1603-065-N-7-11

4

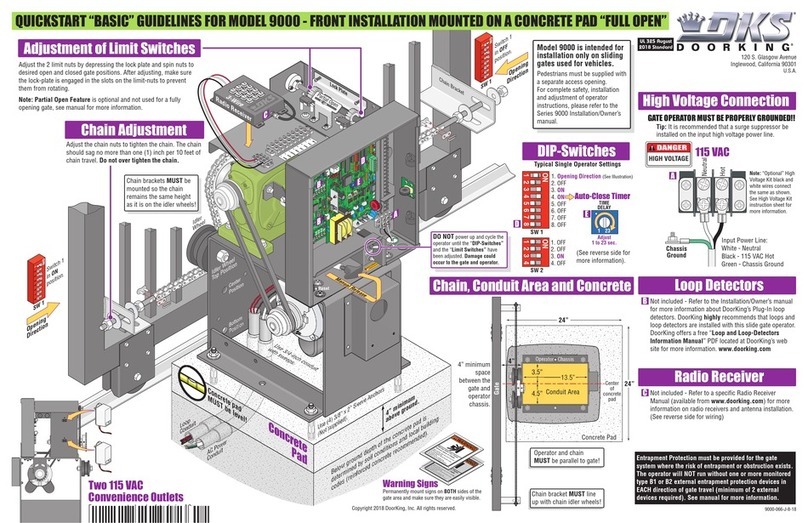

UL 325 Entrapment Protection

Class I and II

Class III

Class IV

Class II

Class III Class IV

A vehicular gate operator (or system) intended for use in a

home of one-to four single family dwelling, or a garage or

parking area associated therewith.

A vehicular gate operator (or system) intended for use in a

commercial location or building such as a multi-family

housing unit (five or more single family units) hotel,

garages, retail store or other building servicing the general

public.

A vehicular gate operator (or system) intended for use in a

industrial location or building such as a factory or loading

dock area or other locations not intended to service the

general public.

A vehicular gate operator (or system) intended for use in a

guarded industrial location or building such as an airport

security area or other restricted access locations not

servicing the general public, in which unauthorized access

is prevented via supervision by security personnel.

This table illustrates the entrapment protection requirements for each of the four UL 325 classes.

A- Inherent entrapment protection system.

B1 - Provision for connection of, or supplied with, a non-contact sensor (photoelectric sensor or the equivalent).

When used as the PRIMARY device, must be monitored.

B2 - Provision for connection of, or supplied with, a contact sensor (edge device or the equivalent).

When used as the PRIMARY device, must be monitored.

C- Inherent adjustable clutch or pressure relief device.

D- Provision for connection of, or supplied with, an actuating device requiring continuous pressure to maintain

opening or closing motion of the gate.

E- An inherent audio alarm.

STATE PRISON

UL 325

Classifications

Horizontal Slide, Vertical Lift, Vertical Pivot Swing and Vertical Barrier (arm)

Primary Protection

A B1, B2 or D A, B1, B2, C or DA or C

A, B1 or B2 A, B1, B2, D or E A, B1, B2, C or DA, B1, B2 or C

A, B1, B2 or D A, B1, B2, D or E A, B1, B2, C, D or EA, B1, B2, C or D

Secondary Protection Primary Protection Secondary Protection

Class I