311.01.21 en / 335A

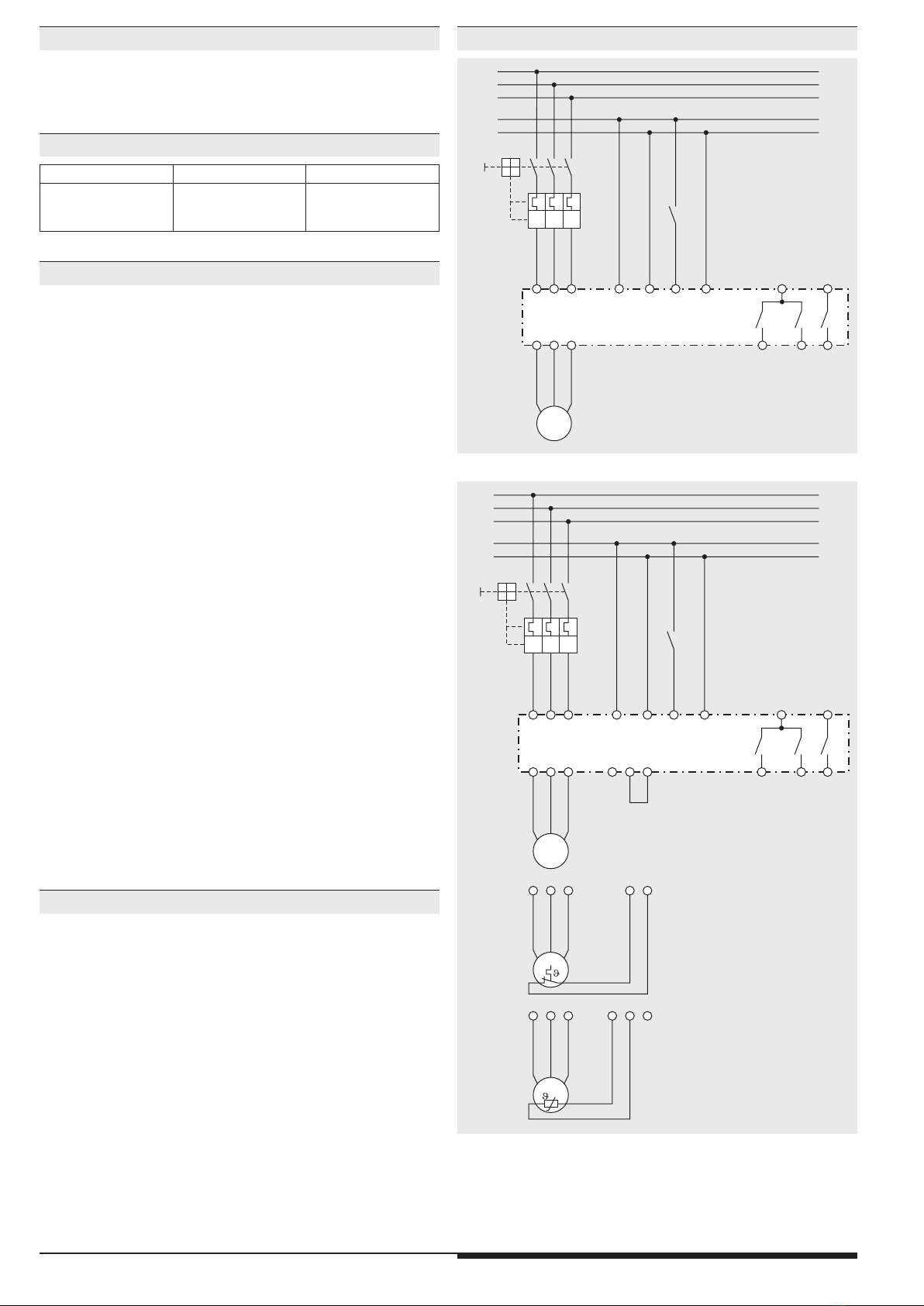

Phase / motor

voltage L1/L2/L3: 3 AC 200 V -10 % ... 480 V + 10 %

Nominal frequency: 50 / 60 Hz

Nominal motor power PN

at 400 V: 11 kW

Switching frequency

at 3 x IN, 5 s, ϑU= 45°C: 20 / h

max. permissable braking current: 50 A eff.

