52

B

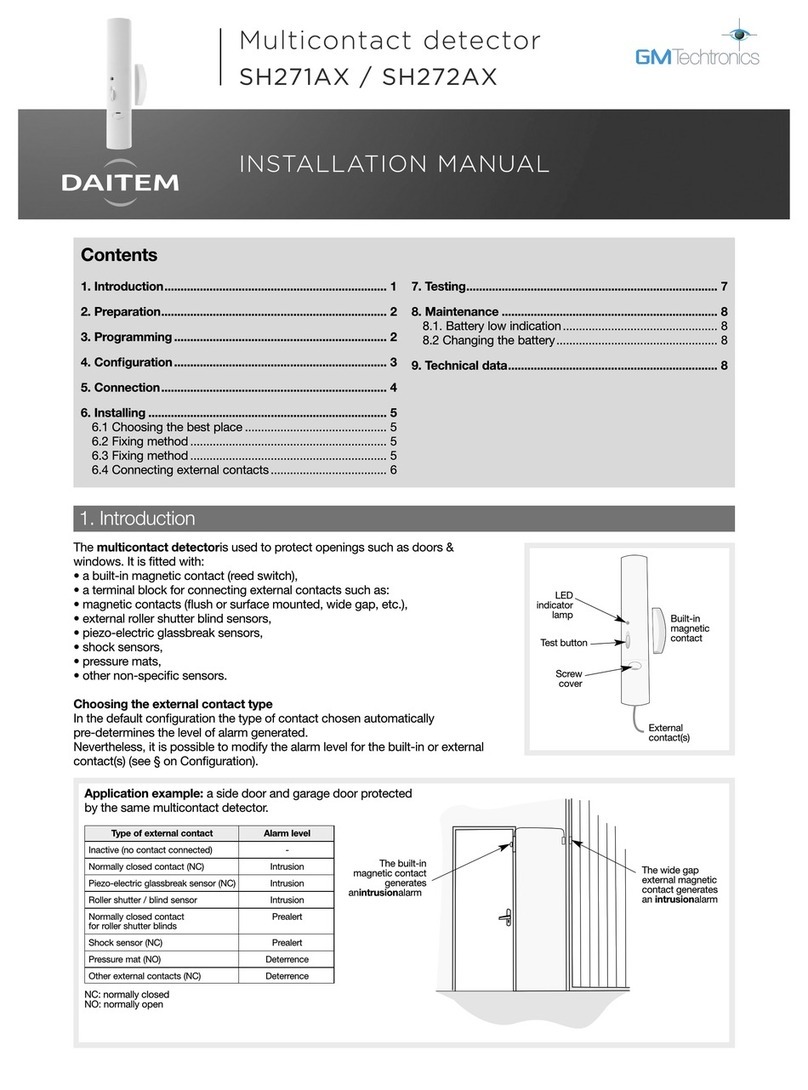

The special animal immune external movement detector monitors the inside or the

outside of buildings and distinguishes between humans and animals.

It is equipped with two sets of detection beams (higher and lower) which must be broken

simultaneously to activate a pre-alarm or a full alarm. Its detection range can be

adjusted, reducing false alarms due to unwanted detections (cars, people or animals

outside the desired protection area).

