Dryo, MMA and MMB

ii

Contents

IMPORTANT NOTES.......................................................................................................................................................................i

1 Safety Communication ..............................................................................................................................................................1

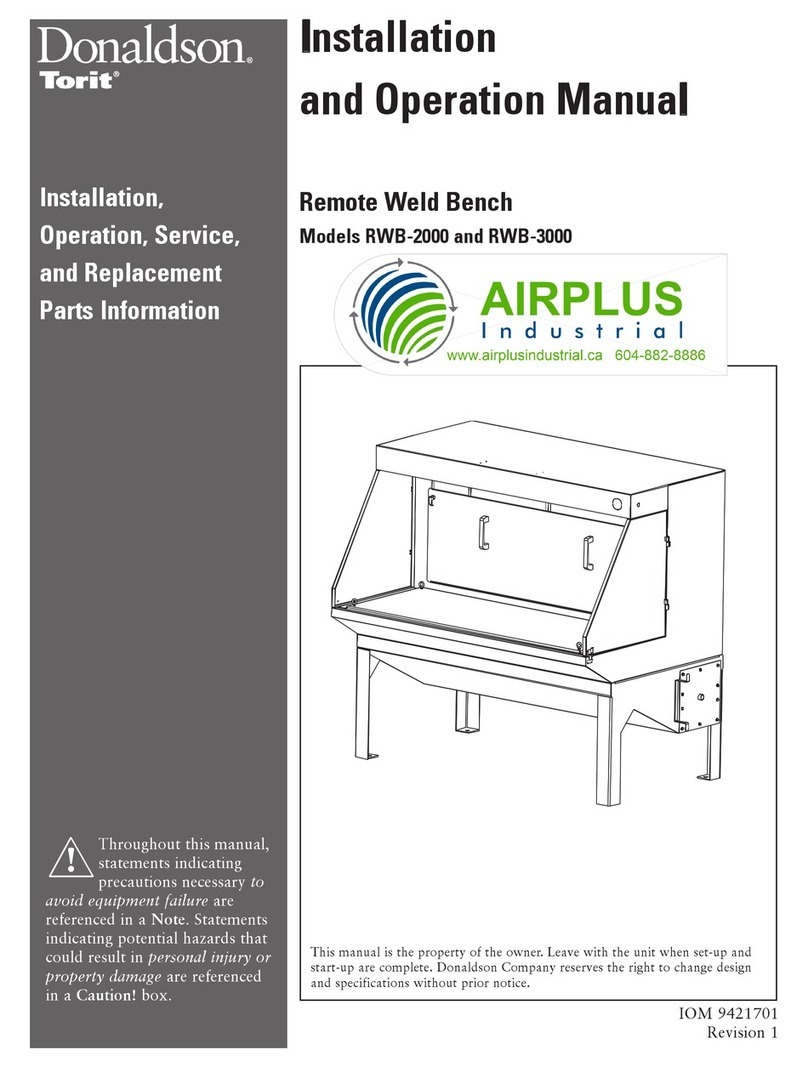

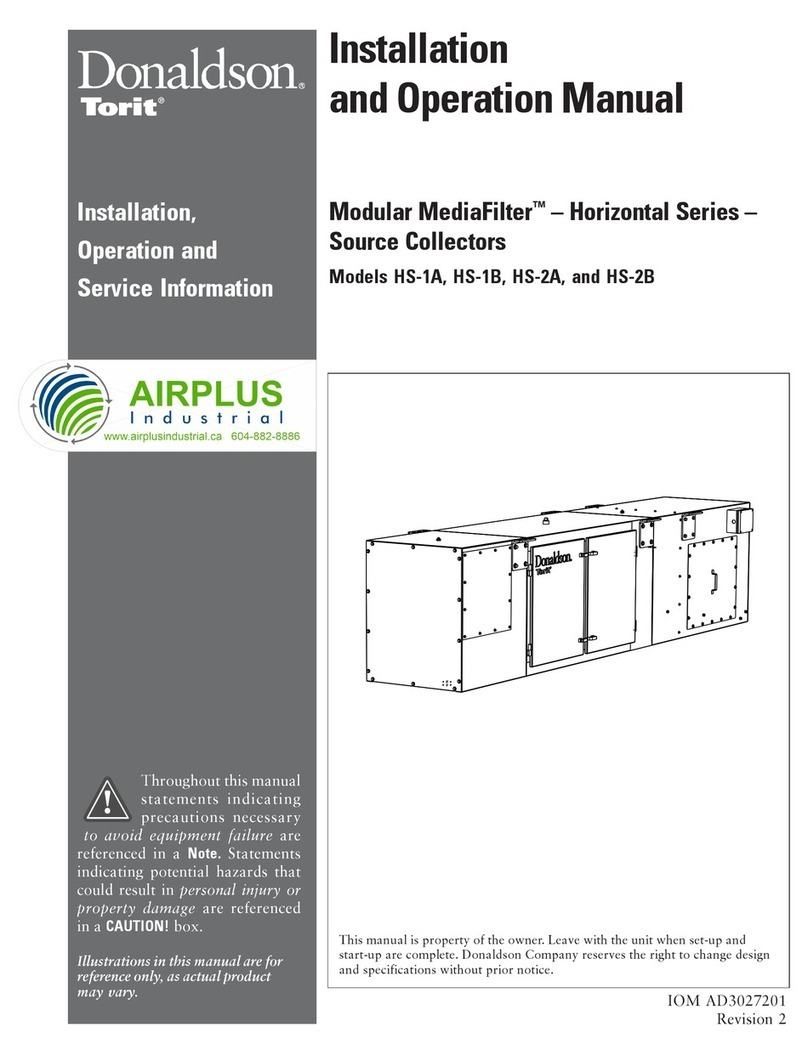

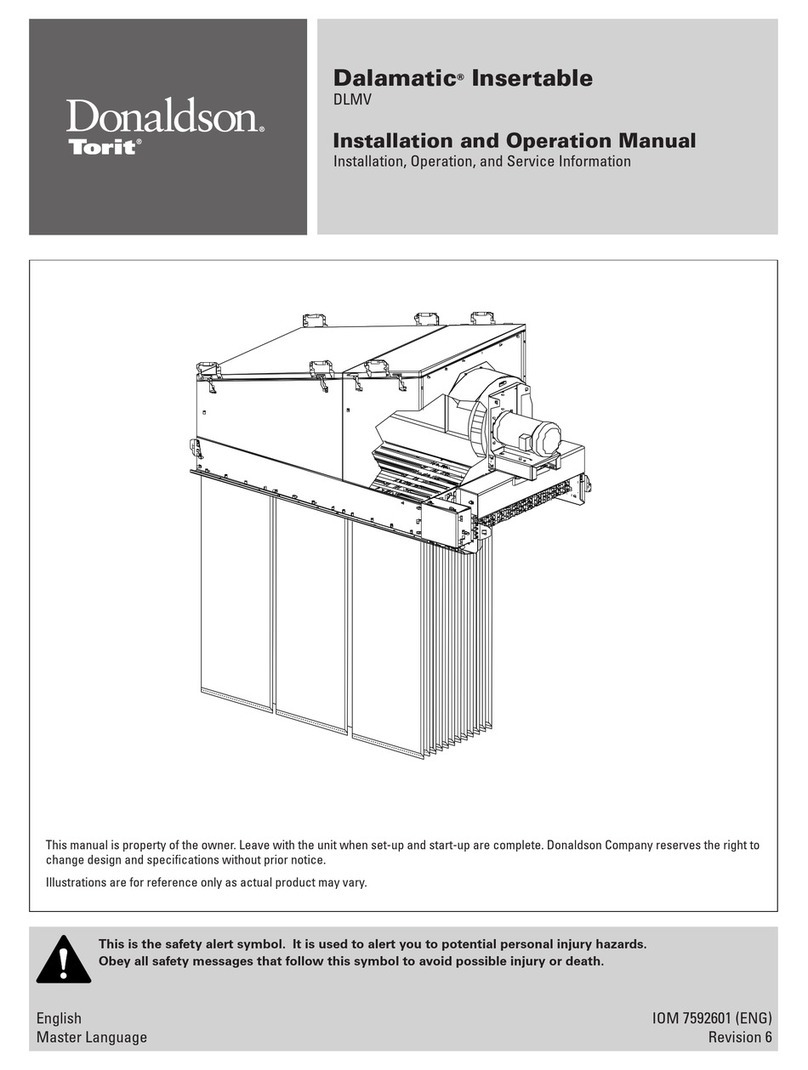

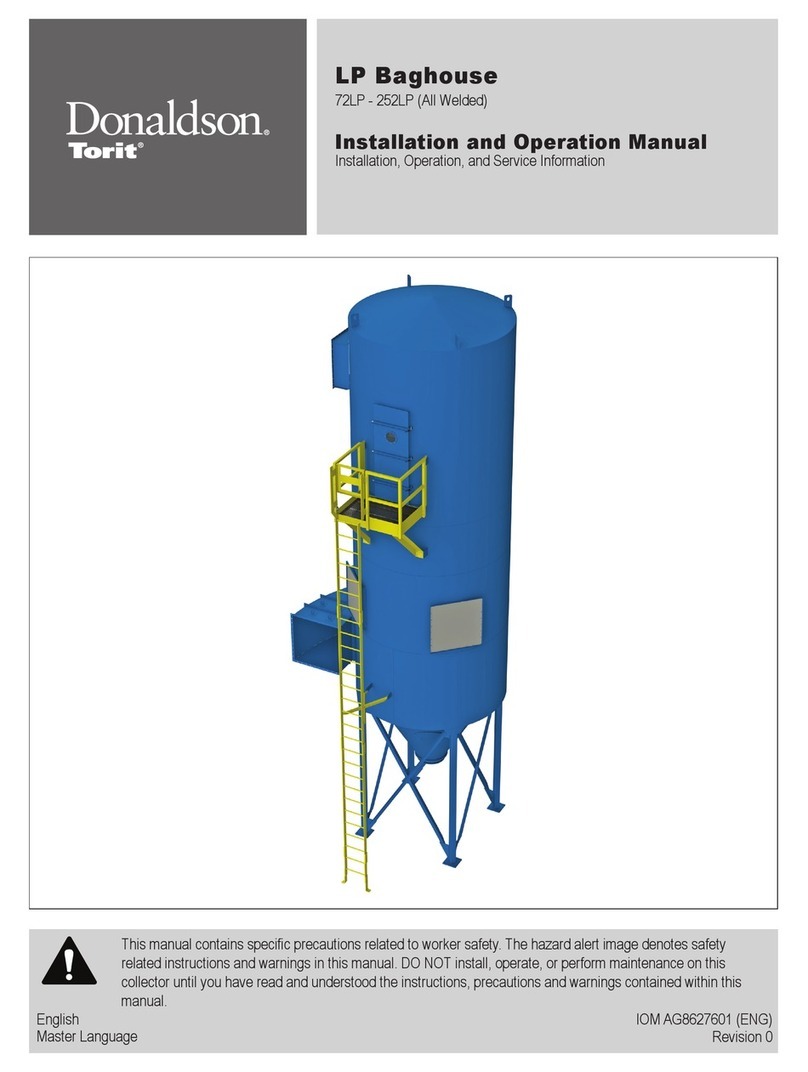

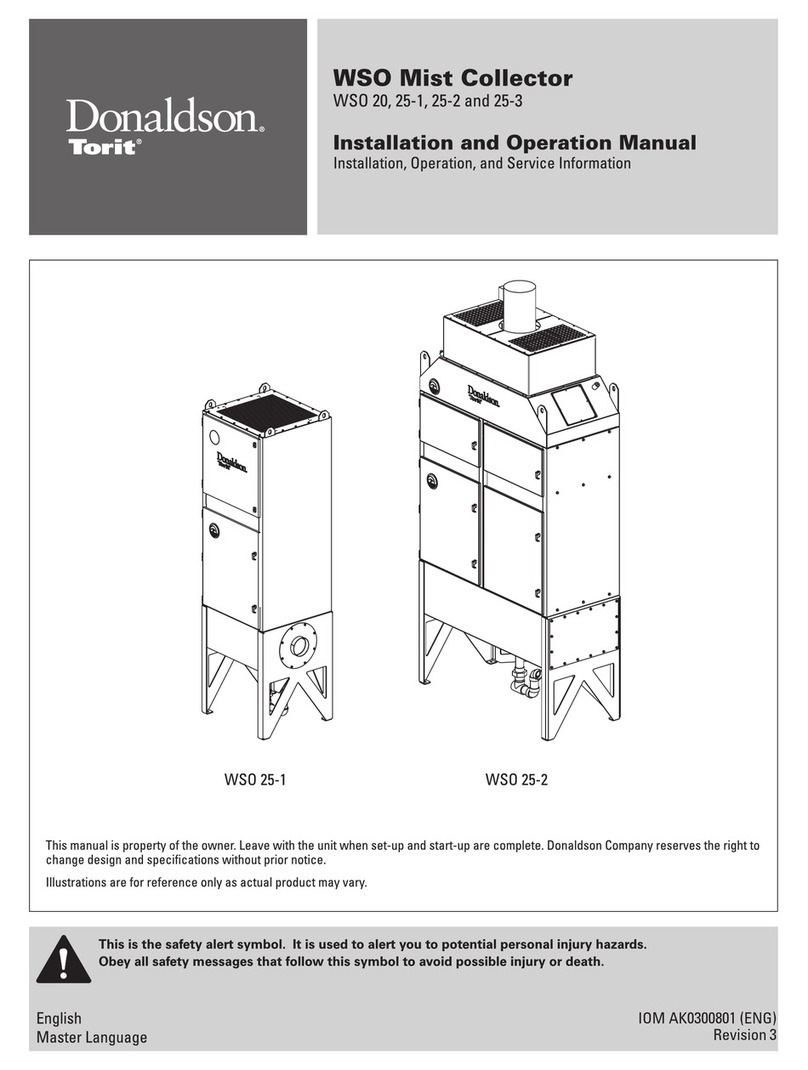

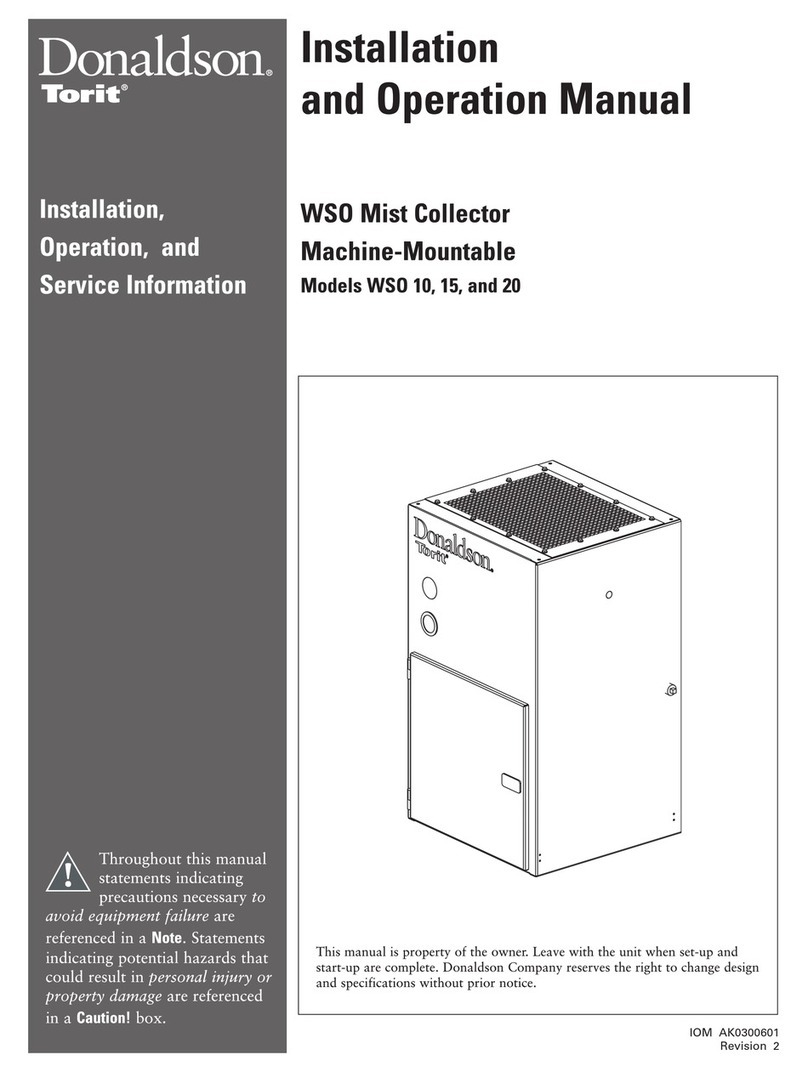

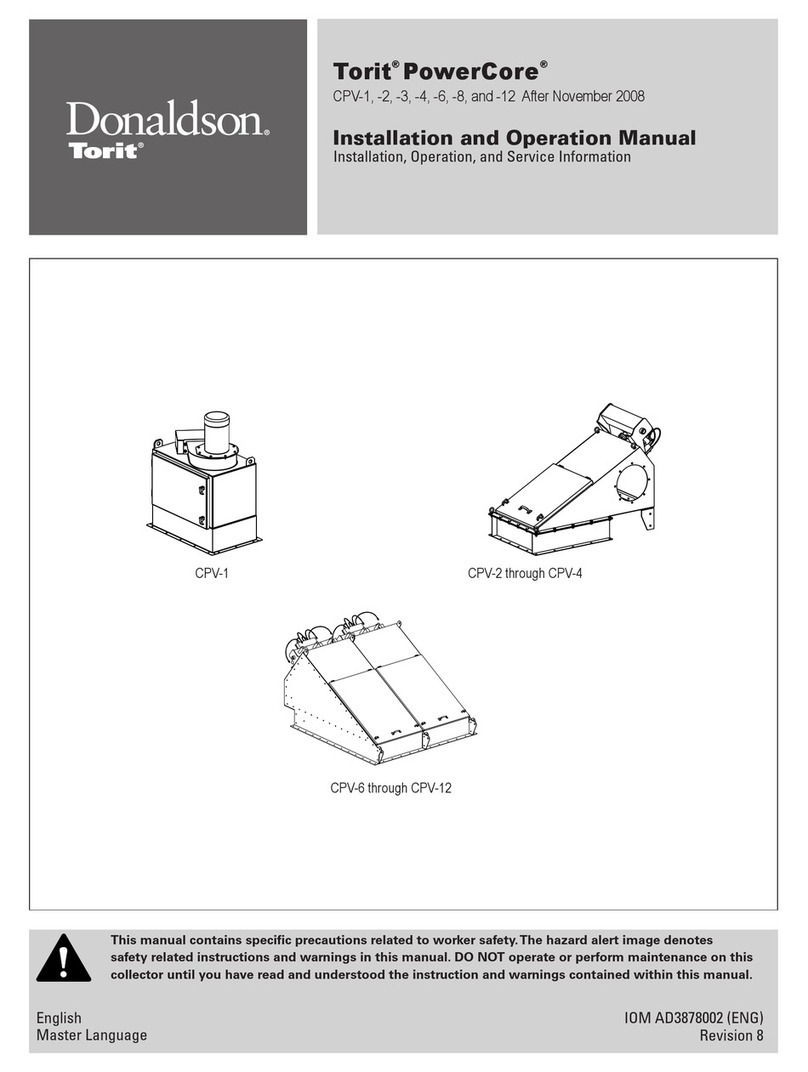

2 Product Description...................................................................................................................................................................3

Standard Equipment...........................................................................................................................................................3

Machine Mount ...........................................................................................................................................................3

Inlet Gasket .................................................................................................................................................................3

Integral Housed Fan....................................................................................................................................................3

Minihelic®Gauge .........................................................................................................................................................3