Min. motor power: 0.1 PN

Start torque: 20 ... 80 %

Ramp time: 1 ... 20 s

Braking time: Max. 20 s

Braking delay: 750 ms

Braking voltage: DC 10 ... 90 V

Start delay: 250 ms

Auxiliary voltage UH

model DC 24 V: A1/A2, DC 24 V, + 10 %, - 15 %

Power consumption: 2 W

Residual ripple max.: 5 %

Max. semiconductor fuse: 6600 A2 s

Inputs

Control input X1, X2: DC 24 V / 2.5 mA / edge triggered

Input P2 / P3 for bi-metal contact

Switching current: DC 1 mA

Switch voltage: DC 5 V

Input P1 / P2 for PTC-sensor

Thermal sensor: According to DIN 44081

Number of sensors: 1 ... 6 in series

Response value: 3 kΩ

Measuring voltage: Max. DC 5V

Monitoring Output

Contacts: 3 x 1 NO contacts

Thermal continous current Ith:4 A

Switching capacity

to AC 15

NO contact: 3 A / 230 V IEC/EN 60947-5-1

Electrical life:

to AC 15 at 3 A,

AC 230 V: 2 x 105switch. cycl. IEC/EN 60947-5-1

Short circuit strength

max. fuse rating: 4 A gG / gL IEC/EN 60947-5-1

General Data

Temperature range

Operation: 0 ... + 45 °C

Storage: - 25 ... + 75 °C

Altitude: < 2000 m

Clearance and creepage

distances

Rated impulse voltage /

pollution degree

Control voltage to auxiliary

voltage, motor voltage: 4 kV / 2 IEC 60664-1

Auxiliary voltage to

motor voltage: 4 kV / 2 IEC 60664-1

motor voltage to heat sink: 6 kV / 2 IEC 60664-1

EMC

Electrostatic discharge: 8 kV (air) IEC/EN 61000-4-2

HF-irradiation

80 MHz ... 1 GHz: 10 V / m IEC/EN 61000-4-3

1 GHz ... 2,5 GHz: 3 V / m IEC/EN 61000-4-3

2,5 GHz ... 6 GHz: 1 V / m IEC/EN 61000-4-3

Fast transients: 2 kV IEC/EN 61000-4-4

Surge voltages

between

wire for power supply: 1 kV IEC/EN 61000-4-5

between wire and ground: 2 kV IEC/EN 61000-4-5

HF wire guided: 10 V IEC/EN 61000-4-6

BL 9028.03 3 AC 200 ... 480 V 50/60 Hz UHDC 24 V 11 kW

Article number: 0068352

•Nominal motor power

at 3 AC 400 V: 11 kW

•Control input X1, X2: DC 24 V

•Width: 112.5 mm

Technical Data Technical Data

Standard Type

Interference emission

Wire guided: Limit value class A IEC/EN 60947-4-2

Radio irradiation: Limit value class A IEC/EN 60947-4-2

The device is designed for the usage

under industrial conditions (Class A,

EN 55011). When connected to a

low voltage public system (Class B,

EN 55011) radio interference can be

generated. To avoid this, appropriate

measures have to be taken.

Degree of protection:

