refuelling. The stove is not suitable for overnight burning.

For optimum performance the stove should not be overlled with

fuel above the height of the rear brick. To do so can cause poor

operation, excessive smoke to occur and possible damage to bafe

plate. The stove must not be operated with the door left open.

This stove is capable of intermittent operation.

Notes on Wood Burning

Burn only dry, well seasoned wood (< 20% moisture), which should

have been cut, split and stacked for a minimum of 12 months (24

months is better) with free air movement around all sides of the

stack to enable it to dry out. Burning wet or unseasoned wood will

create tar deposits in the stove and chimney and will not produce

a satisfactory heat output. When loading wood, make sure that the

end grain of the wood in the stove is pointing away from the glass

otherwise the moisture and gases coming from the end grain of

the wood will dirty the glass.

Table 6 - Maximum log lengths

Bellingham Inset 4.7kW 230mm (9”)

Notes on Solid Fuel burning (Other than Wood)

Always de-ash the stove before burning solid fuel and do not let the

ash build up to the underside of the grate bars. Solid fuel produces

ash, which if allowed to build up it will stie the air ow through the

grate and will eventually cause the re to die. Air passing through

the rebed cools the grate. Distortion or burning out of the grate

bars is nearly always caused by ash being allowed to build up

on the underside of the grate. With some solid fuels a residue of

burnt fuel or clinker will accumulate on the grate. It is important to

empty the ash pan and remove clinker after each ring of the stove.

We recommend the use of HETAS approved manufactured

smokeless fuels. Note that different types of fuel will give different

performances. Using the stove as an incinerator for household

waste invalidates the warranty is not recommended as fumes from

plastic, etc will cause pollution to the atmosphere and will cause

damage to the stove.

Petroleum coke fuels, bituminous (smokey) coal or household

waste should not be burned in this appliance.

Shutting Down

To shut down the stove, close the primary air controls and then

the secondary air controls by moving both sliders to the left. If the

controls are left in this position the re will be starved of air and will

go out. To revive the re if it has not already extinguished, open

the primary air controls rst, then the secondary air.