SHPT-487168127-329_v.2.0 Page 6 of 60

7.2 Pneumatic Connection 26

7.3 Power Connection 27

7.4 USB to RS232 Connection 27

7.5 Connection to Remote Chamber 28

7.6 Mitos Sensor Unit Electrical Connection 28

8Mitos Sensor Units Connection 29

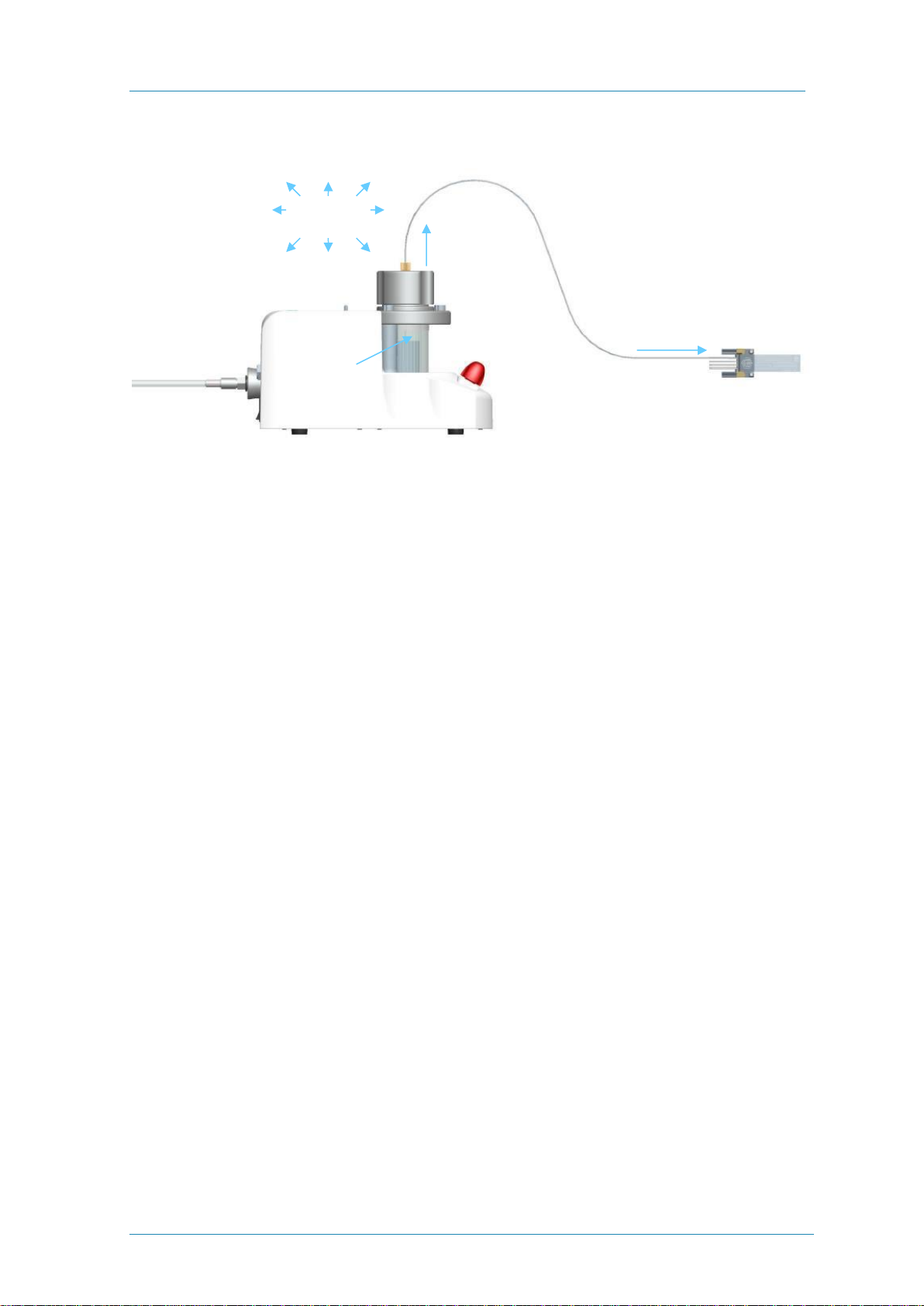

8.1 Standalone device 29

8.2 Connection to the top of the Mitos P-Pump 30

8.3 USB Connection 30

8.4 Electrical Connection 31

9Controlling the pumps 32

10 Manual User Control 33

Manual Control Functions 33

10.1 Pressure Control 33

10.2 User Controls 34

10.3 Menu Option: Tare 35

10.4 Menu Option: Timer 36

10.5 Menu Option: Configuration –Units 36