Housing: IP 40 IEC/EN 60529

Terminals: IP 20 IEC/EN 60529

Vibration resistance IEC/EN 60068-2-6

Frequency range: 10 ... 100 Hz

Amplitude: 0.35mm peak to peak up to 54 Hz

Acceleration: Above 54 Hz constant acceleration 4 g

Climate resistance: 0 / 045 / 04 IEC/EN 60068-1

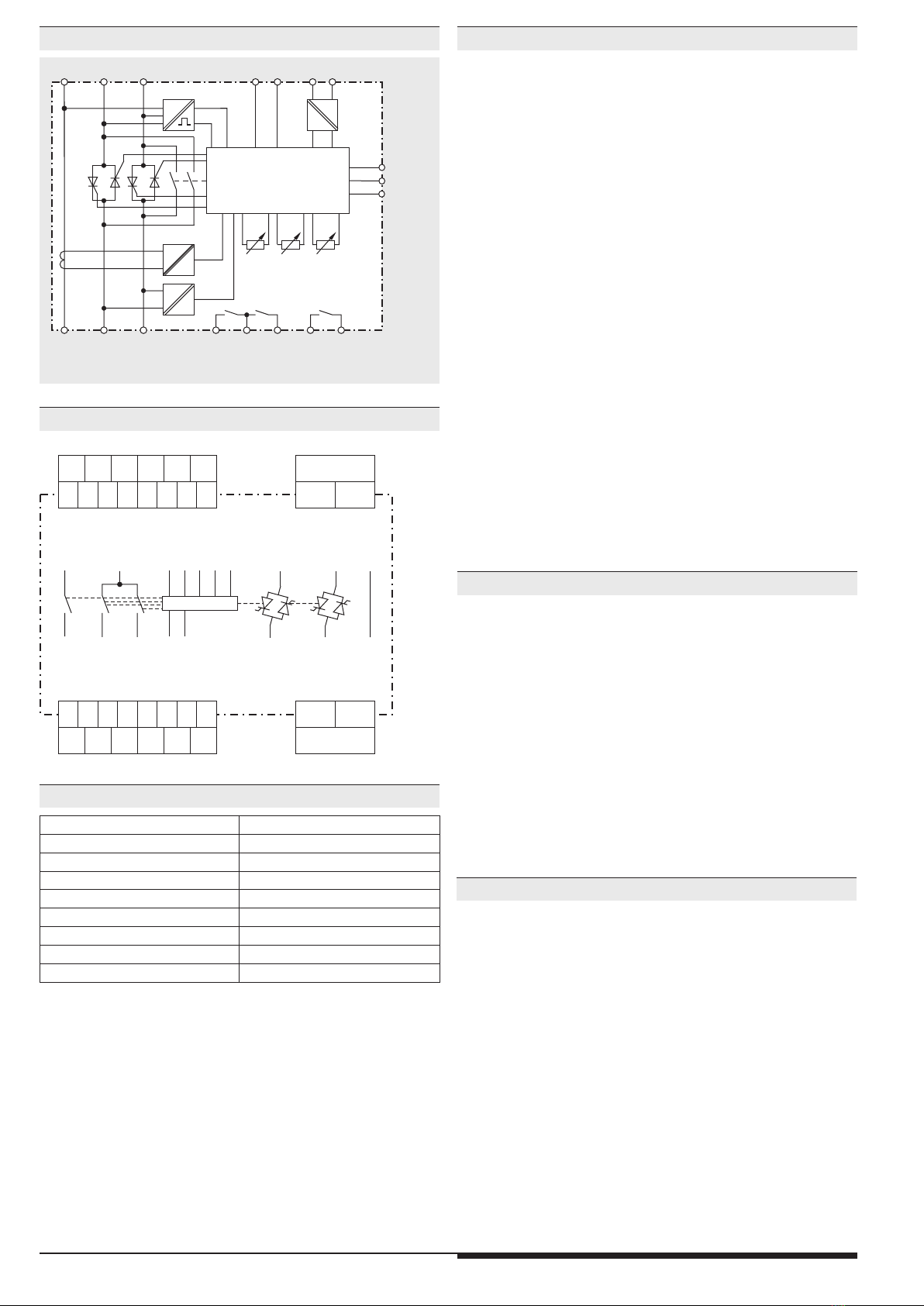

Wire connection

Load terminals: 1 x 10 mm2solid

1 x 6 mm2stranded ferruled

Control terminals: 1 x 4 mm2solid or

1 x 2.5 mm2stranded ferruled (isolated) or

2 x 1.5 mm2stranded ferruled (isolated)