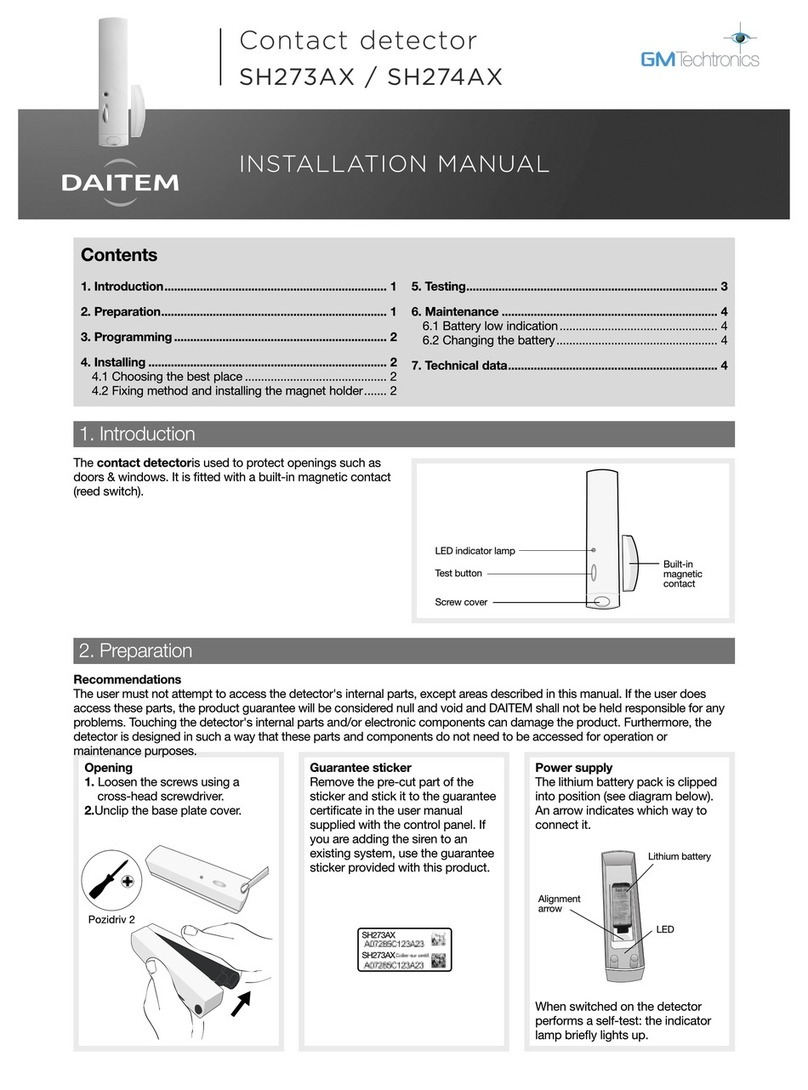

Description

Summary

1. Introduction ............................................... 52

2. Preparation ................................................ 53

2.1 Opening the detector............................ 53

2.2 Power supply ........................................ 53

3. Programming............................................. 54

4. Configuration............................................. 55

5. Installation precautions............................ 55

6. Installation.................................................. 56

6.1 Testing the radio link............................. 56

6.2 Wall fixing.............................................. 56

6.3 Pole fixing.............................................. 56

7. Configuration and adjustments

of detection................................................ 57

7.1 Range of detection ............................... 57

7.2 Horizontal orientation............................ 57

7.3 Mask a zone.......................................... 58

7.4 Adjustment of the sensitivity ................ 58

7.5 Adjustment of the operational

options .................................................. 58

8. Operating test............................................ 59

9. Maintenance.............................................. 60

