6400-065-E-05-07 6400 installation guide 5

1

general information / safety information

Gate Construction

Instructions for Intended Installation

Vehicular gates should be constructed and installed in

accordance with ASTM F2200; Standard Specification

for Automated Vehicular Gate Construction. For a copy

of this standard, contact ASTM directly at 610-832-9585;

Controls intended for user activation must be located

at least ten feet (10’) away from any moving part of the

gate and where the user is prevented from reaching

over, under, around or through the gate to operate the

controls. Outdoor or easily accessible controls should

have a security feature to prevent unauthorized use.

The Stop and/or Reset button must be located in the

line-of-sight of the gate. Activation of the reset control

shall not cause the operator to start.

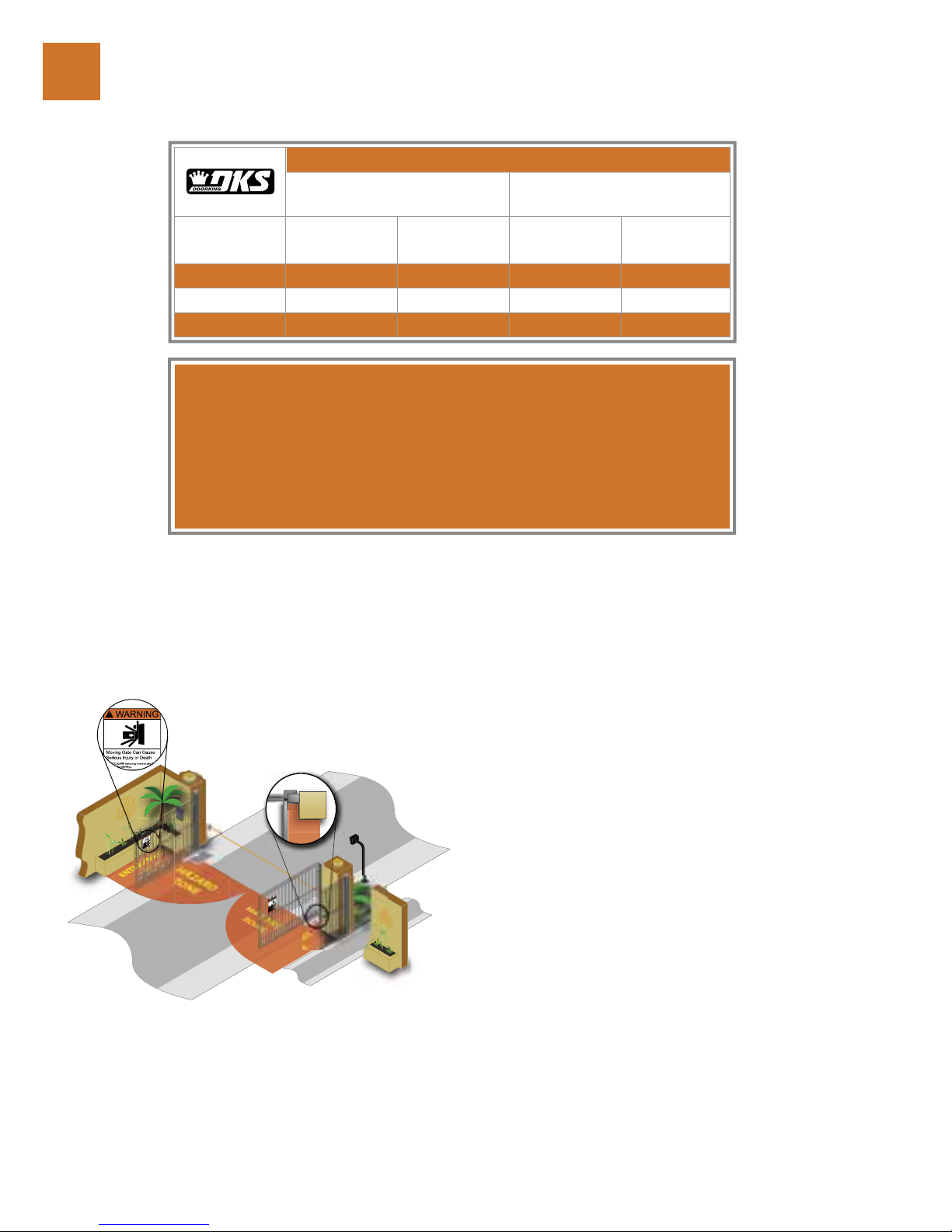

A minimum of two (2)WARNING SIGNS shall be installed,

one on each side of the gate where easily visible.

For gate operators utilizing a non-contact sensor:

1. See the instructions on the placement

of non-contact sensors for each type

of application.

2. Care shall be exercised to reduce the risk of

nuisance tripping, such as when a vehicle

trips the sensor while the gate is still moving

in the opening direction.