Exhaust Pack ..............................................................................................................................................................3

Options and Accessories....................................................................................................................................................4

Inlet Hopper with Impact Separator.............................................................................................................................4

Inlet Hopper with Flex-Duct .........................................................................................................................................4

Drain Collection Container ..........................................................................................................................................4

Junction Box................................................................................................................................................................4

HEPA Filter ..................................................................................................................................................................4

Inlet Hopper with Vibration Isolators ...........................................................................................................................4

Inlet Hopper with Legs.................................................................................................................................................4

Collector Stand............................................................................................................................................................4

Cart..............................................................................................................................................................................4

Inlet Hopper with Gussets ...........................................................................................................................................4

3 Operation...................................................................................................................................................................................5

4 Product Service.........................................................................................................................................................................6

Operational Checklist .........................................................................................................................................................6

Filter Replacement .............................................................................................................................................................6

Integral Housed Fan...........................................................................................................................................................8

Minihelic Gauge..................................................................................................................................................................8

Options and Accessories Replacement..............................................................................................................................9

Inlet Hopper with Impact Separator.............................................................................................................................9

Drain Collection Container ........................................................................................................................................10

Troubleshooting................................................................................................................................................................11

Appendix A - Installation................................................................................................................................................................13

Installation ........................................................................................................................................................................14

Electrical Wiring................................................................................................................................................................15

Machine Installation..........................................................................................................................................................16

Integral Housed Fans .......................................................................................................................................................18

Minihelic Gauge................................................................................................................................................................19

Exhaust Pack....................................................................................................................................................................19

Motor Starter.....................................................................................................................................................................19

Options and Accessories..................................................................................................................................................20

Pre-Wired Collectors ........................................................................................................................................................27

Unwired Collectors ...........................................................................................................................................................27

Start-up / Commissioning .................................................................................................................................................28

Decommissioning Collector..............................................................................................................................................29

Product Information ..........................................................................................................................................................30

Service Notes ...................................................................................................................................................................31

Donaldson Industrial Air Filtration Warranty..............................................................................................................................32