9.1 Fault indication...................................... 60

9.2 Changing the battery............................ 60

10. Technical data ......................................... 61

1. Introduction

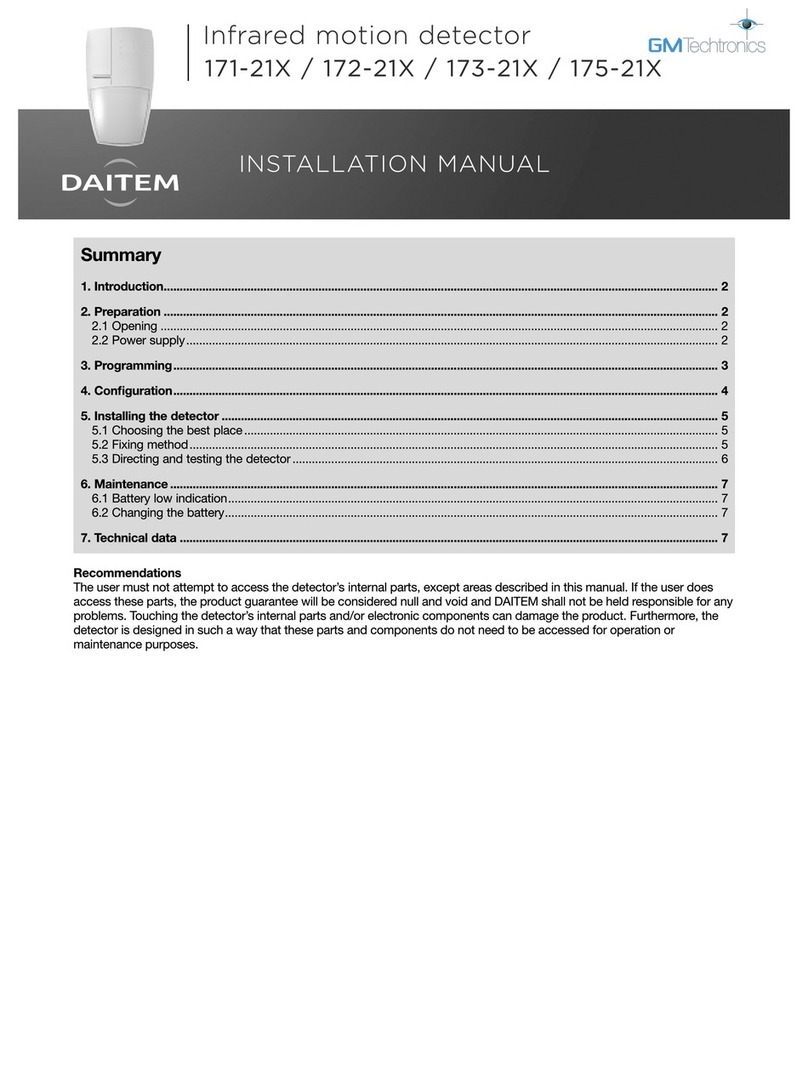

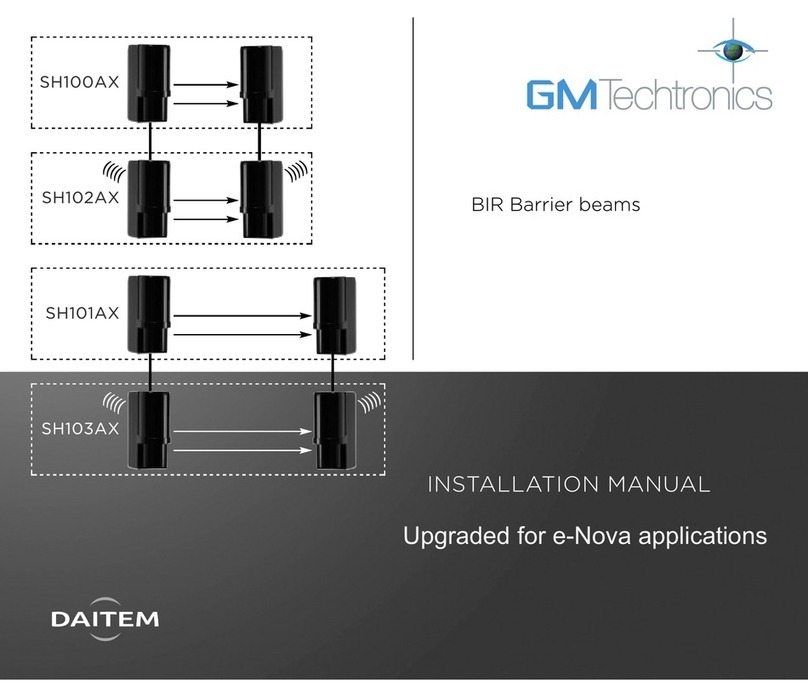

Detector module

Top pyro sensor

Bottom pyro sensor

Switch for sensitivity optionsDip-switch for operational

options

Range

detection

switch

Cover

Led

Indicator

Locking screw

Back box

Clamps

for

post

Screws

IMPORTANT

• Some functions are only available with control panel version 2.0.0 or later

(enter ) on the control panel keypad to check the version).

• Operating differences with respect to former ranges are described in the compatibility booklet

available in the Daitem Installers section at www.daitem.co.uk.

Recommendations

The user must not attempt to access the detector’s internal parts, except areas described in this manual. If the user does access these

parts, the product guarantee will be considered null and void and DAITEM shall not be held responsible for any problems. Touching

the detector’s internal parts and/or electronic components can damage the product. Furthermore, the detector is designed in such a

way that these parts and components do not need to be accessed for operation or maintenance purposes.