DMF series - Torque reaction arms 60353-12/20

3. SETTINGS................................................................................................ 26

3.1 Balancer setting..........................................................................................26

4. USE............................................................................................................27

4.1 Standard use...............................................................................................27

4.2 Position control use................................................................................... 27

5. MAINTENANCE...................................................................................... 28

5.1 Maintenance............................................................................................... 28

5.1.1 General maintenance.................................................................................. 28

5.1.2 Encoder cable replacement (LPC, LAPC series)....................................28

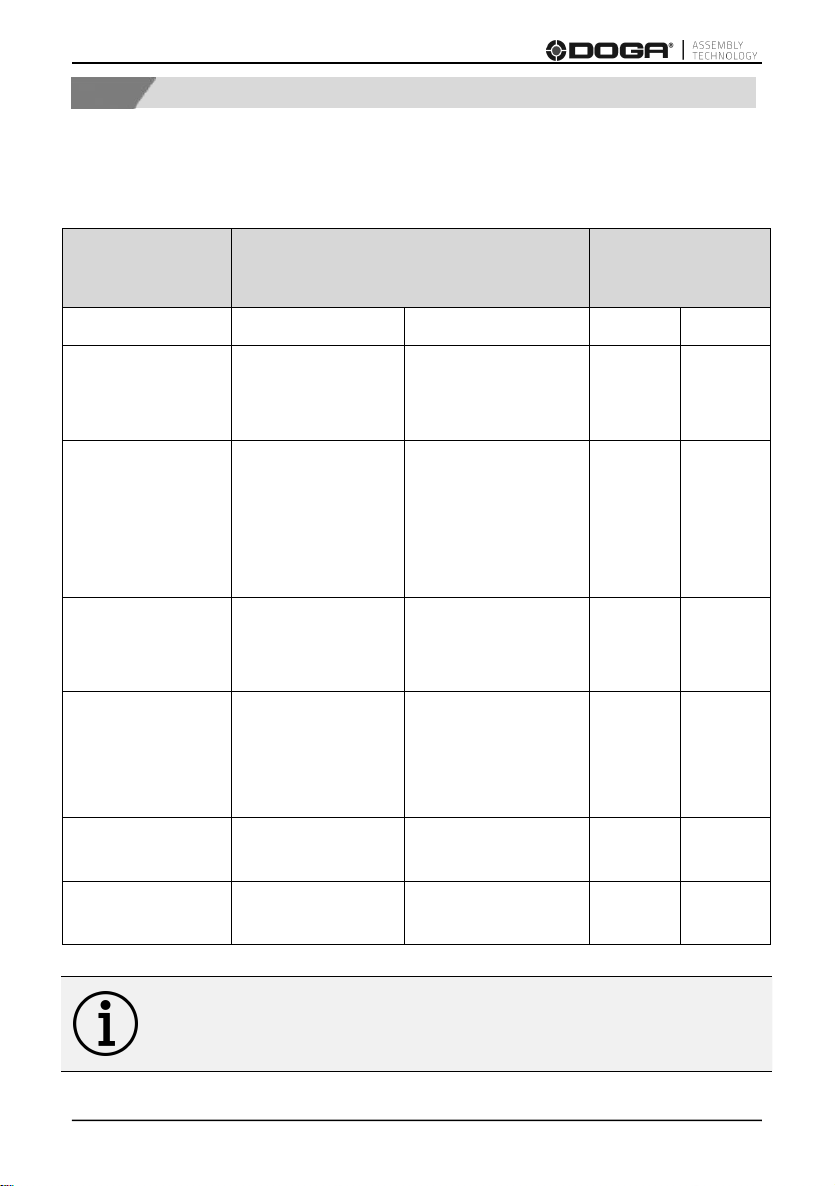

5.2 Troubleshooting..........................................................................................30

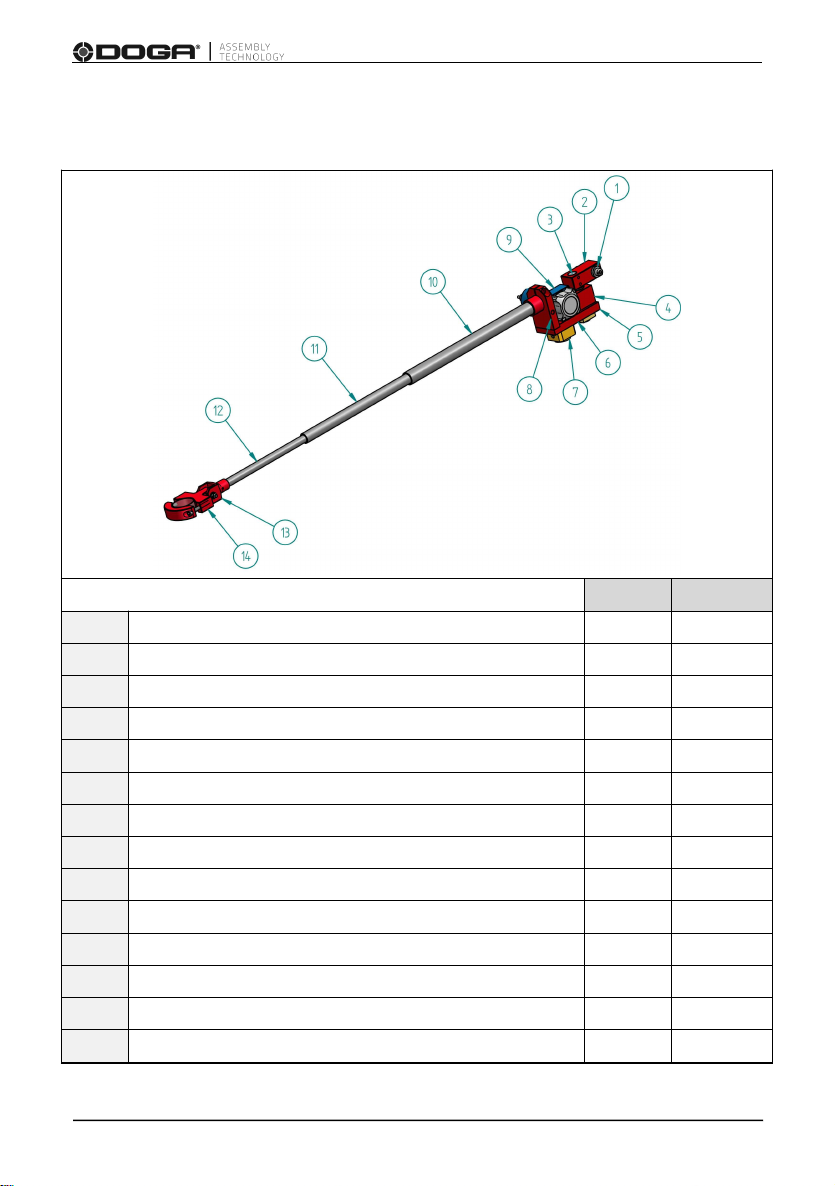

5.3 Spare parts..................................................................................................31

5.4 Phone support............................................................................................ 31

5.5 After-sales return........................................................................................32

5.5.1 Download the after-sales return form........................................................32

5.5.2 Send your equipment.................................................................................. 33

5.6 On-site repair.............................................................................................. 33

5.7 Warranty...................................................................................................... 34

6. SAFETY.................................................................................................... 35

6.1 General provisions..................................................................................... 35

6.2 Residuals risks........................................................................................... 36

6.2.1 Pinching or Cutting Risks............................................................................36

6.2.2. Injury Risk.....................................................................................................36

6.3 Contra-indications...................................................................................... 36

7. STANDARDS........................................................................................... 37

7.1 Manufacturer details.................................................................................. 37

7.2 Markings...................................................................................................... 37

7.3 Transport and storage............................................................................... 38

7.3.1 Transport........................................................................................................38

7.3.2 Storage.......................................................................................................... 38

7.4 Recycling and end of service life............................................................. 38

8. ANNEXES.................................................................................................39

8.2 EC Declaration of Conformity...................................................................39