3. One or more non-contact sensors shall

be located where the risk of entrapment or

obstruction exist, such as the perimeter

reachable by a moving gate or barrier.

For gate operators utilizing contact sensors:

1. One or more contact sensors shall be

located where the risk of entrapment or

obstruction exist, such as at the leading

edge, trailing edge, and post mounted both

inside and outside of a vehicular horizontal

slide gate.

2. One or more contact sensors shall be

located at the bottom edge of a vehicular

vertical lift gate.

3. One or more contact sensors shall

be located at the pinch point of a

vehicular vertical pivot gate.

4. A hardwired contact sensor shall be

located and its wiring arranged so that the

communication between the sensor and the

gate operator is not subjected to mechanical

damage.

5. A wireless contact sensor such as one that

transmits radio frequency (RF) signals to

the gate operator for entrapment protection

functions shall be located where the

transmission of the signals are not obstructed

or impeded by building structures, natural

landscaping or similar obstructions. A

wireless contact sensor shall function under

the intended end-use conditions.

6. One or more contact sensors shall be located

at the bottom edge of a vertical barrier (arm).

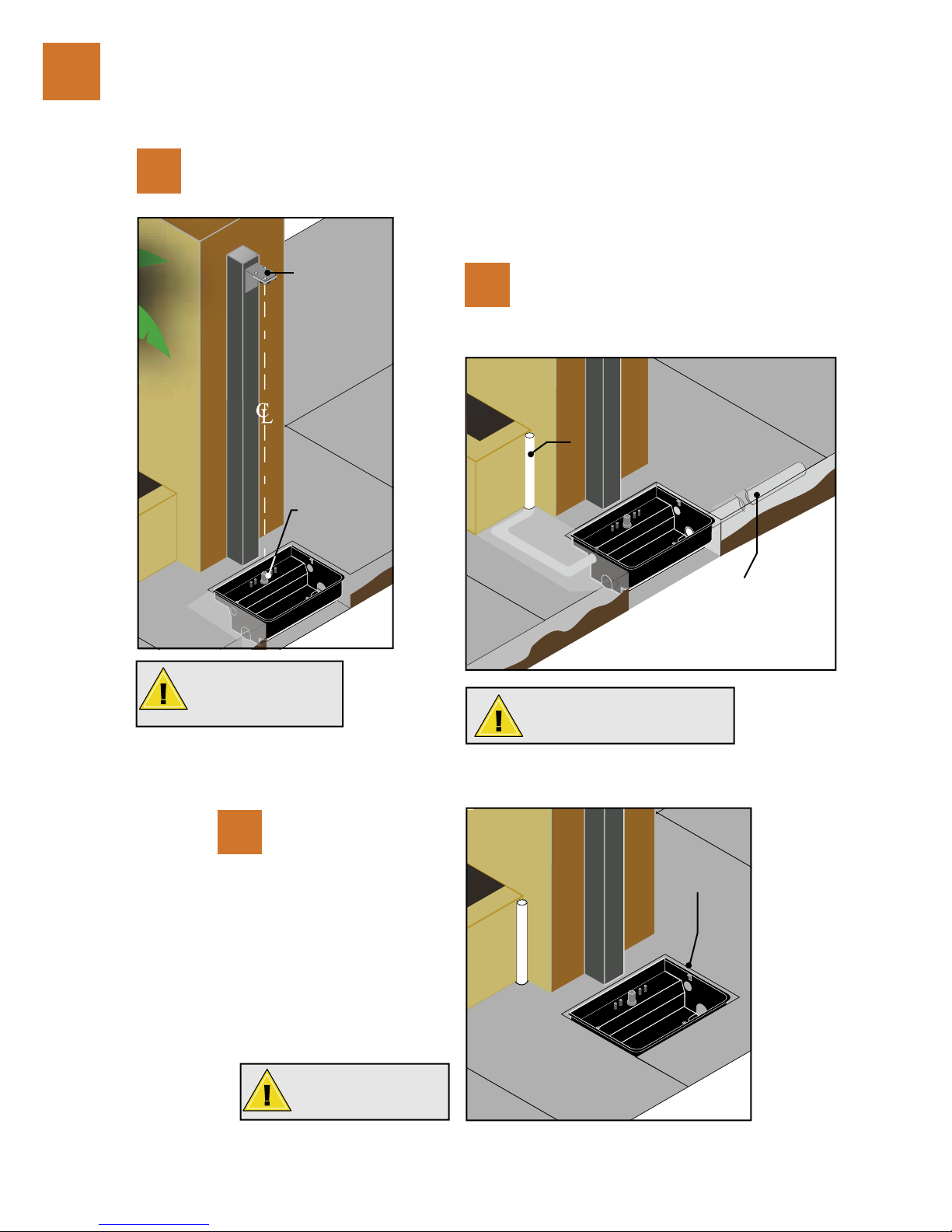

Install the gate operator only if:

1. The operator is appropriate for the construction

of the gate and the usage class of the gate.