10.6 Menu Option: Configuration –Mode 37

10.7 Menu Option: Configuration –Resolution 37

10.8 Menu Option: Error Log 38

10.9 Menu Option: USB Data Export 39

10.10 Menu Option: Screensaver 40

10.11 Menu Option: Information 40

11 PC Software User Control 41

11.1 Detect devices 41

11.1.1 USB connection 41

11.1.2 Connection via a serial cable 41

11.2 Using the PC software 42

12 Using Flow Resistors 44

12.1 Flow Resistors 44

12.2 Flow Rate Calibration 47

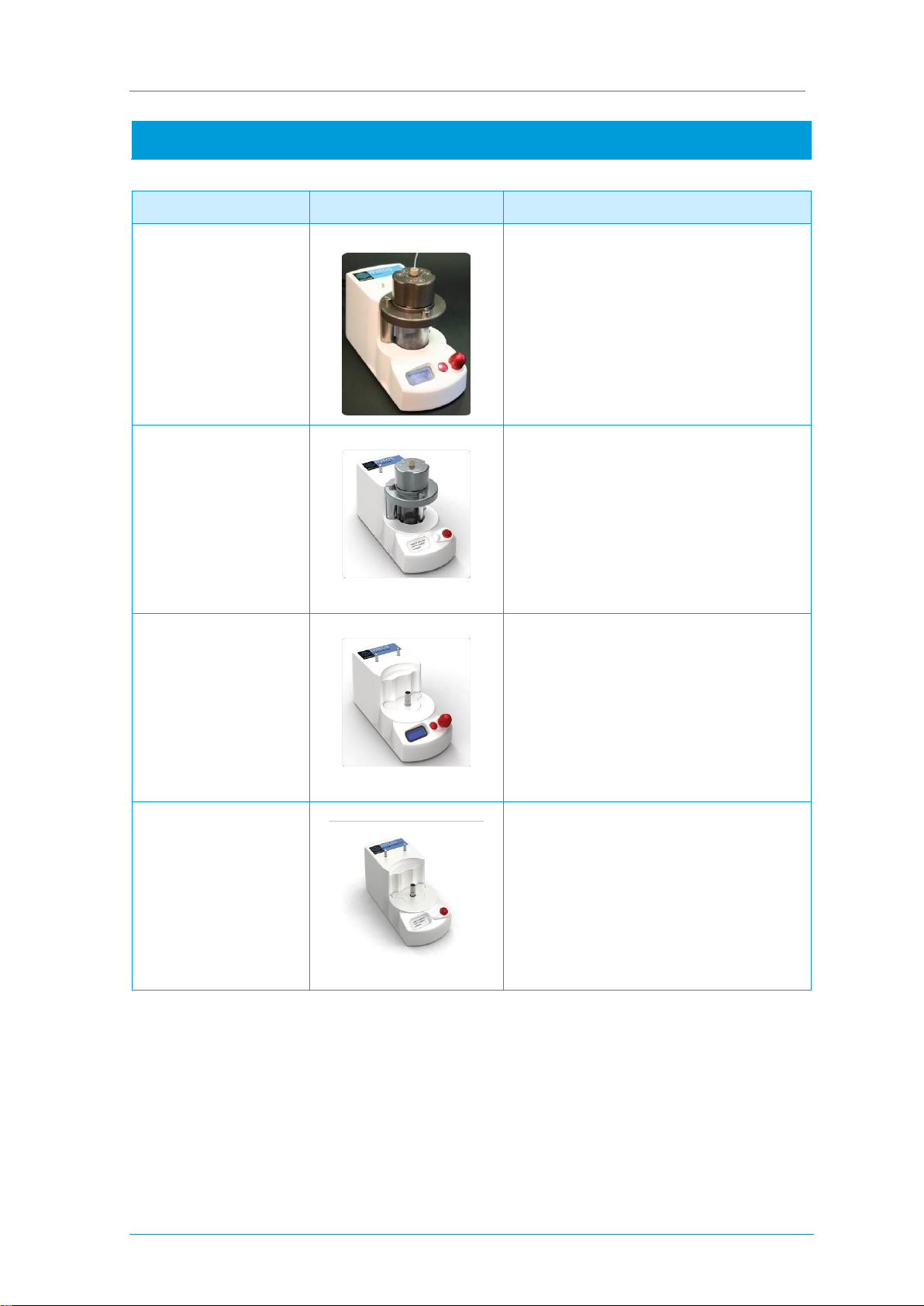

13 Accessories 48

Dolomite offers a broad range of accessories including flow resistors, vessel holders

and starter kits. 48

13.1 Accessories compatibility 50