DIN 46228-1/-2/-3/-4 or

2 x 2.5 mm2stranded ferruled

DIN 46228-1/-2/-3

Stripping length: 10 mm

Wire fixing

Load terminals: Plus-minus terminal screws M4

box terminals with wire protection

Fixing torque: 1.2 Nm

Control terminals: Plus-minus terminal screws M3.5

box terminals with wire protection

Fixing torque: 0.8 Nm

Mounting: DIN rail mounting IEC/EN 60715

Weight: 1135 g

Dimensions

Width x height x depth: 112.5 x 85 x 121 mm

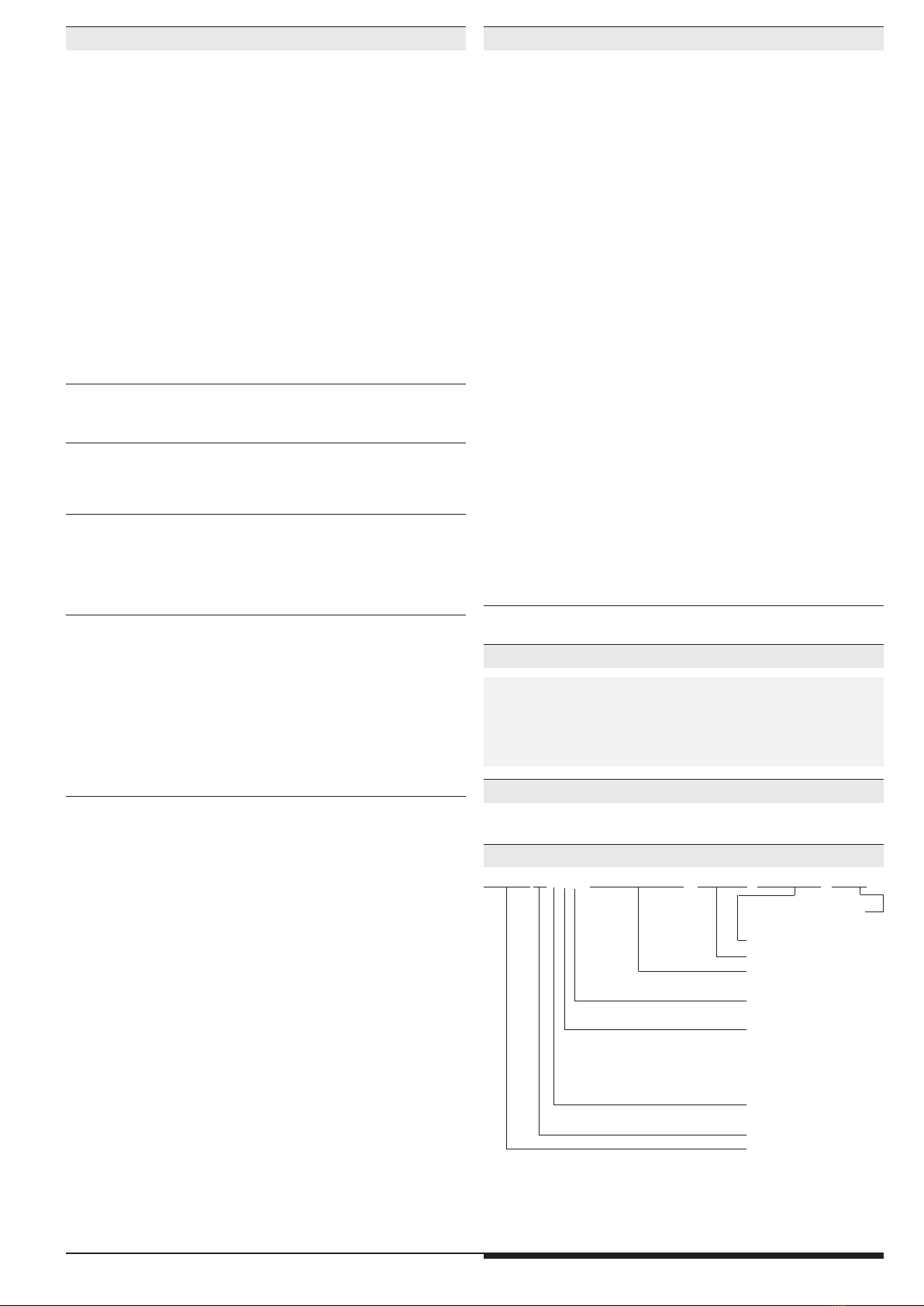

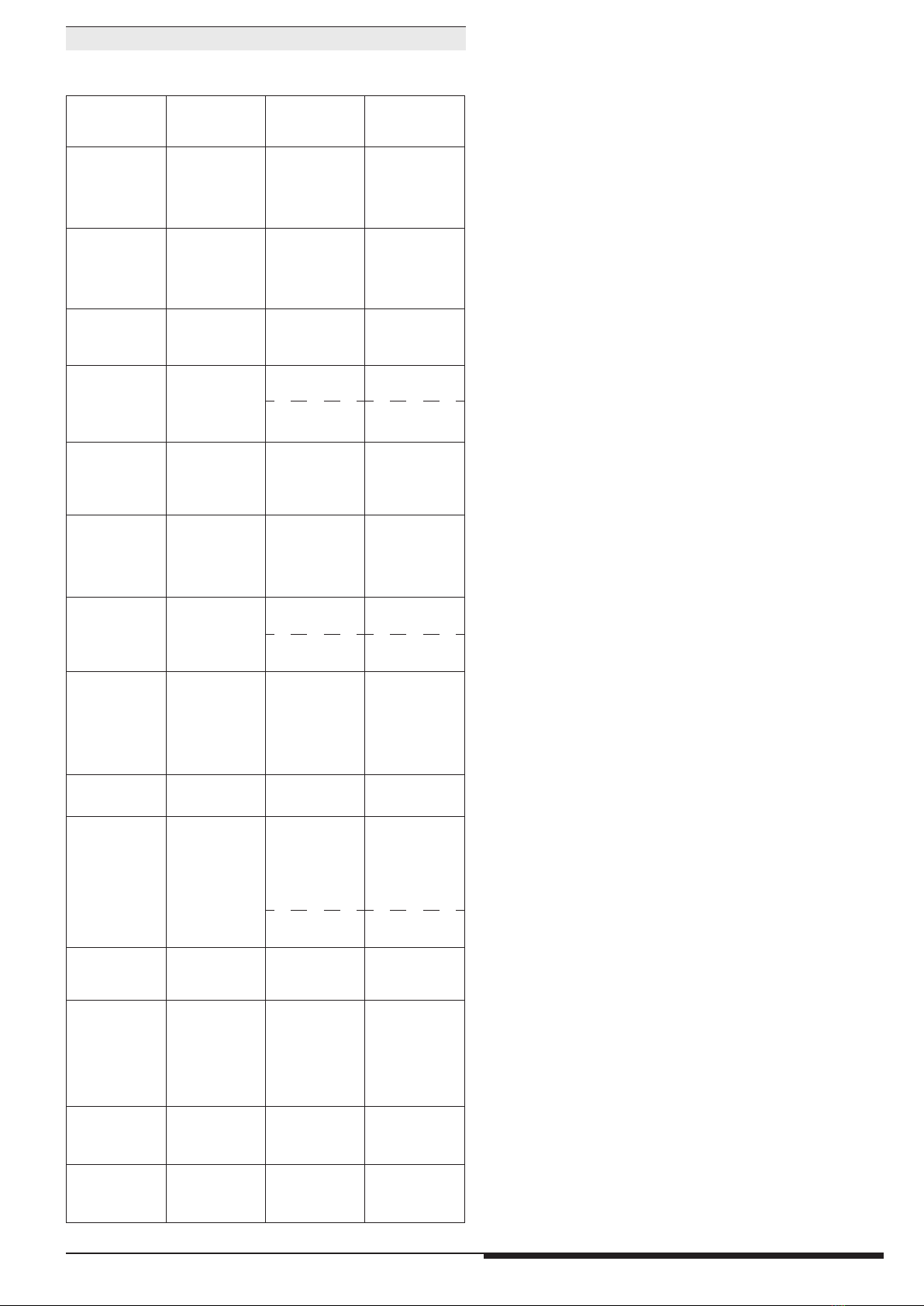

BL 9028. 03/_ _ _ 3 AC 200...480 V 50/60 Hz UHDC 24 V 11 kW

Nom. motor power

at 3 AC 400 V

Aux./Control voltage

Nom. frequency

Phase / motor voltage

Variant

0 = Standard

0 = Standard

1 = Input P1/P2/P3

for motor temp.

monitoring

0 = With standstill

detection

Contacts

Type

Ordering Example

Variant

BL 9028.03/_1_: Motor protection with bi-metal contact or

PTC thermal sensor