2. All openings of a horizontal slide gate are

guarded or screened from the bottom

of the gate to a minimum of 4 feet (1.22 m)

above the ground to prevent a 2 ¼ inch

(57.2 mm) diameter sphere from passing

through the openings anywhere in the gate,

and in that portion of the adjacent fence that

the gate covers in the open position.

3. All exposed pinch points are eliminated or

guarded.

4. Guarding is supplied for exposed rollers.

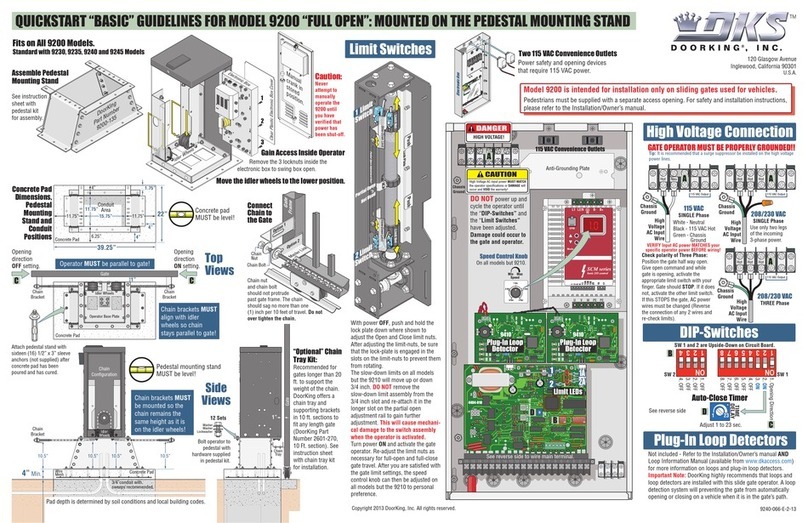

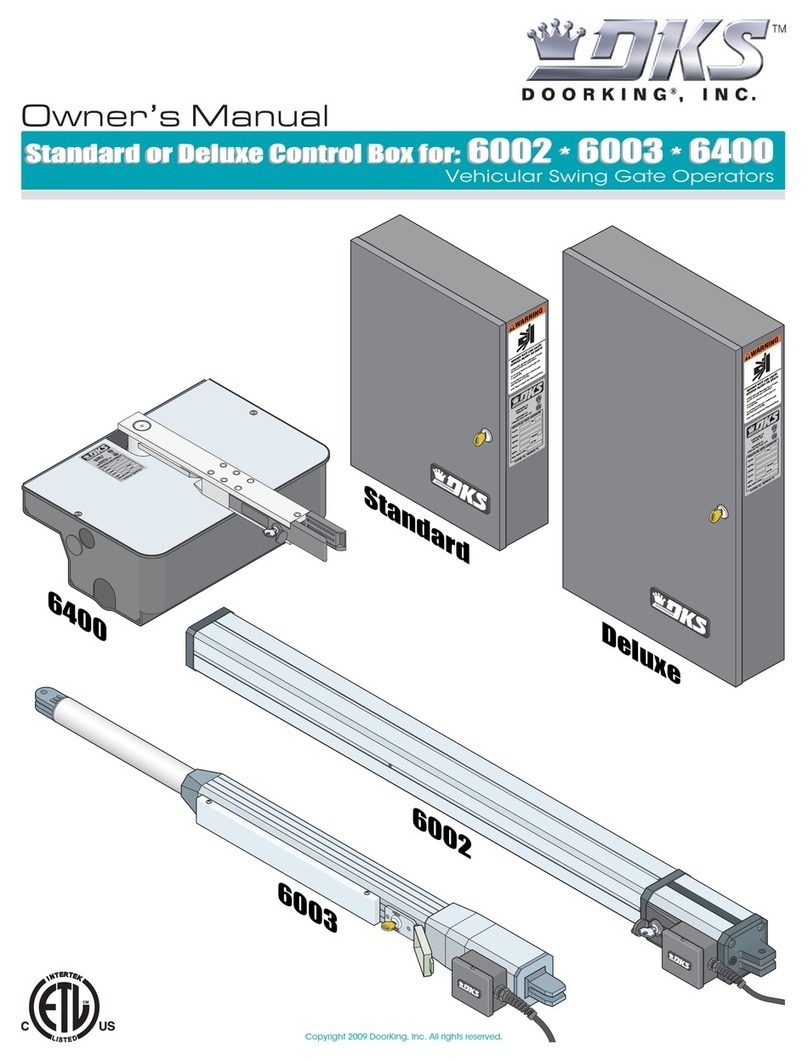

The operator is intended for installation only on gates

used for vehicles. Pedestrians must be supplied with a

separate access opening. The pedestrian access opening

shall be designed to promote pedestrian usage. Locate

the gate such that persons will not come in contact with

the vehicular gate during the entire path of travel of the

vehicular gate.

