6002-065-G-08-06

4 installation guide

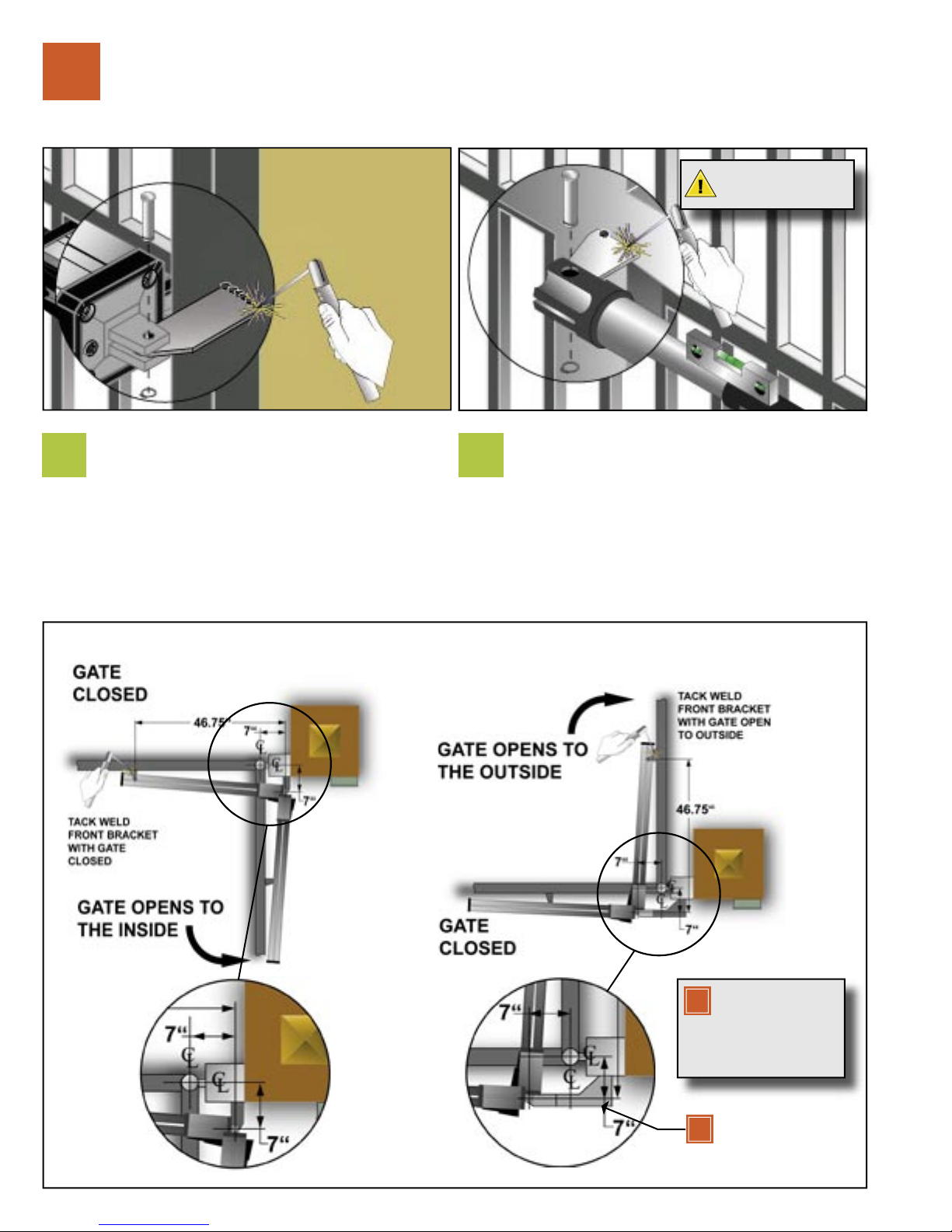

HAZARD ZONE

general information / safety instructions

1

Residents should be familiar

with proper use of gate, gate-

operator and possible hazards

associated with the gate system.

Eliminate or guard all exposed pinch points

and rollers.

Keep children away from gate controls.

Keep remote control away from children.

Security features should be installed to

avoid unauthorized use.

Controls must be installed away from the

gate (min. 10’ ft. away from gate) to avoid any

contact when operating the gate controls.

Keep adults, children and objects away from

the gate and HAZARD ZONES while in motion.

Speed limit through gate area is 5 MPH.

Install speed bumps and warning signs where

visible in the area of the gate. Failure to do so

may result in damage to the gate, gate-operator

and vehicle.

Gate operator is intended for installation on

gates used ONLY FOR VEHICULAR TRAFFIC.

Pedestrians must be provided with a separate

access and must stay out of the HAZARD

ZONE.

When removing the gate operator set to

the full open position and shut off power at the

service panel.

Vehicular gates should be constructed and

installed in accordance with ASTM F2200-

02, Standard Specifi cation for Automated

Vehicular Gate Construction. Contact ASTM at

610.832.9585 or www.astm.org.

Gates should be properly installed,

move freely and maintained following the

recommended service schedule. Contact your

service dealer for any maintenance or repairs.

User should be familiar with the following

functions:

Gate Operating System

Reversing Functions and Testing

Reversing Loops

Inherent Reversing System

Electric Edges

Photoelectric Cells

Related External Devices

Vehicular gate systems can produce high

levels of force; therefore it is important that you

are aware of possible hazards.

Pinch Points

Entrapment

Absence of Controlled Pedestrian Access

Traffi c Backup