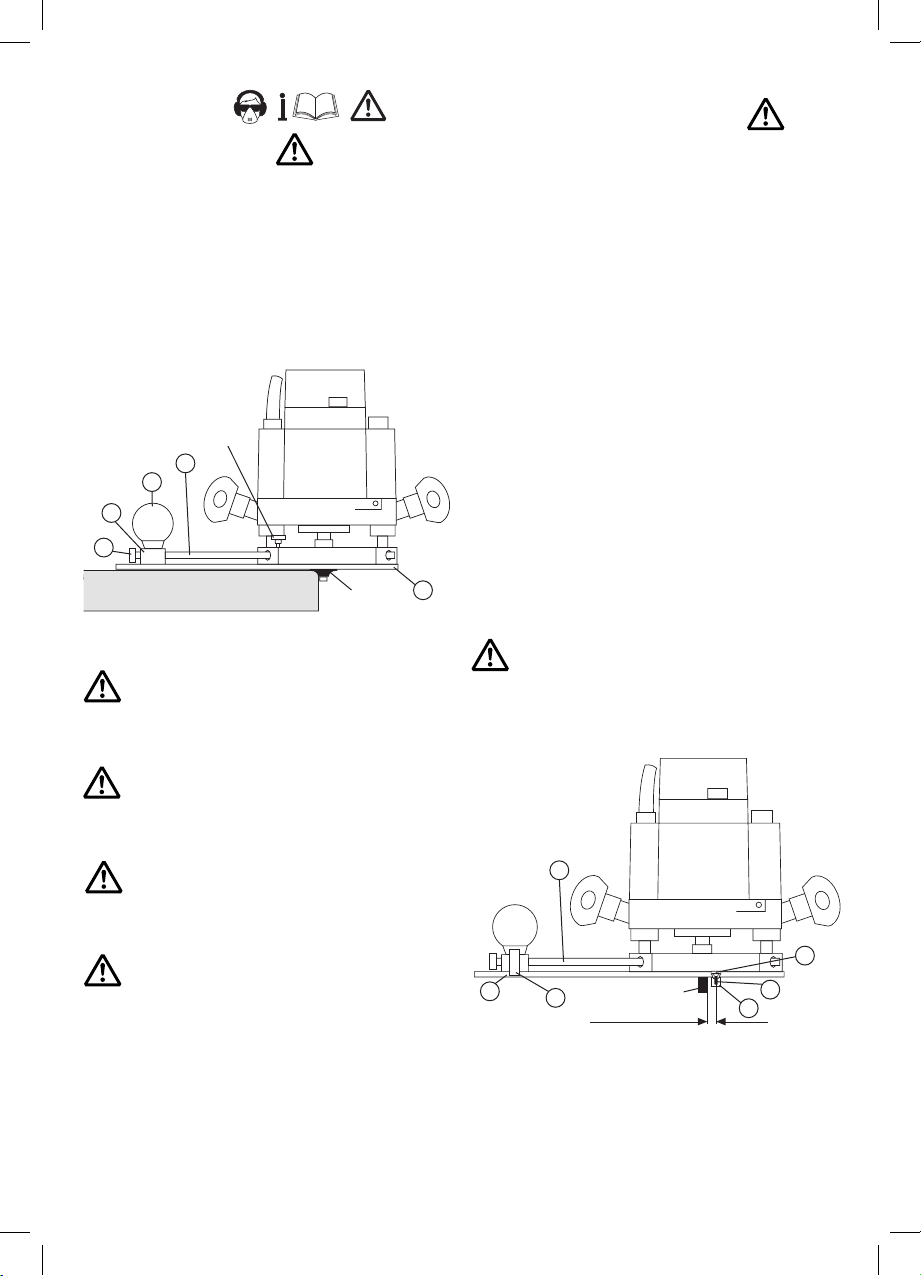

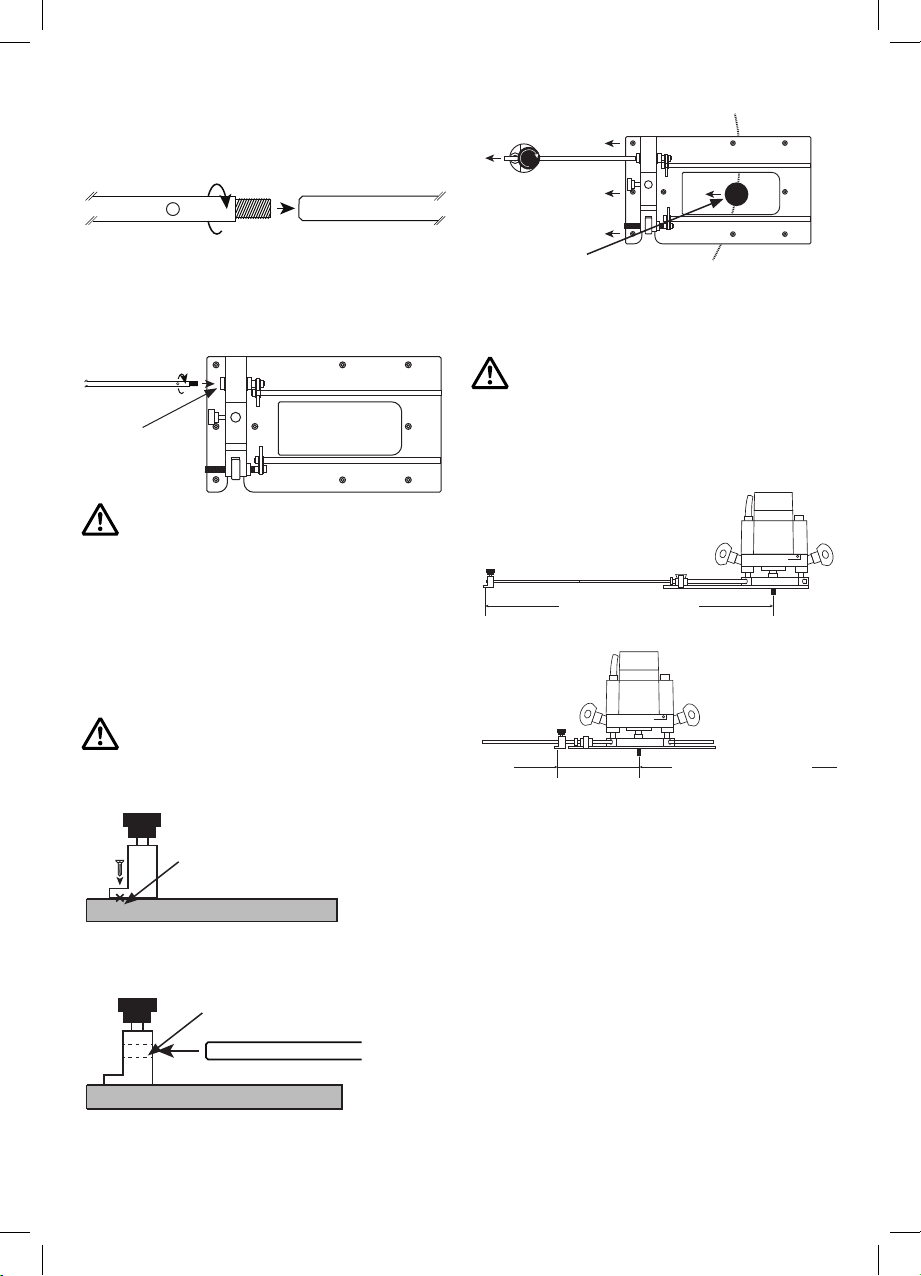

Set the depth of the cutter as usual and rest the router on the

work piece as if to start a routing pass. Release the bridge

pinch-bolt so the anti-tilt leg drops down and the foot rests

on the bench top. Without moving the router or anti-tilt leg

retighten the bridge pinch-bolt locking the anti-tilt leg at the

height which will then support the previously unsupported side

of the router.

Before completing the routing pass check that

the bench surrounding the work piece is smooth

and even. Complete a couple of dry runs with the

router around the work piece ensuring that the

anti-tilt leg has a clear path and the router remains

stable whilst the pass is completed.

4. Anti-tilt Support

The CRB’s anti-tilt leg is designed specifically to aid stability

when routing narrow sections of material. The leg is in two

parts so its height if necessary can be reduced by unscrewing

the rods.

Slide the anti-tilt leg into the bridge pinch-bolt hole from the

underside of the baseplate. Lock it in position with the plastic

foot up against the underside of the baseplate. Slide the router

onto the CRB’s rods and lock the router in position using the

router fence rod knobs. Ensure that the router is positioned

to allow the router cutter to sit safely within the baseplate

‘letterbox’.