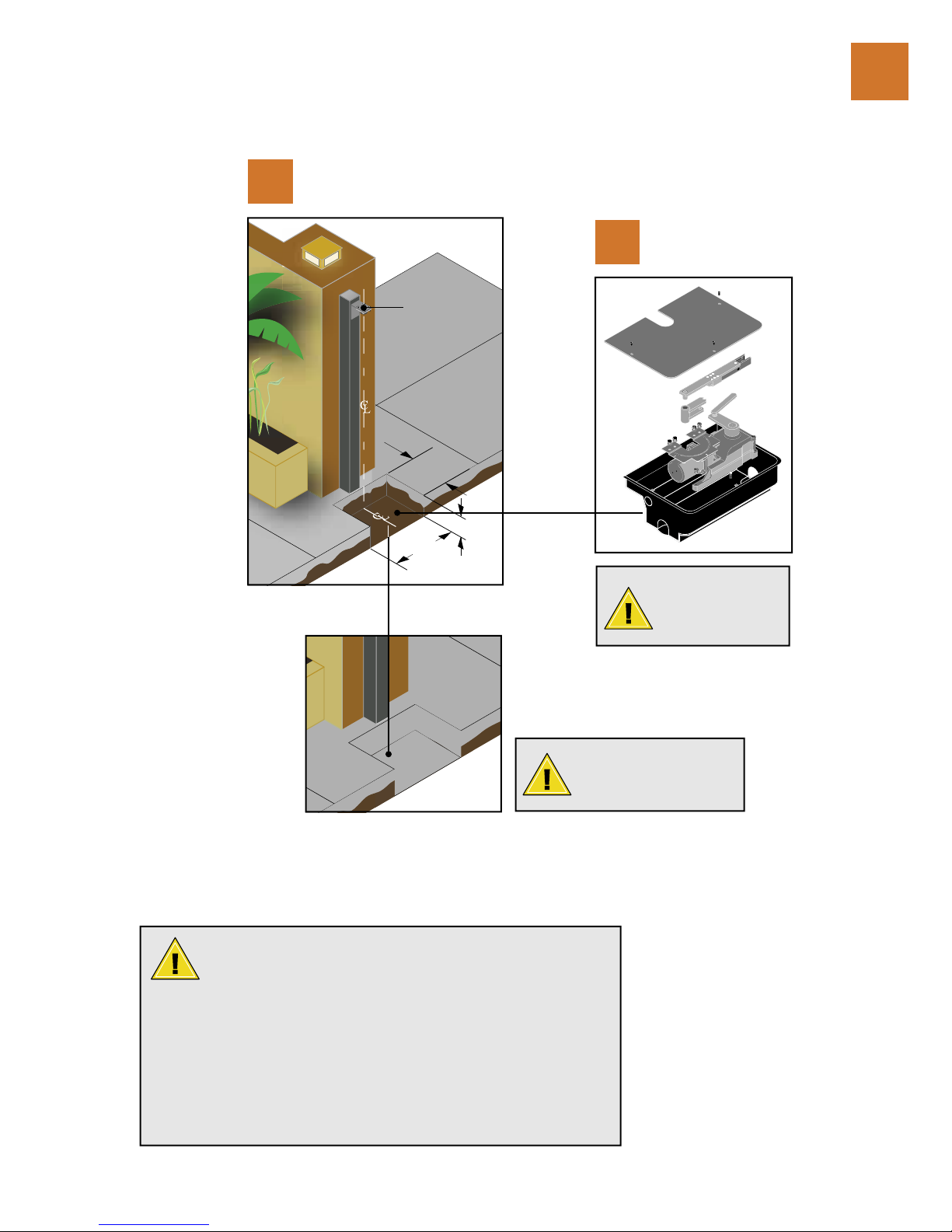

The gate must be installed in a location so that enough

clearance is supplied between the gate and adjacent

structures when opening and closing to reduce the risk of

entrapment. Swinging gates should not open into public

access areas.

The gate must be properly installed and work freely in both

directions prior to the installation of the gate operator.

Do not over-tighten the operator clutch, pressure relief

valve or reduce reversing sensitivity to compensate for a

damaged gate.

For gate operators utilizing Type D protection:

1. The gate operator controls must be placed so

that the user has full view of the gate area when

the gate is moving.

2. A warning placard shall be placed adjacent to

the controls.

3. An automatic closing device (such as a timer,

loop sensor, or similar device) shall not be used.

4. No other activation device shall be connected.