CONTENTS

1.YOUR NEW PIPETTE .......................................................................................1

1.1 ADJUSTABLE VOLUME PIPETTES ........................................................................1

1.2 FULLYAUTOCLAVABLE ......................................................................................2

2.UNPACKING......................................................................................................2

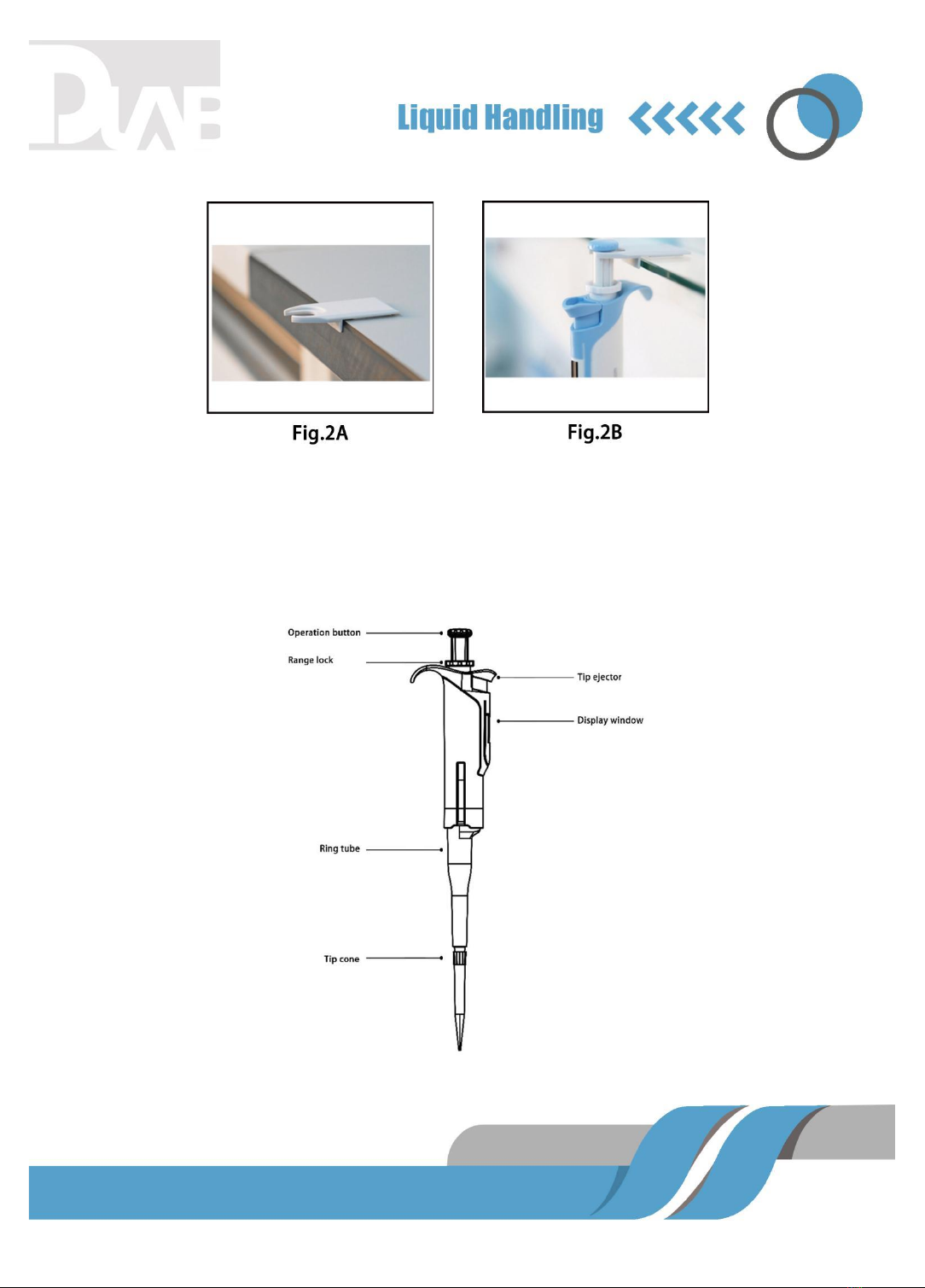

3.INSTALLING THE PIPETTE HOLDER ..............................................................3

4.PIPETTE COMPONENTS.................................................................................4

5.PIPETTE OPERATION......................................................................................5

5.1 VOLUME SETTING ............................................................................................5

5.2 RANGE LOCK ..................................................................................................5

5.3 SEALING AND EJECTING TIPS .............................................................................6

6.PIPETTING TECHNIQUES ...............................................................................6

6.1 FORWARD PIPETTING .......................................................................................7

6.2 REVERSE PIPETTING ........................................................................................7

7.PIPETTING RECOMMENDATIONS..................................................................8

8.STORAGE.........................................................................................................9