Maximum height = 80mm (3 1/8”)

Minimum height = 8mm (5/16”)

Component

8

41

Cutter

Router fence knob

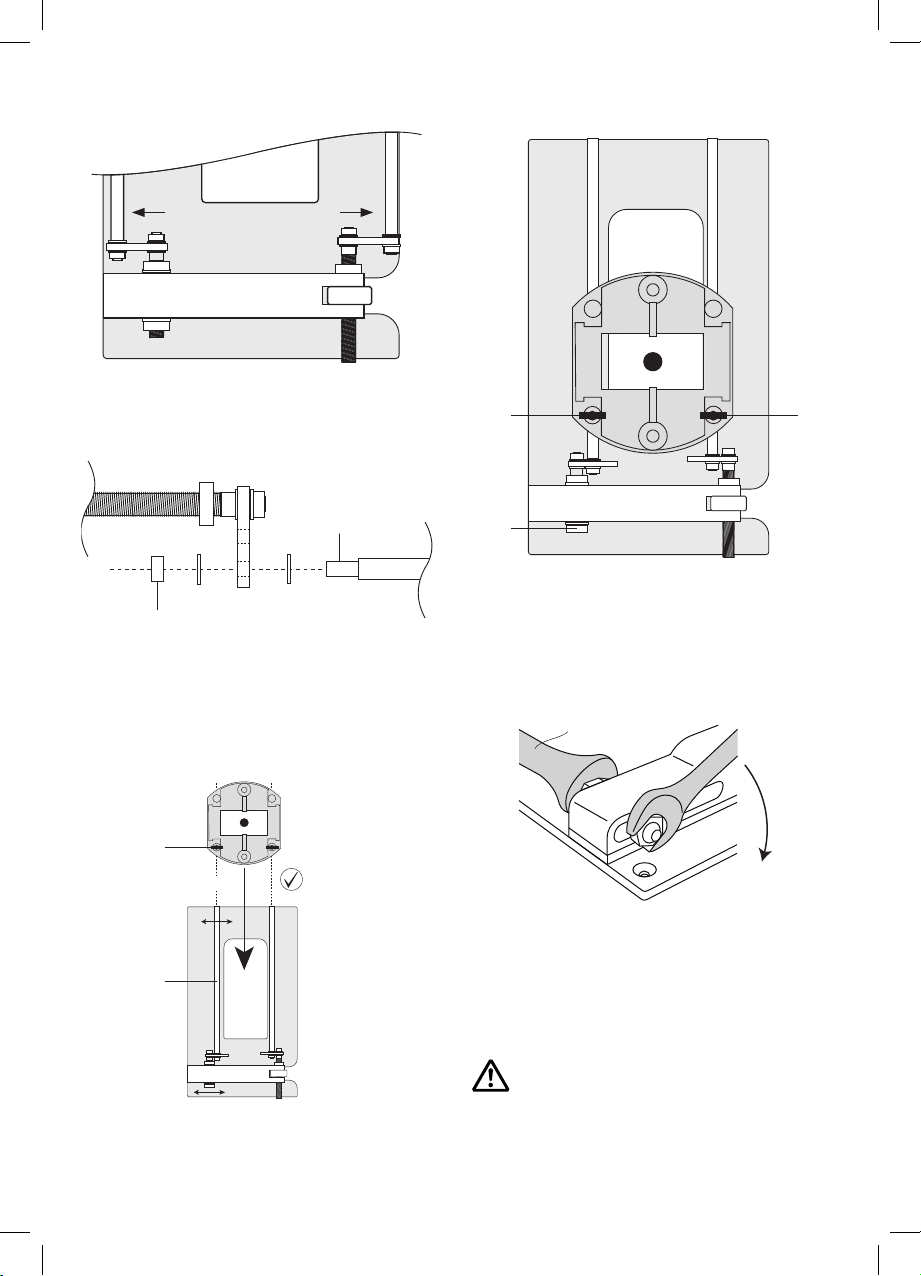

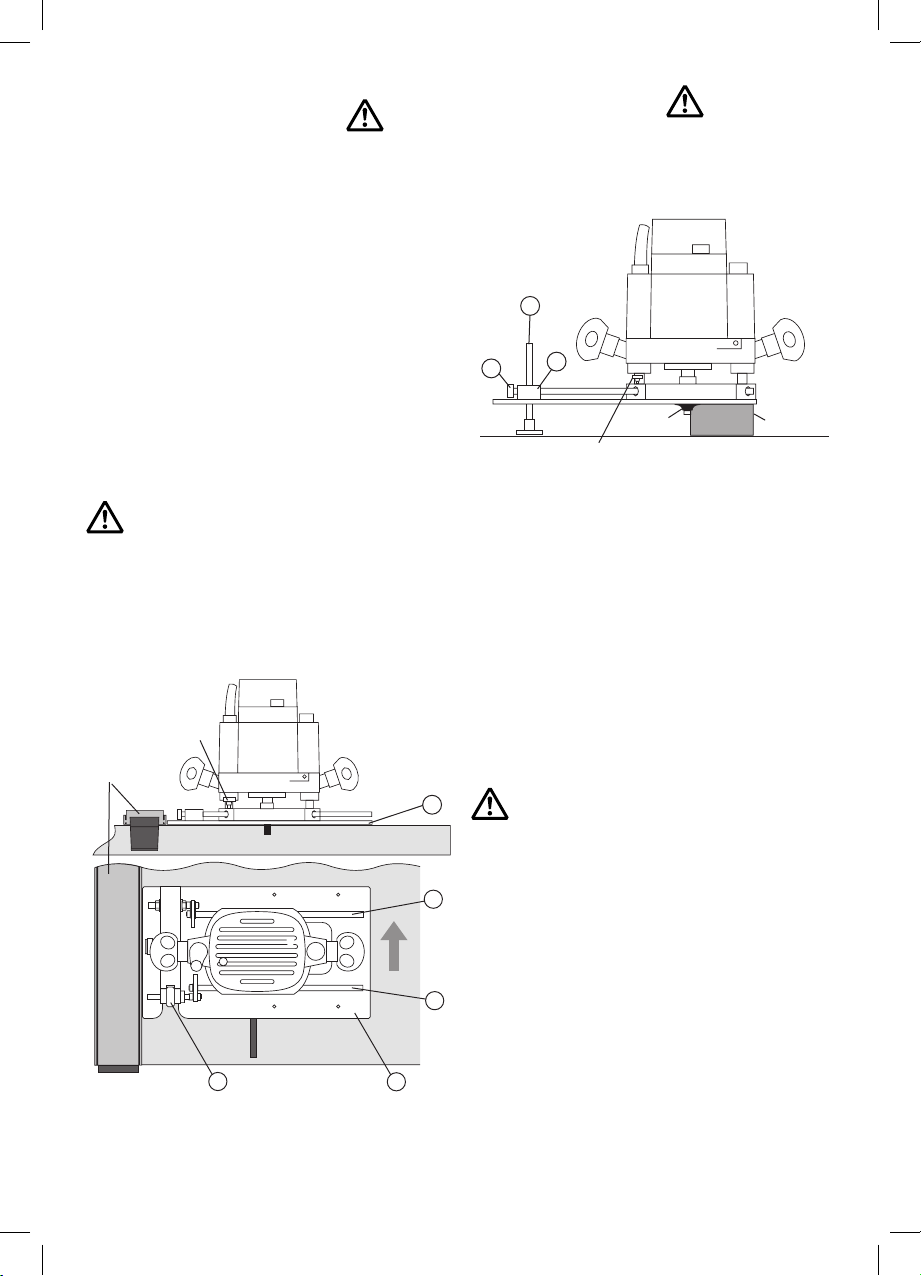

3. Using the CRB with a

Clamp Guide

Using a clamp guide and router to groove across the width

of a work piece is a useful and common practice. However

considerable time is taken to accurately set the clamp guide at

right angles to the edge of the board simultaneously ensuring

a precise distance from the desired position of the rebate.

The CRB’s micro adjuster removes the need to set the

distance between clamp guide and groove.

Ensure the clamp guide is set at right angles to the board

edge and within the range of the routers movement on the

CRB’s rods. Slide the router to the approximate position of the

required rebate and using the router fence rod knob on the

router base lock the router onto the CRB’s adjuster rod.

Plunge the cutter to the work piece surface (with the router

turned off) and using the micro adjuster bring the edge of the

cutter up to the line denoting the location of the rebate. Run

the bridge end of the CRB’s baseplate up against the clamp

guide and using an even pressure ensure the router moves

smoothly down the length of the clamp guide.

If a deep rebate or groove is needed several lighter

cutting passes may result in a better finish.

If two grooves are needed within 110mm centre to centre of

each other, (using a 1/4” cutter) they can be routed without

moving the clamp guide by simply sliding the router down the

CRB’s rods to the next location.

2

6B

5B

2

4

Clamp

guide

Router fence

rod knob

-9-