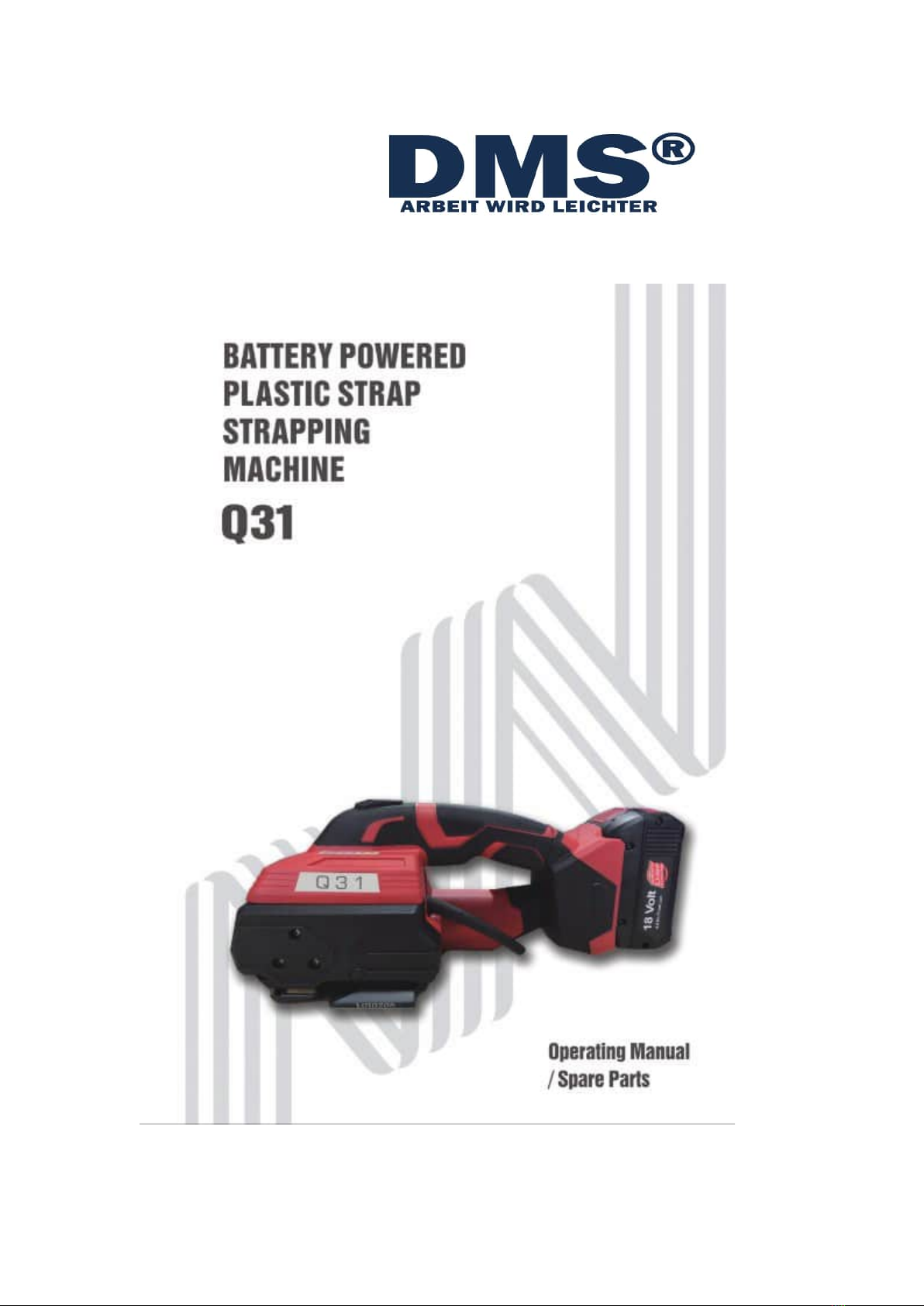

Operating Manual / Spare Parts

CONTENT

1. SAFETY INSTRUCTION ............................................................................................................ 3

1.1 Personal Safety .................................................................................................................... 3

1.2 Work Area Safety ................................................................................................................ 4

1.3 Power Tool Use And Care ................................................................................................... 4

1.4 Battery Tool Use And Care ................................................................................................. 4

1.5 Hazards of Incorrect Operation ........................................................................................... 5

1.6 Straps Dispenser .................................................................................................................. 5

1.7 Welding Effects ................................................................................................................... 5

1.8 Correct Strap Cutting .......................................................................................................... 6

1.9 Regular Maintenance .......................................................................................................... 6

2. TECHNICAL PARAMETERS ..................................................................................................... 6

2.1 Machine Introduction .......................................................................................................... 6

2.2 Dimensions.......................................................................................................................... 7

2.3 Strap Specification .............................................................................................................. 7

2.4 Strap Strength ...................................................................................................................... 7

2.5 Working Temperature .......................................................................................................... 7

3. ATTACHMENT ............................................................................................................................ 7

3.1 Battery Specification ........................................................................................................... 7

3.2 Charger Specification .......................................................................................................... 8

3.3 One Set of Tool Kit For Free ............................................................................................... 8

3.4 Suspension System(optional) .............................................................................................. 8

4. MACHINE APPEARANCE AND OPERATING PANEL ........................................................... 9

5. OPERATION STEPS .................................................................................................................. 10

5.1 Installation ......................................................................................................................... 10

5.2 Operation Function Description ........................................................................................ 11

5.2.1 Operation Panel And Buttons ................................................................................. 11

5.2.2 Basic Settings ......................................................................................................... 13

5.2.3 Strapping Operation Steps ...................................................................................... 15

5.2.4 Operation Methods for Three Modes ..................................................................... 16

5.2.5 Operation Essentials For Three Modes .................................................................. 17

5.3 Strapping Effect and Adjustment ...................................................................................... 18

5.3.1 Strap Welding Effect Judgment .............................................................................. 18

5.3.2 Appropriate Parameter Adjustment ........................................................................ 18

5.3.3 Reference for Tension Force (Unit: N) ................................................................... 19

6. WIRING DIAGRAM .................................................................................................................. 20

7. COMMON FAULT INDICATION AND TROUBLESHOOTING ............................................ 20

7.1 Machine Fault Code Description ...................................................................................... 21