33. Test fit your winch to the mounting bracket

and do up loosely with the clutch handle on

the left hand side of the vehicle.

34. This may require the clutch handle and gear-

box housing to be rotated forward one or 2

bolt holes to allow easy access through the

bulbar holes. See instructions in winch user

manual.

35. Determine where the winch control box will

be located and mount the control box. See

instructions in winch user manual for control

box mounting options. If mounting to the top

of the bullbar using the supplied bracket,

check clearance of control box to grill and also

check where the wires will route as if the

wires are passing through the holes in the top

of the bullbar the control box may not be able

to be wired until the bullbar has been fitted as

below.

36. Wire the winch up as per the winch

instruction manual and bolt the winch to the

mounting bracket, ensure the mounting bolts

are not too long and tighten correctly. Route

the wires and connect to battery and also

route the breather hose.

37. Unwind some cable from the winch, and pass

the cable through the fairlead hole in the

bullbar and through the roller fairlead. This

may require removing a circlip from the

fairlead and re installing once the cable is

passed through.

38. Install the roller fairlead into the bulbar.

39. Check the poly bulbar over riders, fog light

and top loop bolts are tight (Do not over

tighten the stainless steel loop mounting

bolts. Do not over tighten the poly bullbar

over riders as they will pull the over riders out

of shape).

40. Fit the rubber headlight to bumper inserts on

the top of each bar and tighten (Do not over

tighten).

41. With help, fit the bulbar into position and

install nuts and bolts supplied.

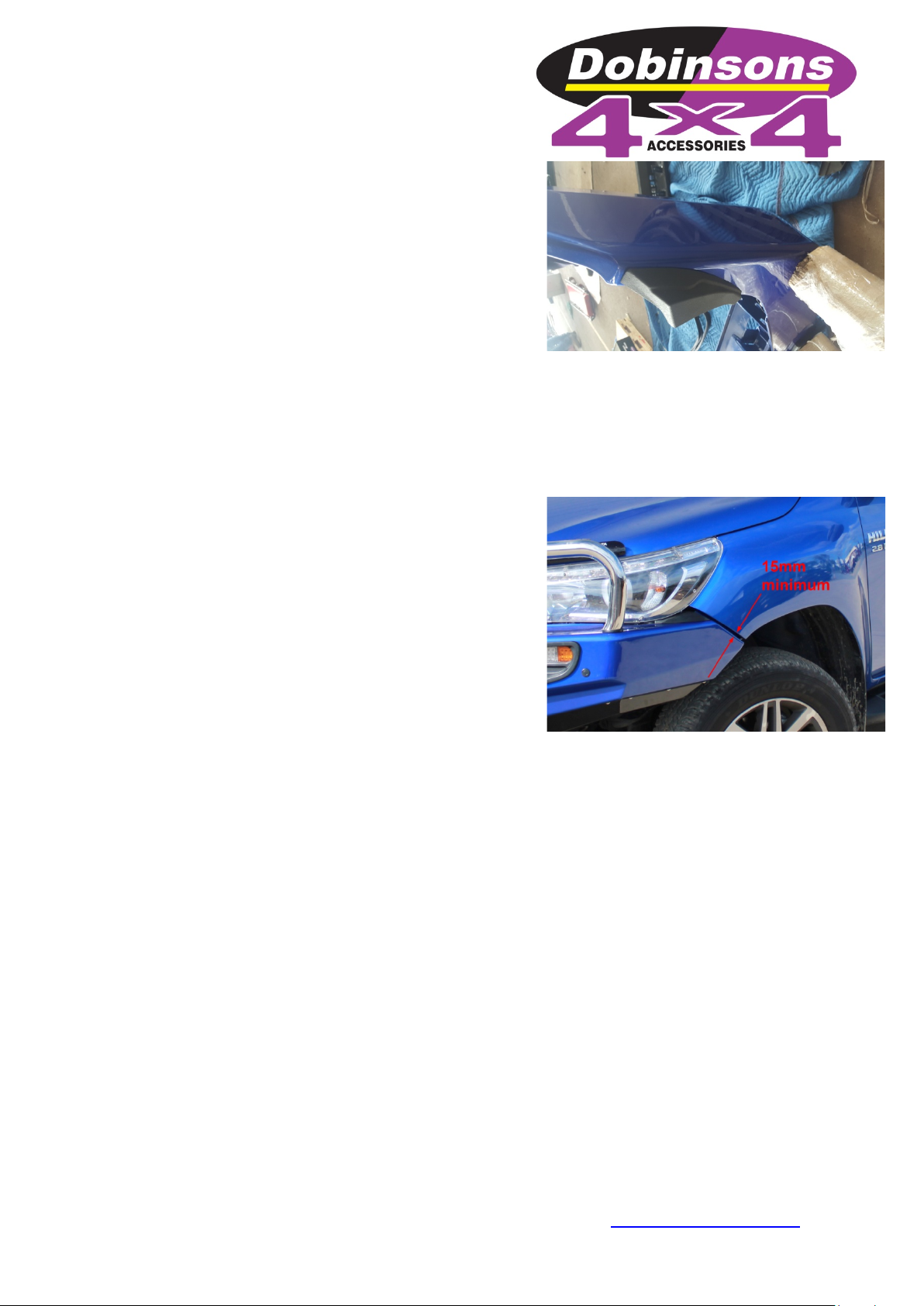

42. Align the bar with the vehicle into its correct

position leaving a gap of about 15mm

between the bullbar wing and the bottom of

the quarter panel.

43. Once you are happy with the alignment

tighten the 3 nuts and bolts on each side.

44. Once happy with the alignment of the bullbar

drill through the pinning holes on each side of

the bullbar bracket mounting plate. Fix with

bolts and nyloc nuts the same diameter as the

pinning hole to keep the bullbar in its

position.

45. Plug the wires into the indicator and parker

light plug. Test all lights and adjust the

position of the fog lights if required.

46. Fit the under bar protection kit now with the

bolts supplied.

47. Cut along the bottom of both wheel arch

splash guard so that they are flush with the

bottom of the side protection plate ensuring

you do not cut into washer bottle bracket on

the LH side and secure to the back side of the

bash plates. For the LH side you may need to

Dobinsons Springs and Suspension www.dobinsonsprings.com